Types Of Transfer Molding . Transfer molding and injection molding are both popular techniques for manufacturing plastic parts, but they differ in several ways. How topgrid can help you ? The purpose and advantages of transfer molding. Transfer molding is a precision manufacturing process. When it comes to manufacturing complex shapes, transfer molding is a popular manufacturing process offering design flexibility and short cycle time. The transfer molding process utilizes a closed mold and the. Learn more as one of our. In transfer molding, the material. So, it combines the principles of injection and compression molding. Moving further, we will discuss transfer molding processes, the history of technology, pros & cons, and. The important variables of transfer molding are the polymer type, melt temperature, pot hold time, transfer pressure, transfer rate, holdup time in. What is transfer molding ?

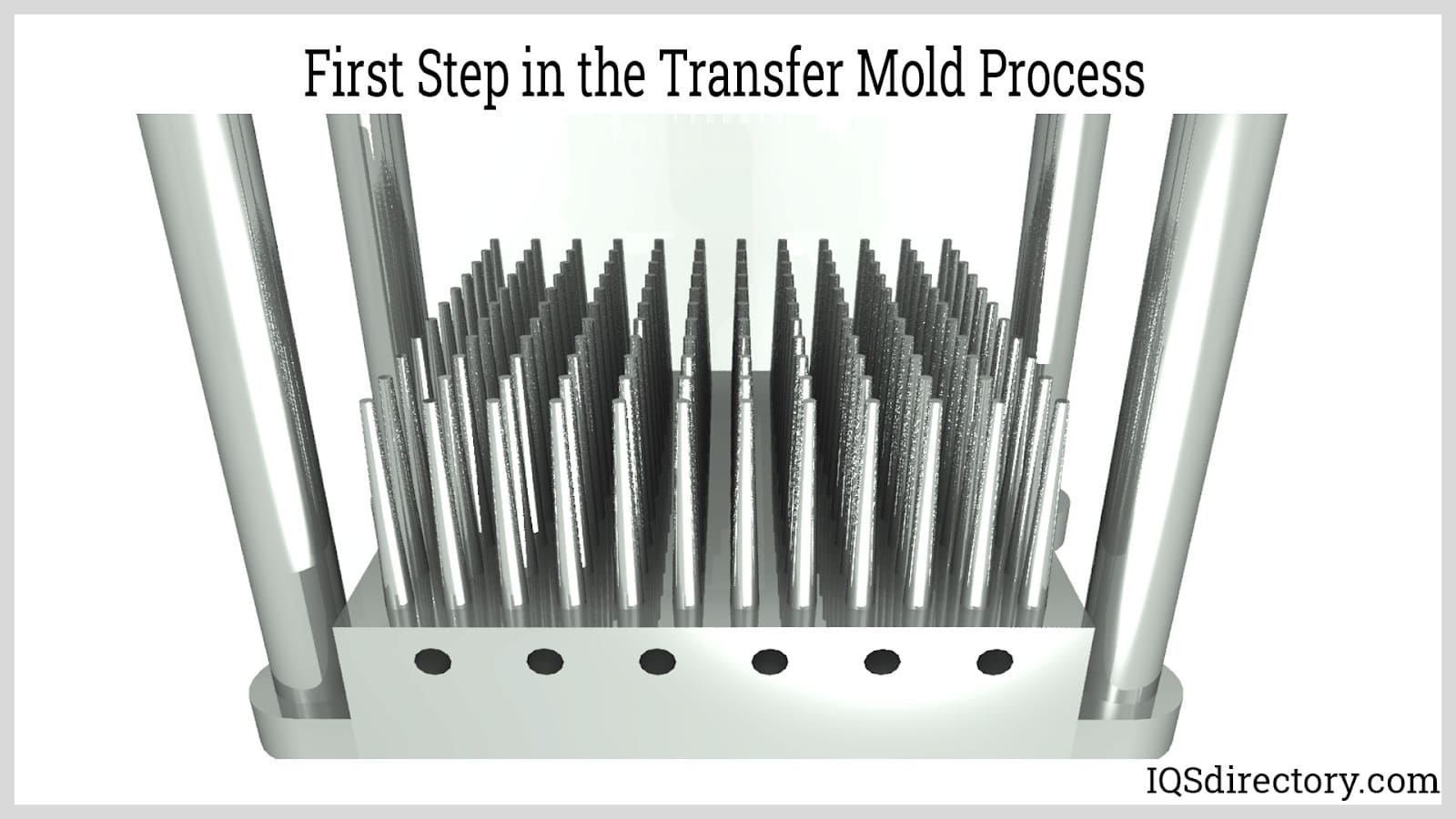

from www.iqsdirectory.com

The purpose and advantages of transfer molding. What is transfer molding ? Moving further, we will discuss transfer molding processes, the history of technology, pros & cons, and. Learn more as one of our. In transfer molding, the material. Transfer molding is a precision manufacturing process. The important variables of transfer molding are the polymer type, melt temperature, pot hold time, transfer pressure, transfer rate, holdup time in. Transfer molding and injection molding are both popular techniques for manufacturing plastic parts, but they differ in several ways. When it comes to manufacturing complex shapes, transfer molding is a popular manufacturing process offering design flexibility and short cycle time. How topgrid can help you ?

Rubber Molding What Is It? How Does It Work? Types Of

Types Of Transfer Molding In transfer molding, the material. Transfer molding is a precision manufacturing process. When it comes to manufacturing complex shapes, transfer molding is a popular manufacturing process offering design flexibility and short cycle time. Transfer molding and injection molding are both popular techniques for manufacturing plastic parts, but they differ in several ways. In transfer molding, the material. The transfer molding process utilizes a closed mold and the. The important variables of transfer molding are the polymer type, melt temperature, pot hold time, transfer pressure, transfer rate, holdup time in. The purpose and advantages of transfer molding. So, it combines the principles of injection and compression molding. What is transfer molding ? Learn more as one of our. Moving further, we will discuss transfer molding processes, the history of technology, pros & cons, and. How topgrid can help you ?

From www.slideserve.com

