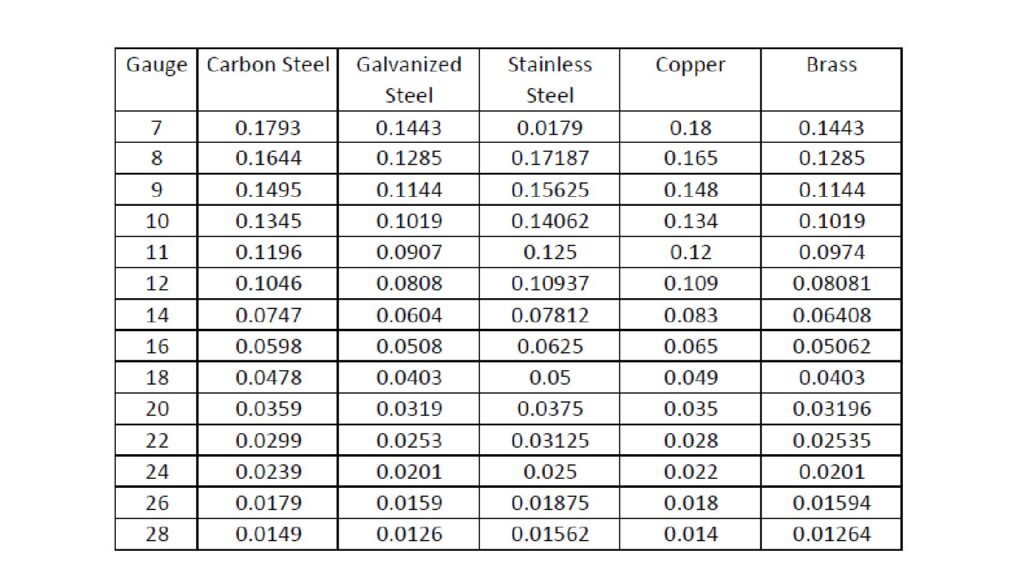

What Material Is Best For Gauges . A sheet metal gauge chart is an essential reference tool in metal fabrication that correlates gauge numbers with precise material. There are different gauges for a specific material, stainless steel, galvanized steel, sheet steel, brass, aluminum, and copper. Due to differences in density and composition, gauge numbers vary between materials. These sheet metal gauge charts will help you choose the correct measurement units for your specific metal material. In our detailed gauge chart, we will compare gauge numbers and their corresponding thicknesses in millimetres across various materials such as stainless steel, aluminum, and copper. Find a thickness gauge that matches your material properties, precision requirements and budget. There are two basic thickness gauge categories for measuring thin materials. On the other hand, thinner gauges are less expensive and lighter, which can be advantageous for projects where cost and. The purpose of this guide is to delve into the complexities of the sheet metal gauge chart, providing a clearer understanding to make informed decisions for your specific applications. Thicker gauges are typically stronger and heavier, making them suitable for projects requiring durable, sturdy components. The “best” sheet metal gauge depends entirely on your specific project requirements. Ensuring you select the right sheet metal gauge, or thickness, is crucial for the integrity, durability, and efficiency of the final product. Among these sheet metal gauges for steel are the standard ones in manufacturing, which is based on the idea that an inch of steel weighs 41.82 pounds per square foot.

from proleantech.com

The “best” sheet metal gauge depends entirely on your specific project requirements. The purpose of this guide is to delve into the complexities of the sheet metal gauge chart, providing a clearer understanding to make informed decisions for your specific applications. Thicker gauges are typically stronger and heavier, making them suitable for projects requiring durable, sturdy components. Find a thickness gauge that matches your material properties, precision requirements and budget. In our detailed gauge chart, we will compare gauge numbers and their corresponding thicknesses in millimetres across various materials such as stainless steel, aluminum, and copper. There are two basic thickness gauge categories for measuring thin materials. Due to differences in density and composition, gauge numbers vary between materials. A sheet metal gauge chart is an essential reference tool in metal fabrication that correlates gauge numbers with precise material. On the other hand, thinner gauges are less expensive and lighter, which can be advantageous for projects where cost and. These sheet metal gauge charts will help you choose the correct measurement units for your specific metal material.

