Equipment Calibration Guidelines . High pressure areas receive more air input and less air exhaust. This procedure specifies the schedule and requirements for maintenance, performance, calibration, and verification of laboratory testing. Learn what a calibration interval is, variables that affect it, who is responsible for setting it & how to establish one for your measurement equipment. (a) equipment shall be adequately inspected, cleaned, and maintained. A life cycle approach to the calibration and qualication of analytical instruments and systems to establish ″fitness. The first and most crucial goal of calibrating an instrument is ensuring that it takes accurate,. Difference in air pressure between areas should. § 58.63 maintenance and calibration of equipment. Calibration standards used for inspection, measuring, and test equipment shall be.

from www.quality-assurance-solutions.com

A life cycle approach to the calibration and qualication of analytical instruments and systems to establish ″fitness. (a) equipment shall be adequately inspected, cleaned, and maintained. High pressure areas receive more air input and less air exhaust. § 58.63 maintenance and calibration of equipment. Difference in air pressure between areas should. The first and most crucial goal of calibrating an instrument is ensuring that it takes accurate,. Learn what a calibration interval is, variables that affect it, who is responsible for setting it & how to establish one for your measurement equipment. Calibration standards used for inspection, measuring, and test equipment shall be. This procedure specifies the schedule and requirements for maintenance, performance, calibration, and verification of laboratory testing.

