Braze Welding Lap Joint . We’ve said that a brazed joint “makes itself”—or that capillary action, more than. A range of joint configurations can be used,. Brazing depends on what is happening inside the joint, not on the outside. The two most common joints are the butt and the lap. The joints described in this document cover the majority of field based brazed or silver soldered lap joints, copper to copper or copper to steel or brass. Ensure the surfaces to be welded are metallically clean, while taking care to not damage any coating. The rest are essentially modifications of these. What type of brazed joint should you design? Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature.

from engineeringlearn.com

The rest are essentially modifications of these. Brazing depends on what is happening inside the joint, not on the outside. The joints described in this document cover the majority of field based brazed or silver soldered lap joints, copper to copper or copper to steel or brass. We’ve said that a brazed joint “makes itself”—or that capillary action, more than. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. The two most common joints are the butt and the lap. A range of joint configurations can be used,. Ensure the surfaces to be welded are metallically clean, while taking care to not damage any coating. What type of brazed joint should you design?

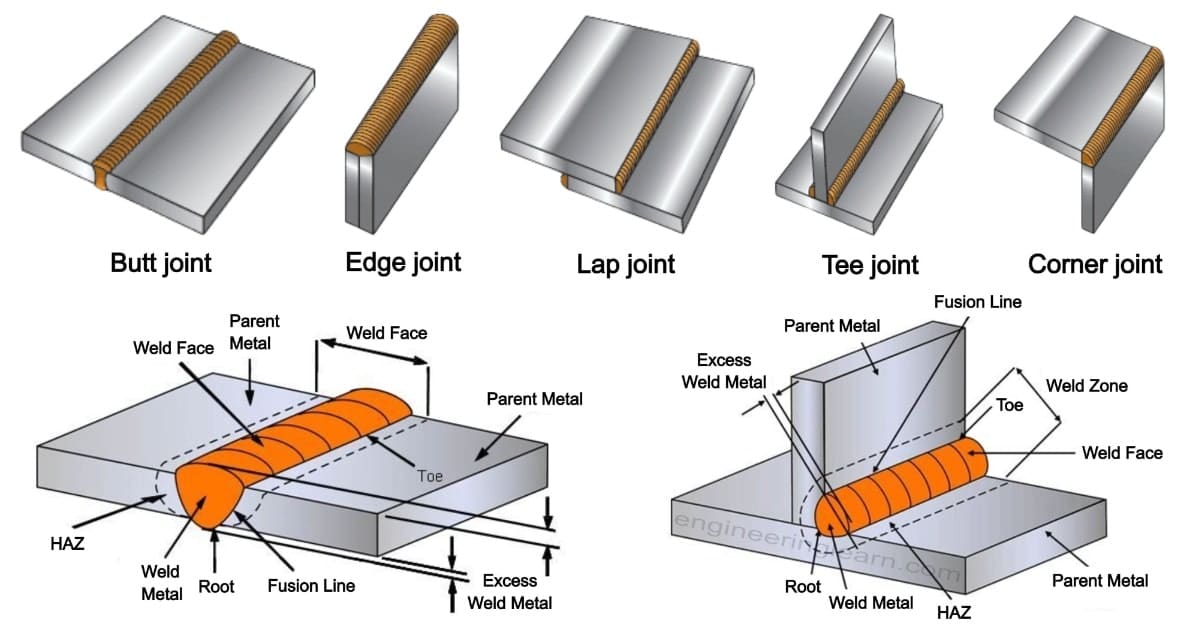

Type of Welding Joints Applications, Advantages & Disadvantages

Braze Welding Lap Joint A range of joint configurations can be used,. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. The rest are essentially modifications of these. Ensure the surfaces to be welded are metallically clean, while taking care to not damage any coating. Brazing depends on what is happening inside the joint, not on the outside. We’ve said that a brazed joint “makes itself”—or that capillary action, more than. The two most common joints are the butt and the lap. A range of joint configurations can be used,. The joints described in this document cover the majority of field based brazed or silver soldered lap joints, copper to copper or copper to steel or brass. What type of brazed joint should you design?

From www.nwpipe.com

Joint Detail Bell and Spigot Lap Weld Joint Northwest Pipe Company Braze Welding Lap Joint A range of joint configurations can be used,. We’ve said that a brazed joint “makes itself”—or that capillary action, more than. The joints described in this document cover the majority of field based brazed or silver soldered lap joints, copper to copper or copper to steel or brass. Ensure the surfaces to be welded are metallically clean, while taking care. Braze Welding Lap Joint.

