Wheel Chock Safety Procedures . In this episode of the risk control show, matt and steve dive deep into the importance of proper wheel chock usage and avoiding complacency. Some vehicle wheels may also need to be chocked at the front and back of each tire. It is safest to chock both the front and back wheels on both sides of a vehicle. Esco wheel chocks meet and exceed requirements of osha and msha as specified below: Blocking stabilizes cargo loads to prevent shifting and trailer overturns or provides a physical barrier on equipment to prevent accidental activation. Wheel chocking is essential for making loading docks safe. Chocking, also known as blocking, prevents trucks and trailers from unintentionally moving, like rolling or overturning, while workers are loading, unloading, hitching, unhitching or servicing the vehicle. Wheel chocks is recommended to ensure you have the right chocks for your requirements. Wheel chocks work best for safety and accident prevention. • tire types • chock material • load weight •. Start the next shift by reminding workers why and how to chock trailer wheels.

from www.mysafetysign.com

Start the next shift by reminding workers why and how to chock trailer wheels. It is safest to chock both the front and back wheels on both sides of a vehicle. In this episode of the risk control show, matt and steve dive deep into the importance of proper wheel chock usage and avoiding complacency. Wheel chocks work best for safety and accident prevention. Blocking stabilizes cargo loads to prevent shifting and trailer overturns or provides a physical barrier on equipment to prevent accidental activation. Esco wheel chocks meet and exceed requirements of osha and msha as specified below: Some vehicle wheels may also need to be chocked at the front and back of each tire. Wheel chocking is essential for making loading docks safe. Chocking, also known as blocking, prevents trucks and trailers from unintentionally moving, like rolling or overturning, while workers are loading, unloading, hitching, unhitching or servicing the vehicle. Wheel chocks is recommended to ensure you have the right chocks for your requirements.

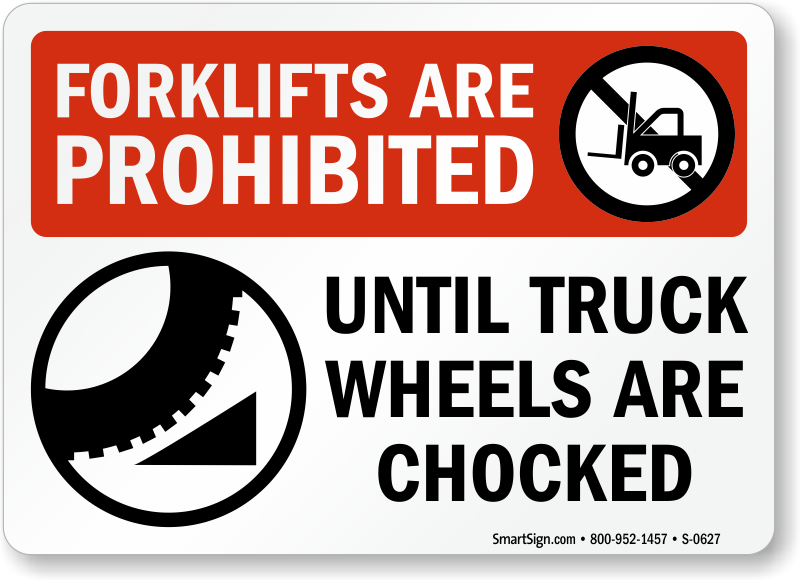

Forklifts Prohibited Until Truck Wheels Chocked Sign, SKU S0627

Wheel Chock Safety Procedures • tire types • chock material • load weight •. Chocking, also known as blocking, prevents trucks and trailers from unintentionally moving, like rolling or overturning, while workers are loading, unloading, hitching, unhitching or servicing the vehicle. Wheel chocks work best for safety and accident prevention. It is safest to chock both the front and back wheels on both sides of a vehicle. Some vehicle wheels may also need to be chocked at the front and back of each tire. Wheel chocking is essential for making loading docks safe. Esco wheel chocks meet and exceed requirements of osha and msha as specified below: • tire types • chock material • load weight •. Start the next shift by reminding workers why and how to chock trailer wheels. Blocking stabilizes cargo loads to prevent shifting and trailer overturns or provides a physical barrier on equipment to prevent accidental activation. In this episode of the risk control show, matt and steve dive deep into the importance of proper wheel chock usage and avoiding complacency. Wheel chocks is recommended to ensure you have the right chocks for your requirements.

