What Size Hole To Drill When Tapping . When it comes to tapping holes, knowing what size hole to drill is crucial. For reliability, use a nice thick cutting oil, and any time it's possible use a spiral point hss plug tap. Too big of a hole and the tap won't hold properly, too small of a hole and it can be difficult. 52 rows tap drill clearance drill aluminum, brass, plastics steel, stainless steel, iron close fit standard fit 75% thread 50% thread screw size major dia (mm) mm per thread drill size. A rule of thumb is that the right tap drill is around 85% for coarse threads and 90% for fine threads which feature a higher number of threads per axial distance. As a general practice, tapping torque should equal approximately 70% of the fasteners torsional strength. In production tapping we never use hand taps, because they trap chips and. 162 rows the tap size chart provides a list of standard size taps, specifying the diameter and thread spacing, for fractional, metric, and screw sizes. Adjust hole size to accommodate. Here you will learn how to get the right drill diameter depending on the tap type and required thread height. By default, the size you will find on most charts is the diameter for 75% thread depth on a cutting tap. The decimal equivalents of the. “tap dill size” is the drill diameter we should use before a tapping operation.

from www.engineeringclicks.com

A rule of thumb is that the right tap drill is around 85% for coarse threads and 90% for fine threads which feature a higher number of threads per axial distance. By default, the size you will find on most charts is the diameter for 75% thread depth on a cutting tap. In production tapping we never use hand taps, because they trap chips and. Adjust hole size to accommodate. When it comes to tapping holes, knowing what size hole to drill is crucial. Here you will learn how to get the right drill diameter depending on the tap type and required thread height. Too big of a hole and the tap won't hold properly, too small of a hole and it can be difficult. The decimal equivalents of the. “tap dill size” is the drill diameter we should use before a tapping operation. As a general practice, tapping torque should equal approximately 70% of the fasteners torsional strength.