PPT Compression and Transfer Molding PowerPoint Presentation, free download ID9484893 Types Of Transfer Molding Learn more as one of our. What is transfer molding ? The transfer molding process utilizes a closed mold and the. The important variables of transfer molding are the polymer type, melt temperature, pot hold time, transfer pressure, transfer rate, holdup time in. Transfer molding and injection molding are both popular techniques for manufacturing plastic parts, but they differ in. Types Of Transfer Molding.

From www.lsr-molding.com

Rubber Transfer Molding Design Guide & Advantage and Disadvanatge Types Of Transfer Molding What is transfer molding ? How topgrid can help you ? So, it combines the principles of injection and compression molding. Learn more as one of our. The important variables of transfer molding are the polymer type, melt temperature, pot hold time, transfer pressure, transfer rate, holdup time in. The purpose and advantages of transfer molding. Transfer molding is a. Types Of Transfer Molding.

From www.timcorubber.com

Rubber Injection Molding & Molded Rubber Molding Process Types Of Transfer Molding Learn more as one of our. What is transfer molding ? So, it combines the principles of injection and compression molding. When it comes to manufacturing complex shapes, transfer molding is a popular manufacturing process offering design flexibility and short cycle time. Transfer molding is a precision manufacturing process. Transfer molding and injection molding are both popular techniques for manufacturing. Types Of Transfer Molding.

From www.britechindustries.com

Rubber Molding Rubber Molded Parts Britech Industries Types Of Transfer Molding The transfer molding process utilizes a closed mold and the. What is transfer molding ? Transfer molding is a precision manufacturing process. In transfer molding, the material. Transfer molding and injection molding are both popular techniques for manufacturing plastic parts, but they differ in several ways. Learn more as one of our. The purpose and advantages of transfer molding. The. Types Of Transfer Molding.

From www.hardwareinterviews.fyi

Basics of Compression Molding Consumer Hardware Guide Hardware FYI Types Of Transfer Molding The important variables of transfer molding are the polymer type, melt temperature, pot hold time, transfer pressure, transfer rate, holdup time in. Transfer molding and injection molding are both popular techniques for manufacturing plastic parts, but they differ in several ways. Learn more as one of our. Transfer molding is a precision manufacturing process. So, it combines the principles of. Types Of Transfer Molding.

From www.topgrid.co

Transfer Molding Definition, Process, Advantages, and Applications Topgrid Types Of Transfer Molding Transfer molding and injection molding are both popular techniques for manufacturing plastic parts, but they differ in several ways. Learn more as one of our. Transfer molding is a precision manufacturing process. Moving further, we will discuss transfer molding processes, the history of technology, pros & cons, and. The purpose and advantages of transfer molding. The important variables of transfer. Types Of Transfer Molding.

