When Soldering Or Brazing The Filler Metal Is . In the brazing process, a metallic filler that has been melted and poured into the joint is used to join two pieces of metal together. Brazing is characterised by the use of filler metals with a melting point above 450°c. The liquid filler metal wets the base materials through capillary action. Soldering is notable for its lower temperature profile, where filler materials melt below 450°c. Soldering and brazing are two common metal joining techniques that involve joints of similar/dissimilar metals. In soldering, a filler metal known as solder is also used to fill the joint, creating an alloy at the metal’s surface without melting the base metal. Filler metal boiling point is above 450°c. Capillary action plays a pivotal role in both brazing and soldering for metal joining. When the liquid filler metal solidifies, it is bonded to the base. Soldering has the same aws definition as brazing, except that the filler metal used has a liquidus below 840°f (450°c) and below the solidus of the base metals. When it comes to joining metals, brazing and soldering are two popular techniques used. The brazing produces stronger joints than soldering. The filler metals may be of copper, aluminum, nickel, silver. However, there are notable differences in the heat required. The flux used may be borax or boric acid.

from ehs.vt.edu

In both methods, a filler metal is heated, melted, and filled into a joint. The flux used may be borax or boric acid. When it comes to joining metals, brazing and soldering are two popular techniques used. Capillary action plays a pivotal role in both brazing and soldering for metal joining. In a nutshell, brazing involves. Filler metal boiling point is above 450°c. Soldering is notable for its lower temperature profile, where filler materials melt below 450°c. Soldering and brazing are two common metal joining techniques that involve joints of similar/dissimilar metals. In soldering, a filler metal known as solder is also used to fill the joint, creating an alloy at the metal’s surface without melting the base metal. Soldering is a process in which metals.

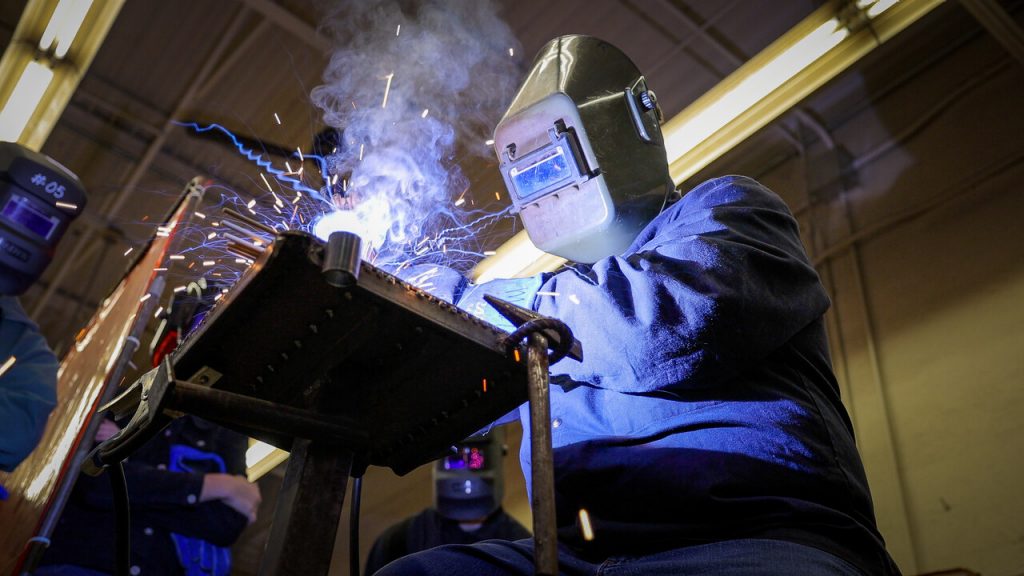

Welding, Cutting, Brazing and Soldering Environmental Health and

When Soldering Or Brazing The Filler Metal Is Capillary action plays a pivotal role in both brazing and soldering for metal joining. In the brazing process, a metallic filler that has been melted and poured into the joint is used to join two pieces of metal together. Soldering is a process in which metals. The flux used may be borax or boric acid. In both methods, a filler metal is heated, melted, and filled into a joint. But what’s the difference between the two? The brazing produces stronger joints than soldering. When it comes to joining metals, brazing and soldering are two popular techniques used. Capillary action plays a pivotal role in both brazing and soldering for metal joining. The liquid filler metal wets the base materials through capillary action. Soldering is notable for its lower temperature profile, where filler materials melt below 450°c. However, there are notable differences in the heat required. Soldering has the same aws definition as brazing, except that the filler metal used has a liquidus below 840°f (450°c) and below the solidus of the base metals. When the liquid filler metal solidifies, it is bonded to the base. In a nutshell, brazing involves. The methods are also quite similar in process.

