Bushing Manufacturing Process . All the information you need to learn how to design rubber bushings and determining the maximum radial and axial loads a bushing can take. These bushings reduce friction, wear, and maintenance requirements by releasing lubricant during operation. The bushing manufacturing process begins by taking a steel bar and cutting it into small pieces called blanks or rods. The primary function of a rubber bushing is to prevent movement and vibrations between connected parts, thereby reducing wear and potential damage. The next step is to drill. These versatile and practical devices provide mechanical support and reduce friction between two moving parts. Understanding the principles of bushing design, manufacturing, and application is crucial for anyone working with mechanical. Despite their compact size and. This article will explore the.

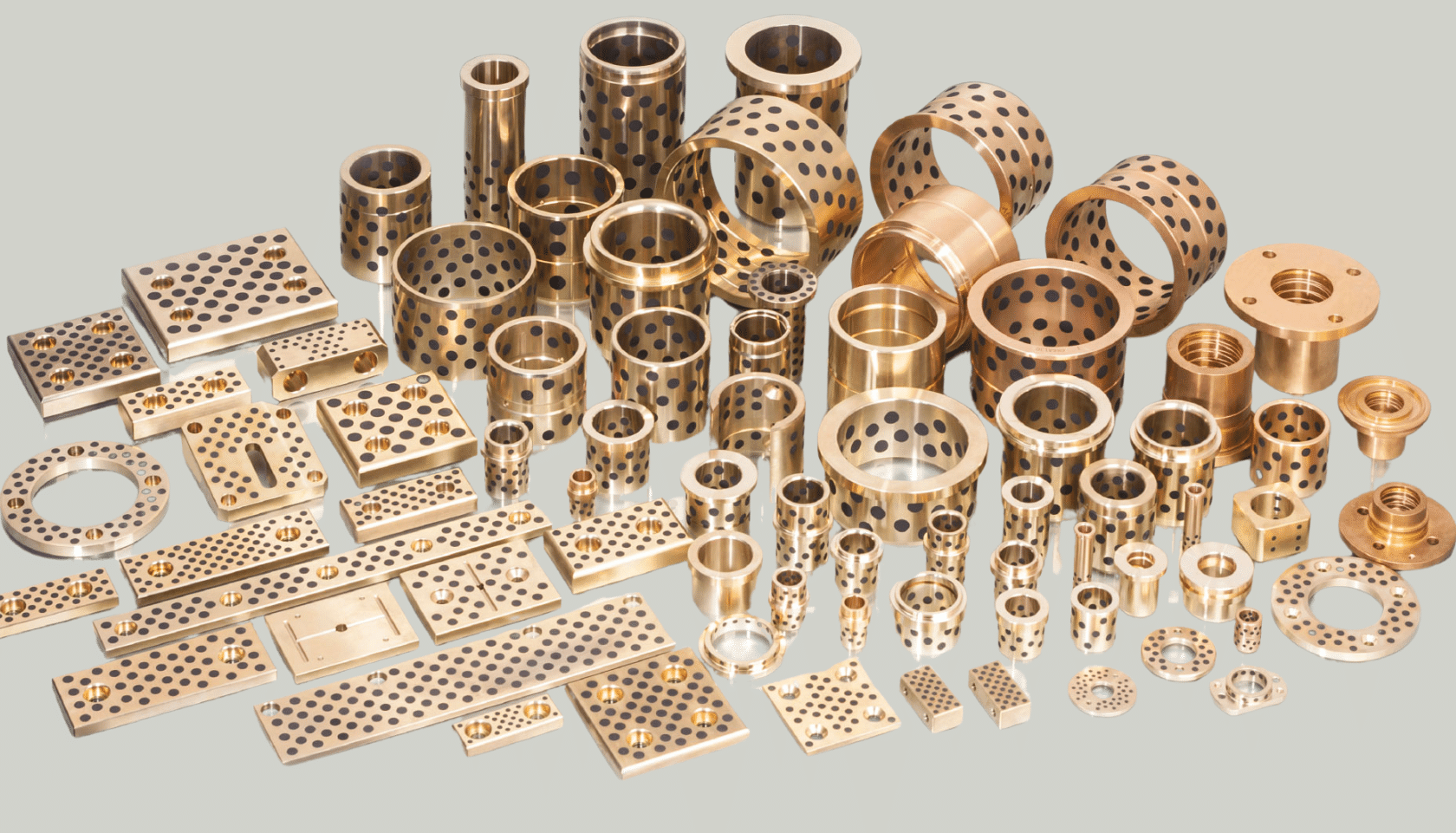

from www.bronzelube.com

The bushing manufacturing process begins by taking a steel bar and cutting it into small pieces called blanks or rods. This article will explore the. The next step is to drill. Understanding the principles of bushing design, manufacturing, and application is crucial for anyone working with mechanical. All the information you need to learn how to design rubber bushings and determining the maximum radial and axial loads a bushing can take. The primary function of a rubber bushing is to prevent movement and vibrations between connected parts, thereby reducing wear and potential damage. These bushings reduce friction, wear, and maintenance requirements by releasing lubricant during operation. Despite their compact size and. These versatile and practical devices provide mechanical support and reduce friction between two moving parts.

QAL94 Brass Bushing, Manufacturing Process, Applications

Bushing Manufacturing Process Understanding the principles of bushing design, manufacturing, and application is crucial for anyone working with mechanical. This article will explore the. Understanding the principles of bushing design, manufacturing, and application is crucial for anyone working with mechanical. All the information you need to learn how to design rubber bushings and determining the maximum radial and axial loads a bushing can take. These bushings reduce friction, wear, and maintenance requirements by releasing lubricant during operation. Despite their compact size and. The primary function of a rubber bushing is to prevent movement and vibrations between connected parts, thereby reducing wear and potential damage. The next step is to drill. These versatile and practical devices provide mechanical support and reduce friction between two moving parts. The bushing manufacturing process begins by taking a steel bar and cutting it into small pieces called blanks or rods.

From www.bearingface.com