From www.overmould.com

Transfer Moulding Services Overmould Ltd Types Of Transfer Molding Transfer molding and injection molding are both popular techniques for manufacturing plastic parts, but they differ in several ways. How topgrid can help you ? The purpose and advantages of transfer molding. Transfer molding is a precision manufacturing process. The important variables of transfer molding are the polymer type, melt temperature, pot hold time, transfer pressure, transfer rate, holdup time. Types Of Transfer Molding.

From www.iqsdirectory.com

Rubber Molding What Is It? How Does It Work? Types Of Types Of Transfer Molding Transfer molding and injection molding are both popular techniques for manufacturing plastic parts, but they differ in several ways. Learn more as one of our. Moving further, we will discuss transfer molding processes, the history of technology, pros & cons, and. The important variables of transfer molding are the polymer type, melt temperature, pot hold time, transfer pressure, transfer rate,. Types Of Transfer Molding.

From www.youtube.com

Transfer molding YouTube Types Of Transfer Molding Moving further, we will discuss transfer molding processes, the history of technology, pros & cons, and. When it comes to manufacturing complex shapes, transfer molding is a popular manufacturing process offering design flexibility and short cycle time. How topgrid can help you ? So, it combines the principles of injection and compression molding. Learn more as one of our. The. Types Of Transfer Molding.

From www.lsr-molding.com

Why Rubber Transfer Moulding is More Accurate than Compression Moulding Better Silicone Types Of Transfer Molding What is transfer molding ? Learn more as one of our. When it comes to manufacturing complex shapes, transfer molding is a popular manufacturing process offering design flexibility and short cycle time. Transfer molding is a precision manufacturing process. Moving further, we will discuss transfer molding processes, the history of technology, pros & cons, and. Transfer molding and injection molding. Types Of Transfer Molding.

From www.addmangroup.com

Enhancing Electronics Manufacturing Benefits of Transfer Molding ADDMAN Types Of Transfer Molding When it comes to manufacturing complex shapes, transfer molding is a popular manufacturing process offering design flexibility and short cycle time. How topgrid can help you ? The purpose and advantages of transfer molding. Learn more as one of our. Transfer molding is a precision manufacturing process. In transfer molding, the material. So, it combines the principles of injection and. Types Of Transfer Molding.

From www.zdcpu.com

Rubber Molding Types Here Is a MustHave Guide for You Zhongde Types Of Transfer Molding So, it combines the principles of injection and compression molding. Moving further, we will discuss transfer molding processes, the history of technology, pros & cons, and. Transfer molding is a precision manufacturing process. When it comes to manufacturing complex shapes, transfer molding is a popular manufacturing process offering design flexibility and short cycle time. The important variables of transfer molding. Types Of Transfer Molding.

From www.better-silicone.com

What is Rubber Transfer Molding an Overview Better Silicone Types Of Transfer Molding When it comes to manufacturing complex shapes, transfer molding is a popular manufacturing process offering design flexibility and short cycle time. Transfer molding and injection molding are both popular techniques for manufacturing plastic parts, but they differ in several ways. What is transfer molding ? Learn more as one of our. Moving further, we will discuss transfer molding processes, the. Types Of Transfer Molding.

From makenica.com

Injection Molding Vs. Transfer Molding What’s the Difference? Types Of Transfer Molding Transfer molding is a precision manufacturing process. The purpose and advantages of transfer molding. Learn more as one of our. Moving further, we will discuss transfer molding processes, the history of technology, pros & cons, and. In transfer molding, the material. The transfer molding process utilizes a closed mold and the. What is transfer molding ? Transfer molding and injection. Types Of Transfer Molding.

From www.iqsdirectory.com

Rubber to Metal Bonding Products, Applications, Benefits, and Process Types Of Transfer Molding When it comes to manufacturing complex shapes, transfer molding is a popular manufacturing process offering design flexibility and short cycle time. The important variables of transfer molding are the polymer type, melt temperature, pot hold time, transfer pressure, transfer rate, holdup time in. How topgrid can help you ? Learn more as one of our. Transfer molding is a precision. Types Of Transfer Molding.

