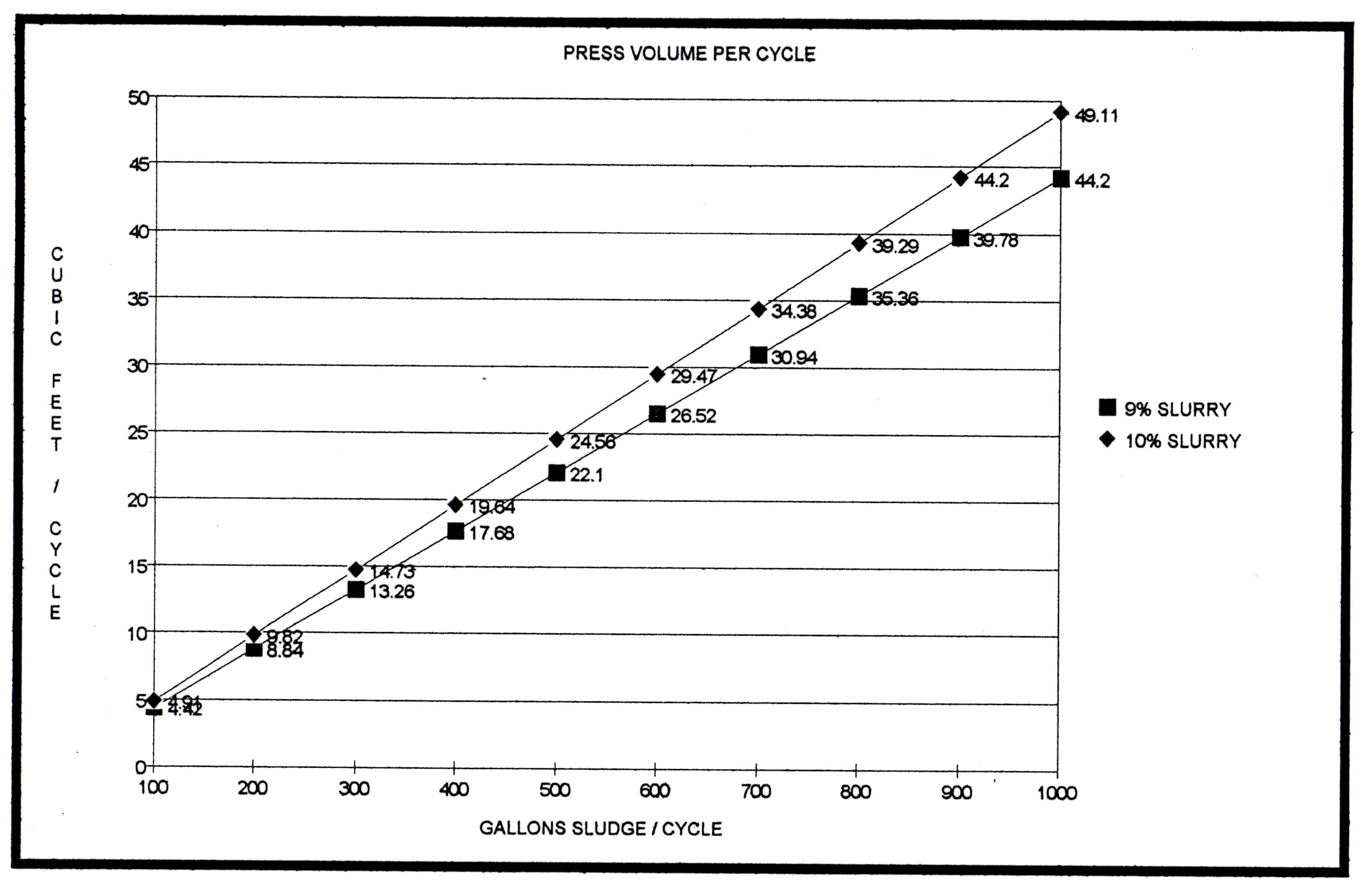

Filter Press Flow Rate . The attached graphs and data sheets are for your use in estimating filter press sizing and chemical dosing requirements. Note plate data is found in table 12 (for the 470 and 500 mm plates) on page 49, table 14 on page 55 (for the 300 mm plates), and table 15 on page 56 (for the bench press). Filter presses are machines allowing to filtrate suspension under pressure in order to separate the liquid and the solid phases. This limited flow rate is held constant until a minimum. The filter dewaters and washes a 4 mm cake in 4 minutes which results in a per hour rate of 0.9 m3 (60/4 x 15m2x 4/1000m) of cake per hour. The cakes result from the dewatering process. To help reduce cloth wear around the filter plate feed hole areas, the fill flow rate is limited by controlling the pump speed. All calculations used in preparing.

