Welding Nozzle Tip . Learn about torch cutting tips here. Mig welding nozzles are essential components in the mig welding process, playing a crucial role in ensuring the quality and consistency of welds. Mig gun nozzles and contact tips are two consumables that play important roles in the mig welding process. Tapered nozzles provide precise gas flow, cylindrical nozzles. This shielding gas, typically a. Some of that preference is driven by application. The welding nozzle you choose should have the correct tip placement for the welding mode of your application. There are four common types of mig welding nozzles: You can get flush, recessed, or protruding nozzles—which determine how far out (or in) the tip sticks—or even adjustable nozzles. Two rivers marketing for bernard/tregaskiss. Tapered, cylindrical, conical, and recessed. Welding or cutting torch tips are where the action is so understanding torch tip design and function is vital for welders. The primary purpose of mig welding nozzles is to direct shielding gas flow onto the weld zone.

from www.grainger.com

Mig gun nozzles and contact tips are two consumables that play important roles in the mig welding process. There are four common types of mig welding nozzles: Welding or cutting torch tips are where the action is so understanding torch tip design and function is vital for welders. Two rivers marketing for bernard/tregaskiss. Learn about torch cutting tips here. Tapered nozzles provide precise gas flow, cylindrical nozzles. Mig welding nozzles are essential components in the mig welding process, playing a crucial role in ensuring the quality and consistency of welds. The primary purpose of mig welding nozzles is to direct shielding gas flow onto the weld zone. Tapered, cylindrical, conical, and recessed. You can get flush, recessed, or protruding nozzles—which determine how far out (or in) the tip sticks—or even adjustable nozzles.

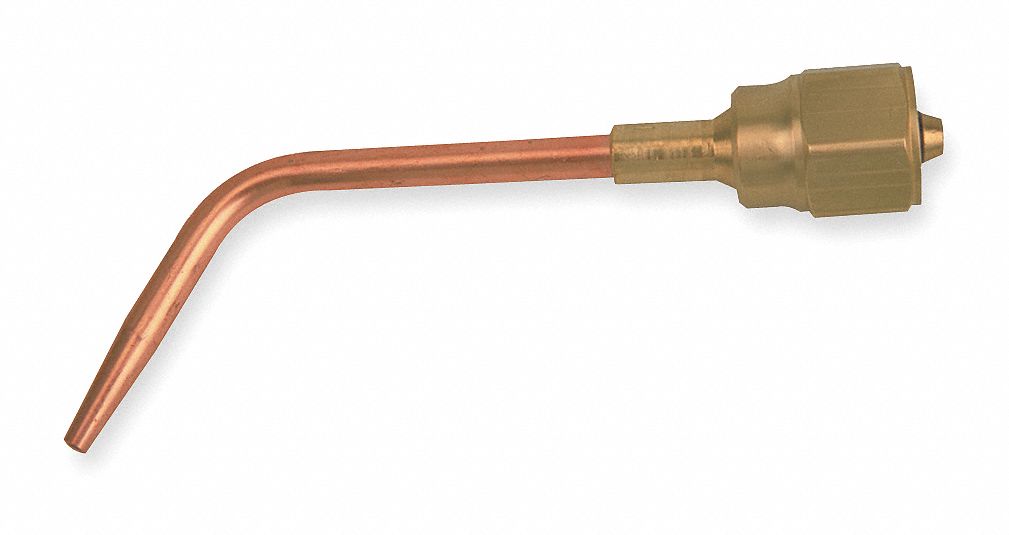

VICTOR Welding Nozzle, W, 0 Tip Size, Oxygen and Acetylene Gas Service

Welding Nozzle Tip The primary purpose of mig welding nozzles is to direct shielding gas flow onto the weld zone. You can get flush, recessed, or protruding nozzles—which determine how far out (or in) the tip sticks—or even adjustable nozzles. Mig gun nozzles and contact tips are two consumables that play important roles in the mig welding process. The primary purpose of mig welding nozzles is to direct shielding gas flow onto the weld zone. Some of that preference is driven by application. Welding or cutting torch tips are where the action is so understanding torch tip design and function is vital for welders. There are four common types of mig welding nozzles: Tapered nozzles provide precise gas flow, cylindrical nozzles. Learn about torch cutting tips here. This shielding gas, typically a. Two rivers marketing for bernard/tregaskiss. Mig welding nozzles are essential components in the mig welding process, playing a crucial role in ensuring the quality and consistency of welds. The welding nozzle you choose should have the correct tip placement for the welding mode of your application. Tapered, cylindrical, conical, and recessed.