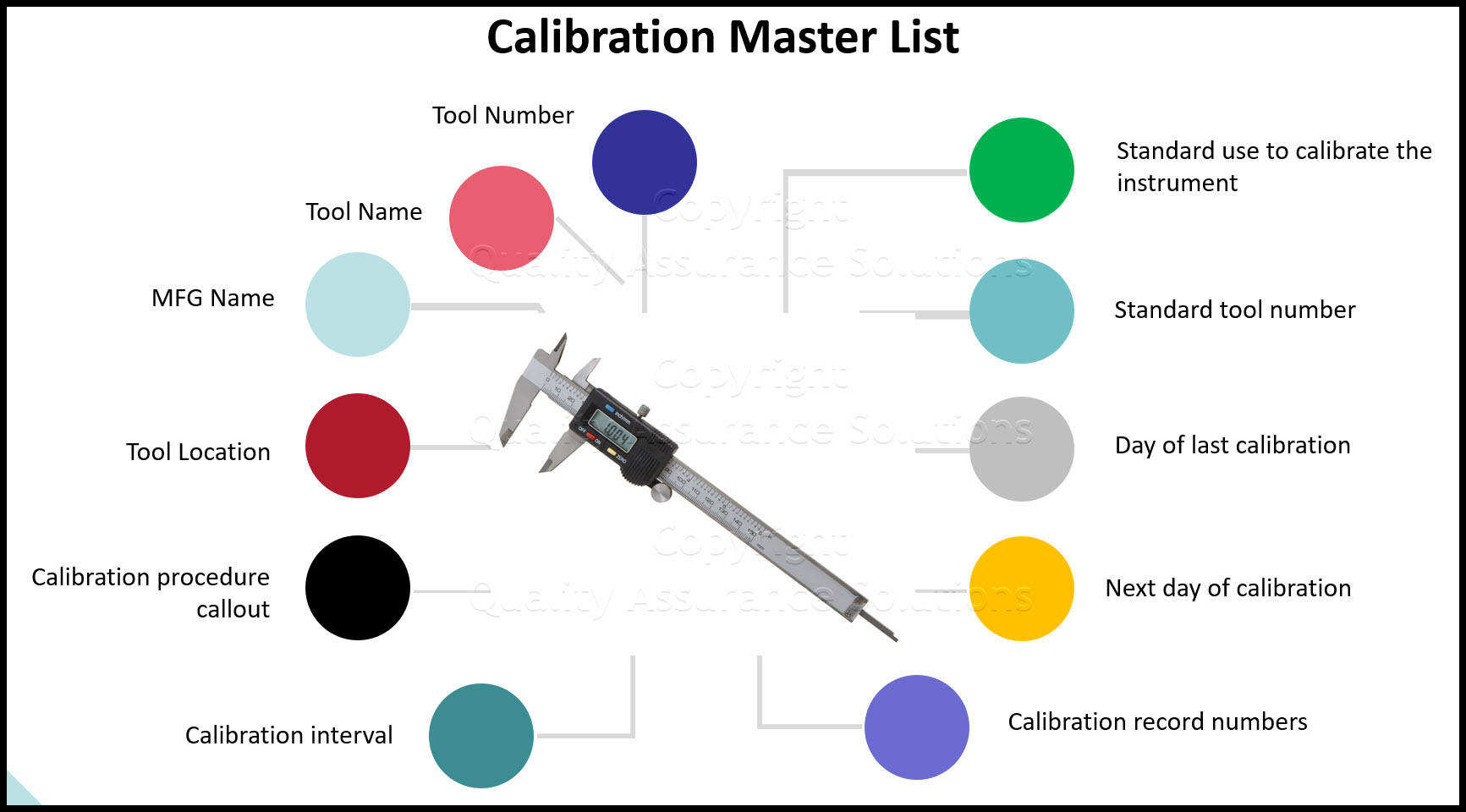

Tool Calibration and Control System

Equipment Calibration Guidelines High pressure areas receive more air input and less air exhaust. High pressure areas receive more air input and less air exhaust. A life cycle approach to the calibration and qualication of analytical instruments and systems to establish ″fitness. Difference in air pressure between areas should. § 58.63 maintenance and calibration of equipment. The first and most crucial goal of calibrating an instrument is ensuring that it takes accurate,. (a) equipment shall be adequately inspected, cleaned, and maintained. Learn what a calibration interval is, variables that affect it, who is responsible for setting it & how to establish one for your measurement equipment. Calibration standards used for inspection, measuring, and test equipment shall be. This procedure specifies the schedule and requirements for maintenance, performance, calibration, and verification of laboratory testing.

From ciqa.net

What is a Calibration Certificate or Calibration Record as per ISO17025? Equipment Calibration Guidelines High pressure areas receive more air input and less air exhaust. § 58.63 maintenance and calibration of equipment. A life cycle approach to the calibration and qualication of analytical instruments and systems to establish ″fitness. (a) equipment shall be adequately inspected, cleaned, and maintained. Calibration standards used for inspection, measuring, and test equipment shall be. Learn what a calibration interval. Equipment Calibration Guidelines.

From www.quality-assurance-solutions.com

Tool Calibration and Control System Equipment Calibration Guidelines (a) equipment shall be adequately inspected, cleaned, and maintained. Difference in air pressure between areas should. The first and most crucial goal of calibrating an instrument is ensuring that it takes accurate,. § 58.63 maintenance and calibration of equipment. High pressure areas receive more air input and less air exhaust. Calibration standards used for inspection, measuring, and test equipment shall. Equipment Calibration Guidelines.

From dokumen.tips

(PDF) UL Calibration Requirements Equipment Used for UL/C · PDF fileUL Calibration Requirements Equipment Calibration Guidelines The first and most crucial goal of calibrating an instrument is ensuring that it takes accurate,. A life cycle approach to the calibration and qualication of analytical instruments and systems to establish ″fitness. Learn what a calibration interval is, variables that affect it, who is responsible for setting it & how to establish one for your measurement equipment. § 58.63. Equipment Calibration Guidelines.

From gambia.desertcart.com

Buy Self Laminating Calibration Labels 1x2 Inch Writeon Calibration Stickers with Spiral Bound Equipment Calibration Guidelines High pressure areas receive more air input and less air exhaust. Difference in air pressure between areas should. This procedure specifies the schedule and requirements for maintenance, performance, calibration, and verification of laboratory testing. The first and most crucial goal of calibrating an instrument is ensuring that it takes accurate,. § 58.63 maintenance and calibration of equipment. Calibration standards used. Equipment Calibration Guidelines.

From www.slideserve.com

PPT Overview of Instrument Calibration PowerPoint Presentation, free download ID6358286 Equipment Calibration Guidelines Learn what a calibration interval is, variables that affect it, who is responsible for setting it & how to establish one for your measurement equipment. (a) equipment shall be adequately inspected, cleaned, and maintained. § 58.63 maintenance and calibration of equipment. The first and most crucial goal of calibrating an instrument is ensuring that it takes accurate,. Difference in air. Equipment Calibration Guidelines.

From techmaster.us

Best practices for Equipment Calibration Techmaster Electronics Equipment Calibration Guidelines The first and most crucial goal of calibrating an instrument is ensuring that it takes accurate,. High pressure areas receive more air input and less air exhaust. Learn what a calibration interval is, variables that affect it, who is responsible for setting it & how to establish one for your measurement equipment. This procedure specifies the schedule and requirements for. Equipment Calibration Guidelines.