Sheet Metal Gauge Using, Affecting Factors & Advantages

What Material Is Best For Gauges Due to differences in density and composition, gauge numbers vary between materials. The purpose of this guide is to delve into the complexities of the sheet metal gauge chart, providing a clearer understanding to make informed decisions for your specific applications. On the other hand, thinner gauges are less expensive and lighter, which can be advantageous for projects where cost and. Among these sheet metal gauges for steel are the standard ones in manufacturing, which is based on the idea that an inch of steel weighs 41.82 pounds per square foot. Find a thickness gauge that matches your material properties, precision requirements and budget. Thicker gauges are typically stronger and heavier, making them suitable for projects requiring durable, sturdy components. Due to differences in density and composition, gauge numbers vary between materials. The “best” sheet metal gauge depends entirely on your specific project requirements. These sheet metal gauge charts will help you choose the correct measurement units for your specific metal material. There are two basic thickness gauge categories for measuring thin materials. There are different gauges for a specific material, stainless steel, galvanized steel, sheet steel, brass, aluminum, and copper. Ensuring you select the right sheet metal gauge, or thickness, is crucial for the integrity, durability, and efficiency of the final product. In our detailed gauge chart, we will compare gauge numbers and their corresponding thicknesses in millimetres across various materials such as stainless steel, aluminum, and copper. A sheet metal gauge chart is an essential reference tool in metal fabrication that correlates gauge numbers with precise material.

From theinstrumentguru.com

Gauge Factor THE INSTRUMENT GURU What Material Is Best For Gauges On the other hand, thinner gauges are less expensive and lighter, which can be advantageous for projects where cost and. Due to differences in density and composition, gauge numbers vary between materials. The “best” sheet metal gauge depends entirely on your specific project requirements. The purpose of this guide is to delve into the complexities of the sheet metal gauge. What Material Is Best For Gauges.

From www.pinterest.com

Types of Gauges Gauges, Informative, Explained What Material Is Best For Gauges A sheet metal gauge chart is an essential reference tool in metal fabrication that correlates gauge numbers with precise material. There are different gauges for a specific material, stainless steel, galvanized steel, sheet steel, brass, aluminum, and copper. Due to differences in density and composition, gauge numbers vary between materials. These sheet metal gauge charts will help you choose the. What Material Is Best For Gauges.

From www.youtube.com

Types of Gauges in Measurement YouTube What Material Is Best For Gauges There are two basic thickness gauge categories for measuring thin materials. On the other hand, thinner gauges are less expensive and lighter, which can be advantageous for projects where cost and. The purpose of this guide is to delve into the complexities of the sheet metal gauge chart, providing a clearer understanding to make informed decisions for your specific applications.. What Material Is Best For Gauges.

From www.metalsupermarkets.com

Sheet Metal Gauge Chart Metal Supermarkets What Material Is Best For Gauges These sheet metal gauge charts will help you choose the correct measurement units for your specific metal material. The purpose of this guide is to delve into the complexities of the sheet metal gauge chart, providing a clearer understanding to make informed decisions for your specific applications. Find a thickness gauge that matches your material properties, precision requirements and budget.. What Material Is Best For Gauges.

From www.selfgrowth.com

4 Major Types Of Level Gauges What Material Is Best For Gauges Find a thickness gauge that matches your material properties, precision requirements and budget. On the other hand, thinner gauges are less expensive and lighter, which can be advantageous for projects where cost and. The “best” sheet metal gauge depends entirely on your specific project requirements. These sheet metal gauge charts will help you choose the correct measurement units for your. What Material Is Best For Gauges.

From sendcutsend.com

Guide to Understanding Gauge Thickness SendCutSend What Material Is Best For Gauges A sheet metal gauge chart is an essential reference tool in metal fabrication that correlates gauge numbers with precise material. The purpose of this guide is to delve into the complexities of the sheet metal gauge chart, providing a clearer understanding to make informed decisions for your specific applications. There are different gauges for a specific material, stainless steel, galvanized. What Material Is Best For Gauges.

From www.customplugs.com

The Complete Guide to Materials for Plugs, Gauges & Tunnels UK Custom What Material Is Best For Gauges There are two basic thickness gauge categories for measuring thin materials. The purpose of this guide is to delve into the complexities of the sheet metal gauge chart, providing a clearer understanding to make informed decisions for your specific applications. In our detailed gauge chart, we will compare gauge numbers and their corresponding thicknesses in millimetres across various materials such. What Material Is Best For Gauges.

