Low Pressure Die Casting Mould Design . Unlike the traditional die casting process , it has a. There are two main types of this process: This process data sheet describes the basic steps involved in the lpdc process as well as the benefits and limitations of the process: Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. An essential component of the. May 29, 2022 reading time: Die casting is a significant process for applications in various industries. Low pressure die casting is a method of production that involves molten metal being forced, under low pressure, into a die rather than relying on gravity to fill a mould as is the case.

from www.aluminiumdiecastingmould.com

May 29, 2022 reading time: An essential component of the. Die casting is a significant process for applications in various industries. Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. This process data sheet describes the basic steps involved in the lpdc process as well as the benefits and limitations of the process: Low pressure die casting is a method of production that involves molten metal being forced, under low pressure, into a die rather than relying on gravity to fill a mould as is the case. Unlike the traditional die casting process , it has a. There are two main types of this process:

Single / Multi Cavity Al Low Pressure Die Casting Mould lamp cover

Low Pressure Die Casting Mould Design Unlike the traditional die casting process , it has a. An essential component of the. Low pressure die casting is a method of production that involves molten metal being forced, under low pressure, into a die rather than relying on gravity to fill a mould as is the case. Die casting is a significant process for applications in various industries. This process data sheet describes the basic steps involved in the lpdc process as well as the benefits and limitations of the process: Unlike the traditional die casting process , it has a. May 29, 2022 reading time: Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. There are two main types of this process:

From www.inoxcast.com

Low Pressure Die Casting Services Expert Inox Casting Low Pressure Die Casting Mould Design May 29, 2022 reading time: Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. Low pressure die casting is a method of production that involves molten metal being forced, under low pressure, into a die rather than relying on gravity to fill a mould as is the case.. Low Pressure Die Casting Mould Design.

From www.nkr-engineering.com

Low Pressure Casting Mold Low Pressure Die Casting Mould Design This process data sheet describes the basic steps involved in the lpdc process as well as the benefits and limitations of the process: May 29, 2022 reading time: Low pressure die casting is a method of production that involves molten metal being forced, under low pressure, into a die rather than relying on gravity to fill a mould as is. Low Pressure Die Casting Mould Design.

From www.youtube.com

Permanent Mold Low Pressure Die Casting Animation YouTube Low Pressure Die Casting Mould Design May 29, 2022 reading time: Die casting is a significant process for applications in various industries. Unlike the traditional die casting process , it has a. An essential component of the. There are two main types of this process: This process data sheet describes the basic steps involved in the lpdc process as well as the benefits and limitations of. Low Pressure Die Casting Mould Design.

