Water Cutting Vs Laser Cutting . Generates vapors that need to be extracted. This question comes up a lot among industrial professionals before they buy a machine to fulfill their needs for cutting materials. Waterjet cuts thick materials into intricate shapes, while laser cutting meets high precision demands. Waterjet and laser cutting accomplish largely the same results, but in. Waterjet cutting, while precise, is better suited for broader cuts. Laser cutting vs waterjet cutting: Laser cutting introduces heat, which can sometimes alter the material’s properties or leave burn marks. The minimum size of the cutting slit is 0.006’’ (0.15 mm) for laser cutting. The process is relatively quiet. While waterjet and laser cutting are both relatively environmentally friendly technologies, waterjet cutting uses more raw materials (abrasive, water). If heat is a concern, especially for sensitive materials, waterjet cutting’s cold process is advantageous. Laser cutting is much more precise than waterjet cutting.

from www.mac-tech.com

Generates vapors that need to be extracted. Waterjet and laser cutting accomplish largely the same results, but in. This question comes up a lot among industrial professionals before they buy a machine to fulfill their needs for cutting materials. Waterjet cutting, while precise, is better suited for broader cuts. The minimum size of the cutting slit is 0.006’’ (0.15 mm) for laser cutting. While waterjet and laser cutting are both relatively environmentally friendly technologies, waterjet cutting uses more raw materials (abrasive, water). Laser cutting vs waterjet cutting: Waterjet cuts thick materials into intricate shapes, while laser cutting meets high precision demands. Laser cutting introduces heat, which can sometimes alter the material’s properties or leave burn marks. Laser cutting is much more precise than waterjet cutting.