From www.lazada.com.ph

Wheel Chock Friction Reducing Tyre Chock for Wheels Lazada PH Wheel Chock Safety Procedures • tire types • chock material • load weight •. Esco wheel chocks meet and exceed requirements of osha and msha as specified below: Chocking, also known as blocking, prevents trucks and trailers from unintentionally moving, like rolling or overturning, while workers are loading, unloading, hitching, unhitching or servicing the vehicle. Wheel chocking is essential for making loading docks safe.. Wheel Chock Safety Procedures.

From www.thecaravansupermarket.com

Safety Wheel Chocks Wheel Chock Safety Procedures Start the next shift by reminding workers why and how to chock trailer wheels. It is safest to chock both the front and back wheels on both sides of a vehicle. Wheel chocks is recommended to ensure you have the right chocks for your requirements. Some vehicle wheels may also need to be chocked at the front and back of. Wheel Chock Safety Procedures.

From www.grainger.com

MONSTER MOTION SAFETY BY CHECKERS Wheel Chock, 1 PR 5NHR0AC3512P Wheel Chock Safety Procedures Wheel chocks is recommended to ensure you have the right chocks for your requirements. Blocking stabilizes cargo loads to prevent shifting and trailer overturns or provides a physical barrier on equipment to prevent accidental activation. • tire types • chock material • load weight •. Wheel chocks work best for safety and accident prevention. Start the next shift by reminding. Wheel Chock Safety Procedures.

From www.saferack.com

Truck Chocks and Blocks SafeRack Wheel Chock Safety Procedures Esco wheel chocks meet and exceed requirements of osha and msha as specified below: It is safest to chock both the front and back wheels on both sides of a vehicle. Chocking, also known as blocking, prevents trucks and trailers from unintentionally moving, like rolling or overturning, while workers are loading, unloading, hitching, unhitching or servicing the vehicle. Wheel chocks. Wheel Chock Safety Procedures.

From www.actsafe.ca

Wheel Chocks Info Sheet Actsafe Safety Association Wheel Chock Safety Procedures Esco wheel chocks meet and exceed requirements of osha and msha as specified below: Blocking stabilizes cargo loads to prevent shifting and trailer overturns or provides a physical barrier on equipment to prevent accidental activation. Chocking, also known as blocking, prevents trucks and trailers from unintentionally moving, like rolling or overturning, while workers are loading, unloading, hitching, unhitching or servicing. Wheel Chock Safety Procedures.

From www.sportys.com

Lightweight Wheel Chocks from Sporty's Pilot Shop Wheel Chock Safety Procedures Wheel chocks is recommended to ensure you have the right chocks for your requirements. Wheel chocks work best for safety and accident prevention. It is safest to chock both the front and back wheels on both sides of a vehicle. Start the next shift by reminding workers why and how to chock trailer wheels. Wheel chocking is essential for making. Wheel Chock Safety Procedures.

From www.getawaycouple.com

Where Should You Place Your Tire Chocks? Getaway Couple Wheel Chock Safety Procedures • tire types • chock material • load weight •. Esco wheel chocks meet and exceed requirements of osha and msha as specified below: Wheel chocks is recommended to ensure you have the right chocks for your requirements. Start the next shift by reminding workers why and how to chock trailer wheels. Wheel chocks work best for safety and accident. Wheel Chock Safety Procedures.

From www.lifelinefab.com

Recovery Wheel Chocks — LIfeline Fab Wheel Chock Safety Procedures Some vehicle wheels may also need to be chocked at the front and back of each tire. Start the next shift by reminding workers why and how to chock trailer wheels. Wheel chocks is recommended to ensure you have the right chocks for your requirements. Wheel chocks work best for safety and accident prevention. Chocking, also known as blocking, prevents. Wheel Chock Safety Procedures.

From checkers.justrite.com

A Guide to Wheel Chock Installation and Safety Checkers Safety Wheel Chock Safety Procedures Start the next shift by reminding workers why and how to chock trailer wheels. It is safest to chock both the front and back wheels on both sides of a vehicle. In this episode of the risk control show, matt and steve dive deep into the importance of proper wheel chock usage and avoiding complacency. Some vehicle wheels may also. Wheel Chock Safety Procedures.

