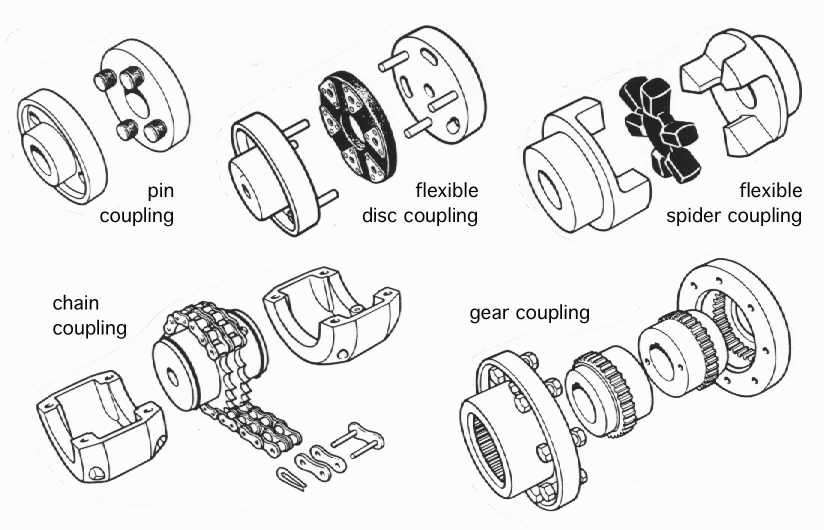

Types Of Coupling In Pump . Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and. In general, rigid couplings are best suited to applications in which a solid. So you need a coupling, but not just any coupling. 2.4 coupling service factors for pumping applications. So, what are the different types of pump coupling and when should they be used? You need the right coupling, in the right size, for the right pump application. the. 9 chapter • three flexible couplings, 11 3.1 purpose of a flexible coupling. Its primary function is to. Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. Like everything else on the pump, selecting the right coupling for the application can have a positive or negative impact on the pump’s lifetime performance. As their name suggests, rigid couplings connect. Pump couplings can be organised into two overarching categories: A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine.

from meroock.blogspot.com

So you need a coupling, but not just any coupling. Its primary function is to. So, what are the different types of pump coupling and when should they be used? As their name suggests, rigid couplings connect. In general, rigid couplings are best suited to applications in which a solid. Like everything else on the pump, selecting the right coupling for the application can have a positive or negative impact on the pump’s lifetime performance. Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and. 9 chapter • three flexible couplings, 11 3.1 purpose of a flexible coupling. 2.4 coupling service factors for pumping applications. You need the right coupling, in the right size, for the right pump application. the.

mechanical rocks February 2013

Types Of Coupling In Pump 2.4 coupling service factors for pumping applications. Like everything else on the pump, selecting the right coupling for the application can have a positive or negative impact on the pump’s lifetime performance. A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. Its primary function is to. Pump couplings can be organised into two overarching categories: So, what are the different types of pump coupling and when should they be used? Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and. 9 chapter • three flexible couplings, 11 3.1 purpose of a flexible coupling. So you need a coupling, but not just any coupling. In general, rigid couplings are best suited to applications in which a solid. Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. 2.4 coupling service factors for pumping applications. You need the right coupling, in the right size, for the right pump application. the. As their name suggests, rigid couplings connect.

From hxeiwwqrv.blob.core.windows.net

Types Of Hydraulic Coupling at Johnnie Mack blog Types Of Coupling In Pump Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and. In general, rigid couplings are best suited to applications in which a solid. Pump couplings can be organised into two overarching categories: Its primary function is to. As their name suggests, rigid couplings connect. So you need a coupling, but not just any coupling. 9 chapter. Types Of Coupling In Pump.

From ar.inspiredpencil.com

Different Types Of Couplings Types Of Coupling In Pump So, what are the different types of pump coupling and when should they be used? 2.4 coupling service factors for pumping applications. Like everything else on the pump, selecting the right coupling for the application can have a positive or negative impact on the pump’s lifetime performance. 9 chapter • three flexible couplings, 11 3.1 purpose of a flexible coupling.. Types Of Coupling In Pump.

From www.directindustry.com

Flexible coupling MEGIFLEX S series VULKAN Drive Tech shaft / for Types Of Coupling In Pump Pump couplings can be organised into two overarching categories: Like everything else on the pump, selecting the right coupling for the application can have a positive or negative impact on the pump’s lifetime performance. So, what are the different types of pump coupling and when should they be used? So you need a coupling, but not just any coupling. 2.4. Types Of Coupling In Pump.

From www.youtube.com

Types of Couplings, Usage and Applications YouTube Types Of Coupling In Pump So you need a coupling, but not just any coupling. You need the right coupling, in the right size, for the right pump application. the. So, what are the different types of pump coupling and when should they be used? In general, rigid couplings are best suited to applications in which a solid. 2.4 coupling service factors for pumping applications.. Types Of Coupling In Pump.

From mavink.com

Pump Coupling Types Types Of Coupling In Pump So, what are the different types of pump coupling and when should they be used? Pump couplings can be organised into two overarching categories: 2.4 coupling service factors for pumping applications. Like everything else on the pump, selecting the right coupling for the application can have a positive or negative impact on the pump’s lifetime performance. Different coupling types cater. Types Of Coupling In Pump.