From instrumentationtools.com

Instrument Maintenance and Calibration System InstrumentationTools Equipment Calibration Guidelines A life cycle approach to the calibration and qualication of analytical instruments and systems to establish ″fitness. § 58.63 maintenance and calibration of equipment. The first and most crucial goal of calibrating an instrument is ensuring that it takes accurate,. This procedure specifies the schedule and requirements for maintenance, performance, calibration, and verification of laboratory testing. Learn what a calibration. Equipment Calibration Guidelines.

From www.strancoinc.com

Calibration Labels manufactured by Stranco Inc. Stranco Inc Equipment Calibration Guidelines Difference in air pressure between areas should. The first and most crucial goal of calibrating an instrument is ensuring that it takes accurate,. Calibration standards used for inspection, measuring, and test equipment shall be. A life cycle approach to the calibration and qualication of analytical instruments and systems to establish ″fitness. Learn what a calibration interval is, variables that affect. Equipment Calibration Guidelines.

From www.slideserve.com

PPT TOF System Performance Calibrations & Time Resolutions PowerPoint Presentation ID2483972 Equipment Calibration Guidelines A life cycle approach to the calibration and qualication of analytical instruments and systems to establish ″fitness. This procedure specifies the schedule and requirements for maintenance, performance, calibration, and verification of laboratory testing. Learn what a calibration interval is, variables that affect it, who is responsible for setting it & how to establish one for your measurement equipment. Calibration standards. Equipment Calibration Guidelines.

From www.qualitydigest.com

Equipment Calibration The What’s, Why’s, and How’s Quality Digest Equipment Calibration Guidelines The first and most crucial goal of calibrating an instrument is ensuring that it takes accurate,. A life cycle approach to the calibration and qualication of analytical instruments and systems to establish ″fitness. Learn what a calibration interval is, variables that affect it, who is responsible for setting it & how to establish one for your measurement equipment. This procedure. Equipment Calibration Guidelines.

From urslabs.com

The Importance of Instrument and Equipment Calibration URS Testings Laboratory LLC Equipment Calibration Guidelines High pressure areas receive more air input and less air exhaust. (a) equipment shall be adequately inspected, cleaned, and maintained. The first and most crucial goal of calibrating an instrument is ensuring that it takes accurate,. This procedure specifies the schedule and requirements for maintenance, performance, calibration, and verification of laboratory testing. Difference in air pressure between areas should. Learn. Equipment Calibration Guidelines.

From www.keysight.com

Defining Calibration Requirements for Electrical Test Equipment PDF Asset Page Keysight Equipment Calibration Guidelines (a) equipment shall be adequately inspected, cleaned, and maintained. The first and most crucial goal of calibrating an instrument is ensuring that it takes accurate,. This procedure specifies the schedule and requirements for maintenance, performance, calibration, and verification of laboratory testing. § 58.63 maintenance and calibration of equipment. Difference in air pressure between areas should. High pressure areas receive more. Equipment Calibration Guidelines.

From teamuis.com

Instrument Calibration is a must! Team UIS Equipment Calibration Guidelines The first and most crucial goal of calibrating an instrument is ensuring that it takes accurate,. Learn what a calibration interval is, variables that affect it, who is responsible for setting it & how to establish one for your measurement equipment. High pressure areas receive more air input and less air exhaust. Calibration standards used for inspection, measuring, and test. Equipment Calibration Guidelines.

From www.slideshare.net

List of ISO 170252017 documents for calibration laboratory Equipment Calibration Guidelines The first and most crucial goal of calibrating an instrument is ensuring that it takes accurate,. § 58.63 maintenance and calibration of equipment. Calibration standards used for inspection, measuring, and test equipment shall be. Difference in air pressure between areas should. (a) equipment shall be adequately inspected, cleaned, and maintained. A life cycle approach to the calibration and qualication of. Equipment Calibration Guidelines.

From blog.dmsystemsgroup.co.uk

A complete guide to international calibration standards Equipment Calibration Guidelines A life cycle approach to the calibration and qualication of analytical instruments and systems to establish ″fitness. § 58.63 maintenance and calibration of equipment. Difference in air pressure between areas should. Learn what a calibration interval is, variables that affect it, who is responsible for setting it & how to establish one for your measurement equipment. Calibration standards used for. Equipment Calibration Guidelines.

From www.slideserve.com

PPT Equipment PowerPoint Presentation, free download ID2693785 Equipment Calibration Guidelines (a) equipment shall be adequately inspected, cleaned, and maintained. § 58.63 maintenance and calibration of equipment. Calibration standards used for inspection, measuring, and test equipment shall be. High pressure areas receive more air input and less air exhaust. This procedure specifies the schedule and requirements for maintenance, performance, calibration, and verification of laboratory testing. The first and most crucial goal. Equipment Calibration Guidelines.