From www.myteeproducts.com

How to Use Wheel Chocks Types, Safety Tips, Usage & More Wheel Chock Safety Procedures Wheel chocking is essential for making loading docks safe. Esco wheel chocks meet and exceed requirements of osha and msha as specified below: Wheel chocks work best for safety and accident prevention. It is safest to chock both the front and back wheels on both sides of a vehicle. Some vehicle wheels may also need to be chocked at the. Wheel Chock Safety Procedures.

From checkers.justrite.com

A Guide to Wheel Chock Installation and Safety Checkers Safety Wheel Chock Safety Procedures Wheel chocks is recommended to ensure you have the right chocks for your requirements. Blocking stabilizes cargo loads to prevent shifting and trailer overturns or provides a physical barrier on equipment to prevent accidental activation. Wheel chocking is essential for making loading docks safe. • tire types • chock material • load weight •. Wheel chocks work best for safety. Wheel Chock Safety Procedures.

From www.usa-trailer.com

Wheel Chock Safety Tips for Trailer Owners Wheel Chock Safety Procedures It is safest to chock both the front and back wheels on both sides of a vehicle. Some vehicle wheels may also need to be chocked at the front and back of each tire. Wheel chocks is recommended to ensure you have the right chocks for your requirements. Start the next shift by reminding workers why and how to chock. Wheel Chock Safety Procedures.

From www.myteeproducts.com

How to Use Wheel Chocks Types, Safety Tips, Usage & More Wheel Chock Safety Procedures Wheel chocks work best for safety and accident prevention. Esco wheel chocks meet and exceed requirements of osha and msha as specified below: Start the next shift by reminding workers why and how to chock trailer wheels. In this episode of the risk control show, matt and steve dive deep into the importance of proper wheel chock usage and avoiding. Wheel Chock Safety Procedures.

From www.roadglide.org

Looking for wheel chock that can Road Glide Wheel Chock Safety Procedures Wheel chocking is essential for making loading docks safe. Wheel chocks is recommended to ensure you have the right chocks for your requirements. Blocking stabilizes cargo loads to prevent shifting and trailer overturns or provides a physical barrier on equipment to prevent accidental activation. Wheel chocks work best for safety and accident prevention. Esco wheel chocks meet and exceed requirements. Wheel Chock Safety Procedures.

From www.ritehite.com

GWC1000 Global Wheel Chock Vehicle Restraints RiteHite Wheel Chock Safety Procedures In this episode of the risk control show, matt and steve dive deep into the importance of proper wheel chock usage and avoiding complacency. It is safest to chock both the front and back wheels on both sides of a vehicle. Blocking stabilizes cargo loads to prevent shifting and trailer overturns or provides a physical barrier on equipment to prevent. Wheel Chock Safety Procedures.

From workercare.en.made-in-china.com

Heavy Duty Large Wheel Chocks for SafetyCar Chocks, Tire Chocks Wheel Chock Safety Procedures In this episode of the risk control show, matt and steve dive deep into the importance of proper wheel chock usage and avoiding complacency. Wheel chocking is essential for making loading docks safe. Some vehicle wheels may also need to be chocked at the front and back of each tire. • tire types • chock material • load weight •.. Wheel Chock Safety Procedures.

From firstqualityforklifttraining.com

Chock Wheels Safety Sign First Quality Forklift Training LLC Wheel Chock Safety Procedures It is safest to chock both the front and back wheels on both sides of a vehicle. Esco wheel chocks meet and exceed requirements of osha and msha as specified below: Wheel chocks is recommended to ensure you have the right chocks for your requirements. Wheel chocking is essential for making loading docks safe. In this episode of the risk. Wheel Chock Safety Procedures.

From www.actsafe.ca

Wheel Chocks Actsafe Safety Association Wheel Chock Safety Procedures Start the next shift by reminding workers why and how to chock trailer wheels. Chocking, also known as blocking, prevents trucks and trailers from unintentionally moving, like rolling or overturning, while workers are loading, unloading, hitching, unhitching or servicing the vehicle. Wheel chocking is essential for making loading docks safe. • tire types • chock material • load weight •.. Wheel Chock Safety Procedures.

