Brazing Aluminum Angle . Aluminum brazing has become a widely used method for repairing cracks, fixing leaks in aluminum pipes or tanks, repairing castings, or fabricating aluminum parts. Aluminum wire is supported and manufactured by a team with. This process, melting a filler metal at lower temperatures than the base metal, joins. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. As a premium filler metal solution, hobart. Not only is brazing often. For effective brazing, the filler metal’s. Aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. − to describe the characteristics of brazing aluminium and the process involved − to understand the use potential and the limitations. The degree of wetting is quantified by the contact angle (θ) formed between the liquid and solid phases at their interface. In this technique, an aluminium angle is laid on top of a cladded aluminium coupon where the legs of the angle are raised using stainless steel wire.

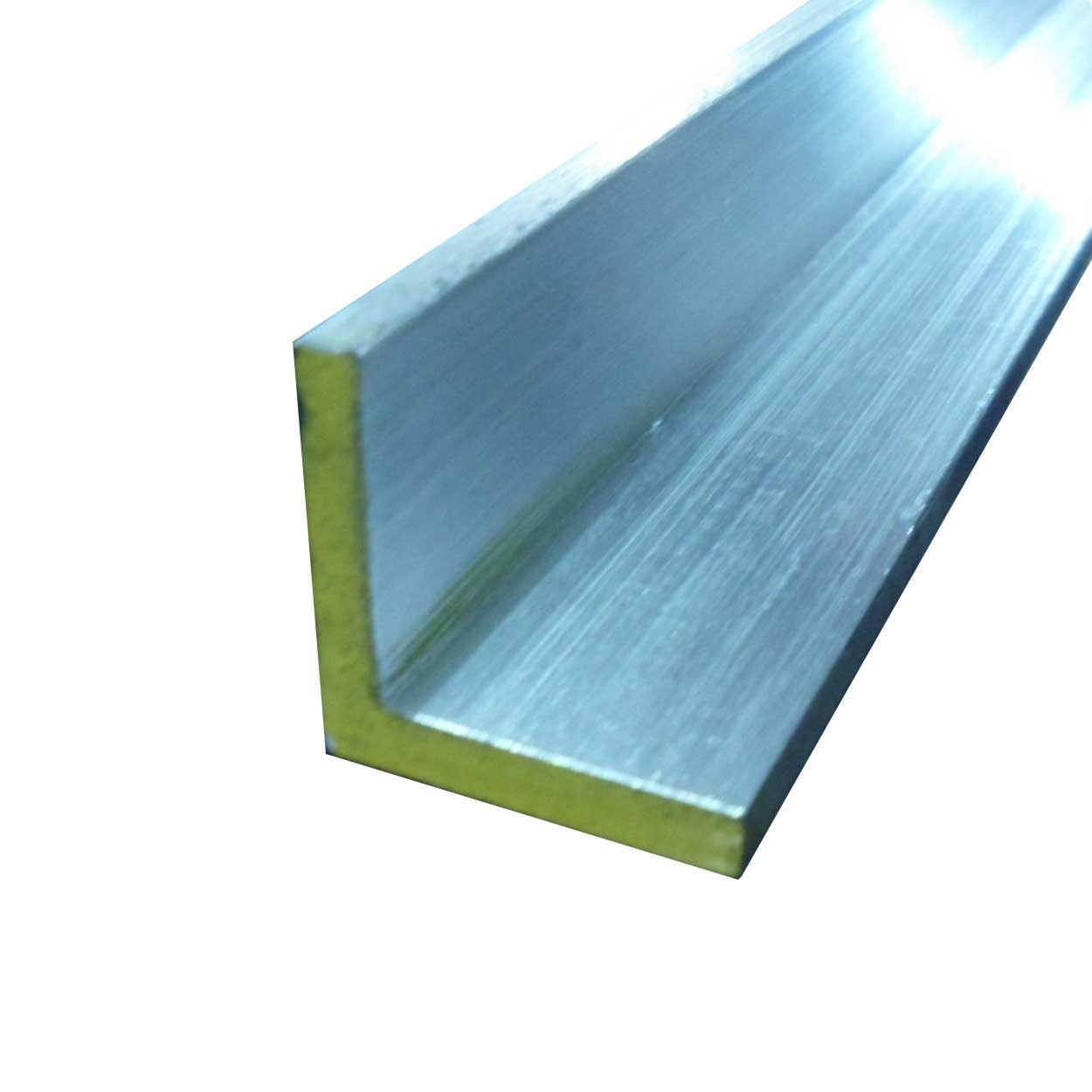

from onlinemetalsupply.com

Aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. The degree of wetting is quantified by the contact angle (θ) formed between the liquid and solid phases at their interface. As a premium filler metal solution, hobart. This process, melting a filler metal at lower temperatures than the base metal, joins. Not only is brazing often. Aluminum brazing has become a widely used method for repairing cracks, fixing leaks in aluminum pipes or tanks, repairing castings, or fabricating aluminum parts. For effective brazing, the filler metal’s. In this technique, an aluminium angle is laid on top of a cladded aluminium coupon where the legs of the angle are raised using stainless steel wire. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. − to describe the characteristics of brazing aluminium and the process involved − to understand the use potential and the limitations.

Guide to Aluminum Angle Online Metal Supply

Brazing Aluminum Angle In this technique, an aluminium angle is laid on top of a cladded aluminium coupon where the legs of the angle are raised using stainless steel wire. For effective brazing, the filler metal’s. Aluminum brazing has become a widely used method for repairing cracks, fixing leaks in aluminum pipes or tanks, repairing castings, or fabricating aluminum parts. Aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. In this technique, an aluminium angle is laid on top of a cladded aluminium coupon where the legs of the angle are raised using stainless steel wire. The degree of wetting is quantified by the contact angle (θ) formed between the liquid and solid phases at their interface. This process, melting a filler metal at lower temperatures than the base metal, joins. Aluminum wire is supported and manufactured by a team with. − to describe the characteristics of brazing aluminium and the process involved − to understand the use potential and the limitations. Not only is brazing often. As a premium filler metal solution, hobart. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage.

