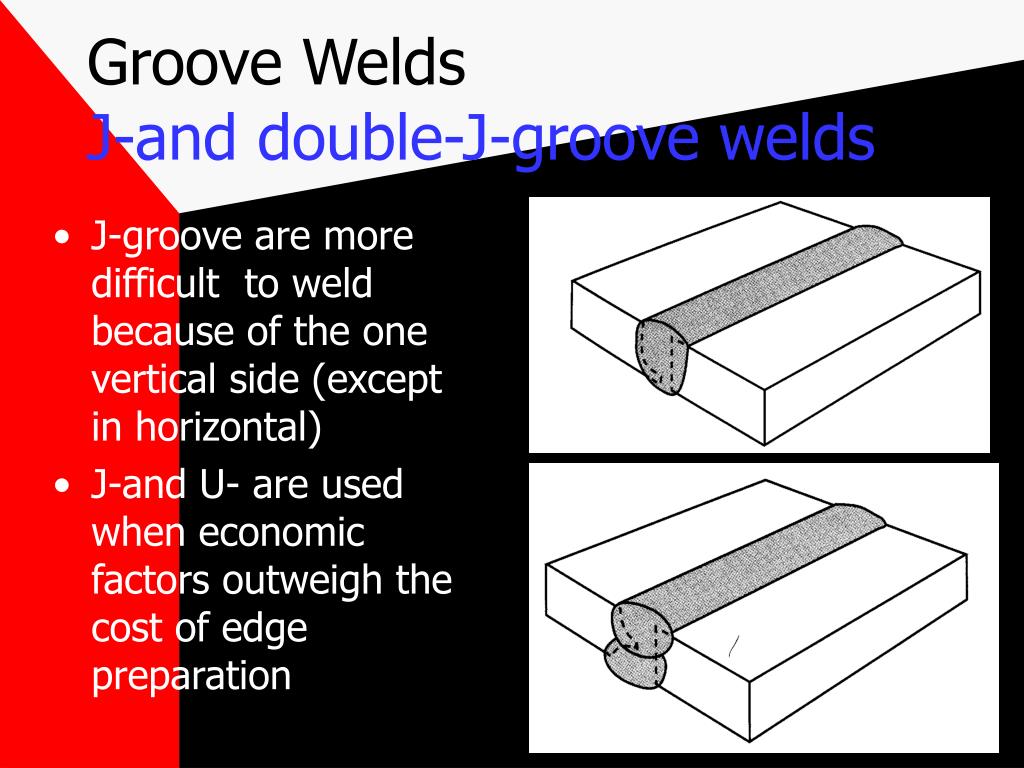

Welding J Groove . a j groove weld is where a j shaped groove is created in the joint between two pieces of metal. The process of creating the bevels is. It requires special machinery to precisely shape the groove. common weld joint designs are best described with letters. a groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the. this guide aims to help you understand bevel and v groove weld symbols and the joint preparations they call for. j groove weld is a special type of groove weld that is more economical by lowering the weld metal volume. “v,” “u,” and “j” weld joints. groove welding is used to create a beveled opening in a weld joint before welding to achieve the necessary penetration. This type of groove can be used to join thicker materials by creating a narrow groove weld configuration.

from www.slideserve.com

this guide aims to help you understand bevel and v groove weld symbols and the joint preparations they call for. j groove weld is a special type of groove weld that is more economical by lowering the weld metal volume. It requires special machinery to precisely shape the groove. groove welding is used to create a beveled opening in a weld joint before welding to achieve the necessary penetration. a j groove weld is where a j shaped groove is created in the joint between two pieces of metal. a groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the. “v,” “u,” and “j” weld joints. This type of groove can be used to join thicker materials by creating a narrow groove weld configuration. common weld joint designs are best described with letters. The process of creating the bevels is.

