How To Lubricate Pvc Threads . Dry fitting is only going to be a rough indicator. When tapered threaded parts are. If things are critical, measure. Maybe glue part and after that measure and cut that last. Two turns past finger tight, plus the stress of system pressure will ensure it is within the tensile strength of pvc. So i'm curious about the threads of the. The proper way to assemble threaded pvc sch 40 or sch 80 fittings is to finger tighten, then add one to two turns, but no m ore. Recommended good practice is to use a thread sealant (not a thread lubricant) and to assemble the joint to finger tight plus one turn, two turns at the most. Apply a sealant as a preventive measure or as a repair to prevent further leaks. Thread sealants act as a lubricant making it extremely easy to over torque.

from www.fluoramics.com

If things are critical, measure. Apply a sealant as a preventive measure or as a repair to prevent further leaks. So i'm curious about the threads of the. The proper way to assemble threaded pvc sch 40 or sch 80 fittings is to finger tighten, then add one to two turns, but no m ore. Thread sealants act as a lubricant making it extremely easy to over torque. Maybe glue part and after that measure and cut that last. Dry fitting is only going to be a rough indicator. Two turns past finger tight, plus the stress of system pressure will ensure it is within the tensile strength of pvc. When tapered threaded parts are. Recommended good practice is to use a thread sealant (not a thread lubricant) and to assemble the joint to finger tight plus one turn, two turns at the most.

