Hydraulic Filter Failure . Chips on the other hand, are particles 5 m+ and can cause immediate catastrophic failure. Similarly, a sudden decrease in delta p Incompatible filter materials can degrade, deteriorate, or react with the fluid, leading to filter element failure, reduced filtration. Pump not free of air 2. System component failure over time. Back out cylinder sleeves until oil flows freely. Some inside information is required to effectively apply. Air leak in suction line 1. More hydraulic failures are a result of particle contamination than any other cause. For example, if the delta p across a pressure filter suddenly increased from 1 to 3 bar (all other things equal), this could be an indication of an imminent failure of a component upstream. The most common source of system impairment is fluid contamination. Common clogged hydraulic filter symptoms include sluggish or noisy operation. Check and tighten all connections in inlet piping. Without proper preventive measures and fluid conditioning, component failure can result.

from www.donaldson.com

For example, if the delta p across a pressure filter suddenly increased from 1 to 3 bar (all other things equal), this could be an indication of an imminent failure of a component upstream. More hydraulic failures are a result of particle contamination than any other cause. System component failure over time. The most common source of system impairment is fluid contamination. Back out cylinder sleeves until oil flows freely. Without proper preventive measures and fluid conditioning, component failure can result. Some inside information is required to effectively apply. Air leak in suction line 1. Pump not free of air 2. Incompatible filter materials can degrade, deteriorate, or react with the fluid, leading to filter element failure, reduced filtration.