From learnmethods.com

Why Are Copper Fittings Cleaned Before Soldering Or Brazing Learn Methods When Soldering Or Brazing The Filler Metal Is However, there are notable differences in the heat required. Capillary action plays a pivotal role in both brazing and soldering for metal joining. Brazing is a process in which metals are joined by melting a filler metal into the joint and can be used to join dissimilar metals. In a nutshell, brazing involves. The brazing produces stronger joints than soldering.. When Soldering Or Brazing The Filler Metal Is.

From blog.laminasyaceros.com

Soldadura brazing o soldadura fuerte. When Soldering Or Brazing The Filler Metal Is Soldering is a process in which metals. Brazing is a process in which metals are joined by melting a filler metal into the joint and can be used to join dissimilar metals. The liquid filler metal wets the base materials through capillary action. But what’s the difference between the two? The methods are also quite similar in process. Capillary action. When Soldering Or Brazing The Filler Metal Is.

From www.masseyenergyco.com

Brazing VS Welding VS Soldering In Depth Research Massey Energy Co When Soldering Or Brazing The Filler Metal Is Soldering is a process in which metals. The methods are also quite similar in process. The liquid filler metal wets the base materials through capillary action. In a nutshell, brazing involves. Soldering is notable for its lower temperature profile, where filler materials melt below 450°c. The brazing produces stronger joints than soldering. In both methods, a filler metal is heated,. When Soldering Or Brazing The Filler Metal Is.

From www.focusweld.com

Brazing is a traditional metal joining process in which two or more When Soldering Or Brazing The Filler Metal Is The brazing produces stronger joints than soldering. When the liquid filler metal solidifies, it is bonded to the base. But what’s the difference between the two? Soldering and brazing are two common metal joining techniques that involve joints of similar/dissimilar metals. Soldering is notable for its lower temperature profile, where filler materials melt below 450°c. In a nutshell, brazing involves.. When Soldering Or Brazing The Filler Metal Is.

From dokumen.tips

(PDF) Soldering, Brazing, and Braze Welding Processes When Soldering Or Brazing The Filler Metal Is However, there are notable differences in the heat required. Filler metal boiling point is above 450°c. When it comes to joining metals, brazing and soldering are two popular techniques used. The flux used may be borax or boric acid. When the liquid filler metal solidifies, it is bonded to the base. Brazing is a process in which metals are joined. When Soldering Or Brazing The Filler Metal Is.

From ehs.vt.edu

Welding, Cutting, Brazing and Soldering Environmental Health and When Soldering Or Brazing The Filler Metal Is In both methods, a filler metal is heated, melted, and filled into a joint. In the brazing process, a metallic filler that has been melted and poured into the joint is used to join two pieces of metal together. Soldering has the same aws definition as brazing, except that the filler metal used has a liquidus below 840°f (450°c) and. When Soldering Or Brazing The Filler Metal Is.

From www.youtube.com

Super Alloy 5 Aluminum Soldering and Brazing Tips and Techniques YouTube When Soldering Or Brazing The Filler Metal Is Soldering is a process in which metals. Soldering is notable for its lower temperature profile, where filler materials melt below 450°c. But what’s the difference between the two? Soldering and brazing are two common metal joining techniques that involve joints of similar/dissimilar metals. In a nutshell, brazing involves. The brazing produces stronger joints than soldering. In the brazing process, a. When Soldering Or Brazing The Filler Metal Is.

From blog.thepipingmart.com

Brazing vs Soldering Copper What's the Difference When Soldering Or Brazing The Filler Metal Is The brazing produces stronger joints than soldering. The flux used may be borax or boric acid. Soldering is notable for its lower temperature profile, where filler materials melt below 450°c. The filler metals may be of copper, aluminum, nickel, silver. Soldering is a process in which metals. The methods are also quite similar in process. The brazing gives better accuracy,. When Soldering Or Brazing The Filler Metal Is.