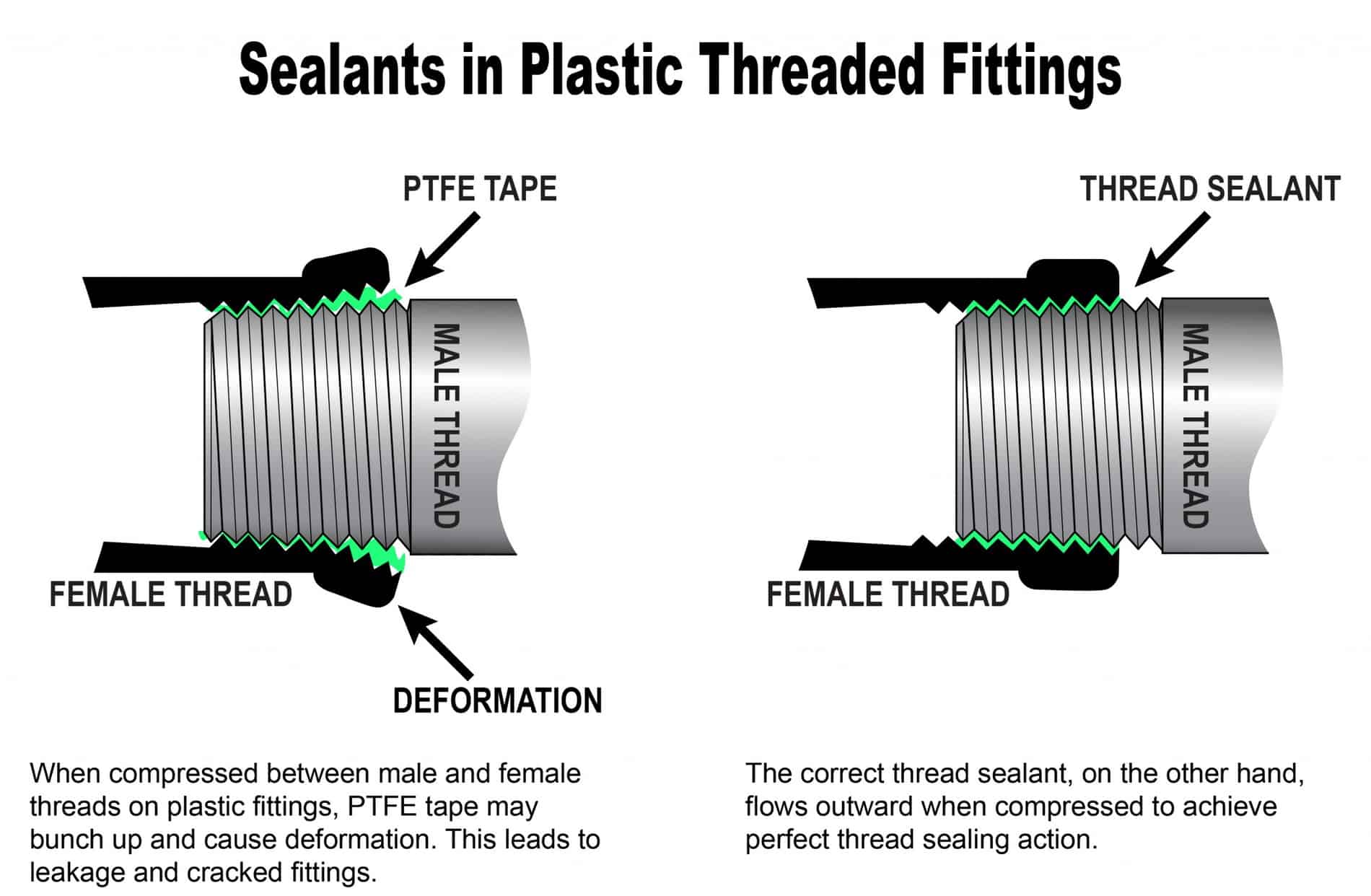

Dos and Don'ts of Assembling Threaded Plastic Fittings

How To Lubricate Pvc Threads So i'm curious about the threads of the. When tapered threaded parts are. Thread sealants act as a lubricant making it extremely easy to over torque. Maybe glue part and after that measure and cut that last. If things are critical, measure. So i'm curious about the threads of the. Dry fitting is only going to be a rough indicator. Two turns past finger tight, plus the stress of system pressure will ensure it is within the tensile strength of pvc. Apply a sealant as a preventive measure or as a repair to prevent further leaks. The proper way to assemble threaded pvc sch 40 or sch 80 fittings is to finger tighten, then add one to two turns, but no m ore. Recommended good practice is to use a thread sealant (not a thread lubricant) and to assemble the joint to finger tight plus one turn, two turns at the most.

From www.youtube.com

HOW TO LUBRICATE YOUR OVERLOCKER YouTube How To Lubricate Pvc Threads Recommended good practice is to use a thread sealant (not a thread lubricant) and to assemble the joint to finger tight plus one turn, two turns at the most. Two turns past finger tight, plus the stress of system pressure will ensure it is within the tensile strength of pvc. When tapered threaded parts are. So i'm curious about the. How To Lubricate Pvc Threads.

From www.samaro.fr

How to lubricate a plastic and elastomers parts ? Samaro How To Lubricate Pvc Threads If things are critical, measure. Thread sealants act as a lubricant making it extremely easy to over torque. When tapered threaded parts are. Recommended good practice is to use a thread sealant (not a thread lubricant) and to assemble the joint to finger tight plus one turn, two turns at the most. Two turns past finger tight, plus the stress. How To Lubricate Pvc Threads.

From allbe.ca

How to lubricate joints naturally A 6 Steps Guide Allbe Canada How To Lubricate Pvc Threads If things are critical, measure. Maybe glue part and after that measure and cut that last. When tapered threaded parts are. Dry fitting is only going to be a rough indicator. The proper way to assemble threaded pvc sch 40 or sch 80 fittings is to finger tighten, then add one to two turns, but no m ore. So i'm. How To Lubricate Pvc Threads.

From www.youtube.com

Stripped Thread Repair How To Install Thread Inserts YouTube How To Lubricate Pvc Threads Recommended good practice is to use a thread sealant (not a thread lubricant) and to assemble the joint to finger tight plus one turn, two turns at the most. Apply a sealant as a preventive measure or as a repair to prevent further leaks. When tapered threaded parts are. Two turns past finger tight, plus the stress of system pressure. How To Lubricate Pvc Threads.

From joilbuxal.blob.core.windows.net

What To Use To Seal Plastic Pipes at Betty Doyle blog How To Lubricate Pvc Threads Thread sealants act as a lubricant making it extremely easy to over torque. So i'm curious about the threads of the. The proper way to assemble threaded pvc sch 40 or sch 80 fittings is to finger tighten, then add one to two turns, but no m ore. Two turns past finger tight, plus the stress of system pressure will. How To Lubricate Pvc Threads.

From www.youtube.com

External threading on pvc pipe YouTube How To Lubricate Pvc Threads Dry fitting is only going to be a rough indicator. Recommended good practice is to use a thread sealant (not a thread lubricant) and to assemble the joint to finger tight plus one turn, two turns at the most. The proper way to assemble threaded pvc sch 40 or sch 80 fittings is to finger tighten, then add one to. How To Lubricate Pvc Threads.