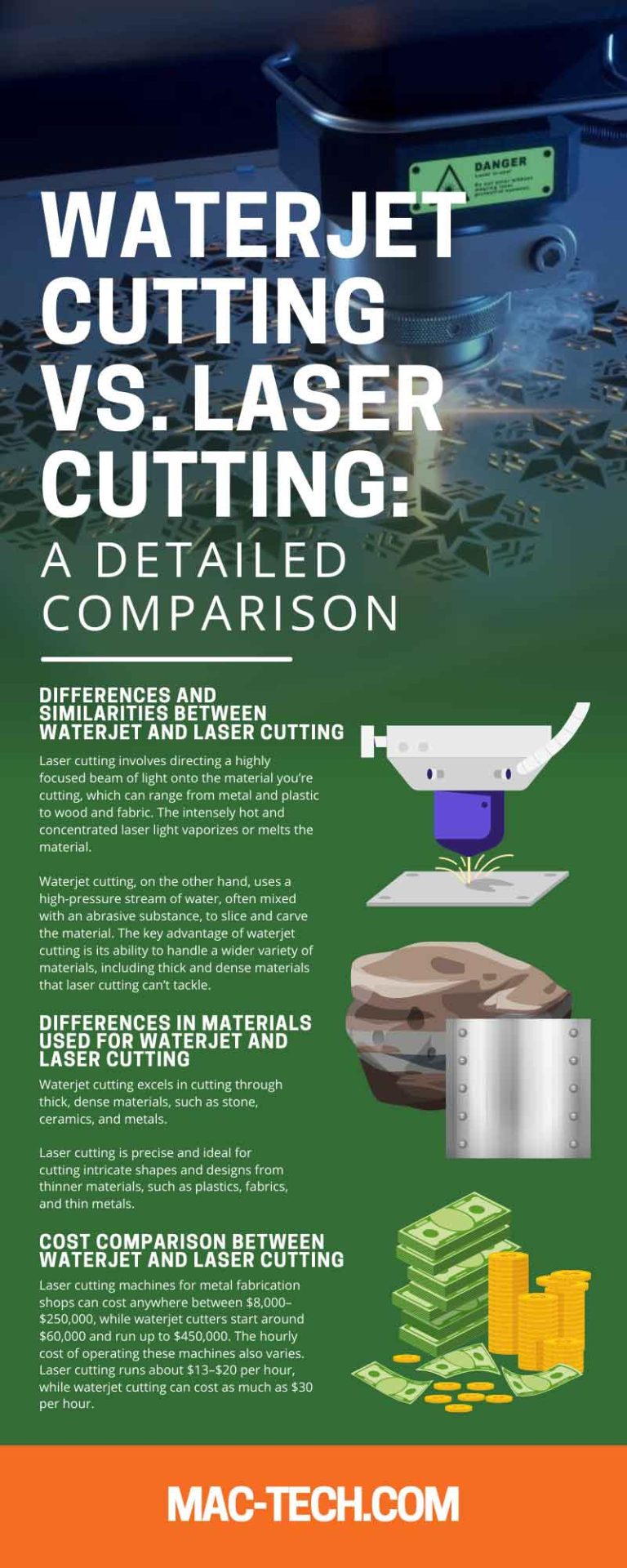

Waterjet Cutting vs. Laser Cutting A Detailed Comparison

Water Cutting Vs Laser Cutting Waterjet cuts thick materials into intricate shapes, while laser cutting meets high precision demands. Waterjet cutting, while precise, is better suited for broader cuts. If heat is a concern, especially for sensitive materials, waterjet cutting’s cold process is advantageous. The process is relatively quiet. Generates vapors that need to be extracted. This question comes up a lot among industrial professionals before they buy a machine to fulfill their needs for cutting materials. Waterjet cuts thick materials into intricate shapes, while laser cutting meets high precision demands. Waterjet and laser cutting accomplish largely the same results, but in. Laser cutting vs waterjet cutting: Laser cutting is much more precise than waterjet cutting. While waterjet and laser cutting are both relatively environmentally friendly technologies, waterjet cutting uses more raw materials (abrasive, water). Laser cutting introduces heat, which can sometimes alter the material’s properties or leave burn marks. The minimum size of the cutting slit is 0.006’’ (0.15 mm) for laser cutting.

From www.approvedsheetmetal.com

Laser Cutting vs. Waterjet Cutting (Updated for 2024) ASM Water Cutting Vs Laser Cutting Waterjet and laser cutting accomplish largely the same results, but in. Generates vapors that need to be extracted. If heat is a concern, especially for sensitive materials, waterjet cutting’s cold process is advantageous. Waterjet cuts thick materials into intricate shapes, while laser cutting meets high precision demands. Laser cutting is much more precise than waterjet cutting. Laser cutting introduces heat,. Water Cutting Vs Laser Cutting.

From www.southshoremanufacturing.com

Laser Cutting vs. Water Jet Cutting South Shore Manufacturing Water Cutting Vs Laser Cutting Waterjet cutting, while precise, is better suited for broader cuts. While waterjet and laser cutting are both relatively environmentally friendly technologies, waterjet cutting uses more raw materials (abrasive, water). If heat is a concern, especially for sensitive materials, waterjet cutting’s cold process is advantageous. Laser cutting is much more precise than waterjet cutting. Generates vapors that need to be extracted.. Water Cutting Vs Laser Cutting.

From www.mac-tech.com

Waterjet Cutting vs. Laser Cutting A Detailed Comparison Water Cutting Vs Laser Cutting The process is relatively quiet. The minimum size of the cutting slit is 0.006’’ (0.15 mm) for laser cutting. This question comes up a lot among industrial professionals before they buy a machine to fulfill their needs for cutting materials. Laser cutting introduces heat, which can sometimes alter the material’s properties or leave burn marks. Waterjet and laser cutting accomplish. Water Cutting Vs Laser Cutting.

From www.vrogue.co

Die Cut Vs Laser Cut What Makes The Difference vrogue.co Water Cutting Vs Laser Cutting The minimum size of the cutting slit is 0.006’’ (0.15 mm) for laser cutting. If heat is a concern, especially for sensitive materials, waterjet cutting’s cold process is advantageous. Waterjet and laser cutting accomplish largely the same results, but in. This question comes up a lot among industrial professionals before they buy a machine to fulfill their needs for cutting. Water Cutting Vs Laser Cutting.