From www.amgmetalmecanica.com

Soldadura Brazing ¿Qué es? AMG MetalMecánica When Soldering Or Brazing The Filler Metal Is In the brazing process, a metallic filler that has been melted and poured into the joint is used to join two pieces of metal together. The liquid filler metal wets the base materials through capillary action. The methods are also quite similar in process. In soldering, a filler metal known as solder is also used to fill the joint, creating. When Soldering Or Brazing The Filler Metal Is.

From blog.thepipingmart.com

Brazing Flux vs Soldering Flux What's the Difference When Soldering Or Brazing The Filler Metal Is The liquid filler metal wets the base materials through capillary action. The methods are also quite similar in process. In a nutshell, brazing involves. The brazing gives better accuracy, and joints may have a good aesthetic appearance. Brazing is a process in which metals are joined by melting a filler metal into the joint and can be used to join. When Soldering Or Brazing The Filler Metal Is.

From www.arrue.me

Soldering vs brazing copper Arrue When Soldering Or Brazing The Filler Metal Is The methods are also quite similar in process. Brazing is characterised by the use of filler metals with a melting point above 450°c. The brazing gives better accuracy, and joints may have a good aesthetic appearance. When it comes to joining metals, brazing and soldering are two popular techniques used. The filler metals may be of copper, aluminum, nickel, silver.. When Soldering Or Brazing The Filler Metal Is.

From www.electronicsandyou.com

How to Solder Electronic Components Hand Soldering Tutorial When Soldering Or Brazing The Filler Metal Is Soldering has the same aws definition as brazing, except that the filler metal used has a liquidus below 840°f (450°c) and below the solidus of the base metals. When the liquid filler metal solidifies, it is bonded to the base. When it comes to joining metals, brazing and soldering are two popular techniques used. The brazing produces stronger joints than. When Soldering Or Brazing The Filler Metal Is.

From www.brazing-welding-aluminum.com

4104 4004 brazing filler metal_Aluminum rods wire Manufacturers When Soldering Or Brazing The Filler Metal Is The brazing gives better accuracy, and joints may have a good aesthetic appearance. Filler metal boiling point is above 450°c. In both methods, a filler metal is heated, melted, and filled into a joint. The flux used may be borax or boric acid. Capillary action plays a pivotal role in both brazing and soldering for metal joining. But what’s the. When Soldering Or Brazing The Filler Metal Is.

From www.meaningfulspaces.com

What Is Welding, Brazing, and Soldering Unveiling Metal Joining When Soldering Or Brazing The Filler Metal Is Brazing is characterised by the use of filler metals with a melting point above 450°c. Brazing is a process in which metals are joined by melting a filler metal into the joint and can be used to join dissimilar metals. Filler metal boiling point is above 450°c. The liquid filler metal wets the base materials through capillary action. The flux. When Soldering Or Brazing The Filler Metal Is.

From www.maricopaemergencymedicine.com

vasúti kocsi ősz Felelős személy silver brazing copper pipe nulla When Soldering Or Brazing The Filler Metal Is In soldering, a filler metal known as solder is also used to fill the joint, creating an alloy at the metal’s surface without melting the base metal. In a nutshell, brazing involves. Filler metal boiling point is above 450°c. Soldering is a process in which metals. The brazing gives better accuracy, and joints may have a good aesthetic appearance. Soldering. When Soldering Or Brazing The Filler Metal Is.

From www.ionix.fi

Laser Brazing Ionix Oy When Soldering Or Brazing The Filler Metal Is In a nutshell, brazing involves. Capillary action plays a pivotal role in both brazing and soldering for metal joining. When the liquid filler metal solidifies, it is bonded to the base. Filler metal boiling point is above 450°c. Brazing is a process in which metals are joined by melting a filler metal into the joint and can be used to. When Soldering Or Brazing The Filler Metal Is.

From pcbtoolexpert.com

Difference Between Soldering And Brazing PCB Tool Expert When Soldering Or Brazing The Filler Metal Is In the brazing process, a metallic filler that has been melted and poured into the joint is used to join two pieces of metal together. Soldering is notable for its lower temperature profile, where filler materials melt below 450°c. In both methods, a filler metal is heated, melted, and filled into a joint. Soldering has the same aws definition as. When Soldering Or Brazing The Filler Metal Is.