Unlock Precision Free Bearing Manufacturing Company Guide Bushing Manufacturing Process These bushings reduce friction, wear, and maintenance requirements by releasing lubricant during operation. All the information you need to learn how to design rubber bushings and determining the maximum radial and axial loads a bushing can take. Understanding the principles of bushing design, manufacturing, and application is crucial for anyone working with mechanical. The next step is to drill. The. Bushing Manufacturing Process.

From www.teknorot.com

Bushing Production Teknorot Bushing Manufacturing Process The primary function of a rubber bushing is to prevent movement and vibrations between connected parts, thereby reducing wear and potential damage. Understanding the principles of bushing design, manufacturing, and application is crucial for anyone working with mechanical. Despite their compact size and. These bushings reduce friction, wear, and maintenance requirements by releasing lubricant during operation. All the information you. Bushing Manufacturing Process.

From www.bearingface.com

Bushing Manufacturing Process SelfLubricating Discover Bushing Manufacturing Process This article will explore the. The next step is to drill. Understanding the principles of bushing design, manufacturing, and application is crucial for anyone working with mechanical. These versatile and practical devices provide mechanical support and reduce friction between two moving parts. These bushings reduce friction, wear, and maintenance requirements by releasing lubricant during operation. The bushing manufacturing process begins. Bushing Manufacturing Process.

From www.bearingface.com

Bushing Manufacturing Process SelfLubricating Discover Bushing Manufacturing Process Understanding the principles of bushing design, manufacturing, and application is crucial for anyone working with mechanical. These bushings reduce friction, wear, and maintenance requirements by releasing lubricant during operation. This article will explore the. The next step is to drill. Despite their compact size and. The bushing manufacturing process begins by taking a steel bar and cutting it into small. Bushing Manufacturing Process.

From www.bearingface.com

Bushing Manufacturing Process SelfLubricating Discover Bushing Manufacturing Process The next step is to drill. All the information you need to learn how to design rubber bushings and determining the maximum radial and axial loads a bushing can take. The bushing manufacturing process begins by taking a steel bar and cutting it into small pieces called blanks or rods. Despite their compact size and. These versatile and practical devices. Bushing Manufacturing Process.

From www.bearingface.com

Bushing Manufacturing Process SelfLubricating Discover Bushing Manufacturing Process All the information you need to learn how to design rubber bushings and determining the maximum radial and axial loads a bushing can take. Understanding the principles of bushing design, manufacturing, and application is crucial for anyone working with mechanical. These versatile and practical devices provide mechanical support and reduce friction between two moving parts. The primary function of a. Bushing Manufacturing Process.