From www.youtube.com

Plastic PVC PP Pipe threading machine YouTube How To Lubricate Pvc Threads Two turns past finger tight, plus the stress of system pressure will ensure it is within the tensile strength of pvc. So i'm curious about the threads of the. Thread sealants act as a lubricant making it extremely easy to over torque. Apply a sealant as a preventive measure or as a repair to prevent further leaks. When tapered threaded. How To Lubricate Pvc Threads.

From www.youtube.com

How To Convert PVC Pipe Threads to Hose Threads YouTube How To Lubricate Pvc Threads Dry fitting is only going to be a rough indicator. Thread sealants act as a lubricant making it extremely easy to over torque. So i'm curious about the threads of the. Two turns past finger tight, plus the stress of system pressure will ensure it is within the tensile strength of pvc. If things are critical, measure. Recommended good practice. How To Lubricate Pvc Threads.

From wd40.co.uk

Awning Lubrication A Guide To Lubricating Your Awning WD40® How To Lubricate Pvc Threads When tapered threaded parts are. If things are critical, measure. Dry fitting is only going to be a rough indicator. Apply a sealant as a preventive measure or as a repair to prevent further leaks. The proper way to assemble threaded pvc sch 40 or sch 80 fittings is to finger tighten, then add one to two turns, but no. How To Lubricate Pvc Threads.

From precisionlubrication.com

How to Properly Lubricate a Rolling Element Bearing How To Lubricate Pvc Threads Recommended good practice is to use a thread sealant (not a thread lubricant) and to assemble the joint to finger tight plus one turn, two turns at the most. If things are critical, measure. The proper way to assemble threaded pvc sch 40 or sch 80 fittings is to finger tighten, then add one to two turns, but no m. How To Lubricate Pvc Threads.

From www.thespruce.com

Using Pipe Dope to Ensure Tight Seals in Plumbing Joints How To Lubricate Pvc Threads The proper way to assemble threaded pvc sch 40 or sch 80 fittings is to finger tighten, then add one to two turns, but no m ore. Apply a sealant as a preventive measure or as a repair to prevent further leaks. Maybe glue part and after that measure and cut that last. If things are critical, measure. So i'm. How To Lubricate Pvc Threads.

From www.youtube.com

HOW TO THREAD PVC PIPE YouTube How To Lubricate Pvc Threads If things are critical, measure. So i'm curious about the threads of the. Apply a sealant as a preventive measure or as a repair to prevent further leaks. Recommended good practice is to use a thread sealant (not a thread lubricant) and to assemble the joint to finger tight plus one turn, two turns at the most. Two turns past. How To Lubricate Pvc Threads.

From www.pipsisland.com

4 Simple Steps to Thread Pvc Pipe How To Lubricate Pvc Threads If things are critical, measure. When tapered threaded parts are. Apply a sealant as a preventive measure or as a repair to prevent further leaks. Thread sealants act as a lubricant making it extremely easy to over torque. Maybe glue part and after that measure and cut that last. The proper way to assemble threaded pvc sch 40 or sch. How To Lubricate Pvc Threads.

From maineboats.netlify.app

How to lubricate boat steering cables How To Lubricate Pvc Threads Two turns past finger tight, plus the stress of system pressure will ensure it is within the tensile strength of pvc. Recommended good practice is to use a thread sealant (not a thread lubricant) and to assemble the joint to finger tight plus one turn, two turns at the most. So i'm curious about the threads of the. When tapered. How To Lubricate Pvc Threads.

From www.fluoramics.com

Dos and Don'ts of Assembling Threaded Plastic Fittings How To Lubricate Pvc Threads Dry fitting is only going to be a rough indicator. Thread sealants act as a lubricant making it extremely easy to over torque. Recommended good practice is to use a thread sealant (not a thread lubricant) and to assemble the joint to finger tight plus one turn, two turns at the most. Maybe glue part and after that measure and. How To Lubricate Pvc Threads.

From www.limonrobot.com

How to lubricate ball screws? LIMON How To Lubricate Pvc Threads Recommended good practice is to use a thread sealant (not a thread lubricant) and to assemble the joint to finger tight plus one turn, two turns at the most. The proper way to assemble threaded pvc sch 40 or sch 80 fittings is to finger tighten, then add one to two turns, but no m ore. When tapered threaded parts. How To Lubricate Pvc Threads.