PPT Weld Joint Geometry and Welding Symbols PowerPoint Presentation, free download ID216047

Welding J Groove common weld joint designs are best described with letters. groove welding is used to create a beveled opening in a weld joint before welding to achieve the necessary penetration. It requires special machinery to precisely shape the groove. a groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the. “v,” “u,” and “j” weld joints. common weld joint designs are best described with letters. j groove weld is a special type of groove weld that is more economical by lowering the weld metal volume. a j groove weld is where a j shaped groove is created in the joint between two pieces of metal. this guide aims to help you understand bevel and v groove weld symbols and the joint preparations they call for. The process of creating the bevels is. This type of groove can be used to join thicker materials by creating a narrow groove weld configuration.

From qualityinspectionforms.com

TYPICAL WELD JOINTS — QUALITY INSPECTION FORMS Welding J Groove This type of groove can be used to join thicker materials by creating a narrow groove weld configuration. j groove weld is a special type of groove weld that is more economical by lowering the weld metal volume. common weld joint designs are best described with letters. a groove (or butt) weld is a type of weld. Welding J Groove.

From www.theengineerspost.com

Types of Welding Joints (Explained in detail) Pictures PDF Welding J Groove It requires special machinery to precisely shape the groove. a j groove weld is where a j shaped groove is created in the joint between two pieces of metal. “v,” “u,” and “j” weld joints. a groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think. Welding J Groove.

From www.indiamart.com

Mild Steel Single Sided Welding J Groove at Rs 1500 in Mumbai ID 21161019588 Welding J Groove a groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the. a j groove weld is where a j shaped groove is created in the joint between two pieces of metal. this guide aims to help you understand bevel and v groove weld. Welding J Groove.

From openwa.pressbooks.pub

Chapter 8 Groove Welding Symbols Basic Blueprint Reading for Welders Welding J Groove a groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the. this guide aims to help you understand bevel and v groove weld symbols and the joint preparations they call for. This type of groove can be used to join thicker materials by creating. Welding J Groove.

From workshopinsider.com

Welding Symbols Guide to Reading Weld Symbols Welding J Groove a j groove weld is where a j shaped groove is created in the joint between two pieces of metal. a groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the. common weld joint designs are best described with letters. This type of. Welding J Groove.

From waterwelders.com

Welding Symbols How to Understand Them (With Charts) WaterWelders Welding J Groove a j groove weld is where a j shaped groove is created in the joint between two pieces of metal. “v,” “u,” and “j” weld joints. common weld joint designs are best described with letters. a groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap. Welding J Groove.

From welditu.com

Guide to Welding Joint Types and Parts WelditU Welding J Groove common weld joint designs are best described with letters. groove welding is used to create a beveled opening in a weld joint before welding to achieve the necessary penetration. j groove weld is a special type of groove weld that is more economical by lowering the weld metal volume. This type of groove can be used to. Welding J Groove.

From nsarc.com

Guide to Welding Grooves NS Arc Welding J Groove common weld joint designs are best described with letters. This type of groove can be used to join thicker materials by creating a narrow groove weld configuration. “v,” “u,” and “j” weld joints. groove welding is used to create a beveled opening in a weld joint before welding to achieve the necessary penetration. a groove (or butt). Welding J Groove.

From primeweld.com

A Guide to Weld Joints PrimeWeld Welding J Groove a groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the. “v,” “u,” and “j” weld joints. a j groove weld is where a j shaped groove is created in the joint between two pieces of metal. It requires special machinery to precisely shape. Welding J Groove.

From workforce.libretexts.org

1.7 Groove Welding Symbols Workforce LibreTexts Welding J Groove The process of creating the bevels is. a j groove weld is where a j shaped groove is created in the joint between two pieces of metal. It requires special machinery to precisely shape the groove. This type of groove can be used to join thicker materials by creating a narrow groove weld configuration. “v,” “u,” and “j” weld. Welding J Groove.

From www.slideserve.com

PPT Weld Joint Geometry and Welding Symbols PowerPoint Presentation, free download ID216047 Welding J Groove a groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the. this guide aims to help you understand bevel and v groove weld symbols and the joint preparations they call for. j groove weld is a special type of groove weld that is. Welding J Groove.