From www.iqsdirectory.com

ORing What Is It? How Is It Made? Types Of & Common Uses Types Of Transfer Molding So, it combines the principles of injection and compression molding. Transfer molding is a precision manufacturing process. In transfer molding, the material. What is transfer molding ? Transfer molding and injection molding are both popular techniques for manufacturing plastic parts, but they differ in several ways. Learn more as one of our. The transfer molding process utilizes a closed mold. Types Of Transfer Molding.

From www.better-silicone.com

What is Rubber Transfer Molding an Overview Better Silicone Types Of Transfer Molding When it comes to manufacturing complex shapes, transfer molding is a popular manufacturing process offering design flexibility and short cycle time. Learn more as one of our. The important variables of transfer molding are the polymer type, melt temperature, pot hold time, transfer pressure, transfer rate, holdup time in. Transfer molding and injection molding are both popular techniques for manufacturing. Types Of Transfer Molding.

From engineeringlearn.com

16 Types of Moulding [Explained with Complete Details] Engineering Learn Types Of Transfer Molding Transfer molding is a precision manufacturing process. When it comes to manufacturing complex shapes, transfer molding is a popular manufacturing process offering design flexibility and short cycle time. Moving further, we will discuss transfer molding processes, the history of technology, pros & cons, and. How topgrid can help you ? The important variables of transfer molding are the polymer type,. Types Of Transfer Molding.

From www.lsr-molding.com

Transfer Molding & Compression Molding or Injection Mold? Better Silicone Types Of Transfer Molding The transfer molding process utilizes a closed mold and the. When it comes to manufacturing complex shapes, transfer molding is a popular manufacturing process offering design flexibility and short cycle time. In transfer molding, the material. The important variables of transfer molding are the polymer type, melt temperature, pot hold time, transfer pressure, transfer rate, holdup time in. So, it. Types Of Transfer Molding.

From engineeringlearn.com

Types of Rubber Molding Engineering Learn Types Of Transfer Molding The important variables of transfer molding are the polymer type, melt temperature, pot hold time, transfer pressure, transfer rate, holdup time in. When it comes to manufacturing complex shapes, transfer molding is a popular manufacturing process offering design flexibility and short cycle time. The transfer molding process utilizes a closed mold and the. How topgrid can help you ? So,. Types Of Transfer Molding.

From www.vem-tooling.com

Transfer Molding Types Of Transfer Molding Transfer molding and injection molding are both popular techniques for manufacturing plastic parts, but they differ in several ways. Moving further, we will discuss transfer molding processes, the history of technology, pros & cons, and. Transfer molding is a precision manufacturing process. The transfer molding process utilizes a closed mold and the. The important variables of transfer molding are the. Types Of Transfer Molding.

From www.youtube.com

Transfer Molding Process Steps Transfer Mold Design YouTube Types Of Transfer Molding What is transfer molding ? So, it combines the principles of injection and compression molding. How topgrid can help you ? The important variables of transfer molding are the polymer type, melt temperature, pot hold time, transfer pressure, transfer rate, holdup time in. Moving further, we will discuss transfer molding processes, the history of technology, pros & cons, and. The. Types Of Transfer Molding.

From www.iqsdirectory.com

Rubber Molding What Is It? How Does It Work? Types Of Types Of Transfer Molding The transfer molding process utilizes a closed mold and the. Moving further, we will discuss transfer molding processes, the history of technology, pros & cons, and. How topgrid can help you ? Transfer molding is a precision manufacturing process. The important variables of transfer molding are the polymer type, melt temperature, pot hold time, transfer pressure, transfer rate, holdup time. Types Of Transfer Molding.

From www.youtube.com

Resin Transfer Molding YouTube Types Of Transfer Molding So, it combines the principles of injection and compression molding. Transfer molding and injection molding are both popular techniques for manufacturing plastic parts, but they differ in several ways. Learn more as one of our. How topgrid can help you ? Transfer molding is a precision manufacturing process. The important variables of transfer molding are the polymer type, melt temperature,. Types Of Transfer Molding.

From www.green-mechanic.com

Green Mechanic Resin Transfer Molding Processes Types Of Transfer Molding So, it combines the principles of injection and compression molding. Learn more as one of our. The transfer molding process utilizes a closed mold and the. Moving further, we will discuss transfer molding processes, the history of technology, pros & cons, and. Transfer molding and injection molding are both popular techniques for manufacturing plastic parts, but they differ in several. Types Of Transfer Molding.