From www.bearingface.com

SelfLubricating Bushing Manufacturing Process Find More! Bushing Manufacturing Process Understanding the principles of bushing design, manufacturing, and application is crucial for anyone working with mechanical. The primary function of a rubber bushing is to prevent movement and vibrations between connected parts, thereby reducing wear and potential damage. These bushings reduce friction, wear, and maintenance requirements by releasing lubricant during operation. These versatile and practical devices provide mechanical support and. Bushing Manufacturing Process.

From www.teknorot.com

Bushing Production Teknorot Bushing Manufacturing Process Understanding the principles of bushing design, manufacturing, and application is crucial for anyone working with mechanical. The next step is to drill. All the information you need to learn how to design rubber bushings and determining the maximum radial and axial loads a bushing can take. The primary function of a rubber bushing is to prevent movement and vibrations between. Bushing Manufacturing Process.

From www.bearingface.com

Bushing Manufacturing Process SelfLubricating Discover Bushing Manufacturing Process Understanding the principles of bushing design, manufacturing, and application is crucial for anyone working with mechanical. This article will explore the. The next step is to drill. The bushing manufacturing process begins by taking a steel bar and cutting it into small pieces called blanks or rods. All the information you need to learn how to design rubber bushings and. Bushing Manufacturing Process.

From www.bearingface.com

Bushing Manufacturing Process SelfLubricating Discover Bushing Manufacturing Process Understanding the principles of bushing design, manufacturing, and application is crucial for anyone working with mechanical. The primary function of a rubber bushing is to prevent movement and vibrations between connected parts, thereby reducing wear and potential damage. The next step is to drill. All the information you need to learn how to design rubber bushings and determining the maximum. Bushing Manufacturing Process.

From www.viiplus.com

Plain Bushing Manufacturing Process Bushing Production Bushing Manufacturing Process The bushing manufacturing process begins by taking a steel bar and cutting it into small pieces called blanks or rods. Despite their compact size and. Understanding the principles of bushing design, manufacturing, and application is crucial for anyone working with mechanical. The primary function of a rubber bushing is to prevent movement and vibrations between connected parts, thereby reducing wear. Bushing Manufacturing Process.

From www.bronzelube.com

QAL94 Brass Bushing, Manufacturing Process, Applications Bushing Manufacturing Process Despite their compact size and. The bushing manufacturing process begins by taking a steel bar and cutting it into small pieces called blanks or rods. Understanding the principles of bushing design, manufacturing, and application is crucial for anyone working with mechanical. These versatile and practical devices provide mechanical support and reduce friction between two moving parts. This article will explore. Bushing Manufacturing Process.

From alldrawings.ru

Develop an operational technological process for manufacturing a Bushing Manufacturing Process These bushings reduce friction, wear, and maintenance requirements by releasing lubricant during operation. Understanding the principles of bushing design, manufacturing, and application is crucial for anyone working with mechanical. The primary function of a rubber bushing is to prevent movement and vibrations between connected parts, thereby reducing wear and potential damage. The next step is to drill. All the information. Bushing Manufacturing Process.

From www.bearingface.com

Bushing Manufacturing Process SelfLubricating Discover Bushing Manufacturing Process Understanding the principles of bushing design, manufacturing, and application is crucial for anyone working with mechanical. These versatile and practical devices provide mechanical support and reduce friction between two moving parts. The primary function of a rubber bushing is to prevent movement and vibrations between connected parts, thereby reducing wear and potential damage. The bushing manufacturing process begins by taking. Bushing Manufacturing Process.

From www.teknorot.com

Bushing Production Teknorot Bushing Manufacturing Process Despite their compact size and. The primary function of a rubber bushing is to prevent movement and vibrations between connected parts, thereby reducing wear and potential damage. This article will explore the. The next step is to drill. These versatile and practical devices provide mechanical support and reduce friction between two moving parts. The bushing manufacturing process begins by taking. Bushing Manufacturing Process.