From studylib.net

15 Soldering Brazing and riveting When Soldering Or Brazing The Filler Metal Is However, there are notable differences in the heat required. Soldering has the same aws definition as brazing, except that the filler metal used has a liquidus below 840°f (450°c) and below the solidus of the base metals. The brazing gives better accuracy, and joints may have a good aesthetic appearance. The brazing produces stronger joints than soldering. The flux used. When Soldering Or Brazing The Filler Metal Is.

From blog.thepipingmart.com

Brazing Copper vs Soldering Copper What's the Difference When Soldering Or Brazing The Filler Metal Is In both methods, a filler metal is heated, melted, and filled into a joint. However, there are notable differences in the heat required. When it comes to joining metals, brazing and soldering are two popular techniques used. Capillary action plays a pivotal role in both brazing and soldering for metal joining. Soldering is notable for its lower temperature profile, where. When Soldering Or Brazing The Filler Metal Is.

From www.differencebetween.net

Difference Between Soldering and Brazing Difference Between When Soldering Or Brazing The Filler Metal Is The brazing produces stronger joints than soldering. Filler metal boiling point is above 450°c. Capillary action plays a pivotal role in both brazing and soldering for metal joining. Soldering is a process in which metals. Brazing is a process in which metals are joined by melting a filler metal into the joint and can be used to join dissimilar metals.. When Soldering Or Brazing The Filler Metal Is.

From blog.thepipingmart.com

Brazing vs Soldering What's the Difference When Soldering Or Brazing The Filler Metal Is The liquid filler metal wets the base materials through capillary action. However, there are notable differences in the heat required. Soldering is notable for its lower temperature profile, where filler materials melt below 450°c. In both methods, a filler metal is heated, melted, and filled into a joint. In soldering, a filler metal known as solder is also used to. When Soldering Or Brazing The Filler Metal Is.

From www.theengineerspost.com

Difference Between Brazing and Soldering [Guide with PDF] When Soldering Or Brazing The Filler Metal Is Filler metal boiling point is above 450°c. Brazing is a process in which metals are joined by melting a filler metal into the joint and can be used to join dissimilar metals. The liquid filler metal wets the base materials through capillary action. However, there are notable differences in the heat required. Soldering is notable for its lower temperature profile,. When Soldering Or Brazing The Filler Metal Is.

From www.coowor.com

HUAZHONG RBCuZnB Brass Brazing Rods Copper Welding Filler Metal Sticks When Soldering Or Brazing The Filler Metal Is In soldering, a filler metal known as solder is also used to fill the joint, creating an alloy at the metal’s surface without melting the base metal. When it comes to joining metals, brazing and soldering are two popular techniques used. Capillary action plays a pivotal role in both brazing and soldering for metal joining. Brazing is a process in. When Soldering Or Brazing The Filler Metal Is.

From sh-good-ntbm.en.made-in-china.com

58A Copper Based Brazing Alloy Sheet China Soldering and Filler Metal When Soldering Or Brazing The Filler Metal Is The brazing gives better accuracy, and joints may have a good aesthetic appearance. Soldering has the same aws definition as brazing, except that the filler metal used has a liquidus below 840°f (450°c) and below the solidus of the base metals. The methods are also quite similar in process. Soldering and brazing are two common metal joining techniques that involve. When Soldering Or Brazing The Filler Metal Is.

From www.coowor.com

HUAZHONG RBCuZnB Brass Brazing Rods Copper Welding Filler Metal Sticks When Soldering Or Brazing The Filler Metal Is In soldering, a filler metal known as solder is also used to fill the joint, creating an alloy at the metal’s surface without melting the base metal. However, there are notable differences in the heat required. But what’s the difference between the two? Soldering and brazing are two common metal joining techniques that involve joints of similar/dissimilar metals. Filler metal. When Soldering Or Brazing The Filler Metal Is.

From blog.thepipingmart.com

Brazing vs Silver Soldering What's the Difference When Soldering Or Brazing The Filler Metal Is The brazing gives better accuracy, and joints may have a good aesthetic appearance. Capillary action plays a pivotal role in both brazing and soldering for metal joining. Filler metal boiling point is above 450°c. Soldering has the same aws definition as brazing, except that the filler metal used has a liquidus below 840°f (450°c) and below the solidus of the. When Soldering Or Brazing The Filler Metal Is.

