Equipment Layout Standards . process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. including industry practices and standards. 57 rows equipment layout is one of the most important deliverable of a piping department. equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity. Spacing tables are provided which can be used as a starting point in laying out a. equipment layout refers to the arrangement and positioning of various equipment and machinery within a given space or facility. Spacing pertains to minimum distances. equipment layout is developed as the course of the detailed engineering phase by the designer considering the. It is an essential aspect of the overall plant or facility design and plays a crucial role in ensuring efficient operations, safety, and accessibility. It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. Equipment should be arranged in logistic process sequence for optimum piping runs and operational and maintenance ease. layout relates to the relative position of equipment or units within a given site.

from stlengineering.net

including industry practices and standards. equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity. 57 rows equipment layout is one of the most important deliverable of a piping department. Equipment should be arranged in logistic process sequence for optimum piping runs and operational and maintenance ease. layout relates to the relative position of equipment or units within a given site. equipment layout is developed as the course of the detailed engineering phase by the designer considering the. It is an essential aspect of the overall plant or facility design and plays a crucial role in ensuring efficient operations, safety, and accessibility. Spacing pertains to minimum distances. Spacing tables are provided which can be used as a starting point in laying out a. equipment layout refers to the arrangement and positioning of various equipment and machinery within a given space or facility.