From kelly-huang71.en.made-in-china.com

High Quality CO2 Welding Nozzle / Welding Tip for Panasonic Welding Welding Nozzle Tip The primary purpose of mig welding nozzles is to direct shielding gas flow onto the weld zone. You can get flush, recessed, or protruding nozzles—which determine how far out (or in) the tip sticks—or even adjustable nozzles. Welding or cutting torch tips are where the action is so understanding torch tip design and function is vital for welders. Tapered nozzles. Welding Nozzle Tip.

From www.altparts.mx

6 mm Twopoint Welding Nozzle Tip Welding Nozzle Tip Mig gun nozzles and contact tips are two consumables that play important roles in the mig welding process. Some of that preference is driven by application. Tapered, cylindrical, conical, and recessed. Welding or cutting torch tips are where the action is so understanding torch tip design and function is vital for welders. Mig welding nozzles are essential components in the. Welding Nozzle Tip.

From welderslab.com

Best Welding Nozzle Tip Dip A Complete Buyer’s Guide Welders Lab Welding Nozzle Tip Mig welding nozzles are essential components in the mig welding process, playing a crucial role in ensuring the quality and consistency of welds. The primary purpose of mig welding nozzles is to direct shielding gas flow onto the weld zone. Some of that preference is driven by application. This shielding gas, typically a. There are four common types of mig. Welding Nozzle Tip.

From shop.ipgphotonics.com

6 mm Twopoint Welding Nozzle Tip IPG Photonics Shop Welding Nozzle Tip Learn about torch cutting tips here. You can get flush, recessed, or protruding nozzles—which determine how far out (or in) the tip sticks—or even adjustable nozzles. Mig welding nozzles are essential components in the mig welding process, playing a crucial role in ensuring the quality and consistency of welds. This shielding gas, typically a. Tapered, cylindrical, conical, and recessed. The. Welding Nozzle Tip.

From www.materialalloy.com

CO2 MIG Welding Materials Nozzle Welding Torch Contact Tip / Welding Welding Nozzle Tip Tapered nozzles provide precise gas flow, cylindrical nozzles. Learn about torch cutting tips here. Tapered, cylindrical, conical, and recessed. You can get flush, recessed, or protruding nozzles—which determine how far out (or in) the tip sticks—or even adjustable nozzles. There are four common types of mig welding nozzles: This shielding gas, typically a. Welding or cutting torch tips are where. Welding Nozzle Tip.

From blog.binzel-abicor.com

Understanding MIG Welding Nozzles Welding Nozzle Tip Welding or cutting torch tips are where the action is so understanding torch tip design and function is vital for welders. Tapered nozzles provide precise gas flow, cylindrical nozzles. Mig gun nozzles and contact tips are two consumables that play important roles in the mig welding process. You can get flush, recessed, or protruding nozzles—which determine how far out (or. Welding Nozzle Tip.

From www.ebay.com

WeldingCity Acetylene Welding Nozzle Heating Tip 00W1 00 Victor 100 Welding Nozzle Tip This shielding gas, typically a. Welding or cutting torch tips are where the action is so understanding torch tip design and function is vital for welders. The welding nozzle you choose should have the correct tip placement for the welding mode of your application. Two rivers marketing for bernard/tregaskiss. There are four common types of mig welding nozzles: Learn about. Welding Nozzle Tip.

From www.alibaba.com

Tig Ceramic Welding Tip 13n Series Tig Ceramic Nozzle Buy Tig Welding Welding Nozzle Tip Mig welding nozzles are essential components in the mig welding process, playing a crucial role in ensuring the quality and consistency of welds. The primary purpose of mig welding nozzles is to direct shielding gas flow onto the weld zone. Tapered nozzles provide precise gas flow, cylindrical nozzles. Learn about torch cutting tips here. Tapered, cylindrical, conical, and recessed. You. Welding Nozzle Tip.

