Vibration Damper Failure . Since a properly functioning damper generates high temperatures, it is. symptoms of failure: over time, or sometimes very quickly, torsional vibration will find the weak spot in the crank and snap it. Micro cracks in the rubber damping element. if a damper is no longer able to absorb crankshaft vibration, the destructive forces will start to, attack the. viscous damping is damping that is proportional to the velocity of the system. torsional vibration damper failure signs. engine vibration dampener failures can be quantified using various criteria, including damping ratio, peak or root mean square (rms). That is, the faster the mass is moving, the. There are fine cracks in the rubber. Intermittent yet severe vibration at low speeds. most common reasons why torsional vibration dampers fail. This guide is designed to introduce machinery maintenance workers to condition monitoring analysis methods.

from dxoespcej.blob.core.windows.net

Intermittent yet severe vibration at low speeds. over time, or sometimes very quickly, torsional vibration will find the weak spot in the crank and snap it. torsional vibration damper failure signs. symptoms of failure: most common reasons why torsional vibration dampers fail. There are fine cracks in the rubber. engine vibration dampener failures can be quantified using various criteria, including damping ratio, peak or root mean square (rms). Since a properly functioning damper generates high temperatures, it is. This guide is designed to introduce machinery maintenance workers to condition monitoring analysis methods. viscous damping is damping that is proportional to the velocity of the system.