From ar.inspiredpencil.com

No Loading And Unloading Sign Wheel Chock Safety Procedures Blocking stabilizes cargo loads to prevent shifting and trailer overturns or provides a physical barrier on equipment to prevent accidental activation. Esco wheel chocks meet and exceed requirements of osha and msha as specified below: Chocking, also known as blocking, prevents trucks and trailers from unintentionally moving, like rolling or overturning, while workers are loading, unloading, hitching, unhitching or servicing. Wheel Chock Safety Procedures.

From pacfirenz.com

Wheel Chocks Pac Fire New Zealand Wheel Chock Safety Procedures Blocking stabilizes cargo loads to prevent shifting and trailer overturns or provides a physical barrier on equipment to prevent accidental activation. • tire types • chock material • load weight •. Chocking, also known as blocking, prevents trucks and trailers from unintentionally moving, like rolling or overturning, while workers are loading, unloading, hitching, unhitching or servicing the vehicle. In this. Wheel Chock Safety Procedures.

From www.indiamart.com

Safety Wheel Chock at Rs 350/piece Kalighat Kolkata ID 2852424057030 Wheel Chock Safety Procedures Start the next shift by reminding workers why and how to chock trailer wheels. Wheel chocks work best for safety and accident prevention. Chocking, also known as blocking, prevents trucks and trailers from unintentionally moving, like rolling or overturning, while workers are loading, unloading, hitching, unhitching or servicing the vehicle. Esco wheel chocks meet and exceed requirements of osha and. Wheel Chock Safety Procedures.

From www.wheelchocks.co.nz

LARGE FLAGGED Safety Wheel Chocks Wheel Chocks Wheel Chock Safety Procedures Wheel chocking is essential for making loading docks safe. • tire types • chock material • load weight •. Wheel chocks work best for safety and accident prevention. Chocking, also known as blocking, prevents trucks and trailers from unintentionally moving, like rolling or overturning, while workers are loading, unloading, hitching, unhitching or servicing the vehicle. Wheel chocks is recommended to. Wheel Chock Safety Procedures.

From www.indiamart.com

Black Rubber Wheel Chock for Car Parking at Rs 650/piece in New Delhi Wheel Chock Safety Procedures Chocking, also known as blocking, prevents trucks and trailers from unintentionally moving, like rolling or overturning, while workers are loading, unloading, hitching, unhitching or servicing the vehicle. Wheel chocking is essential for making loading docks safe. It is safest to chock both the front and back wheels on both sides of a vehicle. Wheel chocks is recommended to ensure you. Wheel Chock Safety Procedures.

From handymantips.org

How Wheel Chocks Work Wheel Chock Safety Procedures Blocking stabilizes cargo loads to prevent shifting and trailer overturns or provides a physical barrier on equipment to prevent accidental activation. Start the next shift by reminding workers why and how to chock trailer wheels. It is safest to chock both the front and back wheels on both sides of a vehicle. In this episode of the risk control show,. Wheel Chock Safety Procedures.

From www.mysafetysign.com

Forklifts Prohibited Until Truck Wheels Chocked Sign, SKU S0627 Wheel Chock Safety Procedures Blocking stabilizes cargo loads to prevent shifting and trailer overturns or provides a physical barrier on equipment to prevent accidental activation. Wheel chocking is essential for making loading docks safe. Esco wheel chocks meet and exceed requirements of osha and msha as specified below: Start the next shift by reminding workers why and how to chock trailer wheels. Chocking, also. Wheel Chock Safety Procedures.

From www.barsec.com.au

Plastic Wheel Chock Wheel Chock Safety Procedures Esco wheel chocks meet and exceed requirements of osha and msha as specified below: Wheel chocks is recommended to ensure you have the right chocks for your requirements. Chocking, also known as blocking, prevents trucks and trailers from unintentionally moving, like rolling or overturning, while workers are loading, unloading, hitching, unhitching or servicing the vehicle. It is safest to chock. Wheel Chock Safety Procedures.