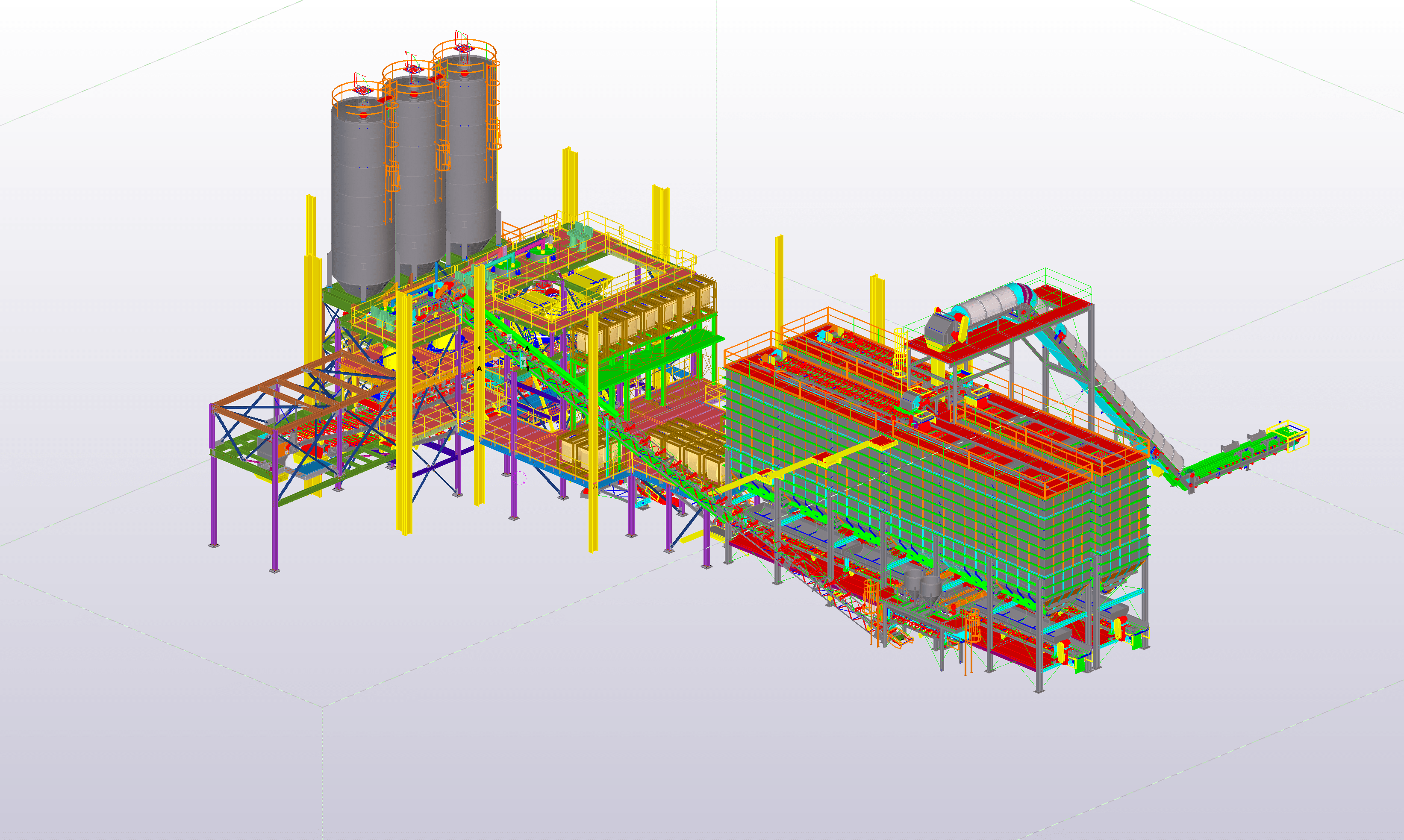

Equipment Layout, Selection, and Specification STL Engineering, LLC

Equipment Layout Standards including industry practices and standards. 57 rows equipment layout is one of the most important deliverable of a piping department. including industry practices and standards. equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity. equipment layout refers to the arrangement and positioning of various equipment and machinery within a given space or facility. process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. equipment layout is developed as the course of the detailed engineering phase by the designer considering the. It is an essential aspect of the overall plant or facility design and plays a crucial role in ensuring efficient operations, safety, and accessibility. Equipment should be arranged in logistic process sequence for optimum piping runs and operational and maintenance ease. Spacing tables are provided which can be used as a starting point in laying out a. layout relates to the relative position of equipment or units within a given site. Spacing pertains to minimum distances. It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas.

From bavengineering.com

Equipment layouts BAV Engineering Equipment Layout Standards including industry practices and standards. It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. equipment layout refers to the arrangement and positioning of various equipment and machinery within a given space or facility. Spacing tables are provided which can be used as a. Equipment Layout Standards.

From www.scribd.com

Electrical Equipment Layout PDF Electrical Engineering Electricity Equipment Layout Standards equipment layout is developed as the course of the detailed engineering phase by the designer considering the. equipment layout refers to the arrangement and positioning of various equipment and machinery within a given space or facility. process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. Spacing. Equipment Layout Standards.

From www.wsl.hk

5S Guide wslwarehousesystem Equipment Layout Standards It is an essential aspect of the overall plant or facility design and plays a crucial role in ensuring efficient operations, safety, and accessibility. equipment layout is developed as the course of the detailed engineering phase by the designer considering the. 57 rows equipment layout is one of the most important deliverable of a piping department. Equipment should. Equipment Layout Standards.

From www.fitnessgallery.com

How to Design and Layout a Functional Commercial Gym Fitness Gallery Equipment Layout Standards Spacing pertains to minimum distances. equipment layout is developed as the course of the detailed engineering phase by the designer considering the. layout relates to the relative position of equipment or units within a given site. process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. . Equipment Layout Standards.

From fitsmallbusiness.com

Planning Your Warehouse Layout How to Set Up Efficient Storage Equipment Layout Standards 57 rows equipment layout is one of the most important deliverable of a piping department. process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. Spacing tables are provided which can be used as a starting point in laying out a. including industry practices and standards. . Equipment Layout Standards.

From www.amsc-usa.com

Warehouse Layout Guide Design & Tips for Efficient Warehousing Equipment Layout Standards process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity. equipment layout refers to the arrangement and positioning of various equipment and machinery within a given. Equipment Layout Standards.

From prokitchenequipments.com

Professional Kitchen Equipments Layout Equipment Equipment Layout Standards equipment layout refers to the arrangement and positioning of various equipment and machinery within a given space or facility. equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity. including industry practices and standards. 57 rows equipment layout is one of the most important deliverable. Equipment Layout Standards.

From stlengineering.net

Equipment Layout, Selection, and Specification STL Engineering, LLC Equipment Layout Standards equipment layout refers to the arrangement and positioning of various equipment and machinery within a given space or facility. 57 rows equipment layout is one of the most important deliverable of a piping department. It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas.. Equipment Layout Standards.