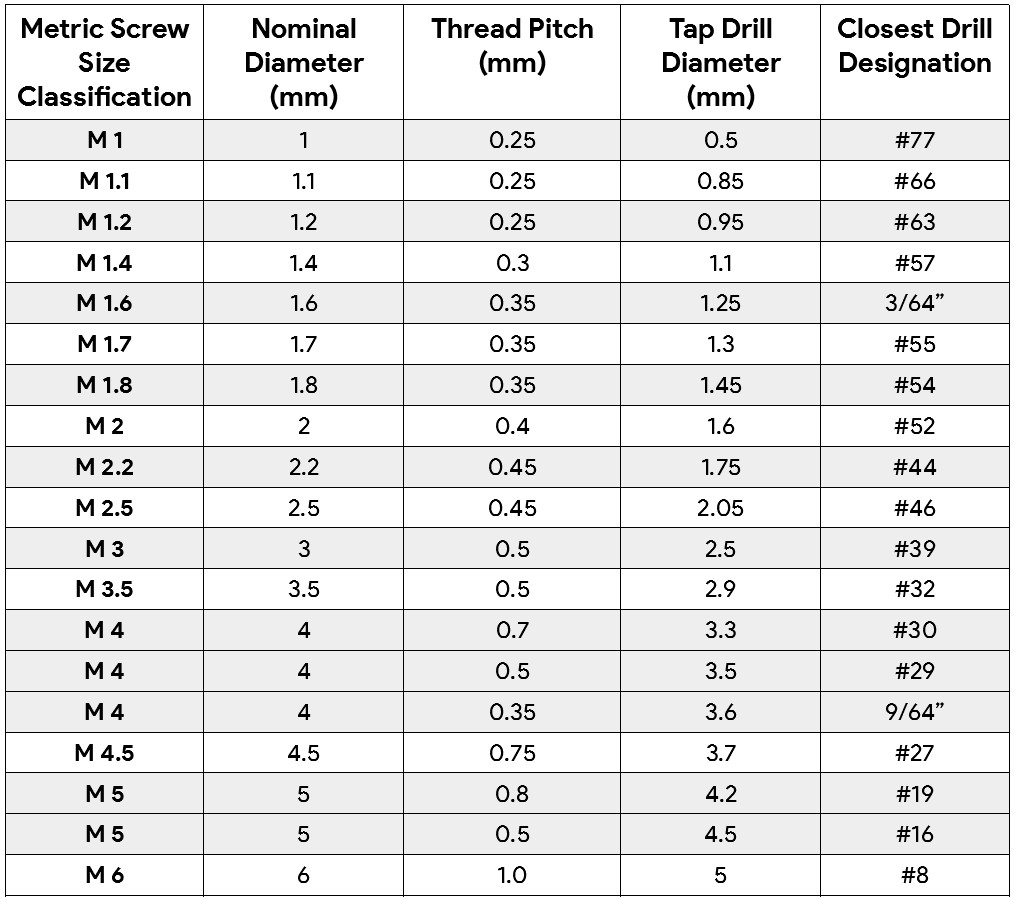

Tap Drill Chart inch and metric EngineeringClicks

What Size Hole To Drill When Tapping As a general practice, tapping torque should equal approximately 70% of the fasteners torsional strength. Adjust hole size to accommodate. Here you will learn how to get the right drill diameter depending on the tap type and required thread height. 162 rows the tap size chart provides a list of standard size taps, specifying the diameter and thread spacing, for fractional, metric, and screw sizes. For reliability, use a nice thick cutting oil, and any time it's possible use a spiral point hss plug tap. When it comes to tapping holes, knowing what size hole to drill is crucial. Too big of a hole and the tap won't hold properly, too small of a hole and it can be difficult. A rule of thumb is that the right tap drill is around 85% for coarse threads and 90% for fine threads which feature a higher number of threads per axial distance. The decimal equivalents of the. By default, the size you will find on most charts is the diameter for 75% thread depth on a cutting tap. In production tapping we never use hand taps, because they trap chips and. As a general practice, tapping torque should equal approximately 70% of the fasteners torsional strength. 52 rows tap drill clearance drill aluminum, brass, plastics steel, stainless steel, iron close fit standard fit 75% thread 50% thread screw size major dia (mm) mm per thread drill size. “tap dill size” is the drill diameter we should use before a tapping operation.

From parts-badger.com

Drill and Tap Reference Guide by PartsBadger What Size Hole To Drill When Tapping For reliability, use a nice thick cutting oil, and any time it's possible use a spiral point hss plug tap. A rule of thumb is that the right tap drill is around 85% for coarse threads and 90% for fine threads which feature a higher number of threads per axial distance. “tap dill size” is the drill diameter we should. What Size Hole To Drill When Tapping.

From exohjgjqq.blob.core.windows.net

How To Drill And Tap A 1 8 Npt Hole at Robert Lowry blog What Size Hole To Drill When Tapping Adjust hole size to accommodate. For reliability, use a nice thick cutting oil, and any time it's possible use a spiral point hss plug tap. In production tapping we never use hand taps, because they trap chips and. By default, the size you will find on most charts is the diameter for 75% thread depth on a cutting tap. The. What Size Hole To Drill When Tapping.

From exykecckc.blob.core.windows.net

What Size Drill Bit To Tap A M6 Hole at Edward Heredia blog What Size Hole To Drill When Tapping Here you will learn how to get the right drill diameter depending on the tap type and required thread height. By default, the size you will find on most charts is the diameter for 75% thread depth on a cutting tap. Adjust hole size to accommodate. In production tapping we never use hand taps, because they trap chips and. When. What Size Hole To Drill When Tapping.

From www.engineeringclicks.com

Tap Drill Chart inch and metric EngineeringClicks What Size Hole To Drill When Tapping A rule of thumb is that the right tap drill is around 85% for coarse threads and 90% for fine threads which feature a higher number of threads per axial distance. For reliability, use a nice thick cutting oil, and any time it's possible use a spiral point hss plug tap. Adjust hole size to accommodate. 162 rows the tap. What Size Hole To Drill When Tapping.

From klaspyfpx.blob.core.windows.net

Tapping A 3/8 Hole What Size Drill Bit at Mary Herman blog What Size Hole To Drill When Tapping The decimal equivalents of the. 162 rows the tap size chart provides a list of standard size taps, specifying the diameter and thread spacing, for fractional, metric, and screw sizes. A rule of thumb is that the right tap drill is around 85% for coarse threads and 90% for fine threads which feature a higher number of threads per axial. What Size Hole To Drill When Tapping.

From crosstools.com.au

Helicoil Type Inserts BSW & BSF Tapped Hole Size Table Cross Tools Co What Size Hole To Drill When Tapping A rule of thumb is that the right tap drill is around 85% for coarse threads and 90% for fine threads which feature a higher number of threads per axial distance. 52 rows tap drill clearance drill aluminum, brass, plastics steel, stainless steel, iron close fit standard fit 75% thread 50% thread screw size major dia (mm) mm per thread. What Size Hole To Drill When Tapping.