From www.museoinclusivo.com

Aluminum Brazing A Comprehensive Guide Aluminum Profile Blog Brazing Aluminum Angle Aluminum brazing has become a widely used method for repairing cracks, fixing leaks in aluminum pipes or tanks, repairing castings, or fabricating aluminum parts. Aluminum wire is supported and manufactured by a team with. − to describe the characteristics of brazing aluminium and the process involved − to understand the use potential and the limitations. This process, melting a filler. Brazing Aluminum Angle.

From www.youtube.com

How to Braze Aluminum Flame & Induction Brazing YouTube Brazing Aluminum Angle This process, melting a filler metal at lower temperatures than the base metal, joins. For effective brazing, the filler metal’s. − to describe the characteristics of brazing aluminium and the process involved − to understand the use potential and the limitations. The degree of wetting is quantified by the contact angle (θ) formed between the liquid and solid phases at. Brazing Aluminum Angle.

From www.museoinclusivo.com

How to Braze Aluminum A StepbyStep Guide Aluminum Profile Blog Brazing Aluminum Angle Aluminum wire is supported and manufactured by a team with. For effective brazing, the filler metal’s. Aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. This process, melting a filler metal at lower temperatures than the base metal, joins. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of. Brazing Aluminum Angle.

From www.chalcoaluminum.com

All About the Aluminium Brazing Process Chalco Aluminum Brazing Aluminum Angle Aluminum brazing has become a widely used method for repairing cracks, fixing leaks in aluminum pipes or tanks, repairing castings, or fabricating aluminum parts. Not only is brazing often. This process, melting a filler metal at lower temperatures than the base metal, joins. In this technique, an aluminium angle is laid on top of a cladded aluminium coupon where the. Brazing Aluminum Angle.

From www.chalcoaluminum.com

All About the Aluminium Brazing Process Chalco Aluminum Brazing Aluminum Angle Not only is brazing often. Aluminum brazing has become a widely used method for repairing cracks, fixing leaks in aluminum pipes or tanks, repairing castings, or fabricating aluminum parts. For effective brazing, the filler metal’s. Aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. This process, melting a filler metal at lower temperatures than the base metal,. Brazing Aluminum Angle.