From theinstrumentguru.com

Calibration Standards Their Importance and Types Equipment Calibration Guidelines The first and most crucial goal of calibrating an instrument is ensuring that it takes accurate,. High pressure areas receive more air input and less air exhaust. Difference in air pressure between areas should. (a) equipment shall be adequately inspected, cleaned, and maintained. This procedure specifies the schedule and requirements for maintenance, performance, calibration, and verification of laboratory testing. §. Equipment Calibration Guidelines.

From www.ge.com

Calibration Planning Equipment Calibration Guidelines (a) equipment shall be adequately inspected, cleaned, and maintained. Calibration standards used for inspection, measuring, and test equipment shall be. The first and most crucial goal of calibrating an instrument is ensuring that it takes accurate,. Learn what a calibration interval is, variables that affect it, who is responsible for setting it & how to establish one for your measurement. Equipment Calibration Guidelines.

From www.slideshare.net

DATION OF EQUIPMENT ICH AND WHO GUIDELINES FOR CALIBRATION AND VALIDA… Equipment Calibration Guidelines A life cycle approach to the calibration and qualication of analytical instruments and systems to establish ″fitness. Learn what a calibration interval is, variables that affect it, who is responsible for setting it & how to establish one for your measurement equipment. This procedure specifies the schedule and requirements for maintenance, performance, calibration, and verification of laboratory testing. § 58.63. Equipment Calibration Guidelines.

From www.researchgate.net

(PDF) ICH and WHO Guideline for validation and calibration Equipment Calibration Guidelines A life cycle approach to the calibration and qualication of analytical instruments and systems to establish ″fitness. Difference in air pressure between areas should. This procedure specifies the schedule and requirements for maintenance, performance, calibration, and verification of laboratory testing. Calibration standards used for inspection, measuring, and test equipment shall be. The first and most crucial goal of calibrating an. Equipment Calibration Guidelines.

From www.slideserve.com

PPT MEASURING AND TEST EQUIPMENT CALIBRATION PowerPoint Presentation ID859630 Equipment Calibration Guidelines A life cycle approach to the calibration and qualication of analytical instruments and systems to establish ″fitness. High pressure areas receive more air input and less air exhaust. Learn what a calibration interval is, variables that affect it, who is responsible for setting it & how to establish one for your measurement equipment. This procedure specifies the schedule and requirements. Equipment Calibration Guidelines.

From www.slideshare.net

Instrument calibration why are iso 9001 calibration requirements vital for efficiency Equipment Calibration Guidelines A life cycle approach to the calibration and qualication of analytical instruments and systems to establish ″fitness. This procedure specifies the schedule and requirements for maintenance, performance, calibration, and verification of laboratory testing. Learn what a calibration interval is, variables that affect it, who is responsible for setting it & how to establish one for your measurement equipment. Difference in. Equipment Calibration Guidelines.

From constructandcommission.com

CALIBRATION CERTIFICATES What They Are And Why They Matter Equipment Calibration Guidelines The first and most crucial goal of calibrating an instrument is ensuring that it takes accurate,. A life cycle approach to the calibration and qualication of analytical instruments and systems to establish ″fitness. § 58.63 maintenance and calibration of equipment. (a) equipment shall be adequately inspected, cleaned, and maintained. Difference in air pressure between areas should. Learn what a calibration. Equipment Calibration Guidelines.

From jarcet.ph

Medical Equipment Calibration Requirements JARCET Shared Services Equipment Calibration Guidelines A life cycle approach to the calibration and qualication of analytical instruments and systems to establish ″fitness. (a) equipment shall be adequately inspected, cleaned, and maintained. § 58.63 maintenance and calibration of equipment. High pressure areas receive more air input and less air exhaust. Learn what a calibration interval is, variables that affect it, who is responsible for setting it. Equipment Calibration Guidelines.

From instrumentationbasic.com

Instrument Calibration Report Instrumentation basics Equipment Calibration Guidelines The first and most crucial goal of calibrating an instrument is ensuring that it takes accurate,. Difference in air pressure between areas should. (a) equipment shall be adequately inspected, cleaned, and maintained. Calibration standards used for inspection, measuring, and test equipment shall be. High pressure areas receive more air input and less air exhaust. Learn what a calibration interval is,. Equipment Calibration Guidelines.

From www.scribd.com

Lab Equipment Calibration PDF Calibration Metrology Equipment Calibration Guidelines (a) equipment shall be adequately inspected, cleaned, and maintained. A life cycle approach to the calibration and qualication of analytical instruments and systems to establish ″fitness. This procedure specifies the schedule and requirements for maintenance, performance, calibration, and verification of laboratory testing. Learn what a calibration interval is, variables that affect it, who is responsible for setting it & how. Equipment Calibration Guidelines.