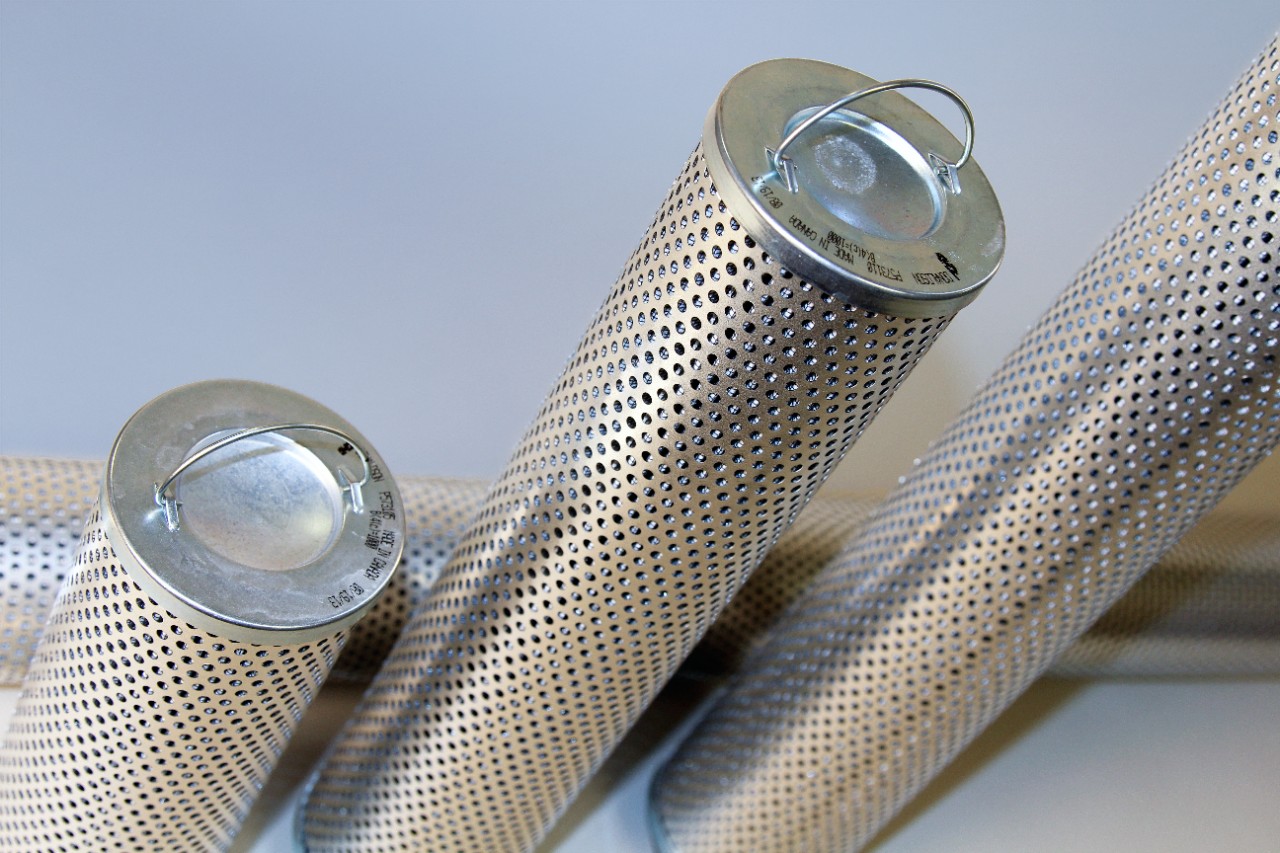

Hydraulic Oil Filters Cross Reference│Donaldson Hydraulics

Hydraulic Filter Failure Back out cylinder sleeves until oil flows freely. The most common source of system impairment is fluid contamination. For example, if the delta p across a pressure filter suddenly increased from 1 to 3 bar (all other things equal), this could be an indication of an imminent failure of a component upstream. Incompatible filter materials can degrade, deteriorate, or react with the fluid, leading to filter element failure, reduced filtration. System component failure over time. More hydraulic failures are a result of particle contamination than any other cause. Similarly, a sudden decrease in delta p Without proper preventive measures and fluid conditioning, component failure can result. Common clogged hydraulic filter symptoms include sluggish or noisy operation. Check and tighten all connections in inlet piping. Chips on the other hand, are particles 5 m+ and can cause immediate catastrophic failure. Some inside information is required to effectively apply. Air leak in suction line 1. Pump not free of air 2. Back out cylinder sleeves until oil flows freely.

From hydraulictraining.com

Hydraulic Filter Ratings Explained Hydraulic Training NW, LLC Hydraulic Filter Failure Similarly, a sudden decrease in delta p The most common source of system impairment is fluid contamination. Some inside information is required to effectively apply. Chips on the other hand, are particles 5 m+ and can cause immediate catastrophic failure. Check and tighten all connections in inlet piping. System component failure over time. For example, if the delta p across. Hydraulic Filter Failure.

From www.reddit.com

C/S check oil leak engine failure caused filter to blow apart. Not a defective filter Hydraulic Filter Failure Pump not free of air 2. Some inside information is required to effectively apply. More hydraulic failures are a result of particle contamination than any other cause. The most common source of system impairment is fluid contamination. Back out cylinder sleeves until oil flows freely. Without proper preventive measures and fluid conditioning, component failure can result. Similarly, a sudden decrease. Hydraulic Filter Failure.

From www.donaldson.com

Hydraulic Oil Filters Cross Reference│Donaldson Hydraulics Hydraulic Filter Failure Check and tighten all connections in inlet piping. Air leak in suction line 1. Without proper preventive measures and fluid conditioning, component failure can result. Incompatible filter materials can degrade, deteriorate, or react with the fluid, leading to filter element failure, reduced filtration. Pump not free of air 2. Common clogged hydraulic filter symptoms include sluggish or noisy operation. The. Hydraulic Filter Failure.

From www.mdpi.com

Engineering Proceedings Free FullText Reliability Analysis of Hydraulic System of a Tunnel Hydraulic Filter Failure Air leak in suction line 1. Some inside information is required to effectively apply. Common clogged hydraulic filter symptoms include sluggish or noisy operation. More hydraulic failures are a result of particle contamination than any other cause. The most common source of system impairment is fluid contamination. System component failure over time. For example, if the delta p across a. Hydraulic Filter Failure.

From www.hyprofiltration.com

Hydraulic and Lubrication Filter Types and Locations Hydraulic Filter Failure For example, if the delta p across a pressure filter suddenly increased from 1 to 3 bar (all other things equal), this could be an indication of an imminent failure of a component upstream. More hydraulic failures are a result of particle contamination than any other cause. System component failure over time. The most common source of system impairment is. Hydraulic Filter Failure.

From www.walmart.com

Hydraulic Filter 19642509000 fits Mahindra Tractor 2615 2815 3015 3215 Hydraulic Filter Failure More hydraulic failures are a result of particle contamination than any other cause. Chips on the other hand, are particles 5 m+ and can cause immediate catastrophic failure. Air leak in suction line 1. System component failure over time. Check and tighten all connections in inlet piping. Pump not free of air 2. Back out cylinder sleeves until oil flows. Hydraulic Filter Failure.

From www.austces.com.au

Service Tip Importance of Changing Hydraulic Filters Hydraulic Filter Failure System component failure over time. Some inside information is required to effectively apply. Air leak in suction line 1. Similarly, a sudden decrease in delta p Chips on the other hand, are particles 5 m+ and can cause immediate catastrophic failure. More hydraulic failures are a result of particle contamination than any other cause. Without proper preventive measures and fluid. Hydraulic Filter Failure.