From parts-badger.com

Drill and Tap Reference Guide by PartsBadger What Size Hole To Drill When Tapping Adjust hole size to accommodate. 52 rows tap drill clearance drill aluminum, brass, plastics steel, stainless steel, iron close fit standard fit 75% thread 50% thread screw size major dia (mm) mm per thread drill size. For reliability, use a nice thick cutting oil, and any time it's possible use a spiral point hss plug tap. Too big of a. What Size Hole To Drill When Tapping.

From www.yamawa.eu

Cored holes Direct tapping with no tool breakage Yamawa What Size Hole To Drill When Tapping “tap dill size” is the drill diameter we should use before a tapping operation. Too big of a hole and the tap won't hold properly, too small of a hole and it can be difficult. In production tapping we never use hand taps, because they trap chips and. By default, the size you will find on most charts is the. What Size Hole To Drill When Tapping.

From klaspyfpx.blob.core.windows.net

Tapping A 3/8 Hole What Size Drill Bit at Mary Herman blog What Size Hole To Drill When Tapping “tap dill size” is the drill diameter we should use before a tapping operation. By default, the size you will find on most charts is the diameter for 75% thread depth on a cutting tap. For reliability, use a nice thick cutting oil, and any time it's possible use a spiral point hss plug tap. 162 rows the tap size. What Size Hole To Drill When Tapping.

From www.sampletemplates.com

FREE 13+ Sample Tap Drill Chart Templates in PDF, Excel What Size Hole To Drill When Tapping Too big of a hole and the tap won't hold properly, too small of a hole and it can be difficult. Here you will learn how to get the right drill diameter depending on the tap type and required thread height. In production tapping we never use hand taps, because they trap chips and. When it comes to tapping holes,. What Size Hole To Drill When Tapping.

From klaspyfpx.blob.core.windows.net

Tapping A 3/8 Hole What Size Drill Bit at Mary Herman blog What Size Hole To Drill When Tapping 162 rows the tap size chart provides a list of standard size taps, specifying the diameter and thread spacing, for fractional, metric, and screw sizes. As a general practice, tapping torque should equal approximately 70% of the fasteners torsional strength. In production tapping we never use hand taps, because they trap chips and. When it comes to tapping holes, knowing. What Size Hole To Drill When Tapping.

From www.scribd.com

Standard Holes and Tapping Chart PDF Machining Cutting Tools What Size Hole To Drill When Tapping 162 rows the tap size chart provides a list of standard size taps, specifying the diameter and thread spacing, for fractional, metric, and screw sizes. Here you will learn how to get the right drill diameter depending on the tap type and required thread height. “tap dill size” is the drill diameter we should use before a tapping operation. By. What Size Hole To Drill When Tapping.

From allpointsfasteners.com

Pilot Holes Guide All Points Fasteners What Size Hole To Drill When Tapping 52 rows tap drill clearance drill aluminum, brass, plastics steel, stainless steel, iron close fit standard fit 75% thread 50% thread screw size major dia (mm) mm per thread drill size. Here you will learn how to get the right drill diameter depending on the tap type and required thread height. Adjust hole size to accommodate. “tap dill size” is. What Size Hole To Drill When Tapping.

From autofopt.weebly.com

Drill bit size for tapping holes chart autofopt What Size Hole To Drill When Tapping For reliability, use a nice thick cutting oil, and any time it's possible use a spiral point hss plug tap. As a general practice, tapping torque should equal approximately 70% of the fasteners torsional strength. A rule of thumb is that the right tap drill is around 85% for coarse threads and 90% for fine threads which feature a higher. What Size Hole To Drill When Tapping.

From mefexport.com

Tapping Chart. Drill and tap size chart for threads M, MF, UN, BSW, G, Tr What Size Hole To Drill When Tapping A rule of thumb is that the right tap drill is around 85% for coarse threads and 90% for fine threads which feature a higher number of threads per axial distance. Too big of a hole and the tap won't hold properly, too small of a hole and it can be difficult. 162 rows the tap size chart provides a. What Size Hole To Drill When Tapping.

From revivalportal.goodwood.com

Drill Bit Size Chart For Taps What Size Hole To Drill When Tapping Here you will learn how to get the right drill diameter depending on the tap type and required thread height. Adjust hole size to accommodate. The decimal equivalents of the. A rule of thumb is that the right tap drill is around 85% for coarse threads and 90% for fine threads which feature a higher number of threads per axial. What Size Hole To Drill When Tapping.