From www.aitaowaterjet.com

Waterjet Cutting Vs Laser Cutting Which Is Better? AITAO Water Cutting Vs Laser Cutting Waterjet cutting, while precise, is better suited for broader cuts. This question comes up a lot among industrial professionals before they buy a machine to fulfill their needs for cutting materials. If heat is a concern, especially for sensitive materials, waterjet cutting’s cold process is advantageous. Generates vapors that need to be extracted. Laser cutting vs waterjet cutting: Laser cutting. Water Cutting Vs Laser Cutting.

From veriform.ca

Water Jet vs Laser Cutting Comparison of Advantages & Cost Water Cutting Vs Laser Cutting Waterjet cutting, while precise, is better suited for broader cuts. Waterjet and laser cutting accomplish largely the same results, but in. Laser cutting vs waterjet cutting: This question comes up a lot among industrial professionals before they buy a machine to fulfill their needs for cutting materials. While waterjet and laser cutting are both relatively environmentally friendly technologies, waterjet cutting. Water Cutting Vs Laser Cutting.

From swaterjet.com

Waterjet Vs Laser Cutting Which is Better & Why? Same Waterjet Water Cutting Vs Laser Cutting Laser cutting introduces heat, which can sometimes alter the material’s properties or leave burn marks. If heat is a concern, especially for sensitive materials, waterjet cutting’s cold process is advantageous. Waterjet cutting, while precise, is better suited for broader cuts. Waterjet cuts thick materials into intricate shapes, while laser cutting meets high precision demands. Laser cutting vs waterjet cutting: Generates. Water Cutting Vs Laser Cutting.

From pbzmfg.com

Laser Cutting vs. Plasma Cutting vs. Waterjet Cutting Water Cutting Vs Laser Cutting The minimum size of the cutting slit is 0.006’’ (0.15 mm) for laser cutting. If heat is a concern, especially for sensitive materials, waterjet cutting’s cold process is advantageous. Laser cutting is much more precise than waterjet cutting. Laser cutting vs waterjet cutting: The process is relatively quiet. Generates vapors that need to be extracted. While waterjet and laser cutting. Water Cutting Vs Laser Cutting.

From cncfirst.com

Waterjet Cutting vs Laser Cutting Which is Right for You? cncfirst Water Cutting Vs Laser Cutting The process is relatively quiet. While waterjet and laser cutting are both relatively environmentally friendly technologies, waterjet cutting uses more raw materials (abrasive, water). Generates vapors that need to be extracted. Waterjet cuts thick materials into intricate shapes, while laser cutting meets high precision demands. Waterjet and laser cutting accomplish largely the same results, but in. This question comes up. Water Cutting Vs Laser Cutting.

From blog.thepipingmart.com

Water Jet Cutting vs Laser Cutting Cost What's the Difference Water Cutting Vs Laser Cutting While waterjet and laser cutting are both relatively environmentally friendly technologies, waterjet cutting uses more raw materials (abrasive, water). The minimum size of the cutting slit is 0.006’’ (0.15 mm) for laser cutting. If heat is a concern, especially for sensitive materials, waterjet cutting’s cold process is advantageous. Laser cutting introduces heat, which can sometimes alter the material’s properties or. Water Cutting Vs Laser Cutting.

From www.techniwaterjet.com

CNC Laser Cutting vs Water Jet Cutting Which One Has The Better Water Cutting Vs Laser Cutting This question comes up a lot among industrial professionals before they buy a machine to fulfill their needs for cutting materials. Waterjet cutting, while precise, is better suited for broader cuts. Laser cutting is much more precise than waterjet cutting. The process is relatively quiet. The minimum size of the cutting slit is 0.006’’ (0.15 mm) for laser cutting. Laser. Water Cutting Vs Laser Cutting.

From www.victoriana.com

Renovieren Berater hell laser wasserstrahlschneiden Kollision Emulieren Water Cutting Vs Laser Cutting This question comes up a lot among industrial professionals before they buy a machine to fulfill their needs for cutting materials. While waterjet and laser cutting are both relatively environmentally friendly technologies, waterjet cutting uses more raw materials (abrasive, water). If heat is a concern, especially for sensitive materials, waterjet cutting’s cold process is advantageous. Waterjet and laser cutting accomplish. Water Cutting Vs Laser Cutting.