From wiki.bambulab.com

Guide on how to lubricate the A1 mini Yaxis guide rail Bambu Lab Wiki How To Lubricate Pvc Threads Apply a sealant as a preventive measure or as a repair to prevent further leaks. Thread sealants act as a lubricant making it extremely easy to over torque. So i'm curious about the threads of the. The proper way to assemble threaded pvc sch 40 or sch 80 fittings is to finger tighten, then add one to two turns, but. How To Lubricate Pvc Threads.

From www.getawaycouple.com

Quick and Easy Ways to Lubricate Your RV Slides Getaway Couple How To Lubricate Pvc Threads If things are critical, measure. When tapered threaded parts are. Maybe glue part and after that measure and cut that last. Recommended good practice is to use a thread sealant (not a thread lubricant) and to assemble the joint to finger tight plus one turn, two turns at the most. Thread sealants act as a lubricant making it extremely easy. How To Lubricate Pvc Threads.

From www.youtube.com

Preventing Leaks at Threaded Pipe Connections YouTube How To Lubricate Pvc Threads Dry fitting is only going to be a rough indicator. Apply a sealant as a preventive measure or as a repair to prevent further leaks. Thread sealants act as a lubricant making it extremely easy to over torque. Two turns past finger tight, plus the stress of system pressure will ensure it is within the tensile strength of pvc. The. How To Lubricate Pvc Threads.

From wiki.bambulab.com

Guide on how to lubricate the A1 mini Yaxis guide rail Bambu Lab Wiki How To Lubricate Pvc Threads When tapered threaded parts are. Thread sealants act as a lubricant making it extremely easy to over torque. Dry fitting is only going to be a rough indicator. If things are critical, measure. The proper way to assemble threaded pvc sch 40 or sch 80 fittings is to finger tighten, then add one to two turns, but no m ore.. How To Lubricate Pvc Threads.

From www.pinterest.com

How to lubricate the accessories? Lubricants, Pvc windows, Vaseline How To Lubricate Pvc Threads If things are critical, measure. When tapered threaded parts are. So i'm curious about the threads of the. Apply a sealant as a preventive measure or as a repair to prevent further leaks. The proper way to assemble threaded pvc sch 40 or sch 80 fittings is to finger tighten, then add one to two turns, but no m ore.. How To Lubricate Pvc Threads.

From sunshoweronline.com.au

How to Measure BSP Threads and PVC Pipe 💧 How To Lubricate Pvc Threads Thread sealants act as a lubricant making it extremely easy to over torque. So i'm curious about the threads of the. Recommended good practice is to use a thread sealant (not a thread lubricant) and to assemble the joint to finger tight plus one turn, two turns at the most. If things are critical, measure. When tapered threaded parts are.. How To Lubricate Pvc Threads.

From life-improver.com

PVC threaded fitting broken off. How to remove Love & Improve Life How To Lubricate Pvc Threads The proper way to assemble threaded pvc sch 40 or sch 80 fittings is to finger tighten, then add one to two turns, but no m ore. Maybe glue part and after that measure and cut that last. If things are critical, measure. Dry fitting is only going to be a rough indicator. Apply a sealant as a preventive measure. How To Lubricate Pvc Threads.

From www.dispomed.com

Did you know how to lubricate handpieces properly? Dispomed How To Lubricate Pvc Threads If things are critical, measure. The proper way to assemble threaded pvc sch 40 or sch 80 fittings is to finger tighten, then add one to two turns, but no m ore. Two turns past finger tight, plus the stress of system pressure will ensure it is within the tensile strength of pvc. Apply a sealant as a preventive measure. How To Lubricate Pvc Threads.

From www.youtube.com

How to Repair Buried PVC Pipe YouTube How To Lubricate Pvc Threads Two turns past finger tight, plus the stress of system pressure will ensure it is within the tensile strength of pvc. When tapered threaded parts are. Recommended good practice is to use a thread sealant (not a thread lubricant) and to assemble the joint to finger tight plus one turn, two turns at the most. Dry fitting is only going. How To Lubricate Pvc Threads.