From selmach.com

How to measure sheet metal gauge and thickness Selmach™ What Material Is Best For Gauges The “best” sheet metal gauge depends entirely on your specific project requirements. Find a thickness gauge that matches your material properties, precision requirements and budget. Due to differences in density and composition, gauge numbers vary between materials. Among these sheet metal gauges for steel are the standard ones in manufacturing, which is based on the idea that an inch of. What Material Is Best For Gauges.

From kraftika.shop

Blog News! Artistic Wire Gauge Guide. AWG The Standard of the What Material Is Best For Gauges In our detailed gauge chart, we will compare gauge numbers and their corresponding thicknesses in millimetres across various materials such as stainless steel, aluminum, and copper. A sheet metal gauge chart is an essential reference tool in metal fabrication that correlates gauge numbers with precise material. Find a thickness gauge that matches your material properties, precision requirements and budget. The. What Material Is Best For Gauges.

From www.craftyhangouts.com

10 Best Bowl Gouges Reviewed and Rated (Jul. 2021) What Material Is Best For Gauges There are different gauges for a specific material, stainless steel, galvanized steel, sheet steel, brass, aluminum, and copper. The purpose of this guide is to delve into the complexities of the sheet metal gauge chart, providing a clearer understanding to make informed decisions for your specific applications. Find a thickness gauge that matches your material properties, precision requirements and budget.. What Material Is Best For Gauges.

From woodcarvingillustrated.com

Great Gouges the Essential Tool Kit Woodcarving Illustrated What Material Is Best For Gauges Find a thickness gauge that matches your material properties, precision requirements and budget. Thicker gauges are typically stronger and heavier, making them suitable for projects requiring durable, sturdy components. The “best” sheet metal gauge depends entirely on your specific project requirements. The purpose of this guide is to delve into the complexities of the sheet metal gauge chart, providing a. What Material Is Best For Gauges.

From allpointsfasteners.com

Sheet Metal Gauge Thickness Chart All Points Fasteners What Material Is Best For Gauges In our detailed gauge chart, we will compare gauge numbers and their corresponding thicknesses in millimetres across various materials such as stainless steel, aluminum, and copper. These sheet metal gauge charts will help you choose the correct measurement units for your specific metal material. Find a thickness gauge that matches your material properties, precision requirements and budget. Ensuring you select. What Material Is Best For Gauges.

From jewelclark.com

Gauge conversion chart Jewel Clark What Material Is Best For Gauges Due to differences in density and composition, gauge numbers vary between materials. These sheet metal gauge charts will help you choose the correct measurement units for your specific metal material. There are different gauges for a specific material, stainless steel, galvanized steel, sheet steel, brass, aluminum, and copper. On the other hand, thinner gauges are less expensive and lighter, which. What Material Is Best For Gauges.

From www.metafab.com

Sheet Metal Material Thicknesses Guide Meta Fab, Inc. What Material Is Best For Gauges These sheet metal gauge charts will help you choose the correct measurement units for your specific metal material. On the other hand, thinner gauges are less expensive and lighter, which can be advantageous for projects where cost and. Among these sheet metal gauges for steel are the standard ones in manufacturing, which is based on the idea that an inch. What Material Is Best For Gauges.

From www.directmaterial.com

What Style of Pressure Gauge Connection Works Best? What Material Is Best For Gauges These sheet metal gauge charts will help you choose the correct measurement units for your specific metal material. A sheet metal gauge chart is an essential reference tool in metal fabrication that correlates gauge numbers with precise material. Find a thickness gauge that matches your material properties, precision requirements and budget. Due to differences in density and composition, gauge numbers. What Material Is Best For Gauges.

From www.craftyhangouts.com

10 Best Bowl Gouges Reviewed and Rated (Jul. 2021) What Material Is Best For Gauges The “best” sheet metal gauge depends entirely on your specific project requirements. A sheet metal gauge chart is an essential reference tool in metal fabrication that correlates gauge numbers with precise material. There are different gauges for a specific material, stainless steel, galvanized steel, sheet steel, brass, aluminum, and copper. These sheet metal gauge charts will help you choose the. What Material Is Best For Gauges.