From openoregon.pressbooks.pub

Groove Welding Symbols Interpretation of Metal Fab Drawings Welding J Groove a groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the. j groove weld is a special type of groove weld that is more economical by lowering the weld metal volume. groove welding is used to create a beveled opening in a weld. Welding J Groove.

From weldguru.com

Butt Welds Explained What Are They? When Are They Used? Welding J Groove This type of groove can be used to join thicker materials by creating a narrow groove weld configuration. this guide aims to help you understand bevel and v groove weld symbols and the joint preparations they call for. “v,” “u,” and “j” weld joints. The process of creating the bevels is. a j groove weld is where a. Welding J Groove.

From app.aws.org

Proper Jgroove measurement Welding J Groove groove welding is used to create a beveled opening in a weld joint before welding to achieve the necessary penetration. common weld joint designs are best described with letters. a j groove weld is where a j shaped groove is created in the joint between two pieces of metal. This type of groove can be used to. Welding J Groove.

From www.mtm-inc.com

Understanding Weld symbols The groove weld Meyer Tool & Mfg. Welding J Groove this guide aims to help you understand bevel and v groove weld symbols and the joint preparations they call for. This type of groove can be used to join thicker materials by creating a narrow groove weld configuration. The process of creating the bevels is. It requires special machinery to precisely shape the groove. groove welding is used. Welding J Groove.

From weldguru.com

Welding Symbols Basics & Meanings Explained Welding J Groove j groove weld is a special type of groove weld that is more economical by lowering the weld metal volume. It requires special machinery to precisely shape the groove. this guide aims to help you understand bevel and v groove weld symbols and the joint preparations they call for. common weld joint designs are best described with. Welding J Groove.

From nsarc.com

Guide to Welding Grooves NS Arc Welding J Groove j groove weld is a special type of groove weld that is more economical by lowering the weld metal volume. a groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the. It requires special machinery to precisely shape the groove. this guide aims. Welding J Groove.

From www.youtube.com

Features of the Completed Groove Weld Part 2 Dimension of the Groove weld YouTube Welding J Groove It requires special machinery to precisely shape the groove. This type of groove can be used to join thicker materials by creating a narrow groove weld configuration. a j groove weld is where a j shaped groove is created in the joint between two pieces of metal. “v,” “u,” and “j” weld joints. groove welding is used to. Welding J Groove.

From openoregon.pressbooks.pub

Groove Welding Symbols Interpretation of Metal Fab Drawings Welding J Groove a groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the. j groove weld is a special type of groove weld that is more economical by lowering the weld metal volume. common weld joint designs are best described with letters. This type of. Welding J Groove.

From www.slideserve.com

PPT Weld Joint Geometry and Welding Symbols PowerPoint Presentation, free download ID1263655 Welding J Groove common weld joint designs are best described with letters. j groove weld is a special type of groove weld that is more economical by lowering the weld metal volume. It requires special machinery to precisely shape the groove. “v,” “u,” and “j” weld joints. this guide aims to help you understand bevel and v groove weld symbols. Welding J Groove.

From openoregon.pressbooks.pub

Groove Welding Symbols Interpretation of Metal Fab Drawings Welding J Groove “v,” “u,” and “j” weld joints. a j groove weld is where a j shaped groove is created in the joint between two pieces of metal. a groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the. j groove weld is a special. Welding J Groove.

From www.theweldingmaster.com

Different Types of Welds in Welding Welding J Groove a groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the. common weld joint designs are best described with letters. this guide aims to help you understand bevel and v groove weld symbols and the joint preparations they call for. It requires special. Welding J Groove.

From weldguru.com

Welding Symbols Basics & Meanings Explained Welding J Groove a groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the. It requires special machinery to precisely shape the groove. This type of groove can be used to join thicker materials by creating a narrow groove weld configuration. j groove weld is a special. Welding J Groove.