From www.researchgate.net

(PDF) A Study of Susceptibility and Evaluation of Causes of Cracks Braze Welding Lap Joint Ensure the surfaces to be welded are metallically clean, while taking care to not damage any coating. Brazing depends on what is happening inside the joint, not on the outside. The rest are essentially modifications of these. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. What type of brazed joint should you. Braze Welding Lap Joint.

From ultraflexpower.com

Induction Braze Copper and Brass Lap Joint Applications Braze Welding Lap Joint A range of joint configurations can be used,. The rest are essentially modifications of these. Ensure the surfaces to be welded are metallically clean, while taking care to not damage any coating. What type of brazed joint should you design? We’ve said that a brazed joint “makes itself”—or that capillary action, more than. The joints described in this document cover. Braze Welding Lap Joint.

From www.youtube.com

How to braze copper coppercopper joint YouTube Braze Welding Lap Joint The rest are essentially modifications of these. We’ve said that a brazed joint “makes itself”—or that capillary action, more than. Brazing depends on what is happening inside the joint, not on the outside. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. The joints described in this document cover the majority of field. Braze Welding Lap Joint.

From www.youtube.com

Symbols Used for WELDING, BRAZING & SOLDERING JOINTS in Engineering Braze Welding Lap Joint A range of joint configurations can be used,. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. The rest are essentially modifications of these. The two most common joints are the butt and the lap. What type of brazed joint should you design? The joints described in this document cover the majority of. Braze Welding Lap Joint.

From openoregon.pressbooks.pub

Joint types and Terminology Interpretation of Metal Fab Drawings Braze Welding Lap Joint What type of brazed joint should you design? The rest are essentially modifications of these. Ensure the surfaces to be welded are metallically clean, while taking care to not damage any coating. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. The two most common joints are the butt and the lap. We’ve. Braze Welding Lap Joint.

From weldinguru.com

Types of Welding Joints Butt, Tee, Corner, Lap & More! Braze Welding Lap Joint A range of joint configurations can be used,. What type of brazed joint should you design? The joints described in this document cover the majority of field based brazed or silver soldered lap joints, copper to copper or copper to steel or brass. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. The. Braze Welding Lap Joint.

From blog.thepipingmart.com

What is Lap Joint Welds? Uses and Working Braze Welding Lap Joint What type of brazed joint should you design? The rest are essentially modifications of these. A range of joint configurations can be used,. Ensure the surfaces to be welded are metallically clean, while taking care to not damage any coating. Brazing depends on what is happening inside the joint, not on the outside. The joints described in this document cover. Braze Welding Lap Joint.

From eziil.com

Welding Joint Types Butt, T, Edge, Lap, Corner Braze Welding Lap Joint The rest are essentially modifications of these. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. We’ve said that a brazed joint “makes itself”—or that capillary action, more than. Brazing depends on what is happening inside the joint, not on the outside. What type of brazed joint should you design? A range of. Braze Welding Lap Joint.

From www.weldingtipsandtricks.com

Tig Welding Carbon Steel lap joints Braze Welding Lap Joint Ensure the surfaces to be welded are metallically clean, while taking care to not damage any coating. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. The joints described in this document cover the majority of field based brazed or silver soldered lap joints, copper to copper or copper to steel or brass.. Braze Welding Lap Joint.

From blog.thepipingmart.com

Advantages and Disadvantages of Lap Joint Welds Braze Welding Lap Joint The two most common joints are the butt and the lap. We’ve said that a brazed joint “makes itself”—or that capillary action, more than. Brazing depends on what is happening inside the joint, not on the outside. The joints described in this document cover the majority of field based brazed or silver soldered lap joints, copper to copper or copper. Braze Welding Lap Joint.

From engineeringlearn.com

Type of Welding Joints Applications, Advantages & Disadvantages Braze Welding Lap Joint The two most common joints are the butt and the lap. A range of joint configurations can be used,. What type of brazed joint should you design? The rest are essentially modifications of these. We’ve said that a brazed joint “makes itself”—or that capillary action, more than. The joints described in this document cover the majority of field based brazed. Braze Welding Lap Joint.