From mechanicaljungle.com

What Is a Coupling? How Does a Shaft Coupling Work? Types of Shaft Types Of Coupling In Pump So you need a coupling, but not just any coupling. 2.4 coupling service factors for pumping applications. Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. 9 chapter • three flexible couplings, 11 3.1 purpose of a flexible coupling. Pump couplings can be organised into two overarching. Types Of Coupling In Pump.

From www.youtube.com

KTR couplings for PumpMotor applications YouTube Types Of Coupling In Pump Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and. As their name suggests, rigid couplings connect. Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. Pump couplings can be organised into two overarching categories: Its primary function is to. In general, rigid. Types Of Coupling In Pump.

From www.pumpsandsystems.com

Grid Coupling vs. Gear Coupling Pumps & Systems Types Of Coupling In Pump 9 chapter • three flexible couplings, 11 3.1 purpose of a flexible coupling. Its primary function is to. Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and. In general, rigid couplings are best suited to applications in which a solid. Pump couplings can be organised into two overarching categories: So you need a coupling, but. Types Of Coupling In Pump.

From ssj-group.com

6 Types of Flexible Couplings with Their Industrial Applications Types Of Coupling In Pump As their name suggests, rigid couplings connect. Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and. A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. So you need a coupling, but not just any coupling. Like everything else. Types Of Coupling In Pump.

From www.couplingtips.com

What are couplings for powertransmission drive shafts? Types Of Coupling In Pump Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and. A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. 9 chapter • three flexible couplings, 11 3.1 purpose of a flexible coupling. So, what are the different types of. Types Of Coupling In Pump.

From rathicouplings.com

Jaw Flex Coupling Lovejoy Coupling Rathi Group Types Of Coupling In Pump So, what are the different types of pump coupling and when should they be used? 2.4 coupling service factors for pumping applications. Its primary function is to. As their name suggests, rigid couplings connect. In general, rigid couplings are best suited to applications in which a solid. Pump couplings can be organised into two overarching categories: Like everything else on. Types Of Coupling In Pump.

From globaltransmissionhoses.in

Types of Stainless Steel Camlock Couplings Global Transmission Types Of Coupling In Pump So you need a coupling, but not just any coupling. A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. So, what are the different types of pump coupling and when should they be used? Pump couplings can be organised into two overarching categories:. Types Of Coupling In Pump.

From engineeringlearn.com

Shaft Coupling Definition, Types, Uses, Working Principle & Advantages Types Of Coupling In Pump Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and. Like everything else on the pump, selecting the right coupling for the application can have a positive or negative impact on the pump’s lifetime performance. In general, rigid couplings are best suited to applications in which a solid. A pump coupling is a mechanical device used. Types Of Coupling In Pump.

From www.pinterest.com.au

Different Types of Couplings and Their Applications Explained Types Of Coupling In Pump So you need a coupling, but not just any coupling. So, what are the different types of pump coupling and when should they be used? As their name suggests, rigid couplings connect. In general, rigid couplings are best suited to applications in which a solid. A pump coupling is a mechanical device used to connect two shafts, typically one from. Types Of Coupling In Pump.

From www.linkedin.com

Types Of Shaft Couplings Types Of Coupling In Pump As their name suggests, rigid couplings connect. Like everything else on the pump, selecting the right coupling for the application can have a positive or negative impact on the pump’s lifetime performance. Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. A pump coupling is a mechanical. Types Of Coupling In Pump.

From www.zeushydratech.com

DCND108B OMT Drive Coupling, Motor Half, 11kw (42mm, 12mm key) Zeus Types Of Coupling In Pump 9 chapter • three flexible couplings, 11 3.1 purpose of a flexible coupling. 2.4 coupling service factors for pumping applications. A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. Pump couplings can be organised into two overarching categories: Pump couplings connect the pump. Types Of Coupling In Pump.

From mungfali.com

Types Of Shaft Couplings Types Of Coupling In Pump You need the right coupling, in the right size, for the right pump application. the. 9 chapter • three flexible couplings, 11 3.1 purpose of a flexible coupling. Like everything else on the pump, selecting the right coupling for the application can have a positive or negative impact on the pump’s lifetime performance. Different coupling types cater to specific requirements,. Types Of Coupling In Pump.

From catalog.udlvirtual.edu.pe

What Is Coupling And Types Of Coupling Catalog Library Types Of Coupling In Pump So, what are the different types of pump coupling and when should they be used? Its primary function is to. A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. Pump couplings can be organised into two overarching categories: 9 chapter • three flexible. Types Of Coupling In Pump.

From whatispiping.com

What is a Pump Coupling? Its Types, Functions, Applications (PDF Types Of Coupling In Pump As their name suggests, rigid couplings connect. 9 chapter • three flexible couplings, 11 3.1 purpose of a flexible coupling. Its primary function is to. 2.4 coupling service factors for pumping applications. A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. So, what. Types Of Coupling In Pump.