From www.aluminiumdiecastingmould.com

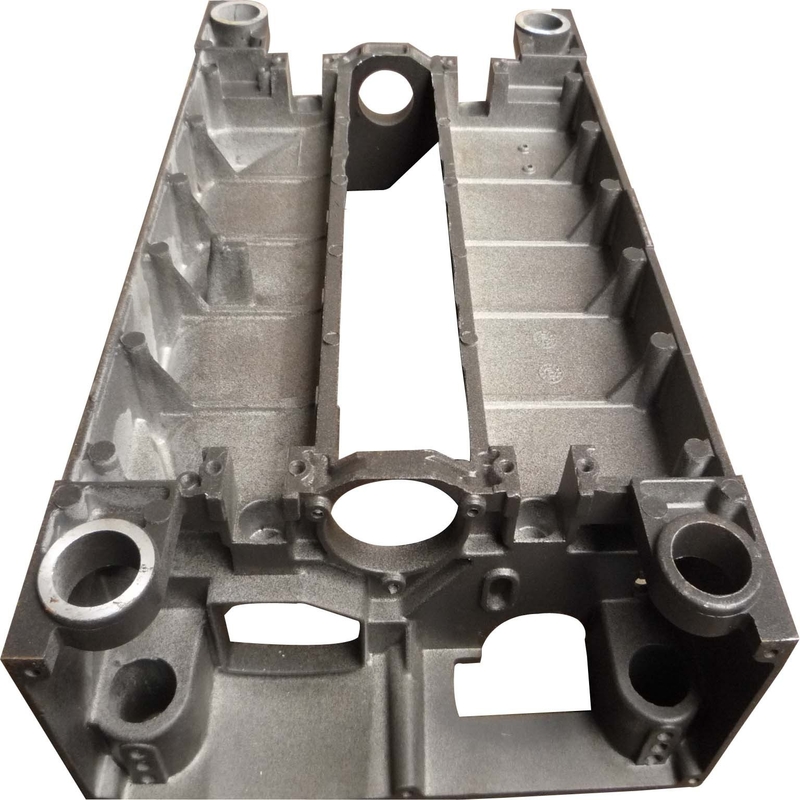

OEM ADC12 A380 Low Pressure Die Casting Mould Military Box Low Pressure Die Casting Mould Design Die casting is a significant process for applications in various industries. There are two main types of this process: May 29, 2022 reading time: Unlike the traditional die casting process , it has a. An essential component of the. Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification.. Low Pressure Die Casting Mould Design.

From www.youtube.com

Low Pressure Die Casting Simulation FLOW3D CAST YouTube Low Pressure Die Casting Mould Design May 29, 2022 reading time: Die casting is a significant process for applications in various industries. Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. This process data sheet describes the basic steps involved in the lpdc process as well as the benefits and limitations of the process:. Low Pressure Die Casting Mould Design.

From www.qc-mold.com

Pressure Die casting mould Low Pressure Die Casting Mould Design This process data sheet describes the basic steps involved in the lpdc process as well as the benefits and limitations of the process: Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. An essential component of the. Die casting is a significant process for applications in various industries.. Low Pressure Die Casting Mould Design.

From www.aluminiumdiecastingmould.com

Single / Multi Cavity Al Low Pressure Die Casting Mould lamp cover Low Pressure Die Casting Mould Design May 29, 2022 reading time: Die casting is a significant process for applications in various industries. An essential component of the. This process data sheet describes the basic steps involved in the lpdc process as well as the benefits and limitations of the process: Low pressure die casting is a method of production that involves molten metal being forced, under. Low Pressure Die Casting Mould Design.

From www.zintilon.com

Precision Die Casting Custom Solutions Zintilon Low Pressure Die Casting Mould Design Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. May 29, 2022 reading time: An essential component of the. Die casting is a significant process for applications in various industries. Low pressure die casting is a method of production that involves molten metal being forced, under low pressure,. Low Pressure Die Casting Mould Design.

From dcmakine.com

Low Pressure Casting Molds DC Makine Low Pressure Die Casting Mould Design May 29, 2022 reading time: Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. Unlike the traditional die casting process , it has a. This process data sheet describes the basic steps involved in the lpdc process as well as the benefits and limitations of the process: Low. Low Pressure Die Casting Mould Design.

From thelibraryofmanufacturing.com

Pressure Casting Low Pressure Die Casting Mould Design There are two main types of this process: This process data sheet describes the basic steps involved in the lpdc process as well as the benefits and limitations of the process: Unlike the traditional die casting process , it has a. An essential component of the. Low pressure die casting is a method of production that involves molten metal being. Low Pressure Die Casting Mould Design.

From www.mdpi.com

Metals Free FullText Advanced Process Simulation of Low Pressure Low Pressure Die Casting Mould Design This process data sheet describes the basic steps involved in the lpdc process as well as the benefits and limitations of the process: Die casting is a significant process for applications in various industries. There are two main types of this process: May 29, 2022 reading time: Die casting is a permanent mould casting process in which molten metal is. Low Pressure Die Casting Mould Design.

From jd-transformer.en.made-in-china.com

Low Pressure Die Casting Process Parameters Aluminum Pressure Die Low Pressure Die Casting Mould Design This process data sheet describes the basic steps involved in the lpdc process as well as the benefits and limitations of the process: There are two main types of this process: May 29, 2022 reading time: Low pressure die casting is a method of production that involves molten metal being forced, under low pressure, into a die rather than relying. Low Pressure Die Casting Mould Design.

From www.sksdiecasting.com

Custom Die Casting Mold Design & Development Services Low Pressure Die Casting Mould Design Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. An essential component of the. Unlike the traditional die casting process , it has a. There are two main types of this process: Die casting is a significant process for applications in various industries. Low pressure die casting is. Low Pressure Die Casting Mould Design.