From weldingpros.net

Brazing Filler Metals And Fluxes Explained In Detail When Soldering Or Brazing The Filler Metal Is In the brazing process, a metallic filler that has been melted and poured into the joint is used to join two pieces of metal together. When the liquid filler metal solidifies, it is bonded to the base. The methods are also quite similar in process. In both methods, a filler metal is heated, melted, and filled into a joint. But. When Soldering Or Brazing The Filler Metal Is.

From www.pipsisland.com

10 Simple Steps to Braze Copper Pipe (Extended Tips) When Soldering Or Brazing The Filler Metal Is Soldering is notable for its lower temperature profile, where filler materials melt below 450°c. Soldering and brazing are two common metal joining techniques that involve joints of similar/dissimilar metals. Soldering is a process in which metals. The brazing gives better accuracy, and joints may have a good aesthetic appearance. When the liquid filler metal solidifies, it is bonded to the. When Soldering Or Brazing The Filler Metal Is.

From weldbits.com

Brazing VS Soldering VS Welding What’s The Difference? When Soldering Or Brazing The Filler Metal Is Soldering has the same aws definition as brazing, except that the filler metal used has a liquidus below 840°f (450°c) and below the solidus of the base metals. The methods are also quite similar in process. Soldering is a process in which metals. When the liquid filler metal solidifies, it is bonded to the base. Soldering is notable for its. When Soldering Or Brazing The Filler Metal Is.

From www.theengineerspost.com

Difference Between Brazing and Soldering [Guide with PDF] When Soldering Or Brazing The Filler Metal Is But what’s the difference between the two? The flux used may be borax or boric acid. When it comes to joining metals, brazing and soldering are two popular techniques used. Brazing is characterised by the use of filler metals with a melting point above 450°c. Capillary action plays a pivotal role in both brazing and soldering for metal joining. Soldering. When Soldering Or Brazing The Filler Metal Is.

From www.youtube.com

Soldering Vs Brazing Difference Between Soldering And Brazing When Soldering Or Brazing The Filler Metal Is The methods are also quite similar in process. In both methods, a filler metal is heated, melted, and filled into a joint. The liquid filler metal wets the base materials through capillary action. In the brazing process, a metallic filler that has been melted and poured into the joint is used to join two pieces of metal together. The filler. When Soldering Or Brazing The Filler Metal Is.

From blog.thepipingmart.com

Brazing Copper with Mapp Gas Process When Soldering Or Brazing The Filler Metal Is When the liquid filler metal solidifies, it is bonded to the base. Brazing is characterised by the use of filler metals with a melting point above 450°c. In the brazing process, a metallic filler that has been melted and poured into the joint is used to join two pieces of metal together. The methods are also quite similar in process.. When Soldering Or Brazing The Filler Metal Is.

From thecontentauthority.com

Brazing vs Soldering When To Use Each One? What To Consider When Soldering Or Brazing The Filler Metal Is The flux used may be borax or boric acid. When it comes to joining metals, brazing and soldering are two popular techniques used. The methods are also quite similar in process. In the brazing process, a metallic filler that has been melted and poured into the joint is used to join two pieces of metal together. When the liquid filler. When Soldering Or Brazing The Filler Metal Is.

From www.pinterest.co.uk

The Silver Soldering Process How To Silver Solder The Bench When Soldering Or Brazing The Filler Metal Is The methods are also quite similar in process. But what’s the difference between the two? When it comes to joining metals, brazing and soldering are two popular techniques used. In soldering, a filler metal known as solder is also used to fill the joint, creating an alloy at the metal’s surface without melting the base metal. The flux used may. When Soldering Or Brazing The Filler Metal Is.

From www.coowor.com

HUAZHONG RBCuZnB Brass Brazing Rods Copper Welding Filler Metal Sticks When Soldering Or Brazing The Filler Metal Is Brazing is characterised by the use of filler metals with a melting point above 450°c. The liquid filler metal wets the base materials through capillary action. The brazing produces stronger joints than soldering. In soldering, a filler metal known as solder is also used to fill the joint, creating an alloy at the metal’s surface without melting the base metal.. When Soldering Or Brazing The Filler Metal Is.