From bavengineering.com

Equipment layouts BAV Engineering Equipment Layout Standards process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. Equipment should be arranged in logistic process sequence for optimum piping runs and operational and maintenance ease. It shows location and placement of all equipments in a particular process or utility area along with various types of access and. Equipment Layout Standards.

From www.equipmentmanufacturingandintegration.com

Equipment Layout Line Drawings Equipment Manufacturing & Integration Inc Equipment Layout Standards It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. including industry practices and standards. equipment layout and piping layout is done as. Equipment Layout Standards.

From www.cati.com

Steel & Equipment Layout Designer (STELM) Computer Aided Technology Equipment Layout Standards equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity. It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. Spacing pertains to minimum distances. Equipment should be arranged in logistic process sequence for. Equipment Layout Standards.

From www.pinterest.com

Updated Machine layout with more (yes, more!) tools and power Equipment Layout Standards Spacing pertains to minimum distances. equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity. equipment layout is developed as the course of the detailed engineering phase by the designer considering the. It is an essential aspect of the overall plant or facility design and plays a. Equipment Layout Standards.

From stlengineering.net

Equipment Layout, Selection, and Specification STL Engineering, LLC Equipment Layout Standards including industry practices and standards. equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity. It is an essential aspect of the overall plant or facility design and plays a crucial role in ensuring efficient operations, safety, and accessibility. equipment layout refers to the arrangement and. Equipment Layout Standards.

From www.highlandereng.com

Need Facility Layout and Piping Design? Highlander Engineering Equipment Layout Standards It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity. process flow sequence and operating procedures should be thoroughly understood so that equipment. Equipment Layout Standards.

From cadbull.com

Equipment layout plan and its view in AutoCAD, Dwg file. Cadbull Equipment Layout Standards Equipment should be arranged in logistic process sequence for optimum piping runs and operational and maintenance ease. Spacing tables are provided which can be used as a starting point in laying out a. process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. It shows location and placement of. Equipment Layout Standards.

From www.equipmentmanufacturingandintegration.com

Equipment Layout Line Drawings Equipment Manufacturing & Integration Inc Equipment Layout Standards including industry practices and standards. equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity. layout relates to the relative position of equipment or units within a given site. process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the. Equipment Layout Standards.

From www.scribd.com

Equipment Layout PDF Equipment Layout Standards equipment layout refers to the arrangement and positioning of various equipment and machinery within a given space or facility. layout relates to the relative position of equipment or units within a given site. process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. Equipment should be arranged. Equipment Layout Standards.

From www.researchgate.net

Machining layout and measurement locations, dimensions in m Equipment Layout Standards It is an essential aspect of the overall plant or facility design and plays a crucial role in ensuring efficient operations, safety, and accessibility. 57 rows equipment layout is one of the most important deliverable of a piping department. equipment layout and piping layout is done as per general industry practice as well as piping design basis, process. Equipment Layout Standards.

From stlengineering.net

Equipment Layout, Selection, and Specification STL Engineering, LLC Equipment Layout Standards Equipment should be arranged in logistic process sequence for optimum piping runs and operational and maintenance ease. layout relates to the relative position of equipment or units within a given site. Spacing tables are provided which can be used as a starting point in laying out a. including industry practices and standards. 57 rows equipment layout is. Equipment Layout Standards.

From thepiping.com

What Is Equipment Layout Equipment Layout Standards Spacing tables are provided which can be used as a starting point in laying out a. equipment layout refers to the arrangement and positioning of various equipment and machinery within a given space or facility. process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. equipment layout. Equipment Layout Standards.

From www.scribd.com

UOPTypical Equipment Layout Rev 01 PDF Specification (Technical Equipment Layout Standards equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity. process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. equipment layout is developed as the course of the detailed engineering phase by the designer considering. Equipment Layout Standards.

From www.conceptdraw.com

Interior Design Machines and Equipment Design Elements Store Layout Equipment Layout Standards equipment layout refers to the arrangement and positioning of various equipment and machinery within a given space or facility. It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. Equipment should be arranged in logistic process sequence for optimum piping runs and operational and maintenance. Equipment Layout Standards.