From www.kaybrazing.com

Braze Joint Design Considerations Braze Welding Lap Joint The rest are essentially modifications of these. The two most common joints are the butt and the lap. What type of brazed joint should you design? Ensure the surfaces to be welded are metallically clean, while taking care to not damage any coating. We’ve said that a brazed joint “makes itself”—or that capillary action, more than. Brazing depends on what. Braze Welding Lap Joint.

From www.researchgate.net

Schematic diagram and images for brazed joints 1 and 1′parent Braze Welding Lap Joint We’ve said that a brazed joint “makes itself”—or that capillary action, more than. A range of joint configurations can be used,. What type of brazed joint should you design? Ensure the surfaces to be welded are metallically clean, while taking care to not damage any coating. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively. Braze Welding Lap Joint.

From welderslab.com

What Are the 5 Basic Types of Welding Joints A Beginner's Guide Braze Welding Lap Joint The joints described in this document cover the majority of field based brazed or silver soldered lap joints, copper to copper or copper to steel or brass. What type of brazed joint should you design? The two most common joints are the butt and the lap. Brazing depends on what is happening inside the joint, not on the outside. Brazing. Braze Welding Lap Joint.

From www.slideshare.net

Brazing Braze Welding Lap Joint Ensure the surfaces to be welded are metallically clean, while taking care to not damage any coating. We’ve said that a brazed joint “makes itself”—or that capillary action, more than. The two most common joints are the butt and the lap. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. What type of. Braze Welding Lap Joint.

From www.youtube.com

7 ways to weld lap joint / Tig welding stainless steel pad YouTube Braze Welding Lap Joint The joints described in this document cover the majority of field based brazed or silver soldered lap joints, copper to copper or copper to steel or brass. The two most common joints are the butt and the lap. A range of joint configurations can be used,. Brazing depends on what is happening inside the joint, not on the outside. What. Braze Welding Lap Joint.

From www.researchgate.net

(PDF) A study of tensile strength of MIG weldingbrazing dissimilar lap Braze Welding Lap Joint What type of brazed joint should you design? Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. The two most common joints are the butt and the lap. Ensure the surfaces to be welded are metallically clean, while taking care to not damage any coating. We’ve said that a brazed joint “makes itself”—or. Braze Welding Lap Joint.

From www.trupply.com

Lap Joint Stub End Butt Weld Fitting SS304 Welded Domestic Braze Welding Lap Joint The two most common joints are the butt and the lap. Brazing depends on what is happening inside the joint, not on the outside. What type of brazed joint should you design? We’ve said that a brazed joint “makes itself”—or that capillary action, more than. Ensure the surfaces to be welded are metallically clean, while taking care to not damage. Braze Welding Lap Joint.

From www.pinterest.co.uk

Welding Symbols Chart in 2020 Welding, Symbols, Welding projects Braze Welding Lap Joint Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. Brazing depends on what is happening inside the joint, not on the outside. The joints described in this document cover the majority of field based brazed or silver soldered lap joints, copper to copper or copper to steel or brass. What type of brazed. Braze Welding Lap Joint.

From www.researchgate.net

FilletWelded Lap Joint Behavior. Download Scientific Diagram Braze Welding Lap Joint The rest are essentially modifications of these. What type of brazed joint should you design? Brazing depends on what is happening inside the joint, not on the outside. A range of joint configurations can be used,. The two most common joints are the butt and the lap. Brazing is ideally suited for joining of dissimilar metals and is performed at. Braze Welding Lap Joint.

From www.mig-welding.co.uk

TIG Tutorial Lap Joints Braze Welding Lap Joint A range of joint configurations can be used,. The two most common joints are the butt and the lap. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. What type of brazed joint should you design? Ensure the surfaces to be welded are metallically clean, while taking care to not damage any coating.. Braze Welding Lap Joint.

From shahab-co.com

What is Induction brazing Brazing uses heat and a filler metal (alloy Braze Welding Lap Joint Brazing depends on what is happening inside the joint, not on the outside. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. The rest are essentially modifications of these. We’ve said that a brazed joint “makes itself”—or that capillary action, more than. A range of joint configurations can be used,. Ensure the surfaces. Braze Welding Lap Joint.

From tropicalcyclocross.com

Welding Joints Types Braze Welding Lap Joint The two most common joints are the butt and the lap. What type of brazed joint should you design? Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. The joints described in this document cover the majority of field based brazed or silver soldered lap joints, copper to copper or copper to steel. Braze Welding Lap Joint.