From www.linkedin.com

CNC Laser Cutting VS Waterjet Cutting Water Cutting Vs Laser Cutting Laser cutting is much more precise than waterjet cutting. If heat is a concern, especially for sensitive materials, waterjet cutting’s cold process is advantageous. Waterjet cutting, while precise, is better suited for broader cuts. Generates vapors that need to be extracted. Waterjet cuts thick materials into intricate shapes, while laser cutting meets high precision demands. Laser cutting introduces heat, which. Water Cutting Vs Laser Cutting.

From blog.thepipingmart.com

Plasma Cutting vs Laser Cutting vs Water Jet Cutting Water Cutting Vs Laser Cutting Laser cutting vs waterjet cutting: The minimum size of the cutting slit is 0.006’’ (0.15 mm) for laser cutting. Generates vapors that need to be extracted. This question comes up a lot among industrial professionals before they buy a machine to fulfill their needs for cutting materials. Waterjet cuts thick materials into intricate shapes, while laser cutting meets high precision. Water Cutting Vs Laser Cutting.

From ivycnc.com

Laser Cutting VS Waterjet Cutting How Are They Different? IVYCNC Water Cutting Vs Laser Cutting Laser cutting vs waterjet cutting: Generates vapors that need to be extracted. This question comes up a lot among industrial professionals before they buy a machine to fulfill their needs for cutting materials. While waterjet and laser cutting are both relatively environmentally friendly technologies, waterjet cutting uses more raw materials (abrasive, water). Laser cutting introduces heat, which can sometimes alter. Water Cutting Vs Laser Cutting.

From solidprint3d.ie

Water Jet Cutting vs. Laser Cutting Which is Right for You? Water Cutting Vs Laser Cutting While waterjet and laser cutting are both relatively environmentally friendly technologies, waterjet cutting uses more raw materials (abrasive, water). The minimum size of the cutting slit is 0.006’’ (0.15 mm) for laser cutting. If heat is a concern, especially for sensitive materials, waterjet cutting’s cold process is advantageous. Waterjet and laser cutting accomplish largely the same results, but in. Generates. Water Cutting Vs Laser Cutting.

From ivycnc.com

Laser Cutting VS Waterjet Cutting How Are They Different? IVYCNC Water Cutting Vs Laser Cutting While waterjet and laser cutting are both relatively environmentally friendly technologies, waterjet cutting uses more raw materials (abrasive, water). Laser cutting vs waterjet cutting: The process is relatively quiet. Generates vapors that need to be extracted. The minimum size of the cutting slit is 0.006’’ (0.15 mm) for laser cutting. This question comes up a lot among industrial professionals before. Water Cutting Vs Laser Cutting.

From laserengravingservice.co.uk

Water Jet Cutting vs Laser Cutting — Laser Engraving Service Water Cutting Vs Laser Cutting If heat is a concern, especially for sensitive materials, waterjet cutting’s cold process is advantageous. Waterjet and laser cutting accomplish largely the same results, but in. Waterjet cutting, while precise, is better suited for broader cuts. Laser cutting is much more precise than waterjet cutting. Laser cutting introduces heat, which can sometimes alter the material’s properties or leave burn marks.. Water Cutting Vs Laser Cutting.

From blog.tormach.com

What is the Difference Between Plasma Cutting, Waterjet, and Laser Cutting? Water Cutting Vs Laser Cutting Waterjet cutting, while precise, is better suited for broader cuts. Waterjet and laser cutting accomplish largely the same results, but in. Waterjet cuts thick materials into intricate shapes, while laser cutting meets high precision demands. Laser cutting vs waterjet cutting: Generates vapors that need to be extracted. The process is relatively quiet. While waterjet and laser cutting are both relatively. Water Cutting Vs Laser Cutting.