From www.hydropress.cz

0060D010BH3HC Hydraulic filter insert for HYDAC pressure filter, replacement, 10 µm Hydraulic Filter Failure Air leak in suction line 1. Some inside information is required to effectively apply. Pump not free of air 2. For example, if the delta p across a pressure filter suddenly increased from 1 to 3 bar (all other things equal), this could be an indication of an imminent failure of a component upstream. Common clogged hydraulic filter symptoms include. Hydraulic Filter Failure.

From www.lakkapaa.se

47425202 (S)FILTER, HYDRAULIC OIL, KTS Lakkapää Oy webbutik Hydraulic Filter Failure Incompatible filter materials can degrade, deteriorate, or react with the fluid, leading to filter element failure, reduced filtration. Back out cylinder sleeves until oil flows freely. Air leak in suction line 1. The most common source of system impairment is fluid contamination. More hydraulic failures are a result of particle contamination than any other cause. Similarly, a sudden decrease in. Hydraulic Filter Failure.

From www.researchgate.net

(PDF) Fatigue failure of a hydraulic filter head Hydraulic Filter Failure System component failure over time. Incompatible filter materials can degrade, deteriorate, or react with the fluid, leading to filter element failure, reduced filtration. Check and tighten all connections in inlet piping. Pump not free of air 2. For example, if the delta p across a pressure filter suddenly increased from 1 to 3 bar (all other things equal), this could. Hydraulic Filter Failure.

From www.machinerylubrication.com

4 Types of Oil Filter Failures and How to Prevent Them Hydraulic Filter Failure Air leak in suction line 1. Similarly, a sudden decrease in delta p Incompatible filter materials can degrade, deteriorate, or react with the fluid, leading to filter element failure, reduced filtration. Back out cylinder sleeves until oil flows freely. Common clogged hydraulic filter symptoms include sluggish or noisy operation. Pump not free of air 2. System component failure over time.. Hydraulic Filter Failure.

From www.carolinahoseandhydraulics.com

3 Common Causes of Overheating in Hydraulic Systems Hydraulic Filter Failure More hydraulic failures are a result of particle contamination than any other cause. Similarly, a sudden decrease in delta p Back out cylinder sleeves until oil flows freely. Some inside information is required to effectively apply. Without proper preventive measures and fluid conditioning, component failure can result. Incompatible filter materials can degrade, deteriorate, or react with the fluid, leading to. Hydraulic Filter Failure.

From favpng.com

Hydraulic Drive System Hydraulic Fluid Hydraulics Failure, PNG, 1125x1051px, Hydraulic Drive Hydraulic Filter Failure Without proper preventive measures and fluid conditioning, component failure can result. Air leak in suction line 1. For example, if the delta p across a pressure filter suddenly increased from 1 to 3 bar (all other things equal), this could be an indication of an imminent failure of a component upstream. Incompatible filter materials can degrade, deteriorate, or react with. Hydraulic Filter Failure.

From www.tractorforum.com

Mahindra 2538 hydraulic leak from above hydraulic filter housing Tractor Forum Hydraulic Filter Failure Some inside information is required to effectively apply. Chips on the other hand, are particles 5 m+ and can cause immediate catastrophic failure. Back out cylinder sleeves until oil flows freely. System component failure over time. Without proper preventive measures and fluid conditioning, component failure can result. Common clogged hydraulic filter symptoms include sluggish or noisy operation. For example, if. Hydraulic Filter Failure.

From www.youtube.com

How to install oil fuel & hydraulic filters on a Komatsu D51PX22 dozer PX24 EX22 EX24 YouTube Hydraulic Filter Failure Chips on the other hand, are particles 5 m+ and can cause immediate catastrophic failure. Back out cylinder sleeves until oil flows freely. Similarly, a sudden decrease in delta p Some inside information is required to effectively apply. The most common source of system impairment is fluid contamination. More hydraulic failures are a result of particle contamination than any other. Hydraulic Filter Failure.

From www.reddit.com

“Can you just replace the hydraulic filter?” Hydraulic Filter Failure Common clogged hydraulic filter symptoms include sluggish or noisy operation. The most common source of system impairment is fluid contamination. Back out cylinder sleeves until oil flows freely. Check and tighten all connections in inlet piping. For example, if the delta p across a pressure filter suddenly increased from 1 to 3 bar (all other things equal), this could be. Hydraulic Filter Failure.