From www.craftyhangouts.com

10 Best Bowl Gouges Reviewed and Rated (Fall 2023) What Material Is Best For Gauges The “best” sheet metal gauge depends entirely on your specific project requirements. Among these sheet metal gauges for steel are the standard ones in manufacturing, which is based on the idea that an inch of steel weighs 41.82 pounds per square foot. Thicker gauges are typically stronger and heavier, making them suitable for projects requiring durable, sturdy components. On the. What Material Is Best For Gauges.

From www.britannica.com

Gauge Types, Uses & Measurement Britannica What Material Is Best For Gauges On the other hand, thinner gauges are less expensive and lighter, which can be advantageous for projects where cost and. There are different gauges for a specific material, stainless steel, galvanized steel, sheet steel, brass, aluminum, and copper. Due to differences in density and composition, gauge numbers vary between materials. In our detailed gauge chart, we will compare gauge numbers. What Material Is Best For Gauges.

From www.youtube.com

Types of Gauges Used in mechanical Industries Fix type measuring What Material Is Best For Gauges A sheet metal gauge chart is an essential reference tool in metal fabrication that correlates gauge numbers with precise material. These sheet metal gauge charts will help you choose the correct measurement units for your specific metal material. Among these sheet metal gauges for steel are the standard ones in manufacturing, which is based on the idea that an inch. What Material Is Best For Gauges.

From cookinglove.com

Gauge chart What Material Is Best For Gauges Ensuring you select the right sheet metal gauge, or thickness, is crucial for the integrity, durability, and efficiency of the final product. The “best” sheet metal gauge depends entirely on your specific project requirements. On the other hand, thinner gauges are less expensive and lighter, which can be advantageous for projects where cost and. These sheet metal gauge charts will. What Material Is Best For Gauges.

From www.freshtrends.com

Gauge Size Chart for Body Piercings and FAQ FreshTrends What Material Is Best For Gauges There are two basic thickness gauge categories for measuring thin materials. On the other hand, thinner gauges are less expensive and lighter, which can be advantageous for projects where cost and. The purpose of this guide is to delve into the complexities of the sheet metal gauge chart, providing a clearer understanding to make informed decisions for your specific applications.. What Material Is Best For Gauges.

From weaversteelweld.com

Sheet Gauge Chart Weaver Steel Welding What Material Is Best For Gauges The purpose of this guide is to delve into the complexities of the sheet metal gauge chart, providing a clearer understanding to make informed decisions for your specific applications. There are different gauges for a specific material, stainless steel, galvanized steel, sheet steel, brass, aluminum, and copper. Due to differences in density and composition, gauge numbers vary between materials. On. What Material Is Best For Gauges.

From tjibc.com

Gauge Steel Thickness Sheet Metal Gauge Chart IBC Group What Material Is Best For Gauges In our detailed gauge chart, we will compare gauge numbers and their corresponding thicknesses in millimetres across various materials such as stainless steel, aluminum, and copper. The “best” sheet metal gauge depends entirely on your specific project requirements. There are two basic thickness gauge categories for measuring thin materials. There are different gauges for a specific material, stainless steel, galvanized. What Material Is Best For Gauges.

From fractory.com

Sheet Metal Materials, Standard Sizes & Forming Processes What Material Is Best For Gauges Ensuring you select the right sheet metal gauge, or thickness, is crucial for the integrity, durability, and efficiency of the final product. A sheet metal gauge chart is an essential reference tool in metal fabrication that correlates gauge numbers with precise material. Thicker gauges are typically stronger and heavier, making them suitable for projects requiring durable, sturdy components. On the. What Material Is Best For Gauges.

From www.ebay.co.uk

4Pcs Wood Carving Roughing Gouges Chisels Set Hand Woodworking What Material Is Best For Gauges A sheet metal gauge chart is an essential reference tool in metal fabrication that correlates gauge numbers with precise material. Thicker gauges are typically stronger and heavier, making them suitable for projects requiring durable, sturdy components. The purpose of this guide is to delve into the complexities of the sheet metal gauge chart, providing a clearer understanding to make informed. What Material Is Best For Gauges.