from automaticfilterpress.com

The cakes result from the dewatering process. Filter presses are machines allowing to filtrate suspension under pressure in order to separate the liquid and the solid phases. The filter dewaters and washes a 4 mm cake in 4 minutes which results in a per hour rate of 0.9 m3 (60/4 x 15m2x 4/1000m) of cake per hour. The attached graphs and data sheets are for your use in estimating filter press sizing and chemical dosing requirements. All calculations used in preparing. To help reduce cloth wear around the filter plate feed hole areas, the fill flow rate is limited by controlling the pump speed. This limited flow rate is held constant until a minimum. Note plate data is found in table 12 (for the 470 and 500 mm plates) on page 49, table 14 on page 55 (for the 300 mm plates), and table 15 on page 56 (for the bench press).

Filter Press Sizing Calculations Universal Filtration & Pumping Solutions, Inc.

Filter Press Flow Rate This limited flow rate is held constant until a minimum. All calculations used in preparing. The cakes result from the dewatering process. This limited flow rate is held constant until a minimum. Note plate data is found in table 12 (for the 470 and 500 mm plates) on page 49, table 14 on page 55 (for the 300 mm plates), and table 15 on page 56 (for the bench press). To help reduce cloth wear around the filter plate feed hole areas, the fill flow rate is limited by controlling the pump speed. The filter dewaters and washes a 4 mm cake in 4 minutes which results in a per hour rate of 0.9 m3 (60/4 x 15m2x 4/1000m) of cake per hour. The attached graphs and data sheets are for your use in estimating filter press sizing and chemical dosing requirements. Filter presses are machines allowing to filtrate suspension under pressure in order to separate the liquid and the solid phases.

From www.researchgate.net

Schematic crosssectional view of the filter press test apparatus. Download Scientific Diagram Filter Press Flow Rate All calculations used in preparing. The cakes result from the dewatering process. This limited flow rate is held constant until a minimum. To help reduce cloth wear around the filter plate feed hole areas, the fill flow rate is limited by controlling the pump speed. Note plate data is found in table 12 (for the 470 and 500 mm plates). Filter Press Flow Rate.

From www.cem-int.com.au

Filter Press Chemical Plant & Engineering (CPE) Filter Press Flow Rate To help reduce cloth wear around the filter plate feed hole areas, the fill flow rate is limited by controlling the pump speed. Note plate data is found in table 12 (for the 470 and 500 mm plates) on page 49, table 14 on page 55 (for the 300 mm plates), and table 15 on page 56 (for the bench. Filter Press Flow Rate.

From www.indiamart.com

Filter Press Pump, For Industrial, Max Flow Rate Upto 105 M3/Hr at Rs 11000 in Ahmedabad Filter Press Flow Rate All calculations used in preparing. Filter presses are machines allowing to filtrate suspension under pressure in order to separate the liquid and the solid phases. Note plate data is found in table 12 (for the 470 and 500 mm plates) on page 49, table 14 on page 55 (for the 300 mm plates), and table 15 on page 56 (for. Filter Press Flow Rate.

From www.andritz.com

ANDRITZ presents heavyduty filter press for mining concentrates and tailings Filter Press Flow Rate The cakes result from the dewatering process. Filter presses are machines allowing to filtrate suspension under pressure in order to separate the liquid and the solid phases. All calculations used in preparing. The filter dewaters and washes a 4 mm cake in 4 minutes which results in a per hour rate of 0.9 m3 (60/4 x 15m2x 4/1000m) of cake. Filter Press Flow Rate.

From napier-reid.com

» Belt Filter Press Filter Press Flow Rate Note plate data is found in table 12 (for the 470 and 500 mm plates) on page 49, table 14 on page 55 (for the 300 mm plates), and table 15 on page 56 (for the bench press). All calculations used in preparing. This limited flow rate is held constant until a minimum. Filter presses are machines allowing to filtrate. Filter Press Flow Rate.