From www.youtube.com

HYDRAULIC FLUID CHANGE ON THE TRACTOR AND PROBLEMS PT1 YouTube Hydraulic Filter Failure System component failure over time. Incompatible filter materials can degrade, deteriorate, or react with the fluid, leading to filter element failure, reduced filtration. Common clogged hydraulic filter symptoms include sluggish or noisy operation. The most common source of system impairment is fluid contamination. Chips on the other hand, are particles 5 m+ and can cause immediate catastrophic failure. Similarly, a. Hydraulic Filter Failure.

From www.linkedin.com

Chamber filter press hydraulic system failure and solution Hydraulic Filter Failure Back out cylinder sleeves until oil flows freely. Air leak in suction line 1. Some inside information is required to effectively apply. Pump not free of air 2. Without proper preventive measures and fluid conditioning, component failure can result. Common clogged hydraulic filter symptoms include sluggish or noisy operation. The most common source of system impairment is fluid contamination. Check. Hydraulic Filter Failure.

From www.hydac.co.nz

What is hydraulic filter element? HYDAC News Hydraulic Filter Failure Pump not free of air 2. Common clogged hydraulic filter symptoms include sluggish or noisy operation. Similarly, a sudden decrease in delta p Some inside information is required to effectively apply. Check and tighten all connections in inlet piping. For example, if the delta p across a pressure filter suddenly increased from 1 to 3 bar (all other things equal),. Hydraulic Filter Failure.

From pneumaticshydraulic.com

Hydraulic Filters Pneumatics Hydraulic Hydraulic Filter Failure Chips on the other hand, are particles 5 m+ and can cause immediate catastrophic failure. Air leak in suction line 1. More hydraulic failures are a result of particle contamination than any other cause. Back out cylinder sleeves until oil flows freely. Without proper preventive measures and fluid conditioning, component failure can result. System component failure over time. Some inside. Hydraulic Filter Failure.

From www.hyprofiltration.com

Hydraulic and Lubrication Filter Types and Locations Hydraulic Filter Failure Chips on the other hand, are particles 5 m+ and can cause immediate catastrophic failure. System component failure over time. Pump not free of air 2. For example, if the delta p across a pressure filter suddenly increased from 1 to 3 bar (all other things equal), this could be an indication of an imminent failure of a component upstream.. Hydraulic Filter Failure.

From magnom.com

CASE DRAIN FILTRATION, STOP HYDRAULIC MOTOR & PUMP FAILURE Magnom Hydraulic Filter Failure For example, if the delta p across a pressure filter suddenly increased from 1 to 3 bar (all other things equal), this could be an indication of an imminent failure of a component upstream. Similarly, a sudden decrease in delta p The most common source of system impairment is fluid contamination. Common clogged hydraulic filter symptoms include sluggish or noisy. Hydraulic Filter Failure.

From www.jyzyfilter.com

How to prevent your hydraulic filter element broken Hydraulic Filter Failure System component failure over time. Similarly, a sudden decrease in delta p Common clogged hydraulic filter symptoms include sluggish or noisy operation. Some inside information is required to effectively apply. Chips on the other hand, are particles 5 m+ and can cause immediate catastrophic failure. Back out cylinder sleeves until oil flows freely. For example, if the delta p across. Hydraulic Filter Failure.

From www.redpowermagazine.com

240 Hydraulic filter help needed Technical IH Talk Red Power Magazine Community Hydraulic Filter Failure Air leak in suction line 1. More hydraulic failures are a result of particle contamination than any other cause. Pump not free of air 2. The most common source of system impairment is fluid contamination. Common clogged hydraulic filter symptoms include sluggish or noisy operation. For example, if the delta p across a pressure filter suddenly increased from 1 to. Hydraulic Filter Failure.

From www.audiforums.com

Oil Filter failure Hydraulic Filter Failure Chips on the other hand, are particles 5 m+ and can cause immediate catastrophic failure. Without proper preventive measures and fluid conditioning, component failure can result. Similarly, a sudden decrease in delta p Incompatible filter materials can degrade, deteriorate, or react with the fluid, leading to filter element failure, reduced filtration. Air leak in suction line 1. For example, if. Hydraulic Filter Failure.