From www.indiamart.com

Aluminium Mild Steel Low Pressure Die Casting Mould at Rs 175000 in Low Pressure Die Casting Mould Design This process data sheet describes the basic steps involved in the lpdc process as well as the benefits and limitations of the process: May 29, 2022 reading time: Unlike the traditional die casting process , it has a. An essential component of the. There are two main types of this process: Low pressure die casting is a method of production. Low Pressure Die Casting Mould Design.

From www.manufacturingguide.com

Low pressure mold casting Find suppliers, processes & material Low Pressure Die Casting Mould Design Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. An essential component of the. Low pressure die casting is a method of production that involves molten metal being forced, under low pressure, into a die rather than relying on gravity to fill a mould as is the case.. Low Pressure Die Casting Mould Design.

From www.giessereilexikon.com

Low pressure gravity die casting process Low Pressure Die Casting Mould Design Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. An essential component of the. May 29, 2022 reading time: There are two main types of this process: Die casting is a significant process for applications in various industries. Low pressure die casting is a method of production that. Low Pressure Die Casting Mould Design.

From oeform.com

Die casting mold design Alu; Zinc;Mg Die casting OEFORM Low Pressure Die Casting Mould Design May 29, 2022 reading time: This process data sheet describes the basic steps involved in the lpdc process as well as the benefits and limitations of the process: Die casting is a significant process for applications in various industries. An essential component of the. Unlike the traditional die casting process , it has a. Low pressure die casting is a. Low Pressure Die Casting Mould Design.

From piq2.com

Die Casting Mold/Mould Design CastleMIND Software PIQ2 Low Pressure Die Casting Mould Design Low pressure die casting is a method of production that involves molten metal being forced, under low pressure, into a die rather than relying on gravity to fill a mould as is the case. May 29, 2022 reading time: Die casting is a significant process for applications in various industries. An essential component of the. There are two main types. Low Pressure Die Casting Mould Design.

From www.aluminiumdiecastingmould.com

Aluminum Low Pressure Die Casting Mould 50,000100,000 Shots Low Pressure Die Casting Mould Design There are two main types of this process: An essential component of the. May 29, 2022 reading time: Low pressure die casting is a method of production that involves molten metal being forced, under low pressure, into a die rather than relying on gravity to fill a mould as is the case. This process data sheet describes the basic steps. Low Pressure Die Casting Mould Design.

From www.gold-scales.com

Pressure Die Cast Mould CNC Machining China, Die Casting China Low Pressure Die Casting Mould Design May 29, 2022 reading time: Unlike the traditional die casting process , it has a. There are two main types of this process: Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. An essential component of the. Die casting is a significant process for applications in various industries.. Low Pressure Die Casting Mould Design.

From www.indiamart.com

Die Steel Low Pressure Die Casting Mould at best price in Chennai ID Low Pressure Die Casting Mould Design There are two main types of this process: Low pressure die casting is a method of production that involves molten metal being forced, under low pressure, into a die rather than relying on gravity to fill a mould as is the case. Unlike the traditional die casting process , it has a. This process data sheet describes the basic steps. Low Pressure Die Casting Mould Design.

From capablemachining.com

LowPressure Die Casting Simple Explained Capable Machining Low Pressure Die Casting Mould Design Unlike the traditional die casting process , it has a. Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. Die casting is a significant process for applications in various industries. This process data sheet describes the basic steps involved in the lpdc process as well as the benefits. Low Pressure Die Casting Mould Design.

From 2021.help.altair.com

Low Pressure Process Low Pressure Die Casting Mould Design Low pressure die casting is a method of production that involves molten metal being forced, under low pressure, into a die rather than relying on gravity to fill a mould as is the case. Die casting is a significant process for applications in various industries. This process data sheet describes the basic steps involved in the lpdc process as well. Low Pressure Die Casting Mould Design.

From upmold.com

9 key points on the die casting die injection mold design UPMOLD Low Pressure Die Casting Mould Design This process data sheet describes the basic steps involved in the lpdc process as well as the benefits and limitations of the process: There are two main types of this process: Die casting is a significant process for applications in various industries. Die casting is a permanent mould casting process in which molten metal is poured into a mould and. Low Pressure Die Casting Mould Design.