From loegiipkc.blob.core.windows.net

What Size Hole To Drill For 1/4 28 Tap at Maria Gonzales blog What Size Hole To Drill When Tapping The decimal equivalents of the. A rule of thumb is that the right tap drill is around 85% for coarse threads and 90% for fine threads which feature a higher number of threads per axial distance. As a general practice, tapping torque should equal approximately 70% of the fasteners torsional strength. 52 rows tap drill clearance drill aluminum, brass, plastics. What Size Hole To Drill When Tapping.

From templatelab.com

23 Printable Tap Drill Charts [PDF] ᐅ TemplateLab What Size Hole To Drill When Tapping 162 rows the tap size chart provides a list of standard size taps, specifying the diameter and thread spacing, for fractional, metric, and screw sizes. The decimal equivalents of the. Here you will learn how to get the right drill diameter depending on the tap type and required thread height. By default, the size you will find on most charts. What Size Hole To Drill When Tapping.

From aliciawatts.z13.web.core.windows.net

Tap Drill Sizes Chart What Size Hole To Drill When Tapping Too big of a hole and the tap won't hold properly, too small of a hole and it can be difficult. By default, the size you will find on most charts is the diameter for 75% thread depth on a cutting tap. A rule of thumb is that the right tap drill is around 85% for coarse threads and 90%. What Size Hole To Drill When Tapping.

From studylib.net

somtadrillsizesfortapping What Size Hole To Drill When Tapping Here you will learn how to get the right drill diameter depending on the tap type and required thread height. 52 rows tap drill clearance drill aluminum, brass, plastics steel, stainless steel, iron close fit standard fit 75% thread 50% thread screw size major dia (mm) mm per thread drill size. For reliability, use a nice thick cutting oil, and. What Size Hole To Drill When Tapping.

From www.scribd.com

Drill Hole Size Chart What Size Hole To Drill When Tapping In production tapping we never use hand taps, because they trap chips and. Too big of a hole and the tap won't hold properly, too small of a hole and it can be difficult. A rule of thumb is that the right tap drill is around 85% for coarse threads and 90% for fine threads which feature a higher number. What Size Hole To Drill When Tapping.

From chartsflow.z13.web.core.windows.net

Drilling Tapping Size Chart Free 13+ sample tap drill chart templates What Size Hole To Drill When Tapping When it comes to tapping holes, knowing what size hole to drill is crucial. “tap dill size” is the drill diameter we should use before a tapping operation. The decimal equivalents of the. 52 rows tap drill clearance drill aluminum, brass, plastics steel, stainless steel, iron close fit standard fit 75% thread 50% thread screw size major dia (mm) mm. What Size Hole To Drill When Tapping.

From exorsrcez.blob.core.windows.net

What Size Hole To Drill For 1 4 Nc Tap at Nellie Cobbs blog What Size Hole To Drill When Tapping By default, the size you will find on most charts is the diameter for 75% thread depth on a cutting tap. When it comes to tapping holes, knowing what size hole to drill is crucial. Adjust hole size to accommodate. 52 rows tap drill clearance drill aluminum, brass, plastics steel, stainless steel, iron close fit standard fit 75% thread 50%. What Size Hole To Drill When Tapping.

From www.engineeringclicks.com

Tap Drill Chart inch and metric EngineeringClicks What Size Hole To Drill When Tapping As a general practice, tapping torque should equal approximately 70% of the fasteners torsional strength. A rule of thumb is that the right tap drill is around 85% for coarse threads and 90% for fine threads which feature a higher number of threads per axial distance. 162 rows the tap size chart provides a list of standard size taps, specifying. What Size Hole To Drill When Tapping.

From www.bassardnath.com

M3X.5 Tap Drill Size A Comprehensive Guide For 2023 Bassard Nath What Size Hole To Drill When Tapping Here you will learn how to get the right drill diameter depending on the tap type and required thread height. A rule of thumb is that the right tap drill is around 85% for coarse threads and 90% for fine threads which feature a higher number of threads per axial distance. As a general practice, tapping torque should equal approximately. What Size Hole To Drill When Tapping.