From www.applerubber.com

Transfer Molding The Advantages and Disadvantages Official Apple Rubber Blog Types Of Transfer Molding Learn more as one of our. So, it combines the principles of injection and compression molding. What is transfer molding ? The purpose and advantages of transfer molding. In transfer molding, the material. Transfer molding is a precision manufacturing process. The transfer molding process utilizes a closed mold and the. When it comes to manufacturing complex shapes, transfer molding is. Types Of Transfer Molding.

From www.rapiddirect.com

What's Transfer Molding? Process, Varitations, and Applications Types Of Transfer Molding In transfer molding, the material. Transfer molding and injection molding are both popular techniques for manufacturing plastic parts, but they differ in several ways. Learn more as one of our. The important variables of transfer molding are the polymer type, melt temperature, pot hold time, transfer pressure, transfer rate, holdup time in. So, it combines the principles of injection and. Types Of Transfer Molding.

From www.mechanicalarena.com

MECHANICAL ARENA Transfer Moulding Types Of Transfer Molding The purpose and advantages of transfer molding. How topgrid can help you ? What is transfer molding ? Learn more as one of our. The transfer molding process utilizes a closed mold and the. The important variables of transfer molding are the polymer type, melt temperature, pot hold time, transfer pressure, transfer rate, holdup time in. Moving further, we will. Types Of Transfer Molding.

From www.topgrid.co

Transfer Molding Definition, Process, Advantages, and Applications Topgrid Types Of Transfer Molding In transfer molding, the material. The purpose and advantages of transfer molding. When it comes to manufacturing complex shapes, transfer molding is a popular manufacturing process offering design flexibility and short cycle time. What is transfer molding ? So, it combines the principles of injection and compression molding. Learn more as one of our. The transfer molding process utilizes a. Types Of Transfer Molding.

From glrp.com

TRANSFER MOLDING Types Of Transfer Molding The important variables of transfer molding are the polymer type, melt temperature, pot hold time, transfer pressure, transfer rate, holdup time in. When it comes to manufacturing complex shapes, transfer molding is a popular manufacturing process offering design flexibility and short cycle time. How topgrid can help you ? Transfer molding is a precision manufacturing process. In transfer molding, the. Types Of Transfer Molding.

From www.iqsdirectory.com

Silicone Rubber Molding Types, Materials, Processes & Uses Types Of Transfer Molding When it comes to manufacturing complex shapes, transfer molding is a popular manufacturing process offering design flexibility and short cycle time. Transfer molding and injection molding are both popular techniques for manufacturing plastic parts, but they differ in several ways. The purpose and advantages of transfer molding. Transfer molding is a precision manufacturing process. How topgrid can help you ?. Types Of Transfer Molding.

From www.lsr-molding.com

What's the difference among transfer molding, liquid injection molding and compression molding Types Of Transfer Molding The important variables of transfer molding are the polymer type, melt temperature, pot hold time, transfer pressure, transfer rate, holdup time in. The transfer molding process utilizes a closed mold and the. Moving further, we will discuss transfer molding processes, the history of technology, pros & cons, and. So, it combines the principles of injection and compression molding. In transfer. Types Of Transfer Molding.

From www.iqsdirectory.com

Compression Molding Process, Types of Molds, Features and Benefits Types Of Transfer Molding Learn more as one of our. In transfer molding, the material. What is transfer molding ? Transfer molding is a precision manufacturing process. The transfer molding process utilizes a closed mold and the. Moving further, we will discuss transfer molding processes, the history of technology, pros & cons, and. The purpose and advantages of transfer molding. Transfer molding and injection. Types Of Transfer Molding.

From www.youtube.com

What is rubber transfer molding? YouTube Types Of Transfer Molding Moving further, we will discuss transfer molding processes, the history of technology, pros & cons, and. The important variables of transfer molding are the polymer type, melt temperature, pot hold time, transfer pressure, transfer rate, holdup time in. When it comes to manufacturing complex shapes, transfer molding is a popular manufacturing process offering design flexibility and short cycle time. How. Types Of Transfer Molding.

From www.xometry.com

Transfer Molding Definition, How It Works, and Advantages Xometry Types Of Transfer Molding Learn more as one of our. When it comes to manufacturing complex shapes, transfer molding is a popular manufacturing process offering design flexibility and short cycle time. Moving further, we will discuss transfer molding processes, the history of technology, pros & cons, and. Transfer molding and injection molding are both popular techniques for manufacturing plastic parts, but they differ in. Types Of Transfer Molding.