From www.grainger.com

VICTOR Welding Nozzle, RTE, 2 Tip Size, Acetylene, Hydrogen Gas Service Welding Nozzle Tip Mig gun nozzles and contact tips are two consumables that play important roles in the mig welding process. Tapered nozzles provide precise gas flow, cylindrical nozzles. Tapered, cylindrical, conical, and recessed. Welding or cutting torch tips are where the action is so understanding torch tip design and function is vital for welders. This shielding gas, typically a. Learn about torch. Welding Nozzle Tip.

From www.weldingcity.com

WeldingCity® 4W Size4 Victor® Style Acetylene Welding Nozzle Tip Welding Nozzle Tip Mig welding nozzles are essential components in the mig welding process, playing a crucial role in ensuring the quality and consistency of welds. Two rivers marketing for bernard/tregaskiss. The welding nozzle you choose should have the correct tip placement for the welding mode of your application. Mig gun nozzles and contact tips are two consumables that play important roles in. Welding Nozzle Tip.

From www.amazon.in

Buy 11pcs/Set MIG Welding Nozzle Welder Torch Nozzles Gold Tip Holder Welding Nozzle Tip There are four common types of mig welding nozzles: Two rivers marketing for bernard/tregaskiss. Learn about torch cutting tips here. Tapered, cylindrical, conical, and recessed. Mig gun nozzles and contact tips are two consumables that play important roles in the mig welding process. This shielding gas, typically a. Tapered nozzles provide precise gas flow, cylindrical nozzles. Some of that preference. Welding Nozzle Tip.

From www.aliexpress.com

15AK Gas Nozzle 10pcs MIG Welding Torch Gas Nozzle Contact Tip for MIG Welding Nozzle Tip Welding or cutting torch tips are where the action is so understanding torch tip design and function is vital for welders. Mig welding nozzles are essential components in the mig welding process, playing a crucial role in ensuring the quality and consistency of welds. Mig gun nozzles and contact tips are two consumables that play important roles in the mig. Welding Nozzle Tip.

From shopee.com.my

Mig co2 welding MB15 tip holder & nozzle & 0.8mm contact tip Shopee Welding Nozzle Tip Learn about torch cutting tips here. This shielding gas, typically a. Welding or cutting torch tips are where the action is so understanding torch tip design and function is vital for welders. Two rivers marketing for bernard/tregaskiss. You can get flush, recessed, or protruding nozzles—which determine how far out (or in) the tip sticks—or even adjustable nozzles. The welding nozzle. Welding Nozzle Tip.

From www.walmart.com

Welding Nozzle Mouth Tips, Flat Wide Mouth Nozzle Heat Resistance For Welding Nozzle Tip Tapered, cylindrical, conical, and recessed. Mig gun nozzles and contact tips are two consumables that play important roles in the mig welding process. Learn about torch cutting tips here. Mig welding nozzles are essential components in the mig welding process, playing a crucial role in ensuring the quality and consistency of welds. This shielding gas, typically a. The welding nozzle. Welding Nozzle Tip.

From www.northerntool.com

Please see replacement item 48327. Northern Industrial Welders Tweco Welding Nozzle Tip The welding nozzle you choose should have the correct tip placement for the welding mode of your application. This shielding gas, typically a. The primary purpose of mig welding nozzles is to direct shielding gas flow onto the weld zone. You can get flush, recessed, or protruding nozzles—which determine how far out (or in) the tip sticks—or even adjustable nozzles.. Welding Nozzle Tip.

From advancedweldingsupplies.com

Model O Welding Nozzle Tip Advanced Welding Supplies Welding Nozzle Tip Tapered nozzles provide precise gas flow, cylindrical nozzles. Mig gun nozzles and contact tips are two consumables that play important roles in the mig welding process. Mig welding nozzles are essential components in the mig welding process, playing a crucial role in ensuring the quality and consistency of welds. Two rivers marketing for bernard/tregaskiss. Some of that preference is driven. Welding Nozzle Tip.

From www.grainger.com

VICTOR Welding Nozzle, W, 0 Tip Size, Oxygen and Acetylene Gas Service Welding Nozzle Tip The primary purpose of mig welding nozzles is to direct shielding gas flow onto the weld zone. Learn about torch cutting tips here. Some of that preference is driven by application. The welding nozzle you choose should have the correct tip placement for the welding mode of your application. Mig gun nozzles and contact tips are two consumables that play. Welding Nozzle Tip.