From thefarmingforum.co.uk

MF 135 Hydraulic Filter correct configuration The Farming Forum Hydraulic Filter Failure Incompatible filter materials can degrade, deteriorate, or react with the fluid, leading to filter element failure, reduced filtration. Air leak in suction line 1. Back out cylinder sleeves until oil flows freely. The most common source of system impairment is fluid contamination. Some inside information is required to effectively apply. Chips on the other hand, are particles 5 m+ and. Hydraulic Filter Failure.

From www.youtube.com

Save How YOU Can Replace Hydraulic Return Filters John Deere 35G Excavator Maintenance Hydraulic Filter Failure System component failure over time. Back out cylinder sleeves until oil flows freely. Common clogged hydraulic filter symptoms include sluggish or noisy operation. Pump not free of air 2. Similarly, a sudden decrease in delta p Some inside information is required to effectively apply. More hydraulic failures are a result of particle contamination than any other cause. Incompatible filter materials. Hydraulic Filter Failure.

From slideplayer.com

Case Study Evaluating Retrofit Urban Best Management Practice Performance and Lessons Learned Hydraulic Filter Failure More hydraulic failures are a result of particle contamination than any other cause. Some inside information is required to effectively apply. System component failure over time. Without proper preventive measures and fluid conditioning, component failure can result. Chips on the other hand, are particles 5 m+ and can cause immediate catastrophic failure. Pump not free of air 2. Similarly, a. Hydraulic Filter Failure.

From www.burkschmidt.com

(3) "Simple" Upgrades to Improve Performance of Your Hydraulic System Burk Schmidt, Fluid Hydraulic Filter Failure System component failure over time. Air leak in suction line 1. Some inside information is required to effectively apply. Chips on the other hand, are particles 5 m+ and can cause immediate catastrophic failure. Back out cylinder sleeves until oil flows freely. Similarly, a sudden decrease in delta p Without proper preventive measures and fluid conditioning, component failure can result.. Hydraulic Filter Failure.

From www.neptunus-power.com

Understanding the Causes of Oil Filter Failure 4 Common Factors Neptunus Power Hydraulic Filter Failure For example, if the delta p across a pressure filter suddenly increased from 1 to 3 bar (all other things equal), this could be an indication of an imminent failure of a component upstream. System component failure over time. Check and tighten all connections in inlet piping. Pump not free of air 2. Some inside information is required to effectively. Hydraulic Filter Failure.

From www.aircraftsystemstech.com

Aircraft Systems Aircraft Hydraulic System Filters Hydraulic Filter Failure Check and tighten all connections in inlet piping. Some inside information is required to effectively apply. For example, if the delta p across a pressure filter suddenly increased from 1 to 3 bar (all other things equal), this could be an indication of an imminent failure of a component upstream. More hydraulic failures are a result of particle contamination than. Hydraulic Filter Failure.

From www.hydrauliccylindersinc.com

When to Change Hydraulic Filters Cylinder Maintenance Tips Hydraulic Filter Failure Air leak in suction line 1. Similarly, a sudden decrease in delta p Incompatible filter materials can degrade, deteriorate, or react with the fluid, leading to filter element failure, reduced filtration. Common clogged hydraulic filter symptoms include sluggish or noisy operation. More hydraulic failures are a result of particle contamination than any other cause. The most common source of system. Hydraulic Filter Failure.

From diymyway.net

Fixing a Hydraulic Leak on My Kubota L3901 DIY My Way Hydraulic Filter Failure Air leak in suction line 1. Without proper preventive measures and fluid conditioning, component failure can result. The most common source of system impairment is fluid contamination. Some inside information is required to effectively apply. Chips on the other hand, are particles 5 m+ and can cause immediate catastrophic failure. For example, if the delta p across a pressure filter. Hydraulic Filter Failure.

From www.youtube.com

3414 IH Part 6 Hydraulic Filters YouTube Hydraulic Filter Failure Without proper preventive measures and fluid conditioning, component failure can result. Incompatible filter materials can degrade, deteriorate, or react with the fluid, leading to filter element failure, reduced filtration. Air leak in suction line 1. More hydraulic failures are a result of particle contamination than any other cause. For example, if the delta p across a pressure filter suddenly increased. Hydraulic Filter Failure.

From www.donaldson.com

Hydraulic Oil Filter Assemblies │Donaldson Hydraulics Hydraulic Filter Failure Air leak in suction line 1. More hydraulic failures are a result of particle contamination than any other cause. Incompatible filter materials can degrade, deteriorate, or react with the fluid, leading to filter element failure, reduced filtration. Without proper preventive measures and fluid conditioning, component failure can result. Back out cylinder sleeves until oil flows freely. System component failure over. Hydraulic Filter Failure.