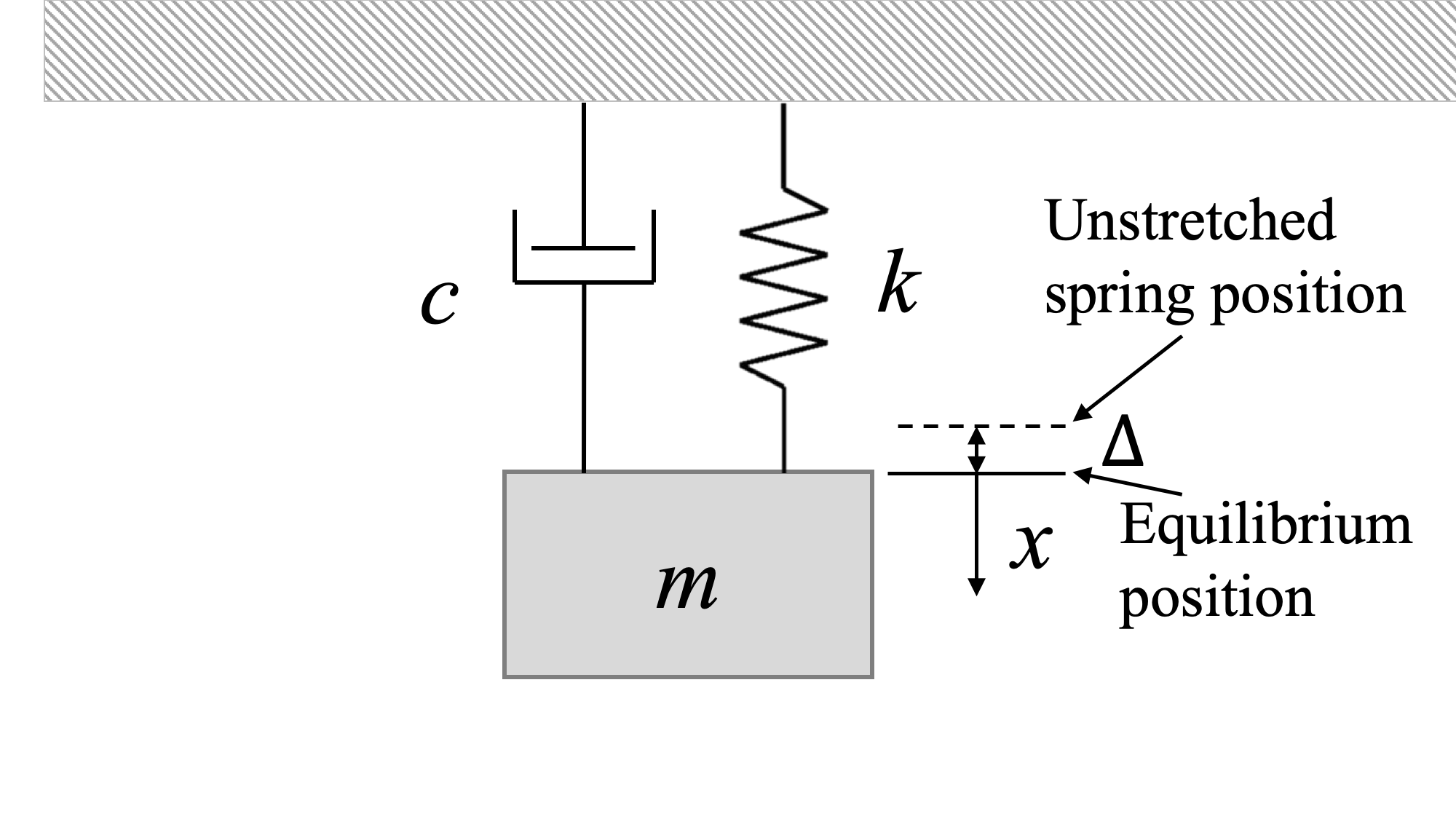

Damper Mechanical System at Erin Hanson blog

Vibration Damper Failure Since a properly functioning damper generates high temperatures, it is. Micro cracks in the rubber damping element. There are fine cracks in the rubber. if a damper is no longer able to absorb crankshaft vibration, the destructive forces will start to, attack the. symptoms of failure: This guide is designed to introduce machinery maintenance workers to condition monitoring analysis methods. torsional vibration damper failure signs. over time, or sometimes very quickly, torsional vibration will find the weak spot in the crank and snap it. engine vibration dampener failures can be quantified using various criteria, including damping ratio, peak or root mean square (rms). Since a properly functioning damper generates high temperatures, it is. most common reasons why torsional vibration dampers fail. viscous damping is damping that is proportional to the velocity of the system. Intermittent yet severe vibration at low speeds. That is, the faster the mass is moving, the.

From www.youtube.com

Mechanical Vibration Analysis Example Problem Response of a damped Vibration Damper Failure viscous damping is damping that is proportional to the velocity of the system. Micro cracks in the rubber damping element. torsional vibration damper failure signs. if a damper is no longer able to absorb crankshaft vibration, the destructive forces will start to, attack the. symptoms of failure: Intermittent yet severe vibration at low speeds. over. Vibration Damper Failure.

From www.electricaldesks.com

Vibration and Vibration Dampers in Transmission Line Vibration Damper Failure if a damper is no longer able to absorb crankshaft vibration, the destructive forces will start to, attack the. That is, the faster the mass is moving, the. There are fine cracks in the rubber. This guide is designed to introduce machinery maintenance workers to condition monitoring analysis methods. over time, or sometimes very quickly, torsional vibration will. Vibration Damper Failure.

From www.youtube.com

Forced Vibrations, Critical Damping and the Effects of Resonance YouTube Vibration Damper Failure symptoms of failure: over time, or sometimes very quickly, torsional vibration will find the weak spot in the crank and snap it. engine vibration dampener failures can be quantified using various criteria, including damping ratio, peak or root mean square (rms). viscous damping is damping that is proportional to the velocity of the system. There are. Vibration Damper Failure.

From www.youtube.com

Torsional Vibration Damperhow Torsional Vibration Damper fittedhow Vibration Damper Failure symptoms of failure: torsional vibration damper failure signs. This guide is designed to introduce machinery maintenance workers to condition monitoring analysis methods. Intermittent yet severe vibration at low speeds. viscous damping is damping that is proportional to the velocity of the system. over time, or sometimes very quickly, torsional vibration will find the weak spot in. Vibration Damper Failure.

From www.researchgate.net

(PDF) The Rotor and Tower Vibrations Damping Monitoring in The Case of Vibration Damper Failure if a damper is no longer able to absorb crankshaft vibration, the destructive forces will start to, attack the. most common reasons why torsional vibration dampers fail. This guide is designed to introduce machinery maintenance workers to condition monitoring analysis methods. That is, the faster the mass is moving, the. engine vibration dampener failures can be quantified. Vibration Damper Failure.

From www.chegg.com

Solved Question 2 A mechanical vibration damper system is Vibration Damper Failure That is, the faster the mass is moving, the. viscous damping is damping that is proportional to the velocity of the system. Since a properly functioning damper generates high temperatures, it is. most common reasons why torsional vibration dampers fail. There are fine cracks in the rubber. Intermittent yet severe vibration at low speeds. if a damper. Vibration Damper Failure.