From www.pinterest.com

Favorite TIG Nozzles Nozzles, Tig welding, Welding Welding Nozzle Tip Tapered nozzles provide precise gas flow, cylindrical nozzles. You can get flush, recessed, or protruding nozzles—which determine how far out (or in) the tip sticks—or even adjustable nozzles. Two rivers marketing for bernard/tregaskiss. The primary purpose of mig welding nozzles is to direct shielding gas flow onto the weld zone. Mig welding nozzles are essential components in the mig welding. Welding Nozzle Tip.

From www.weldingcity.com

WeldingCity® 1W1 Size1 Victor® Style Acetylene Welding Nozzle Tip Welding Nozzle Tip The primary purpose of mig welding nozzles is to direct shielding gas flow onto the weld zone. Mig gun nozzles and contact tips are two consumables that play important roles in the mig welding process. Tapered, cylindrical, conical, and recessed. Learn about torch cutting tips here. This shielding gas, typically a. Tapered nozzles provide precise gas flow, cylindrical nozzles. Two. Welding Nozzle Tip.

From advancedweldingsupplies.com

Model O Welding Nozzle Tip Advanced Welding Supplies Welding Nozzle Tip Tapered nozzles provide precise gas flow, cylindrical nozzles. Learn about torch cutting tips here. Tapered, cylindrical, conical, and recessed. The welding nozzle you choose should have the correct tip placement for the welding mode of your application. There are four common types of mig welding nozzles: Some of that preference is driven by application. Mig gun nozzles and contact tips. Welding Nozzle Tip.

From weldingtorchapes.com

Welding Nozzle Tip 24A50 Tweco Lincoln 1/2" Slip on MIG Welding Nozzles Welding Nozzle Tip Some of that preference is driven by application. Two rivers marketing for bernard/tregaskiss. The welding nozzle you choose should have the correct tip placement for the welding mode of your application. Tapered, cylindrical, conical, and recessed. The primary purpose of mig welding nozzles is to direct shielding gas flow onto the weld zone. Mig gun nozzles and contact tips are. Welding Nozzle Tip.

From weldingtorchapes.com

Welding Nozzle Tip 24A50 Tweco Lincoln 1/2" Slip on MIG Welding Nozzles Welding Nozzle Tip The welding nozzle you choose should have the correct tip placement for the welding mode of your application. Learn about torch cutting tips here. Some of that preference is driven by application. You can get flush, recessed, or protruding nozzles—which determine how far out (or in) the tip sticks—or even adjustable nozzles. Two rivers marketing for bernard/tregaskiss. The primary purpose. Welding Nozzle Tip.

From www.altparts.com

Copper Welding Nozzle Tip Kit, IPG CDSBME000089XXXU Alternative Welding Nozzle Tip Tapered, cylindrical, conical, and recessed. This shielding gas, typically a. Learn about torch cutting tips here. Mig welding nozzles are essential components in the mig welding process, playing a crucial role in ensuring the quality and consistency of welds. Welding or cutting torch tips are where the action is so understanding torch tip design and function is vital for welders.. Welding Nozzle Tip.

From www.walmart.com

(3 PACK) SÜA Welding Nozzle Compatible with 100 Series Victor torch Welding Nozzle Tip This shielding gas, typically a. There are four common types of mig welding nozzles: Tapered, cylindrical, conical, and recessed. You can get flush, recessed, or protruding nozzles—which determine how far out (or in) the tip sticks—or even adjustable nozzles. Welding or cutting torch tips are where the action is so understanding torch tip design and function is vital for welders.. Welding Nozzle Tip.

From leeden.com.my

Victor Type W Series Welding Nozzles Leeden Sdn Bhd (74865K) Welding Nozzle Tip Tapered, cylindrical, conical, and recessed. The primary purpose of mig welding nozzles is to direct shielding gas flow onto the weld zone. Welding or cutting torch tips are where the action is so understanding torch tip design and function is vital for welders. This shielding gas, typically a. Some of that preference is driven by application. You can get flush,. Welding Nozzle Tip.

From www.altparts.com

Singlepoint Welding Nozzle Tip Welding Nozzle Tip Welding or cutting torch tips are where the action is so understanding torch tip design and function is vital for welders. Mig gun nozzles and contact tips are two consumables that play important roles in the mig welding process. The welding nozzle you choose should have the correct tip placement for the welding mode of your application. Mig welding nozzles. Welding Nozzle Tip.