From automaticfilterpress.com

Filter Press System Design Filter Press Operations Manual Filter Press Flow Rate This limited flow rate is held constant until a minimum. Filter presses are machines allowing to filtrate suspension under pressure in order to separate the liquid and the solid phases. The attached graphs and data sheets are for your use in estimating filter press sizing and chemical dosing requirements. The filter dewaters and washes a 4 mm cake in 4. Filter Press Flow Rate.

From automaticfilterpress.com

Filter Press Sizing Calculations Universal Filtration & Pumping Solutions, Inc. Filter Press Flow Rate The attached graphs and data sheets are for your use in estimating filter press sizing and chemical dosing requirements. Note plate data is found in table 12 (for the 470 and 500 mm plates) on page 49, table 14 on page 55 (for the 300 mm plates), and table 15 on page 56 (for the bench press). Filter presses are. Filter Press Flow Rate.

From www.iqsdirectory.com

Liquid Filter What Is It? How Does It Work? Types Of Filter Press Flow Rate To help reduce cloth wear around the filter plate feed hole areas, the fill flow rate is limited by controlling the pump speed. All calculations used in preparing. Note plate data is found in table 12 (for the 470 and 500 mm plates) on page 49, table 14 on page 55 (for the 300 mm plates), and table 15 on. Filter Press Flow Rate.

From abelpumps.com

Filter Press Feed Pumps ABEL Pump Technology Filter Press Flow Rate Filter presses are machines allowing to filtrate suspension under pressure in order to separate the liquid and the solid phases. The cakes result from the dewatering process. All calculations used in preparing. The attached graphs and data sheets are for your use in estimating filter press sizing and chemical dosing requirements. Note plate data is found in table 12 (for. Filter Press Flow Rate.

From www.indiamart.com

Filter Press Pump, Max Flow Rate 500 Lpm at Rs 32500 in Humnabad ID 23001950312 Filter Press Flow Rate To help reduce cloth wear around the filter plate feed hole areas, the fill flow rate is limited by controlling the pump speed. The attached graphs and data sheets are for your use in estimating filter press sizing and chemical dosing requirements. This limited flow rate is held constant until a minimum. Note plate data is found in table 12. Filter Press Flow Rate.

From fluidhandlingpro.com

Next Generation of Filter Presses Flowrox Smart Filter Press • Fluid Handling Pro Filter Press Flow Rate Note plate data is found in table 12 (for the 470 and 500 mm plates) on page 49, table 14 on page 55 (for the 300 mm plates), and table 15 on page 56 (for the bench press). All calculations used in preparing. The attached graphs and data sheets are for your use in estimating filter press sizing and chemical. Filter Press Flow Rate.

From www.bhagwatipharma.co.in

Sparkler Filter Press , Zero Hold Up Filter Press , Horizontal Filter Press Filter Press Flow Rate This limited flow rate is held constant until a minimum. The filter dewaters and washes a 4 mm cake in 4 minutes which results in a per hour rate of 0.9 m3 (60/4 x 15m2x 4/1000m) of cake per hour. Note plate data is found in table 12 (for the 470 and 500 mm plates) on page 49, table 14. Filter Press Flow Rate.

From www.sinofilterpresses.com

Sludge Dewatering Filter Press Knowledge Yuzhou Sino Filtration Equipment Co.,Ltd Filter Press Flow Rate The cakes result from the dewatering process. This limited flow rate is held constant until a minimum. The filter dewaters and washes a 4 mm cake in 4 minutes which results in a per hour rate of 0.9 m3 (60/4 x 15m2x 4/1000m) of cake per hour. Filter presses are machines allowing to filtrate suspension under pressure in order to. Filter Press Flow Rate.

From ffpsystems.ca

Filter Presses Mississauga Slurry Dewatering System Filter Press Flow Rate The cakes result from the dewatering process. To help reduce cloth wear around the filter plate feed hole areas, the fill flow rate is limited by controlling the pump speed. Note plate data is found in table 12 (for the 470 and 500 mm plates) on page 49, table 14 on page 55 (for the 300 mm plates), and table. Filter Press Flow Rate.

From www.filterpress.org

Automatic Membrane Filter Press Operation Procedure Filter Press Flow Rate Note plate data is found in table 12 (for the 470 and 500 mm plates) on page 49, table 14 on page 55 (for the 300 mm plates), and table 15 on page 56 (for the bench press). This limited flow rate is held constant until a minimum. The cakes result from the dewatering process. All calculations used in preparing.. Filter Press Flow Rate.