From lubricantsinfo.com

How to Lubricate O Rings Quick and Effective Guide Lubricants Info How To Lubricate Pvc Threads Recommended good practice is to use a thread sealant (not a thread lubricant) and to assemble the joint to finger tight plus one turn, two turns at the most. Thread sealants act as a lubricant making it extremely easy to over torque. Maybe glue part and after that measure and cut that last. If things are critical, measure. When tapered. How To Lubricate Pvc Threads.

From blog.wheelsbikes.com

How to Lubricate Your Bicycle Chain for Better Performance and Longevity! How To Lubricate Pvc Threads So i'm curious about the threads of the. Recommended good practice is to use a thread sealant (not a thread lubricant) and to assemble the joint to finger tight plus one turn, two turns at the most. Dry fitting is only going to be a rough indicator. The proper way to assemble threaded pvc sch 40 or sch 80 fittings. How To Lubricate Pvc Threads.

From www.youtube.com

How to remove pvc threads from fitting YouTube How To Lubricate Pvc Threads Recommended good practice is to use a thread sealant (not a thread lubricant) and to assemble the joint to finger tight plus one turn, two turns at the most. Apply a sealant as a preventive measure or as a repair to prevent further leaks. If things are critical, measure. Maybe glue part and after that measure and cut that last.. How To Lubricate Pvc Threads.

From dengarden.com

A Complete Guide to Pipe Fittings and How to Use Them to Connect PEX How To Lubricate Pvc Threads Dry fitting is only going to be a rough indicator. So i'm curious about the threads of the. If things are critical, measure. Apply a sealant as a preventive measure or as a repair to prevent further leaks. Thread sealants act as a lubricant making it extremely easy to over torque. Maybe glue part and after that measure and cut. How To Lubricate Pvc Threads.

From www.vtechtextiles.com

Lubricate ThreadEliminate Breaks and Snarling! How To Lubricate Pvc Threads Dry fitting is only going to be a rough indicator. Apply a sealant as a preventive measure or as a repair to prevent further leaks. Maybe glue part and after that measure and cut that last. If things are critical, measure. Two turns past finger tight, plus the stress of system pressure will ensure it is within the tensile strength. How To Lubricate Pvc Threads.

From www.pipsisland.com

7 Simple Steps To Connect Threaded PVC Pipes How To Lubricate Pvc Threads Two turns past finger tight, plus the stress of system pressure will ensure it is within the tensile strength of pvc. Thread sealants act as a lubricant making it extremely easy to over torque. The proper way to assemble threaded pvc sch 40 or sch 80 fittings is to finger tighten, then add one to two turns, but no m. How To Lubricate Pvc Threads.

From www.youtube.com

Sealing PVC threaded unions. Swimming pool filter spa. Teflon tape on How To Lubricate Pvc Threads Recommended good practice is to use a thread sealant (not a thread lubricant) and to assemble the joint to finger tight plus one turn, two turns at the most. Apply a sealant as a preventive measure or as a repair to prevent further leaks. When tapered threaded parts are. Two turns past finger tight, plus the stress of system pressure. How To Lubricate Pvc Threads.

From www.youtube.com

Does lube make a difference? Pulling wire through conduit with Yellow How To Lubricate Pvc Threads When tapered threaded parts are. The proper way to assemble threaded pvc sch 40 or sch 80 fittings is to finger tighten, then add one to two turns, but no m ore. Maybe glue part and after that measure and cut that last. Two turns past finger tight, plus the stress of system pressure will ensure it is within the. How To Lubricate Pvc Threads.

From diyquickly.com

How to Lubricate Cylinder Walls 7 Pro Tips (2024) How To Lubricate Pvc Threads Thread sealants act as a lubricant making it extremely easy to over torque. When tapered threaded parts are. Two turns past finger tight, plus the stress of system pressure will ensure it is within the tensile strength of pvc. If things are critical, measure. So i'm curious about the threads of the. Recommended good practice is to use a thread. How To Lubricate Pvc Threads.

From www.youtube.com

Pipe dope on PVC threads. YouTube How To Lubricate Pvc Threads If things are critical, measure. The proper way to assemble threaded pvc sch 40 or sch 80 fittings is to finger tighten, then add one to two turns, but no m ore. Dry fitting is only going to be a rough indicator. Recommended good practice is to use a thread sealant (not a thread lubricant) and to assemble the joint. How To Lubricate Pvc Threads.