From blog.thepipingmart.com

How to Aluminum Brazing Strength and Benefits Brazing Aluminum Angle For effective brazing, the filler metal’s. Aluminum wire is supported and manufactured by a team with. As a premium filler metal solution, hobart. − to describe the characteristics of brazing aluminium and the process involved − to understand the use potential and the limitations. Not only is brazing often. In this technique, an aluminium angle is laid on top of. Brazing Aluminum Angle.

From onesky.ph

How to Braze Aluminum One Sky Blog Brazing Aluminum Angle Not only is brazing often. − to describe the characteristics of brazing aluminium and the process involved − to understand the use potential and the limitations. In this technique, an aluminium angle is laid on top of a cladded aluminium coupon where the legs of the angle are raised using stainless steel wire. Aluminum brazing has become a widely used. Brazing Aluminum Angle.

From weldingweb.com

Aluminum Brazing Options Brazing Aluminum Angle In this technique, an aluminium angle is laid on top of a cladded aluminium coupon where the legs of the angle are raised using stainless steel wire. Aluminum wire is supported and manufactured by a team with. As a premium filler metal solution, hobart. This process, melting a filler metal at lower temperatures than the base metal, joins. − to. Brazing Aluminum Angle.

From www.youtube.com

How to weld aluminium aluminiumaluminium brazing guide YouTube Brazing Aluminum Angle The degree of wetting is quantified by the contact angle (θ) formed between the liquid and solid phases at their interface. Aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. − to describe the characteristics of brazing aluminium and the process involved − to understand the use potential and the limitations. This process, melting a filler metal. Brazing Aluminum Angle.

From www.museoinclusivo.com

How to Braze Aluminum A StepbyStep Guide Aluminum Profile Blog Brazing Aluminum Angle The degree of wetting is quantified by the contact angle (θ) formed between the liquid and solid phases at their interface. For effective brazing, the filler metal’s. − to describe the characteristics of brazing aluminium and the process involved − to understand the use potential and the limitations. Aluminum brazing has become a widely used method for repairing cracks, fixing. Brazing Aluminum Angle.

From weldersadvice.com

How Strong is Aluminum Brazing Welders Advice Brazing Aluminum Angle Aluminum brazing has become a widely used method for repairing cracks, fixing leaks in aluminum pipes or tanks, repairing castings, or fabricating aluminum parts. This process, melting a filler metal at lower temperatures than the base metal, joins. Not only is brazing often. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts. Brazing Aluminum Angle.

From dw-inductionheater.com

Induction Aluminum Brazing Techniques and Benefits Explained Brazing Aluminum Angle Aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. Not only is brazing often. This process, melting a filler metal at lower temperatures than the base metal, joins. In this technique, an aluminium angle is laid on top of a cladded aluminium coupon where the legs of the angle are raised using stainless steel wire. − to. Brazing Aluminum Angle.

From midsouthsupply.com

Guide to Aluminum Brazing Mid South Supply Brazing Aluminum Angle Aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. In this technique, an aluminium angle is laid on top of a cladded aluminium coupon where the legs of the angle are raised using stainless steel wire. Aluminum wire is supported and manufactured by a team with. For effective brazing, the filler metal’s. Not only is brazing often.. Brazing Aluminum Angle.

From www.youtube.com

How To braze Aluminum to Aluminum YouTube Brazing Aluminum Angle Aluminum brazing has become a widely used method for repairing cracks, fixing leaks in aluminum pipes or tanks, repairing castings, or fabricating aluminum parts. − to describe the characteristics of brazing aluminium and the process involved − to understand the use potential and the limitations. As a premium filler metal solution, hobart. Aluminum wire is supported and manufactured by a. Brazing Aluminum Angle.

From www.museoinclusivo.com

Brazing Aluminum How to Achieve a Strong, Durable Joint Aluminum Brazing Aluminum Angle Aluminum wire is supported and manufactured by a team with. The degree of wetting is quantified by the contact angle (θ) formed between the liquid and solid phases at their interface. For effective brazing, the filler metal’s. Aluminum brazing has become a widely used method for repairing cracks, fixing leaks in aluminum pipes or tanks, repairing castings, or fabricating aluminum. Brazing Aluminum Angle.