From netsolwater.com

What are the advantages of Filter press over vacuum systems Filter Press Flow Rate This limited flow rate is held constant until a minimum. All calculations used in preparing. To help reduce cloth wear around the filter plate feed hole areas, the fill flow rate is limited by controlling the pump speed. The attached graphs and data sheets are for your use in estimating filter press sizing and chemical dosing requirements. The cakes result. Filter Press Flow Rate.

From mse-filterpressen.com

Chamber filter press MSE Filterpressen® (OEM) Filter Press Flow Rate The filter dewaters and washes a 4 mm cake in 4 minutes which results in a per hour rate of 0.9 m3 (60/4 x 15m2x 4/1000m) of cake per hour. All calculations used in preparing. Filter presses are machines allowing to filtrate suspension under pressure in order to separate the liquid and the solid phases. To help reduce cloth wear. Filter Press Flow Rate.

From pharmacyscope.com

Plate and Frame filter press Principle, Construction And Working Filter Press Flow Rate The filter dewaters and washes a 4 mm cake in 4 minutes which results in a per hour rate of 0.9 m3 (60/4 x 15m2x 4/1000m) of cake per hour. Filter presses are machines allowing to filtrate suspension under pressure in order to separate the liquid and the solid phases. The cakes result from the dewatering process. All calculations used. Filter Press Flow Rate.

From marketing.unleashlive.com

Quantifying Filter Press Operational Health Solution Brief Filter Press Flow Rate Filter presses are machines allowing to filtrate suspension under pressure in order to separate the liquid and the solid phases. The attached graphs and data sheets are for your use in estimating filter press sizing and chemical dosing requirements. This limited flow rate is held constant until a minimum. The filter dewaters and washes a 4 mm cake in 4. Filter Press Flow Rate.

From www.filterpress.org

Automatic Membrane Filter Press for Squeeze Filtration Filter Press Flow Rate All calculations used in preparing. To help reduce cloth wear around the filter plate feed hole areas, the fill flow rate is limited by controlling the pump speed. The attached graphs and data sheets are for your use in estimating filter press sizing and chemical dosing requirements. This limited flow rate is held constant until a minimum. The filter dewaters. Filter Press Flow Rate.

From mse-filterpressen.com

Filter press operation MSE Filterpressen® (filter press manufacturer) Filter Press Flow Rate All calculations used in preparing. The attached graphs and data sheets are for your use in estimating filter press sizing and chemical dosing requirements. To help reduce cloth wear around the filter plate feed hole areas, the fill flow rate is limited by controlling the pump speed. The filter dewaters and washes a 4 mm cake in 4 minutes which. Filter Press Flow Rate.

From automaticfilterpress.com

Filter Press Sizing Calculations Universal Filtration & Pumping Solutions, Inc. Filter Press Flow Rate The cakes result from the dewatering process. Note plate data is found in table 12 (for the 470 and 500 mm plates) on page 49, table 14 on page 55 (for the 300 mm plates), and table 15 on page 56 (for the bench press). Filter presses are machines allowing to filtrate suspension under pressure in order to separate the. Filter Press Flow Rate.

From drillingfluid.org

FILTRATION, WALL BUILDING, AND RESISTIVITY OF DRLLING FLUID Drilling Fluid Management & Disposal Filter Press Flow Rate The attached graphs and data sheets are for your use in estimating filter press sizing and chemical dosing requirements. Filter presses are machines allowing to filtrate suspension under pressure in order to separate the liquid and the solid phases. This limited flow rate is held constant until a minimum. The cakes result from the dewatering process. All calculations used in. Filter Press Flow Rate.

From www.youtube.com

Filter Press Working Filter Press Operation How Filter Press Works? 3D Animation YouTube Filter Press Flow Rate The attached graphs and data sheets are for your use in estimating filter press sizing and chemical dosing requirements. The cakes result from the dewatering process. The filter dewaters and washes a 4 mm cake in 4 minutes which results in a per hour rate of 0.9 m3 (60/4 x 15m2x 4/1000m) of cake per hour. To help reduce cloth. Filter Press Flow Rate.

From www.normanfilters.com

Pressure Drops & Flow Calculations Norman Filter Company Filter Press Flow Rate The attached graphs and data sheets are for your use in estimating filter press sizing and chemical dosing requirements. This limited flow rate is held constant until a minimum. The filter dewaters and washes a 4 mm cake in 4 minutes which results in a per hour rate of 0.9 m3 (60/4 x 15m2x 4/1000m) of cake per hour. Filter. Filter Press Flow Rate.