From www.open.edu

Low pressure die casting (counterpressure casting) OpenLearn Open Low Pressure Die Casting Mould Design Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. An essential component of the. May 29, 2022 reading time: Unlike the traditional die casting process , it has a. Low pressure die casting is a method of production that involves molten metal being forced, under low pressure, into. Low Pressure Die Casting Mould Design.

From www.indiamart.com

Aluminium Mild Steel Low Pressure Die Casting Mould at Rs 175000/piece Low Pressure Die Casting Mould Design There are two main types of this process: Unlike the traditional die casting process , it has a. Die casting is a significant process for applications in various industries. Low pressure die casting is a method of production that involves molten metal being forced, under low pressure, into a die rather than relying on gravity to fill a mould as. Low Pressure Die Casting Mould Design.

From www.lesueurinc.com

Low Pressure Permanent Molding LPPM Casting Low Pressure Die Casting Mould Design Die casting is a significant process for applications in various industries. Low pressure die casting is a method of production that involves molten metal being forced, under low pressure, into a die rather than relying on gravity to fill a mould as is the case. An essential component of the. Die casting is a permanent mould casting process in which. Low Pressure Die Casting Mould Design.

From www.superbandmold.com

Low Pressure Die Casting Automotive Wheel Mold Superband Low Pressure Die Casting Mould Design Unlike the traditional die casting process , it has a. An essential component of the. Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. There are two main types of this process: Low pressure die casting is a method of production that involves molten metal being forced, under. Low Pressure Die Casting Mould Design.

From castingmould.en.made-in-china.com

Customized Tooling Aluminum Metal Die Casting Low Pressure Mould Design Low Pressure Die Casting Mould Design This process data sheet describes the basic steps involved in the lpdc process as well as the benefits and limitations of the process: There are two main types of this process: Unlike the traditional die casting process , it has a. Low pressure die casting is a method of production that involves molten metal being forced, under low pressure, into. Low Pressure Die Casting Mould Design.

From www.aluminiumdiecastingmould.com

Low Pressure Die Casting Mould Cast Aluminum Front Bracket Low Pressure Die Casting Mould Design There are two main types of this process: This process data sheet describes the basic steps involved in the lpdc process as well as the benefits and limitations of the process: Low pressure die casting is a method of production that involves molten metal being forced, under low pressure, into a die rather than relying on gravity to fill a. Low Pressure Die Casting Mould Design.

From capablemachining.com

LowPressure Die Casting Simple Explained Capable Machining Low Pressure Die Casting Mould Design There are two main types of this process: Unlike the traditional die casting process , it has a. Die casting is a significant process for applications in various industries. An essential component of the. May 29, 2022 reading time: Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification.. Low Pressure Die Casting Mould Design.

From superband188.en.made-in-china.com

Automobile LowPressure DieCasting Wheel Mold China DieCasting Low Pressure Die Casting Mould Design There are two main types of this process: Die casting is a significant process for applications in various industries. Unlike the traditional die casting process , it has a. An essential component of the. This process data sheet describes the basic steps involved in the lpdc process as well as the benefits and limitations of the process: May 29, 2022. Low Pressure Die Casting Mould Design.

From jd-transformer.en.made-in-china.com

Low Pressure Die Casting Process Parameters Die Casting Components Low Pressure Die Casting Mould Design Die casting is a significant process for applications in various industries. Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. May 29, 2022 reading time: This process data sheet describes the basic steps involved in the lpdc process as well as the benefits and limitations of the process:. Low Pressure Die Casting Mould Design.

From www.diecastingmc.com

Low Pressure Die Casting Mould Low Pressure Die Casting Mould Design Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. Die casting is a significant process for applications in various industries. An essential component of the. This process data sheet describes the basic steps involved in the lpdc process as well as the benefits and limitations of the process:. Low Pressure Die Casting Mould Design.

From www.dolincasting.com

Low Pressure Die Casting Dolin Aluminum Casting Low Pressure Die Casting Mould Design Low pressure die casting is a method of production that involves molten metal being forced, under low pressure, into a die rather than relying on gravity to fill a mould as is the case. May 29, 2022 reading time: An essential component of the. This process data sheet describes the basic steps involved in the lpdc process as well as. Low Pressure Die Casting Mould Design.