From jmproto.com

Waterjet cutting vs laser cutting which is better? Jmproto Water Cutting Vs Laser Cutting The process is relatively quiet. Laser cutting is much more precise than waterjet cutting. Waterjet cutting, while precise, is better suited for broader cuts. If heat is a concern, especially for sensitive materials, waterjet cutting’s cold process is advantageous. This question comes up a lot among industrial professionals before they buy a machine to fulfill their needs for cutting materials.. Water Cutting Vs Laser Cutting.

From shengenmfg.com

Laser cutting vs. Water jet cutting Water Cutting Vs Laser Cutting If heat is a concern, especially for sensitive materials, waterjet cutting’s cold process is advantageous. Generates vapors that need to be extracted. Waterjet and laser cutting accomplish largely the same results, but in. Waterjet cuts thick materials into intricate shapes, while laser cutting meets high precision demands. While waterjet and laser cutting are both relatively environmentally friendly technologies, waterjet cutting. Water Cutting Vs Laser Cutting.

From hillsidecustom.com

Laser Cutting Verse Waterjet Cutting Hillside Custom Machine Shop Water Cutting Vs Laser Cutting Waterjet cuts thick materials into intricate shapes, while laser cutting meets high precision demands. Laser cutting vs waterjet cutting: Waterjet cutting, while precise, is better suited for broader cuts. If heat is a concern, especially for sensitive materials, waterjet cutting’s cold process is advantageous. This question comes up a lot among industrial professionals before they buy a machine to fulfill. Water Cutting Vs Laser Cutting.

From cncfirst.com

Waterjet Cutting vs Laser Cutting Which is Right for You? cncfirst Water Cutting Vs Laser Cutting The process is relatively quiet. Waterjet cuts thick materials into intricate shapes, while laser cutting meets high precision demands. Generates vapors that need to be extracted. If heat is a concern, especially for sensitive materials, waterjet cutting’s cold process is advantageous. This question comes up a lot among industrial professionals before they buy a machine to fulfill their needs for. Water Cutting Vs Laser Cutting.

From www.finepart.com

Micro Waterjet vs Laser Cutting A Detailed Comparison Finepart Water Cutting Vs Laser Cutting The process is relatively quiet. Waterjet cutting, while precise, is better suited for broader cuts. Waterjet and laser cutting accomplish largely the same results, but in. Generates vapors that need to be extracted. Waterjet cuts thick materials into intricate shapes, while laser cutting meets high precision demands. If heat is a concern, especially for sensitive materials, waterjet cutting’s cold process. Water Cutting Vs Laser Cutting.

From australianwaterjetcutting.com.au

Cutting with waterjet vs cutting with laser Australian Waterjet Cutting Water Cutting Vs Laser Cutting Generates vapors that need to be extracted. Waterjet cuts thick materials into intricate shapes, while laser cutting meets high precision demands. The minimum size of the cutting slit is 0.006’’ (0.15 mm) for laser cutting. If heat is a concern, especially for sensitive materials, waterjet cutting’s cold process is advantageous. Waterjet cutting, while precise, is better suited for broader cuts.. Water Cutting Vs Laser Cutting.

From www.thunderlaserusa.com

A Comprehensive Guide to Laser Cutting vs Water Jet Cutting Water Cutting Vs Laser Cutting Laser cutting vs waterjet cutting: Generates vapors that need to be extracted. Laser cutting is much more precise than waterjet cutting. Waterjet cuts thick materials into intricate shapes, while laser cutting meets high precision demands. While waterjet and laser cutting are both relatively environmentally friendly technologies, waterjet cutting uses more raw materials (abrasive, water). Laser cutting introduces heat, which can. Water Cutting Vs Laser Cutting.

From www.paperflodesigns.com

Laser Cutting vs Water Jet 10 Tips to Start Your Craft Business Water Cutting Vs Laser Cutting Laser cutting is much more precise than waterjet cutting. Waterjet cutting, while precise, is better suited for broader cuts. While waterjet and laser cutting are both relatively environmentally friendly technologies, waterjet cutting uses more raw materials (abrasive, water). If heat is a concern, especially for sensitive materials, waterjet cutting’s cold process is advantageous. Waterjet cuts thick materials into intricate shapes,. Water Cutting Vs Laser Cutting.