From www.micronicsinc.com

What is a Filter Press and How Does it Work? Micronics, Inc. Filter Press Flow Rate Filter presses are machines allowing to filtrate suspension under pressure in order to separate the liquid and the solid phases. Note plate data is found in table 12 (for the 470 and 500 mm plates) on page 49, table 14 on page 55 (for the 300 mm plates), and table 15 on page 56 (for the bench press). All calculations. Filter Press Flow Rate.

From www.researchgate.net

2 a) Filterpress type flow cell used in the measurement of pressure... Download Scientific Filter Press Flow Rate Note plate data is found in table 12 (for the 470 and 500 mm plates) on page 49, table 14 on page 55 (for the 300 mm plates), and table 15 on page 56 (for the bench press). All calculations used in preparing. The attached graphs and data sheets are for your use in estimating filter press sizing and chemical. Filter Press Flow Rate.

From metchem.com

Filter Press Operation Overview Filter Press Introduction Videos Filter Press Flow Rate Note plate data is found in table 12 (for the 470 and 500 mm plates) on page 49, table 14 on page 55 (for the 300 mm plates), and table 15 on page 56 (for the bench press). Filter presses are machines allowing to filtrate suspension under pressure in order to separate the liquid and the solid phases. The attached. Filter Press Flow Rate.

From automaticfilterpress.com

Filter Press Sizing Calculations Universal Filtration & Pumping Solutions, Inc. Filter Press Flow Rate The cakes result from the dewatering process. Filter presses are machines allowing to filtrate suspension under pressure in order to separate the liquid and the solid phases. This limited flow rate is held constant until a minimum. The attached graphs and data sheets are for your use in estimating filter press sizing and chemical dosing requirements. All calculations used in. Filter Press Flow Rate.

From www.metawater.co.jp

Filter press(OH) Solution METAWATER Filter Press Flow Rate Filter presses are machines allowing to filtrate suspension under pressure in order to separate the liquid and the solid phases. Note plate data is found in table 12 (for the 470 and 500 mm plates) on page 49, table 14 on page 55 (for the 300 mm plates), and table 15 on page 56 (for the bench press). All calculations. Filter Press Flow Rate.

From www.youtube.com

M.W. Watermark Filter Press 101 How a Filter Press Works YouTube Filter Press Flow Rate Filter presses are machines allowing to filtrate suspension under pressure in order to separate the liquid and the solid phases. This limited flow rate is held constant until a minimum. To help reduce cloth wear around the filter plate feed hole areas, the fill flow rate is limited by controlling the pump speed. The attached graphs and data sheets are. Filter Press Flow Rate.

From www.mediasarangtawon.com

Fungsi Filter Press Sludge Dewatering Treatment Plant Filter Press Flow Rate This limited flow rate is held constant until a minimum. The attached graphs and data sheets are for your use in estimating filter press sizing and chemical dosing requirements. To help reduce cloth wear around the filter plate feed hole areas, the fill flow rate is limited by controlling the pump speed. The filter dewaters and washes a 4 mm. Filter Press Flow Rate.

From mse-filterpressen.com

Optimisation of the filtration with filter presses MSE Filterpressen® Filter Press Flow Rate To help reduce cloth wear around the filter plate feed hole areas, the fill flow rate is limited by controlling the pump speed. The filter dewaters and washes a 4 mm cake in 4 minutes which results in a per hour rate of 0.9 m3 (60/4 x 15m2x 4/1000m) of cake per hour. The cakes result from the dewatering process.. Filter Press Flow Rate.

From c-cemg.org

Working principle of plate and frame filter press ccemg mechanical blog Filter Press Flow Rate All calculations used in preparing. The cakes result from the dewatering process. The attached graphs and data sheets are for your use in estimating filter press sizing and chemical dosing requirements. Filter presses are machines allowing to filtrate suspension under pressure in order to separate the liquid and the solid phases. To help reduce cloth wear around the filter plate. Filter Press Flow Rate.

From mineraldressing.com

Filter Press JXSC Machinery Filter Press Flow Rate All calculations used in preparing. The cakes result from the dewatering process. To help reduce cloth wear around the filter plate feed hole areas, the fill flow rate is limited by controlling the pump speed. Note plate data is found in table 12 (for the 470 and 500 mm plates) on page 49, table 14 on page 55 (for the. Filter Press Flow Rate.