From fractory.com

Types of Couplings Fractory Types Of Coupling In Pump Pump couplings can be organised into two overarching categories: A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and. In general, rigid couplings are best suited to applications in which. Types Of Coupling In Pump.

From ar.inspiredpencil.com

Shafts Couplings Types Of Coupling In Pump A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. As their name suggests, rigid couplings connect. 9 chapter • three flexible couplings, 11 3.1 purpose of a flexible coupling. So, what are the different types of pump coupling and when should they be. Types Of Coupling In Pump.

From romac.com

COUPLINGS — ROMAC INDUSTRIES Types Of Coupling In Pump Like everything else on the pump, selecting the right coupling for the application can have a positive or negative impact on the pump’s lifetime performance. In general, rigid couplings are best suited to applications in which a solid. Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and. As their name suggests, rigid couplings connect. Its. Types Of Coupling In Pump.

From www.amazonhose.com

Hydraulic Quick Couplings Types Of Coupling In Pump You need the right coupling, in the right size, for the right pump application. the. Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and. 9 chapter • three flexible couplings, 11 3.1 purpose. Types Of Coupling In Pump.

From meroock.blogspot.com

mechanical rocks February 2013 Types Of Coupling In Pump Like everything else on the pump, selecting the right coupling for the application can have a positive or negative impact on the pump’s lifetime performance. A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. So, what are the different types of pump coupling. Types Of Coupling In Pump.

From www.myxxgirl.com

What Is A Coupling How Does A Shaft Coupling Work Types Of Shaft My Types Of Coupling In Pump Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. In general, rigid couplings are best suited to applications in which a solid. So, what are the different types of pump coupling and when should they be used? 9 chapter • three flexible couplings, 11 3.1 purpose of. Types Of Coupling In Pump.

From blog.craneengineering.net

The Quick And Dirty Guide To Pump Coupling Types Types Of Coupling In Pump Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. Its primary function is to. Pump couplings can be organised into two overarching categories: 9 chapter • three flexible couplings, 11 3.1 purpose of a flexible coupling. 2.4 coupling service factors for pumping applications. So you need a. Types Of Coupling In Pump.

From blog.craneengineering.net

The Quick And Dirty Guide To Pump Coupling Types Types Of Coupling In Pump You need the right coupling, in the right size, for the right pump application. the. Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and. A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. As their name suggests, rigid. Types Of Coupling In Pump.

From www.deppmann.com

HVAC Centrifugal Pump Coupling Types Close, Split, Flexible Types Of Coupling In Pump So, what are the different types of pump coupling and when should they be used? Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and. Pump couplings can be organised into two overarching categories: A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from. Types Of Coupling In Pump.

From repairmachinedikgaka90.z4.web.core.windows.net

Hydraulic Pump Coupling Types Types Of Coupling In Pump In general, rigid couplings are best suited to applications in which a solid. So, what are the different types of pump coupling and when should they be used? 9 chapter • three flexible couplings, 11 3.1 purpose of a flexible coupling. You need the right coupling, in the right size, for the right pump application. the. A pump coupling is. Types Of Coupling In Pump.

From mavink.com

Pump Coupling Types Types Of Coupling In Pump So, what are the different types of pump coupling and when should they be used? So you need a coupling, but not just any coupling. Pump couplings can be organised into two overarching categories: In general, rigid couplings are best suited to applications in which a solid. 2.4 coupling service factors for pumping applications. You need the right coupling, in. Types Of Coupling In Pump.

From www.reddit.com

Different Types of Couplings r/coolguides Types Of Coupling In Pump Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. So you need a coupling, but not just any coupling. Pump couplings can be organised into two overarching categories: Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and. In general, rigid couplings are. Types Of Coupling In Pump.

From www.theengineerspost.com

13 Types of Coupling Definition, Drawings, Uses & (PDF) Types Of Coupling In Pump You need the right coupling, in the right size, for the right pump application. the. Pump couplings can be organised into two overarching categories: Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. 2.4 coupling service factors for pumping applications. In general, rigid couplings are best suited. Types Of Coupling In Pump.

From www.gouldspumps.com

VIC Vertical Industrial CanType Pumps Goulds Pumps Types Of Coupling In Pump So, what are the different types of pump coupling and when should they be used? Its primary function is to. Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. 2.4 coupling service factors for pumping applications. Pump couplings can be organised into two overarching categories: You need. Types Of Coupling In Pump.

From reubengokegoodwin.blogspot.com

Explain Different Types of Coupling With Suitable Example Types Of Coupling In Pump So you need a coupling, but not just any coupling. Like everything else on the pump, selecting the right coupling for the application can have a positive or negative impact on the pump’s lifetime performance. Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. You need the. Types Of Coupling In Pump.

From www.youtube.com

Types of Coupling YouTube Types Of Coupling In Pump 9 chapter • three flexible couplings, 11 3.1 purpose of a flexible coupling. Pump couplings can be organised into two overarching categories: 2.4 coupling service factors for pumping applications. So, what are the different types of pump coupling and when should they be used? As their name suggests, rigid couplings connect. A pump coupling is a mechanical device used to. Types Of Coupling In Pump.