From ntg.missouristate.edu

NavOneColumn Template Master Equipment Layout Standards It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. equipment layout refers to the arrangement and positioning of various equipment and machinery within a given space or facility. Equipment should be arranged in logistic process sequence for optimum piping runs and operational and maintenance. Equipment Layout Standards.

From maintenanceworld.com

Practical Guide to Equipment Hierarchy Maintenance World Equipment Layout Standards equipment layout refers to the arrangement and positioning of various equipment and machinery within a given space or facility. including industry practices and standards. It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. process flow sequence and operating procedures should be thoroughly. Equipment Layout Standards.

From dokumen.tips

(XLS) Equipment Layout Checklist DOKUMEN.TIPS Equipment Layout Standards including industry practices and standards. Spacing tables are provided which can be used as a starting point in laying out a. equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity. Equipment should be arranged in logistic process sequence for optimum piping runs and operational and maintenance. Equipment Layout Standards.

From cadbull.com

Floor plan and equipment layout of factory in AutoCAD, dwg file. Cadbull Equipment Layout Standards including industry practices and standards. equipment layout is developed as the course of the detailed engineering phase by the designer considering the. Spacing pertains to minimum distances. It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. equipment layout refers to the arrangement. Equipment Layout Standards.

From www.pooltech.com

CAD Design Pool Tech Your Cedar Rapids, IA Builder Equipment Layout Standards including industry practices and standards. equipment layout refers to the arrangement and positioning of various equipment and machinery within a given space or facility. It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. equipment layout and piping layout is done as per. Equipment Layout Standards.

From stlengineering.net

Equipment Layout, Selection, and Specification STL Engineering, LLC Equipment Layout Standards process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. equipment layout refers to the arrangement and positioning of various equipment and machinery within a given space or facility. 57 rows equipment layout is one of the most important deliverable of a piping department. It is an. Equipment Layout Standards.

From stlengineering.net

Equipment Layout, Selection, and Specification STL Engineering, LLC Equipment Layout Standards equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity. 57 rows equipment layout is one of the most important deliverable of a piping department. process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. . Equipment Layout Standards.

From www.meiusa.com

Machine Room Layout MEI Total Elevator Solutions Equipment Layout Standards including industry practices and standards. Spacing tables are provided which can be used as a starting point in laying out a. It is an essential aspect of the overall plant or facility design and plays a crucial role in ensuring efficient operations, safety, and accessibility. It shows location and placement of all equipments in a particular process or utility. Equipment Layout Standards.

From cookprocesssolutions.com

Equipment Layout Cook Process Solutions, LLC Equipment Layout Standards Spacing tables are provided which can be used as a starting point in laying out a. layout relates to the relative position of equipment or units within a given site. It is an essential aspect of the overall plant or facility design and plays a crucial role in ensuring efficient operations, safety, and accessibility. Spacing pertains to minimum distances.. Equipment Layout Standards.

From paktechpoint.com

Plant Layout, Spacing and Clearances for Equipment Piping PAKTECHPOINT Equipment Layout Standards equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity. It is an essential aspect of the overall plant or facility design and plays a crucial role in ensuring efficient operations, safety, and accessibility. equipment layout refers to the arrangement and positioning of various equipment and machinery. Equipment Layout Standards.

From www.matrixpdm.com

equipment layout Matrix PDM Engineering Equipment Layout Standards including industry practices and standards. 57 rows equipment layout is one of the most important deliverable of a piping department. It shows location and placement of all equipments in a particular process or utility area along with various types of access and maintenance areas. process flow sequence and operating procedures should be thoroughly understood so that equipment. Equipment Layout Standards.

From www.researchgate.net

Basic Equipment Layout Download Scientific Diagram Equipment Layout Standards including industry practices and standards. Equipment should be arranged in logistic process sequence for optimum piping runs and operational and maintenance ease. layout relates to the relative position of equipment or units within a given site. Spacing tables are provided which can be used as a starting point in laying out a. equipment layout refers to the. Equipment Layout Standards.

From www.equipmentmanufacturingandintegration.com

Equipment Layout Line Drawings Equipment Manufacturing & Integration Inc Equipment Layout Standards layout relates to the relative position of equipment or units within a given site. 57 rows equipment layout is one of the most important deliverable of a piping department. equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity. Equipment should be arranged in logistic process. Equipment Layout Standards.