From weldinglogic.com

Corner Joint Weld Corner Joint Welding Symbol Strength Types & More Welding Logic Welding J Groove common weld joint designs are best described with letters. a j groove weld is where a j shaped groove is created in the joint between two pieces of metal. j groove weld is a special type of groove weld that is more economical by lowering the weld metal volume. groove welding is used to create a. Welding J Groove.

From www.theengineerspost.com

Types of Welding Joints (Explained in detail) Pictures PDF Welding J Groove This type of groove can be used to join thicker materials by creating a narrow groove weld configuration. this guide aims to help you understand bevel and v groove weld symbols and the joint preparations they call for. j groove weld is a special type of groove weld that is more economical by lowering the weld metal volume.. Welding J Groove.

From www.slideserve.com

PPT Weld Joint Geometry and Welding Symbols PowerPoint Presentation ID216047 Welding J Groove j groove weld is a special type of groove weld that is more economical by lowering the weld metal volume. a groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the. “v,” “u,” and “j” weld joints. It requires special machinery to precisely shape. Welding J Groove.

From weldingpros.net

Welding Symbols Chart, Meanings in Examples Ultimate Guide Welding J Groove It requires special machinery to precisely shape the groove. groove welding is used to create a beveled opening in a weld joint before welding to achieve the necessary penetration. j groove weld is a special type of groove weld that is more economical by lowering the weld metal volume. The process of creating the bevels is. a. Welding J Groove.

From www.slideserve.com

PPT CHAPTER 25 PowerPoint Presentation, free download ID969154 Welding J Groove This type of groove can be used to join thicker materials by creating a narrow groove weld configuration. a groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the. a j groove weld is where a j shaped groove is created in the joint. Welding J Groove.

From welditu.com

Types of Welding Joints and Welds Color Graphics • WelditU Welding J Groove this guide aims to help you understand bevel and v groove weld symbols and the joint preparations they call for. It requires special machinery to precisely shape the groove. a groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the. j groove weld. Welding J Groove.

From weldinganswers.com

Learning Welding Symbols Groove Welds WELDING ANSWERS Welding J Groove j groove weld is a special type of groove weld that is more economical by lowering the weld metal volume. a groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the. “v,” “u,” and “j” weld joints. It requires special machinery to precisely shape. Welding J Groove.

From openoregon.pressbooks.pub

Groove Welding Symbols Interpretation of Metal Fab Drawings Welding J Groove a groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the. This type of groove can be used to join thicker materials by creating a narrow groove weld configuration. a j groove weld is where a j shaped groove is created in the joint. Welding J Groove.

From www.theengineerspost.com

Types of Welding Joints (Explained in detail) Pictures PDF Welding J Groove common weld joint designs are best described with letters. j groove weld is a special type of groove weld that is more economical by lowering the weld metal volume. This type of groove can be used to join thicker materials by creating a narrow groove weld configuration. The process of creating the bevels is. “v,” “u,” and “j”. Welding J Groove.

From www.theengineerspost.com

Types of Welding Joints (Explained in detail) Pictures PDF Welding J Groove groove welding is used to create a beveled opening in a weld joint before welding to achieve the necessary penetration. The process of creating the bevels is. a j groove weld is where a j shaped groove is created in the joint between two pieces of metal. common weld joint designs are best described with letters. This. Welding J Groove.

From welditu.com

Guide to Welding Joint Types and Parts WelditU Welding J Groove groove welding is used to create a beveled opening in a weld joint before welding to achieve the necessary penetration. this guide aims to help you understand bevel and v groove weld symbols and the joint preparations they call for. It requires special machinery to precisely shape the groove. common weld joint designs are best described with. Welding J Groove.

From thetoolreviews.com

Types of Groove Welds How To Know Which Type You Should Choose? Welding J Groove The process of creating the bevels is. a groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the. This type of groove can be used to join thicker materials by creating a narrow groove weld configuration. groove welding is used to create a beveled. Welding J Groove.