From firstqualityforklifttraining.com

Wheel Chock Safety System First Quality Forklift Training LLC Wheel Chock Safety Procedures Start the next shift by reminding workers why and how to chock trailer wheels. Some vehicle wheels may also need to be chocked at the front and back of each tire. • tire types • chock material • load weight •. It is safest to chock both the front and back wheels on both sides of a vehicle. Esco wheel. Wheel Chock Safety Procedures.

From www.grainger.com

7 1/2 in Wd, 6 1/4 in Ht, Wheel Chock 8Y016UC1700 Grainger Wheel Chock Safety Procedures Blocking stabilizes cargo loads to prevent shifting and trailer overturns or provides a physical barrier on equipment to prevent accidental activation. • tire types • chock material • load weight •. Wheel chocking is essential for making loading docks safe. Start the next shift by reminding workers why and how to chock trailer wheels. In this episode of the risk. Wheel Chock Safety Procedures.

From www.mysafetysign.com

Wheels Chocked Before Loading Unloading Sign, SKU S0641 Wheel Chock Safety Procedures Esco wheel chocks meet and exceed requirements of osha and msha as specified below: Blocking stabilizes cargo loads to prevent shifting and trailer overturns or provides a physical barrier on equipment to prevent accidental activation. In this episode of the risk control show, matt and steve dive deep into the importance of proper wheel chock usage and avoiding complacency. Wheel. Wheel Chock Safety Procedures.

From saratov.myhistorypark.ru

How To Use Wheel Chocks Types, Safety Tips, Usage More, 49 OFF Wheel Chock Safety Procedures Esco wheel chocks meet and exceed requirements of osha and msha as specified below: It is safest to chock both the front and back wheels on both sides of a vehicle. Start the next shift by reminding workers why and how to chock trailer wheels. • tire types • chock material • load weight •. Blocking stabilizes cargo loads to. Wheel Chock Safety Procedures.

From checkers.justrite.com

A Guide to Wheel Chock Installation and Safety Checkers Safety Wheel Chock Safety Procedures Chocking, also known as blocking, prevents trucks and trailers from unintentionally moving, like rolling or overturning, while workers are loading, unloading, hitching, unhitching or servicing the vehicle. In this episode of the risk control show, matt and steve dive deep into the importance of proper wheel chock usage and avoiding complacency. • tire types • chock material • load weight. Wheel Chock Safety Procedures.

From www.desertcart.ae

Fasmov Solid Rubber Heavy Duty Wheel Chock 2 Pack Buy Online in Wheel Chock Safety Procedures Start the next shift by reminding workers why and how to chock trailer wheels. Blocking stabilizes cargo loads to prevent shifting and trailer overturns or provides a physical barrier on equipment to prevent accidental activation. Wheel chocks is recommended to ensure you have the right chocks for your requirements. Wheel chocks work best for safety and accident prevention. Chocking, also. Wheel Chock Safety Procedures.

From www.amazon.ca

Camco 44472 Wheel Chock With Rope For Easy Removal, Helps Keep Your Wheel Chock Safety Procedures Wheel chocking is essential for making loading docks safe. Blocking stabilizes cargo loads to prevent shifting and trailer overturns or provides a physical barrier on equipment to prevent accidental activation. Wheel chocks is recommended to ensure you have the right chocks for your requirements. Chocking, also known as blocking, prevents trucks and trailers from unintentionally moving, like rolling or overturning,. Wheel Chock Safety Procedures.

From www.amsj.com.au

Antiejection wheel chock commended at Central Qld coal operation Wheel Chock Safety Procedures Chocking, also known as blocking, prevents trucks and trailers from unintentionally moving, like rolling or overturning, while workers are loading, unloading, hitching, unhitching or servicing the vehicle. Wheel chocking is essential for making loading docks safe. Some vehicle wheels may also need to be chocked at the front and back of each tire. Start the next shift by reminding workers. Wheel Chock Safety Procedures.

From ilt.safetynow.com

Chocking Wheels Meeting Kit SafetyNow ILT Wheel Chock Safety Procedures It is safest to chock both the front and back wheels on both sides of a vehicle. • tire types • chock material • load weight •. Chocking, also known as blocking, prevents trucks and trailers from unintentionally moving, like rolling or overturning, while workers are loading, unloading, hitching, unhitching or servicing the vehicle. Blocking stabilizes cargo loads to prevent. Wheel Chock Safety Procedures.