From www.bronzegleitlager.com

Bronze Casting Process Graphite Bushing Company case Bushing Manufacturing Process The bushing manufacturing process begins by taking a steel bar and cutting it into small pieces called blanks or rods. These bushings reduce friction, wear, and maintenance requirements by releasing lubricant during operation. The next step is to drill. The primary function of a rubber bushing is to prevent movement and vibrations between connected parts, thereby reducing wear and potential. Bushing Manufacturing Process.

From rhmintl.com

High Voltage Transformer Bushings RHM International Bushing Manufacturing Process Despite their compact size and. The next step is to drill. These versatile and practical devices provide mechanical support and reduce friction between two moving parts. Understanding the principles of bushing design, manufacturing, and application is crucial for anyone working with mechanical. The primary function of a rubber bushing is to prevent movement and vibrations between connected parts, thereby reducing. Bushing Manufacturing Process.

From www.bearingface.com

Bushing Manufacturing Process SelfLubricating Discover Bushing Manufacturing Process The next step is to drill. The bushing manufacturing process begins by taking a steel bar and cutting it into small pieces called blanks or rods. The primary function of a rubber bushing is to prevent movement and vibrations between connected parts, thereby reducing wear and potential damage. This article will explore the. All the information you need to learn. Bushing Manufacturing Process.

From www.bearingface.com

Bushing Manufacturing Process SelfLubricating Discover Bushing Manufacturing Process These versatile and practical devices provide mechanical support and reduce friction between two moving parts. The bushing manufacturing process begins by taking a steel bar and cutting it into small pieces called blanks or rods. The primary function of a rubber bushing is to prevent movement and vibrations between connected parts, thereby reducing wear and potential damage. The next step. Bushing Manufacturing Process.

From www.teknorot.com

Bushing Production Teknorot Bushing Manufacturing Process The next step is to drill. These bushings reduce friction, wear, and maintenance requirements by releasing lubricant during operation. These versatile and practical devices provide mechanical support and reduce friction between two moving parts. This article will explore the. The bushing manufacturing process begins by taking a steel bar and cutting it into small pieces called blanks or rods. The. Bushing Manufacturing Process.

From www.ytcasting.com

From Raw Material to Precision Component Inside the Copper Bushing Bushing Manufacturing Process The bushing manufacturing process begins by taking a steel bar and cutting it into small pieces called blanks or rods. These bushings reduce friction, wear, and maintenance requirements by releasing lubricant during operation. This article will explore the. The primary function of a rubber bushing is to prevent movement and vibrations between connected parts, thereby reducing wear and potential damage.. Bushing Manufacturing Process.

From www.teknorot.com

Bushing Production Teknorot Bushing Manufacturing Process The next step is to drill. All the information you need to learn how to design rubber bushings and determining the maximum radial and axial loads a bushing can take. The bushing manufacturing process begins by taking a steel bar and cutting it into small pieces called blanks or rods. These bushings reduce friction, wear, and maintenance requirements by releasing. Bushing Manufacturing Process.

From www.viiplus.com

Plain Bushing Manufacturing Process Bushing Production Bushing Manufacturing Process All the information you need to learn how to design rubber bushings and determining the maximum radial and axial loads a bushing can take. The primary function of a rubber bushing is to prevent movement and vibrations between connected parts, thereby reducing wear and potential damage. This article will explore the. These bushings reduce friction, wear, and maintenance requirements by. Bushing Manufacturing Process.

From www.teknorot.com

Bushing Production Teknorot Bushing Manufacturing Process These versatile and practical devices provide mechanical support and reduce friction between two moving parts. Despite their compact size and. All the information you need to learn how to design rubber bushings and determining the maximum radial and axial loads a bushing can take. The next step is to drill. The primary function of a rubber bushing is to prevent. Bushing Manufacturing Process.

From www.capaero.com

Expanded Bonded Bushing (EB²) CAPAERO Split Sleeve and cold Bushing Manufacturing Process The bushing manufacturing process begins by taking a steel bar and cutting it into small pieces called blanks or rods. These versatile and practical devices provide mechanical support and reduce friction between two moving parts. This article will explore the. Understanding the principles of bushing design, manufacturing, and application is crucial for anyone working with mechanical. Despite their compact size. Bushing Manufacturing Process.