From www.longshengmfg.com

Compare Laser Cutting vs. Water Cutting vs. Plasma Cutting vs. Wire Water Cutting Vs Laser Cutting While waterjet and laser cutting are both relatively environmentally friendly technologies, waterjet cutting uses more raw materials (abrasive, water). Laser cutting introduces heat, which can sometimes alter the material’s properties or leave burn marks. Generates vapors that need to be extracted. If heat is a concern, especially for sensitive materials, waterjet cutting’s cold process is advantageous. This question comes up. Water Cutting Vs Laser Cutting.

From www.vrogue.co

Die Cut Vs Laser Cut What Makes The Difference vrogue.co Water Cutting Vs Laser Cutting Generates vapors that need to be extracted. Laser cutting is much more precise than waterjet cutting. Waterjet cutting, while precise, is better suited for broader cuts. Waterjet and laser cutting accomplish largely the same results, but in. This question comes up a lot among industrial professionals before they buy a machine to fulfill their needs for cutting materials. Laser cutting. Water Cutting Vs Laser Cutting.

From www.linkedin.com

Waterjet Cutting Vs. Laser Cutting. Who’s the Winner? Water Cutting Vs Laser Cutting Laser cutting vs waterjet cutting: Laser cutting is much more precise than waterjet cutting. This question comes up a lot among industrial professionals before they buy a machine to fulfill their needs for cutting materials. If heat is a concern, especially for sensitive materials, waterjet cutting’s cold process is advantageous. Waterjet and laser cutting accomplish largely the same results, but. Water Cutting Vs Laser Cutting.

From laserengravingservice.co.uk

Water Jet Cutting vs Laser Cutting — Laser Engraving Service Water Cutting Vs Laser Cutting This question comes up a lot among industrial professionals before they buy a machine to fulfill their needs for cutting materials. If heat is a concern, especially for sensitive materials, waterjet cutting’s cold process is advantageous. The process is relatively quiet. Waterjet cuts thick materials into intricate shapes, while laser cutting meets high precision demands. The minimum size of the. Water Cutting Vs Laser Cutting.

From mac-tech.com

Waterjet Cutting vs. Laser Cutting A Detailed Comparison Water Cutting Vs Laser Cutting Generates vapors that need to be extracted. Laser cutting vs waterjet cutting: If heat is a concern, especially for sensitive materials, waterjet cutting’s cold process is advantageous. Waterjet and laser cutting accomplish largely the same results, but in. The minimum size of the cutting slit is 0.006’’ (0.15 mm) for laser cutting. This question comes up a lot among industrial. Water Cutting Vs Laser Cutting.

From proleantech.com

Laser Cutting Vs. Waterjet Cutting Comparing Capabilities Water Cutting Vs Laser Cutting Waterjet cuts thick materials into intricate shapes, while laser cutting meets high precision demands. Generates vapors that need to be extracted. This question comes up a lot among industrial professionals before they buy a machine to fulfill their needs for cutting materials. The minimum size of the cutting slit is 0.006’’ (0.15 mm) for laser cutting. While waterjet and laser. Water Cutting Vs Laser Cutting.

From leadrp.net

Metal Laser Cutting Basics And How Does It Work LEADRP Rapid Water Cutting Vs Laser Cutting This question comes up a lot among industrial professionals before they buy a machine to fulfill their needs for cutting materials. Waterjet and laser cutting accomplish largely the same results, but in. Laser cutting introduces heat, which can sometimes alter the material’s properties or leave burn marks. If heat is a concern, especially for sensitive materials, waterjet cutting’s cold process. Water Cutting Vs Laser Cutting.

From staubinc.com

Water Jet Cutting vs. Laser Cutting for Manufacturing Staub Water Cutting Vs Laser Cutting The minimum size of the cutting slit is 0.006’’ (0.15 mm) for laser cutting. The process is relatively quiet. Laser cutting introduces heat, which can sometimes alter the material’s properties or leave burn marks. This question comes up a lot among industrial professionals before they buy a machine to fulfill their needs for cutting materials. Waterjet and laser cutting accomplish. Water Cutting Vs Laser Cutting.