From www.chalcoaluminum.com

All About the Aluminium Brazing Process Chalco Aluminum Brazing Aluminum Angle When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. Aluminum brazing has become a widely used method for repairing cracks, fixing leaks in aluminum pipes or tanks, repairing castings, or fabricating aluminum parts. As a premium filler metal solution, hobart. Aluminum brazing effectively creates strong, durable joints in aluminum and. Brazing Aluminum Angle.

From www.pinterest.com

How to Weld Aluminum Without a Welder Brazing, Welding projects Brazing Aluminum Angle In this technique, an aluminium angle is laid on top of a cladded aluminium coupon where the legs of the angle are raised using stainless steel wire. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. For effective brazing, the filler metal’s. Aluminum brazing has become a widely used method. Brazing Aluminum Angle.

From weldingtroop.com

Aluminum Brazing Complete Guide Advantages Over Welding Brazing Aluminum Angle The degree of wetting is quantified by the contact angle (θ) formed between the liquid and solid phases at their interface. Aluminum wire is supported and manufactured by a team with. For effective brazing, the filler metal’s. Aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. − to describe the characteristics of brazing aluminium and the process. Brazing Aluminum Angle.

From onlinemetalsupply.com

Guide to Aluminum Angle Online Metal Supply Brazing Aluminum Angle Aluminum wire is supported and manufactured by a team with. This process, melting a filler metal at lower temperatures than the base metal, joins. For effective brazing, the filler metal’s. As a premium filler metal solution, hobart. Aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. − to describe the characteristics of brazing aluminium and the process. Brazing Aluminum Angle.

From www.youtube.com

Aluminum Brazing/Welding For Beginners YouTube Brazing Aluminum Angle When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. Aluminum brazing has become a widely used method for repairing cracks, fixing leaks in aluminum pipes or tanks, repairing castings, or fabricating aluminum parts. Not only is brazing often. In this technique, an aluminium angle is laid on top of a. Brazing Aluminum Angle.

From www.youtube.com

Brazing Aluminium Successes & Failures YouTube Brazing Aluminum Angle The degree of wetting is quantified by the contact angle (θ) formed between the liquid and solid phases at their interface. This process, melting a filler metal at lower temperatures than the base metal, joins. Aluminum wire is supported and manufactured by a team with. − to describe the characteristics of brazing aluminium and the process involved − to understand. Brazing Aluminum Angle.

From dw-inductionheater.com

Induction Aluminum Brazing Techniques and Benefits Explained Brazing Aluminum Angle In this technique, an aluminium angle is laid on top of a cladded aluminium coupon where the legs of the angle are raised using stainless steel wire. Not only is brazing often. The degree of wetting is quantified by the contact angle (θ) formed between the liquid and solid phases at their interface. As a premium filler metal solution, hobart.. Brazing Aluminum Angle.

From www.youtube.com

Aluminum Brazing With Acetylene Torch YouTube Brazing Aluminum Angle As a premium filler metal solution, hobart. In this technique, an aluminium angle is laid on top of a cladded aluminium coupon where the legs of the angle are raised using stainless steel wire. Aluminum wire is supported and manufactured by a team with. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high. Brazing Aluminum Angle.

From dzcqksbqeco.blob.core.windows.net

Aluminum Brazed Joints at Jimmy Creech blog Brazing Aluminum Angle As a premium filler metal solution, hobart. Not only is brazing often. Aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. Aluminum wire is supported and manufactured by a team with. Aluminum brazing has become a widely used. Brazing Aluminum Angle.

From altairusa.com

Brazing Aluminum with Vacuum Furnace Brazing Altair USA Brazing Aluminum Angle The degree of wetting is quantified by the contact angle (θ) formed between the liquid and solid phases at their interface. In this technique, an aluminium angle is laid on top of a cladded aluminium coupon where the legs of the angle are raised using stainless steel wire. − to describe the characteristics of brazing aluminium and the process involved. Brazing Aluminum Angle.

From ultraflexpower.com

Brazing of Aluminum Tubes UltraFlex Power Brazing Aluminum Angle Aluminum brazing has become a widely used method for repairing cracks, fixing leaks in aluminum pipes or tanks, repairing castings, or fabricating aluminum parts. − to describe the characteristics of brazing aluminium and the process involved − to understand the use potential and the limitations. Aluminum wire is supported and manufactured by a team with. Aluminum brazing effectively creates strong,. Brazing Aluminum Angle.