From www.density.co.uk

Using & Understanding a Calibration Certificate H&D Fitzgerald Equipment Calibration Guidelines § 58.63 maintenance and calibration of equipment. High pressure areas receive more air input and less air exhaust. (a) equipment shall be adequately inspected, cleaned, and maintained. This procedure specifies the schedule and requirements for maintenance, performance, calibration, and verification of laboratory testing. Learn what a calibration interval is, variables that affect it, who is responsible for setting it &. Equipment Calibration Guidelines.

From www.fireflysci.com

HF Series VIS Photometric Accuracy Calibration Standards (400700nm) (Optical Densities 0.04 Equipment Calibration Guidelines High pressure areas receive more air input and less air exhaust. Learn what a calibration interval is, variables that affect it, who is responsible for setting it & how to establish one for your measurement equipment. A life cycle approach to the calibration and qualication of analytical instruments and systems to establish ″fitness. § 58.63 maintenance and calibration of equipment.. Equipment Calibration Guidelines.

From www.inpaspages.com

Calibration Standard Record Equipment Calibration Guidelines A life cycle approach to the calibration and qualication of analytical instruments and systems to establish ″fitness. § 58.63 maintenance and calibration of equipment. (a) equipment shall be adequately inspected, cleaned, and maintained. The first and most crucial goal of calibrating an instrument is ensuring that it takes accurate,. Difference in air pressure between areas should. Learn what a calibration. Equipment Calibration Guidelines.

From www.slideserve.com

PPT Managing Your Company Calibration Program PowerPoint Presentation ID1033388 Equipment Calibration Guidelines Calibration standards used for inspection, measuring, and test equipment shall be. § 58.63 maintenance and calibration of equipment. The first and most crucial goal of calibrating an instrument is ensuring that it takes accurate,. (a) equipment shall be adequately inspected, cleaned, and maintained. Learn what a calibration interval is, variables that affect it, who is responsible for setting it &. Equipment Calibration Guidelines.

From instrumentationtools.com

How to Create Calibration Records? Instrumentation and Control Equipment Calibration Guidelines This procedure specifies the schedule and requirements for maintenance, performance, calibration, and verification of laboratory testing. Learn what a calibration interval is, variables that affect it, who is responsible for setting it & how to establish one for your measurement equipment. Calibration standards used for inspection, measuring, and test equipment shall be. The first and most crucial goal of calibrating. Equipment Calibration Guidelines.

From automationforum.co

Basic Safety and General Consideration While Executing Calibration Process in process industries Equipment Calibration Guidelines Difference in air pressure between areas should. Learn what a calibration interval is, variables that affect it, who is responsible for setting it & how to establish one for your measurement equipment. A life cycle approach to the calibration and qualication of analytical instruments and systems to establish ″fitness. § 58.63 maintenance and calibration of equipment. (a) equipment shall be. Equipment Calibration Guidelines.

From www.slideserve.com

PPT EQUIPMENT/INSTRUMENT CALIBRATION PowerPoint Presentation, free download ID6680226 Equipment Calibration Guidelines High pressure areas receive more air input and less air exhaust. A life cycle approach to the calibration and qualication of analytical instruments and systems to establish ″fitness. Calibration standards used for inspection, measuring, and test equipment shall be. § 58.63 maintenance and calibration of equipment. Learn what a calibration interval is, variables that affect it, who is responsible for. Equipment Calibration Guidelines.

From automationcommunity.com

Instrument Calibration Questions and Answers Equipment Calibration Guidelines § 58.63 maintenance and calibration of equipment. Learn what a calibration interval is, variables that affect it, who is responsible for setting it & how to establish one for your measurement equipment. High pressure areas receive more air input and less air exhaust. Calibration standards used for inspection, measuring, and test equipment shall be. This procedure specifies the schedule and. Equipment Calibration Guidelines.

From www.medicaldesignbriefs.com

Guide to FDA Requirements and Importance of Medical Device Calibration Medical Design Briefs Equipment Calibration Guidelines (a) equipment shall be adequately inspected, cleaned, and maintained. § 58.63 maintenance and calibration of equipment. Difference in air pressure between areas should. High pressure areas receive more air input and less air exhaust. Calibration standards used for inspection, measuring, and test equipment shall be. A life cycle approach to the calibration and qualication of analytical instruments and systems to. Equipment Calibration Guidelines.