From chartsflow.z13.web.core.windows.net

Drilling Tapping Size Chart Free 13+ sample tap drill chart templates What Size Hole To Drill When Tapping Adjust hole size to accommodate. As a general practice, tapping torque should equal approximately 70% of the fasteners torsional strength. 52 rows tap drill clearance drill aluminum, brass, plastics steel, stainless steel, iron close fit standard fit 75% thread 50% thread screw size major dia (mm) mm per thread drill size. “tap dill size” is the drill diameter we should. What Size Hole To Drill When Tapping.

From www.eduaspirant.com

How To Use The Drill Tap Wall Chart GD&T Basics What Size Hole To Drill When Tapping The decimal equivalents of the. “tap dill size” is the drill diameter we should use before a tapping operation. Too big of a hole and the tap won't hold properly, too small of a hole and it can be difficult. Here you will learn how to get the right drill diameter depending on the tap type and required thread height.. What Size Hole To Drill When Tapping.

From www.scribd.com

Tapping Drill Chart.pdf Units Of Measurement Length What Size Hole To Drill When Tapping For reliability, use a nice thick cutting oil, and any time it's possible use a spiral point hss plug tap. As a general practice, tapping torque should equal approximately 70% of the fasteners torsional strength. In production tapping we never use hand taps, because they trap chips and. By default, the size you will find on most charts is the. What Size Hole To Drill When Tapping.

From edburdick.net

Keeping Bolt Holes Aligned when Drilling and Tapping Ed's Mediawiki What Size Hole To Drill When Tapping As a general practice, tapping torque should equal approximately 70% of the fasteners torsional strength. For reliability, use a nice thick cutting oil, and any time it's possible use a spiral point hss plug tap. “tap dill size” is the drill diameter we should use before a tapping operation. 52 rows tap drill clearance drill aluminum, brass, plastics steel, stainless. What Size Hole To Drill When Tapping.

From templatelab.com

23 Printable Tap Drill Charts [PDF] ᐅ TemplateLab What Size Hole To Drill When Tapping In production tapping we never use hand taps, because they trap chips and. Adjust hole size to accommodate. For reliability, use a nice thick cutting oil, and any time it's possible use a spiral point hss plug tap. A rule of thumb is that the right tap drill is around 85% for coarse threads and 90% for fine threads which. What Size Hole To Drill When Tapping.

From loesmerrn.blob.core.windows.net

What Size Hole Do You Drill For A 1 4 Pipe Tap at Richard Connell blog What Size Hole To Drill When Tapping “tap dill size” is the drill diameter we should use before a tapping operation. For reliability, use a nice thick cutting oil, and any time it's possible use a spiral point hss plug tap. Too big of a hole and the tap won't hold properly, too small of a hole and it can be difficult. When it comes to tapping. What Size Hole To Drill When Tapping.

From spaco.org

Tapping/Drilling Alignment Block What Size Hole To Drill When Tapping By default, the size you will find on most charts is the diameter for 75% thread depth on a cutting tap. For reliability, use a nice thick cutting oil, and any time it's possible use a spiral point hss plug tap. 52 rows tap drill clearance drill aluminum, brass, plastics steel, stainless steel, iron close fit standard fit 75% thread. What Size Hole To Drill When Tapping.

From templatelab.com

23 Printable Tap Drill Charts [PDF] ᐅ TemplateLab What Size Hole To Drill When Tapping “tap dill size” is the drill diameter we should use before a tapping operation. Adjust hole size to accommodate. As a general practice, tapping torque should equal approximately 70% of the fasteners torsional strength. In production tapping we never use hand taps, because they trap chips and. Here you will learn how to get the right drill diameter depending on. What Size Hole To Drill When Tapping.

From www.youtube.com

Tap Drill Size explained in tamil Tap drill size for metric and What Size Hole To Drill When Tapping In production tapping we never use hand taps, because they trap chips and. As a general practice, tapping torque should equal approximately 70% of the fasteners torsional strength. For reliability, use a nice thick cutting oil, and any time it's possible use a spiral point hss plug tap. Here you will learn how to get the right drill diameter depending. What Size Hole To Drill When Tapping.

From www.yamawa.eu

Cored holes Direct tapping with no tool breakage Yamawa What Size Hole To Drill When Tapping “tap dill size” is the drill diameter we should use before a tapping operation. When it comes to tapping holes, knowing what size hole to drill is crucial. The decimal equivalents of the. In production tapping we never use hand taps, because they trap chips and. As a general practice, tapping torque should equal approximately 70% of the fasteners torsional. What Size Hole To Drill When Tapping.