From engineersblog.net

What is Convex Fillet Joint? Explain in details step by step procedure Braze Welding Lap Joint What type of brazed joint should you design? Ensure the surfaces to be welded are metallically clean, while taking care to not damage any coating. A range of joint configurations can be used,. The joints described in this document cover the majority of field based brazed or silver soldered lap joints, copper to copper or copper to steel or brass.. Braze Welding Lap Joint.

From slideplayer.com

Teknologi Dan Rekayasa ppt download Braze Welding Lap Joint Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. Ensure the surfaces to be welded are metallically clean, while taking care to not damage any coating. The rest are essentially modifications of these. What type of brazed joint should you design? The two most common joints are the butt and the lap. Brazing. Braze Welding Lap Joint.

From www.reddit.com

First lap joint, any tips? r/Welding Braze Welding Lap Joint Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. Ensure the surfaces to be welded are metallically clean, while taking care to not damage any coating. Brazing depends on what is happening inside the joint, not on the outside. The two most common joints are the butt and the lap. We’ve said that. Braze Welding Lap Joint.

From eziil.com

8 Welding Defects To Look Out For! (Detailed Images) Braze Welding Lap Joint The joints described in this document cover the majority of field based brazed or silver soldered lap joints, copper to copper or copper to steel or brass. We’ve said that a brazed joint “makes itself”—or that capillary action, more than. Brazing depends on what is happening inside the joint, not on the outside. The two most common joints are the. Braze Welding Lap Joint.

From inductionheat.wordpress.com

Induction Brazing Copper Lap Joints A Reliable and Efficient Joining Braze Welding Lap Joint The two most common joints are the butt and the lap. The joints described in this document cover the majority of field based brazed or silver soldered lap joints, copper to copper or copper to steel or brass. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. We’ve said that a brazed joint. Braze Welding Lap Joint.

From ar.inspiredpencil.com

Fillet Weld Failure Braze Welding Lap Joint Brazing depends on what is happening inside the joint, not on the outside. A range of joint configurations can be used,. The joints described in this document cover the majority of field based brazed or silver soldered lap joints, copper to copper or copper to steel or brass. What type of brazed joint should you design? Brazing is ideally suited. Braze Welding Lap Joint.

From tigbrush.com

Various Types of Welding Joints and Their Uses TIG Brush Braze Welding Lap Joint The joints described in this document cover the majority of field based brazed or silver soldered lap joints, copper to copper or copper to steel or brass. The rest are essentially modifications of these. Brazing depends on what is happening inside the joint, not on the outside. What type of brazed joint should you design? A range of joint configurations. Braze Welding Lap Joint.

From waterwelders.com

What is Braze Welding? How Does It Work? A Complete Guide WaterWelders Braze Welding Lap Joint We’ve said that a brazed joint “makes itself”—or that capillary action, more than. The two most common joints are the butt and the lap. A range of joint configurations can be used,. The joints described in this document cover the majority of field based brazed or silver soldered lap joints, copper to copper or copper to steel or brass. The. Braze Welding Lap Joint.

From www.youtube.com

TIG Welding Sheet Metal Lap Joints YouTube Braze Welding Lap Joint We’ve said that a brazed joint “makes itself”—or that capillary action, more than. The two most common joints are the butt and the lap. The rest are essentially modifications of these. Ensure the surfaces to be welded are metallically clean, while taking care to not damage any coating. Brazing depends on what is happening inside the joint, not on the. Braze Welding Lap Joint.

From www.onestopndt.com

An ultimate Guide to Weld Joints OnestopNDT Braze Welding Lap Joint The joints described in this document cover the majority of field based brazed or silver soldered lap joints, copper to copper or copper to steel or brass. The two most common joints are the butt and the lap. Ensure the surfaces to be welded are metallically clean, while taking care to not damage any coating. Brazing is ideally suited for. Braze Welding Lap Joint.

From rickyswelding.com

What Are Some Common Welding Mistakes And How To Avoid Them? Ricky's Braze Welding Lap Joint Ensure the surfaces to be welded are metallically clean, while taking care to not damage any coating. A range of joint configurations can be used,. The two most common joints are the butt and the lap. What type of brazed joint should you design? The rest are essentially modifications of these. Brazing depends on what is happening inside the joint,. Braze Welding Lap Joint.