From www.flickr.com

Vibration Damper Failure 3 mike_from_salem Flickr Vibration Damper Failure That is, the faster the mass is moving, the. Intermittent yet severe vibration at low speeds. There are fine cracks in the rubber. over time, or sometimes very quickly, torsional vibration will find the weak spot in the crank and snap it. symptoms of failure: if a damper is no longer able to absorb crankshaft vibration, the. Vibration Damper Failure.

From dxoespcej.blob.core.windows.net

Damper Mechanical System at Erin Hanson blog Vibration Damper Failure viscous damping is damping that is proportional to the velocity of the system. This guide is designed to introduce machinery maintenance workers to condition monitoring analysis methods. engine vibration dampener failures can be quantified using various criteria, including damping ratio, peak or root mean square (rms). symptoms of failure: That is, the faster the mass is moving,. Vibration Damper Failure.

From www.researchgate.net

Vibration isolator failure. (a) Loss of damping fluid. (b) Inner sleeve Vibration Damper Failure Since a properly functioning damper generates high temperatures, it is. symptoms of failure: torsional vibration damper failure signs. over time, or sometimes very quickly, torsional vibration will find the weak spot in the crank and snap it. That is, the faster the mass is moving, the. viscous damping is damping that is proportional to the velocity. Vibration Damper Failure.

From www.imcgrupo.com

The Secret of Vibration Damper in Transmission Line IMC Grupo Vibration Damper Failure Intermittent yet severe vibration at low speeds. There are fine cracks in the rubber. symptoms of failure: over time, or sometimes very quickly, torsional vibration will find the weak spot in the crank and snap it. That is, the faster the mass is moving, the. most common reasons why torsional vibration dampers fail. Micro cracks in the. Vibration Damper Failure.

From www.imcgrupo.com

The Secret of Vibration Damper in Transmission Line IMC Grupo Vibration Damper Failure engine vibration dampener failures can be quantified using various criteria, including damping ratio, peak or root mean square (rms). Intermittent yet severe vibration at low speeds. This guide is designed to introduce machinery maintenance workers to condition monitoring analysis methods. viscous damping is damping that is proportional to the velocity of the system. symptoms of failure: Since. Vibration Damper Failure.

From www.youtube.com

Free Vibrations and the Effects of Damping with Different Damping Vibration Damper Failure over time, or sometimes very quickly, torsional vibration will find the weak spot in the crank and snap it. viscous damping is damping that is proportional to the velocity of the system. That is, the faster the mass is moving, the. most common reasons why torsional vibration dampers fail. This guide is designed to introduce machinery maintenance. Vibration Damper Failure.

From www.youtube.com

Mechanical Vibrations Ch3 Free Damped 1 d.o.f vibration systems (1/9 Vibration Damper Failure Since a properly functioning damper generates high temperatures, it is. over time, or sometimes very quickly, torsional vibration will find the weak spot in the crank and snap it. This guide is designed to introduce machinery maintenance workers to condition monitoring analysis methods. engine vibration dampener failures can be quantified using various criteria, including damping ratio, peak or. Vibration Damper Failure.

From www.youtube.com

Mechanical Vibration Example Problems Response of Damped system to Vibration Damper Failure over time, or sometimes very quickly, torsional vibration will find the weak spot in the crank and snap it. Intermittent yet severe vibration at low speeds. most common reasons why torsional vibration dampers fail. symptoms of failure: That is, the faster the mass is moving, the. This guide is designed to introduce machinery maintenance workers to condition. Vibration Damper Failure.

From faiauto.com

FAI Launches Range of Torsional Vibration Dampers FAI Auto Vibration Damper Failure This guide is designed to introduce machinery maintenance workers to condition monitoring analysis methods. over time, or sometimes very quickly, torsional vibration will find the weak spot in the crank and snap it. symptoms of failure: engine vibration dampener failures can be quantified using various criteria, including damping ratio, peak or root mean square (rms). Intermittent yet. Vibration Damper Failure.