From www.majesticsteel.com

Buy Better with the Definitive Cold Rolled Steel Gauge Chart What Material Is Best For Gauges There are different gauges for a specific material, stainless steel, galvanized steel, sheet steel, brass, aluminum, and copper. Find a thickness gauge that matches your material properties, precision requirements and budget. In our detailed gauge chart, we will compare gauge numbers and their corresponding thicknesses in millimetres across various materials such as stainless steel, aluminum, and copper. Thicker gauges are. What Material Is Best For Gauges.

From www.hiproequipment.com

Steel Gauge Chart Hi Pro Equipment What Material Is Best For Gauges The purpose of this guide is to delve into the complexities of the sheet metal gauge chart, providing a clearer understanding to make informed decisions for your specific applications. A sheet metal gauge chart is an essential reference tool in metal fabrication that correlates gauge numbers with precise material. There are different gauges for a specific material, stainless steel, galvanized. What Material Is Best For Gauges.

From www.engraveithouston.com

Engrave It Houston — Stainless Steel Gauge Chart What Material Is Best For Gauges Find a thickness gauge that matches your material properties, precision requirements and budget. On the other hand, thinner gauges are less expensive and lighter, which can be advantageous for projects where cost and. Among these sheet metal gauges for steel are the standard ones in manufacturing, which is based on the idea that an inch of steel weighs 41.82 pounds. What Material Is Best For Gauges.

From awoodstory.com

14 Best Wood Carving Gouges Our Reviews What Material Is Best For Gauges These sheet metal gauge charts will help you choose the correct measurement units for your specific metal material. Find a thickness gauge that matches your material properties, precision requirements and budget. Thicker gauges are typically stronger and heavier, making them suitable for projects requiring durable, sturdy components. Ensuring you select the right sheet metal gauge, or thickness, is crucial for. What Material Is Best For Gauges.

From gtsparkplugs.com

Sheet Metal Gauge Chart GTSparkplugs What Material Is Best For Gauges Among these sheet metal gauges for steel are the standard ones in manufacturing, which is based on the idea that an inch of steel weighs 41.82 pounds per square foot. Thicker gauges are typically stronger and heavier, making them suitable for projects requiring durable, sturdy components. On the other hand, thinner gauges are less expensive and lighter, which can be. What Material Is Best For Gauges.

From www.borrmannmetals.com

Gauge Chart What Material Is Best For Gauges The purpose of this guide is to delve into the complexities of the sheet metal gauge chart, providing a clearer understanding to make informed decisions for your specific applications. A sheet metal gauge chart is an essential reference tool in metal fabrication that correlates gauge numbers with precise material. Due to differences in density and composition, gauge numbers vary between. What Material Is Best For Gauges.

From proleantech.com

Sheet Metal Gauge Using, Affecting Factors & Advantages What Material Is Best For Gauges The “best” sheet metal gauge depends entirely on your specific project requirements. A sheet metal gauge chart is an essential reference tool in metal fabrication that correlates gauge numbers with precise material. These sheet metal gauge charts will help you choose the correct measurement units for your specific metal material. On the other hand, thinner gauges are less expensive and. What Material Is Best For Gauges.

From www.tjfab.com

Sheet Metal Gauge Chart T/J Fabricators Sheet Metal Gauges What Material Is Best For Gauges Thicker gauges are typically stronger and heavier, making them suitable for projects requiring durable, sturdy components. There are two basic thickness gauge categories for measuring thin materials. The purpose of this guide is to delve into the complexities of the sheet metal gauge chart, providing a clearer understanding to make informed decisions for your specific applications. There are different gauges. What Material Is Best For Gauges.

From handicrafts365.com

Best Wood Carving Gouges Top 6 Wood Carving Gouges In the Market What Material Is Best For Gauges Among these sheet metal gauges for steel are the standard ones in manufacturing, which is based on the idea that an inch of steel weighs 41.82 pounds per square foot. A sheet metal gauge chart is an essential reference tool in metal fabrication that correlates gauge numbers with precise material. In our detailed gauge chart, we will compare gauge numbers. What Material Is Best For Gauges.

From www.thecornerguardstore.com

Comparing Stainless Steel Types and Gauges What Material Is Best For Gauges Due to differences in density and composition, gauge numbers vary between materials. Among these sheet metal gauges for steel are the standard ones in manufacturing, which is based on the idea that an inch of steel weighs 41.82 pounds per square foot. There are two basic thickness gauge categories for measuring thin materials. These sheet metal gauge charts will help. What Material Is Best For Gauges.