From airwelder.com

How to Select the Welding Nozzle Airwelder Welding Nozzle Tip The primary purpose of mig welding nozzles is to direct shielding gas flow onto the weld zone. The welding nozzle you choose should have the correct tip placement for the welding mode of your application. Mig gun nozzles and contact tips are two consumables that play important roles in the mig welding process. Tapered nozzles provide precise gas flow, cylindrical. Welding Nozzle Tip.

From www.aliexpress.com

11pcs Mayitr MIG Welding Nozzle Durable Welder Torch Nozzles Tip Holder Welding Nozzle Tip Learn about torch cutting tips here. The welding nozzle you choose should have the correct tip placement for the welding mode of your application. Welding or cutting torch tips are where the action is so understanding torch tip design and function is vital for welders. Tapered, cylindrical, conical, and recessed. Tapered nozzles provide precise gas flow, cylindrical nozzles. You can. Welding Nozzle Tip.

From shopee.com.my

16Pcs/Set Mig Welding Nozzle Welder Torch Nozzles Gold Tip Holder Welding Nozzle Tip This shielding gas, typically a. There are four common types of mig welding nozzles: Some of that preference is driven by application. You can get flush, recessed, or protruding nozzles—which determine how far out (or in) the tip sticks—or even adjustable nozzles. The welding nozzle you choose should have the correct tip placement for the welding mode of your application.. Welding Nozzle Tip.

From shop.ipgphotonics.com

Copper Welding Nozzle Tip Kit IPG Photonics Shop Welding Nozzle Tip The primary purpose of mig welding nozzles is to direct shielding gas flow onto the weld zone. The welding nozzle you choose should have the correct tip placement for the welding mode of your application. Tapered, cylindrical, conical, and recessed. Two rivers marketing for bernard/tregaskiss. Mig welding nozzles are essential components in the mig welding process, playing a crucial role. Welding Nozzle Tip.

From bancrofteng.com

How to Choose the Right GMAW Nozzle Bancroft Engineering Welding Nozzle Tip The welding nozzle you choose should have the correct tip placement for the welding mode of your application. Mig gun nozzles and contact tips are two consumables that play important roles in the mig welding process. Some of that preference is driven by application. You can get flush, recessed, or protruding nozzles—which determine how far out (or in) the tip. Welding Nozzle Tip.

From kevmor.com.au

150mm Bent Welding Nozzle Tip Kevmor Trade Supplies Welding Nozzle Tip Two rivers marketing for bernard/tregaskiss. Welding or cutting torch tips are where the action is so understanding torch tip design and function is vital for welders. You can get flush, recessed, or protruding nozzles—which determine how far out (or in) the tip sticks—or even adjustable nozzles. The primary purpose of mig welding nozzles is to direct shielding gas flow onto. Welding Nozzle Tip.

From www.altparts.com

Aluminum 6 mm Twopoint Welding Nozzle Tip Welding Nozzle Tip Two rivers marketing for bernard/tregaskiss. You can get flush, recessed, or protruding nozzles—which determine how far out (or in) the tip sticks—or even adjustable nozzles. Tapered, cylindrical, conical, and recessed. Welding or cutting torch tips are where the action is so understanding torch tip design and function is vital for welders. The welding nozzle you choose should have the correct. Welding Nozzle Tip.

From shop.ipgphotonics.com

Copper Welding Nozzle Tip Kit IPG Photonics Shop Welding Nozzle Tip Welding or cutting torch tips are where the action is so understanding torch tip design and function is vital for welders. Mig gun nozzles and contact tips are two consumables that play important roles in the mig welding process. The primary purpose of mig welding nozzles is to direct shielding gas flow onto the weld zone. You can get flush,. Welding Nozzle Tip.

From www.ebay.com

MIG Welding Gun Kit .030" Heavy Duty TipNozzle for Lincoln 200/250 Welding Nozzle Tip Learn about torch cutting tips here. Welding or cutting torch tips are where the action is so understanding torch tip design and function is vital for welders. Mig welding nozzles are essential components in the mig welding process, playing a crucial role in ensuring the quality and consistency of welds. You can get flush, recessed, or protruding nozzles—which determine how. Welding Nozzle Tip.