From alldrawings.ru

Development of the technological process of manufacturing a bushing Bushing Manufacturing Process Understanding the principles of bushing design, manufacturing, and application is crucial for anyone working with mechanical. The primary function of a rubber bushing is to prevent movement and vibrations between connected parts, thereby reducing wear and potential damage. These versatile and practical devices provide mechanical support and reduce friction between two moving parts. The bushing manufacturing process begins by taking. Bushing Manufacturing Process.

From www.bearingface.com

Bushing Manufacturing Process SelfLubricating Discover Bushing Manufacturing Process These versatile and practical devices provide mechanical support and reduce friction between two moving parts. The next step is to drill. This article will explore the. The primary function of a rubber bushing is to prevent movement and vibrations between connected parts, thereby reducing wear and potential damage. All the information you need to learn how to design rubber bushings. Bushing Manufacturing Process.

From www.sdchinsun.com

The Production Process of RIS Bushing 24kV 550kV Transformer Bushing Manufacturing Process The next step is to drill. These versatile and practical devices provide mechanical support and reduce friction between two moving parts. This article will explore the. These bushings reduce friction, wear, and maintenance requirements by releasing lubricant during operation. Despite their compact size and. Understanding the principles of bushing design, manufacturing, and application is crucial for anyone working with mechanical.. Bushing Manufacturing Process.

From www.viiplus.com

Plain Bushing Manufacturing Process Bushing Production Bushing Manufacturing Process Despite their compact size and. These versatile and practical devices provide mechanical support and reduce friction between two moving parts. The next step is to drill. The primary function of a rubber bushing is to prevent movement and vibrations between connected parts, thereby reducing wear and potential damage. All the information you need to learn how to design rubber bushings. Bushing Manufacturing Process.

From www.researchgate.net

Machining processes of a bushing part. Download Scientific Diagram Bushing Manufacturing Process Understanding the principles of bushing design, manufacturing, and application is crucial for anyone working with mechanical. The primary function of a rubber bushing is to prevent movement and vibrations between connected parts, thereby reducing wear and potential damage. This article will explore the. The next step is to drill. The bushing manufacturing process begins by taking a steel bar and. Bushing Manufacturing Process.

From www.bearingface.com

Bushing Manufacturing Process SelfLubricating Discover Bushing Manufacturing Process All the information you need to learn how to design rubber bushings and determining the maximum radial and axial loads a bushing can take. These bushings reduce friction, wear, and maintenance requirements by releasing lubricant during operation. The primary function of a rubber bushing is to prevent movement and vibrations between connected parts, thereby reducing wear and potential damage. The. Bushing Manufacturing Process.

From www.bearingface.com

Bushing Manufacturing Process SelfLubricating Discover Bushing Manufacturing Process This article will explore the. The primary function of a rubber bushing is to prevent movement and vibrations between connected parts, thereby reducing wear and potential damage. All the information you need to learn how to design rubber bushings and determining the maximum radial and axial loads a bushing can take. The bushing manufacturing process begins by taking a steel. Bushing Manufacturing Process.

From www.bearingface.com

SelfLubricating Bushing Manufacturing Process Find More! Bushing Manufacturing Process The next step is to drill. This article will explore the. All the information you need to learn how to design rubber bushings and determining the maximum radial and axial loads a bushing can take. These versatile and practical devices provide mechanical support and reduce friction between two moving parts. Understanding the principles of bushing design, manufacturing, and application is. Bushing Manufacturing Process.

From www.youtube.com

SINTERED BUSHING PRODUCTION YouTube Bushing Manufacturing Process The next step is to drill. This article will explore the. The bushing manufacturing process begins by taking a steel bar and cutting it into small pieces called blanks or rods. These bushings reduce friction, wear, and maintenance requirements by releasing lubricant during operation. All the information you need to learn how to design rubber bushings and determining the maximum. Bushing Manufacturing Process.

From www.teknorot.com

Bushing Production Teknorot Bushing Manufacturing Process Despite their compact size and. These bushings reduce friction, wear, and maintenance requirements by releasing lubricant during operation. The bushing manufacturing process begins by taking a steel bar and cutting it into small pieces called blanks or rods. The primary function of a rubber bushing is to prevent movement and vibrations between connected parts, thereby reducing wear and potential damage.. Bushing Manufacturing Process.