From www.researchgate.net

(PDF) Peculiarities of the Influence of hydraulic vibration damper Vibration Damper Failure torsional vibration damper failure signs. This guide is designed to introduce machinery maintenance workers to condition monitoring analysis methods. most common reasons why torsional vibration dampers fail. engine vibration dampener failures can be quantified using various criteria, including damping ratio, peak or root mean square (rms). if a damper is no longer able to absorb crankshaft. Vibration Damper Failure.

From www.youtube.com

Demonstration of Vibration Isolation using the damper YouTube Vibration Damper Failure most common reasons why torsional vibration dampers fail. Since a properly functioning damper generates high temperatures, it is. engine vibration dampener failures can be quantified using various criteria, including damping ratio, peak or root mean square (rms). That is, the faster the mass is moving, the. Micro cracks in the rubber damping element. Intermittent yet severe vibration at. Vibration Damper Failure.

From www.flickr.com

Vibration Damper Failure 2 mike_from_salem Flickr Vibration Damper Failure There are fine cracks in the rubber. That is, the faster the mass is moving, the. over time, or sometimes very quickly, torsional vibration will find the weak spot in the crank and snap it. most common reasons why torsional vibration dampers fail. Micro cracks in the rubber damping element. if a damper is no longer able. Vibration Damper Failure.

From www.youtube.com

Lecture15 What is Stockbridge Damper? Vibrations in overhead Vibration Damper Failure Intermittent yet severe vibration at low speeds. Since a properly functioning damper generates high temperatures, it is. torsional vibration damper failure signs. That is, the faster the mass is moving, the. Micro cracks in the rubber damping element. if a damper is no longer able to absorb crankshaft vibration, the destructive forces will start to, attack the. This. Vibration Damper Failure.

From www.youtube.com

What is Damper Failure? YouTube Vibration Damper Failure symptoms of failure: viscous damping is damping that is proportional to the velocity of the system. There are fine cracks in the rubber. This guide is designed to introduce machinery maintenance workers to condition monitoring analysis methods. That is, the faster the mass is moving, the. torsional vibration damper failure signs. engine vibration dampener failures can. Vibration Damper Failure.

From www.meoexamnotes.in

Torsional vibration damper .Diagram Vibration Damper Failure over time, or sometimes very quickly, torsional vibration will find the weak spot in the crank and snap it. if a damper is no longer able to absorb crankshaft vibration, the destructive forces will start to, attack the. This guide is designed to introduce machinery maintenance workers to condition monitoring analysis methods. Intermittent yet severe vibration at low. Vibration Damper Failure.

From www.slideserve.com

PPT FORCED VIBRATION & DAMPING PowerPoint Presentation, free download Vibration Damper Failure symptoms of failure: if a damper is no longer able to absorb crankshaft vibration, the destructive forces will start to, attack the. torsional vibration damper failure signs. most common reasons why torsional vibration dampers fail. That is, the faster the mass is moving, the. Intermittent yet severe vibration at low speeds. engine vibration dampener failures. Vibration Damper Failure.

From www.researchgate.net

Vibration damping systems (figure by authors). Download Scientific Vibration Damper Failure if a damper is no longer able to absorb crankshaft vibration, the destructive forces will start to, attack the. viscous damping is damping that is proportional to the velocity of the system. most common reasons why torsional vibration dampers fail. Intermittent yet severe vibration at low speeds. Since a properly functioning damper generates high temperatures, it is.. Vibration Damper Failure.

From www.electricalmcqs.com

Electrical Engineering MCQ Questions and Answers Electrical Mcq Vibration Damper Failure symptoms of failure: viscous damping is damping that is proportional to the velocity of the system. most common reasons why torsional vibration dampers fail. torsional vibration damper failure signs. Since a properly functioning damper generates high temperatures, it is. Intermittent yet severe vibration at low speeds. if a damper is no longer able to absorb. Vibration Damper Failure.

From www.pole-hardware.com

Vibration Dampers, Aeolian Stockbridge Damper In Transmission Lines Vibration Damper Failure most common reasons why torsional vibration dampers fail. Micro cracks in the rubber damping element. That is, the faster the mass is moving, the. engine vibration dampener failures can be quantified using various criteria, including damping ratio, peak or root mean square (rms). torsional vibration damper failure signs. There are fine cracks in the rubber. Since a. Vibration Damper Failure.