From weldingtroop.com

Aluminum Brazing Complete Guide Advantages Over Welding Brazing Aluminum Angle The degree of wetting is quantified by the contact angle (θ) formed between the liquid and solid phases at their interface. This process, melting a filler metal at lower temperatures than the base metal, joins. Aluminum brazing has become a widely used method for repairing cracks, fixing leaks in aluminum pipes or tanks, repairing castings, or fabricating aluminum parts. When. Brazing Aluminum Angle.

From exoxedomj.blob.core.windows.net

What Brazing Rod To Use For Aluminum at Thomas Barnes blog Brazing Aluminum Angle Not only is brazing often. For effective brazing, the filler metal’s. The degree of wetting is quantified by the contact angle (θ) formed between the liquid and solid phases at their interface. Aluminum wire is supported and manufactured by a team with. As a premium filler metal solution, hobart. Aluminum brazing has become a widely used method for repairing cracks,. Brazing Aluminum Angle.

From www.youtube.com

Aluminum block/tube brazing machineSK Brazing YouTube Brazing Aluminum Angle For effective brazing, the filler metal’s. In this technique, an aluminium angle is laid on top of a cladded aluminium coupon where the legs of the angle are raised using stainless steel wire. As a premium filler metal solution, hobart. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. Aluminum. Brazing Aluminum Angle.

From blog.thepipingmart.com

Brazing Aluminium vs Welding What's the Difference Brazing Aluminum Angle Aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. Aluminum wire is supported and manufactured by a team with. For effective brazing, the filler metal’s. As a premium filler metal solution, hobart. This process, melting a filler metal at lower temperatures than the base metal, joins. Aluminum brazing has become a widely used method for repairing cracks,. Brazing Aluminum Angle.

From www.youtube.com

The technique of brazing aluminium with its fittings_2 YouTube Brazing Aluminum Angle Aluminum brazing has become a widely used method for repairing cracks, fixing leaks in aluminum pipes or tanks, repairing castings, or fabricating aluminum parts. The degree of wetting is quantified by the contact angle (θ) formed between the liquid and solid phases at their interface. Aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. When compared to. Brazing Aluminum Angle.

From www.aluminium-brazing.com

Aluminium Flame Brazing Basics Part 1 Aluminium Brazing Brazing Aluminum Angle The degree of wetting is quantified by the contact angle (θ) formed between the liquid and solid phases at their interface. Not only is brazing often. Aluminum brazing has become a widely used method for repairing cracks, fixing leaks in aluminum pipes or tanks, repairing castings, or fabricating aluminum parts. Aluminum brazing effectively creates strong, durable joints in aluminum and. Brazing Aluminum Angle.

From www.museoinclusivo.com

How to Braze Aluminum A StepbyStep Guide Aluminum Profile Blog Brazing Aluminum Angle − to describe the characteristics of brazing aluminium and the process involved − to understand the use potential and the limitations. Aluminum brazing has become a widely used method for repairing cracks, fixing leaks in aluminum pipes or tanks, repairing castings, or fabricating aluminum parts. Aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. Not only is. Brazing Aluminum Angle.

From stella-welding.com

Aluminum Brazing Brazing Aluminum Angle Aluminum brazing effectively creates strong, durable joints in aluminum and its alloys. The degree of wetting is quantified by the contact angle (θ) formed between the liquid and solid phases at their interface. Not only is brazing often. This process, melting a filler metal at lower temperatures than the base metal, joins. Aluminum brazing has become a widely used method. Brazing Aluminum Angle.

From onlinemetalsupply.com

Guide to Aluminum Angle Online Metal Supply Brazing Aluminum Angle Aluminum wire is supported and manufactured by a team with. Aluminum brazing has become a widely used method for repairing cracks, fixing leaks in aluminum pipes or tanks, repairing castings, or fabricating aluminum parts. This process, melting a filler metal at lower temperatures than the base metal, joins. For effective brazing, the filler metal’s. In this technique, an aluminium angle. Brazing Aluminum Angle.