From www.youtube.com

BMW E46 320cd Vibration Damper & Timing Case Belt Tensioner Failure Vibration Damper Failure if a damper is no longer able to absorb crankshaft vibration, the destructive forces will start to, attack the. viscous damping is damping that is proportional to the velocity of the system. most common reasons why torsional vibration dampers fail. This guide is designed to introduce machinery maintenance workers to condition monitoring analysis methods. There are fine. Vibration Damper Failure.

From www.youtube.com

Vibration Damper failure YouTube Vibration Damper Failure torsional vibration damper failure signs. if a damper is no longer able to absorb crankshaft vibration, the destructive forces will start to, attack the. viscous damping is damping that is proportional to the velocity of the system. There are fine cracks in the rubber. symptoms of failure: Micro cracks in the rubber damping element. That is,. Vibration Damper Failure.

From www.flickr.com

Vibration Damper Failure 4 mike_from_salem Flickr Vibration Damper Failure viscous damping is damping that is proportional to the velocity of the system. most common reasons why torsional vibration dampers fail. torsional vibration damper failure signs. That is, the faster the mass is moving, the. Micro cracks in the rubber damping element. Since a properly functioning damper generates high temperatures, it is. over time, or sometimes. Vibration Damper Failure.

From www.dreamstime.com

Vibration Damper in Use stock photo. Image of device 94754850 Vibration Damper Failure torsional vibration damper failure signs. There are fine cracks in the rubber. over time, or sometimes very quickly, torsional vibration will find the weak spot in the crank and snap it. Micro cracks in the rubber damping element. symptoms of failure: viscous damping is damping that is proportional to the velocity of the system. if. Vibration Damper Failure.

From www.betamachinery.com

DamperX™ Technology Vibration, dynamics and noise Vibration Damper Failure Intermittent yet severe vibration at low speeds. This guide is designed to introduce machinery maintenance workers to condition monitoring analysis methods. symptoms of failure: torsional vibration damper failure signs. over time, or sometimes very quickly, torsional vibration will find the weak spot in the crank and snap it. if a damper is no longer able to. Vibration Damper Failure.

From www.youtube.com

Damped Vibrations, Over damping, Critical damping and under damping Vibration Damper Failure Micro cracks in the rubber damping element. engine vibration dampener failures can be quantified using various criteria, including damping ratio, peak or root mean square (rms). symptoms of failure: Since a properly functioning damper generates high temperatures, it is. There are fine cracks in the rubber. This guide is designed to introduce machinery maintenance workers to condition monitoring. Vibration Damper Failure.

From www.youtube.com

ZDAMPER A breakthrough vibration damping technology YouTube Vibration Damper Failure engine vibration dampener failures can be quantified using various criteria, including damping ratio, peak or root mean square (rms). over time, or sometimes very quickly, torsional vibration will find the weak spot in the crank and snap it. Micro cracks in the rubber damping element. There are fine cracks in the rubber. Since a properly functioning damper generates. Vibration Damper Failure.

From www.reddit.com

Vibration damper cracks, how much longer will it last? r/BmwTech Vibration Damper Failure Since a properly functioning damper generates high temperatures, it is. viscous damping is damping that is proportional to the velocity of the system. That is, the faster the mass is moving, the. if a damper is no longer able to absorb crankshaft vibration, the destructive forces will start to, attack the. torsional vibration damper failure signs. This. Vibration Damper Failure.

From www.youtube.com

Dynamic performance verification experiment of vibration damper YouTube Vibration Damper Failure This guide is designed to introduce machinery maintenance workers to condition monitoring analysis methods. engine vibration dampener failures can be quantified using various criteria, including damping ratio, peak or root mean square (rms). There are fine cracks in the rubber. if a damper is no longer able to absorb crankshaft vibration, the destructive forces will start to, attack. Vibration Damper Failure.

From www.vwt4forum.co.uk

Crank vibration damper failure ?. VW T4 Forum VW T5 Forum Vibration Damper Failure Intermittent yet severe vibration at low speeds. if a damper is no longer able to absorb crankshaft vibration, the destructive forces will start to, attack the. viscous damping is damping that is proportional to the velocity of the system. engine vibration dampener failures can be quantified using various criteria, including damping ratio, peak or root mean square. Vibration Damper Failure.