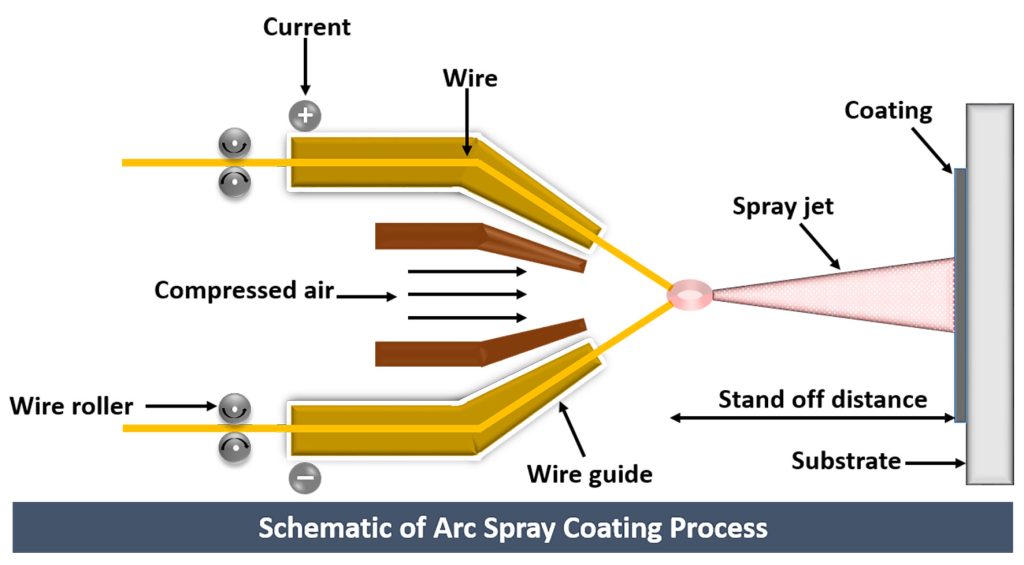

Spray Arc Tig Welding . Tiny droplets of molten metal travel. Flame and arc welding (also called tsa, tsz, twas): Spray arc welding is an efficient and economical method for joining two pieces of metal together, resulting in stronger bonds than other traditional fusion processes. Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. The arc spray process utilizes a dc power source at high amps (usually 650 amp) to energize negative and positive wires. Uses fuel such as acetylene or an electric arc to create required heat.

from www.arcsprayengineering.com.au

The arc spray process utilizes a dc power source at high amps (usually 650 amp) to energize negative and positive wires. Uses fuel such as acetylene or an electric arc to create required heat. Flame and arc welding (also called tsa, tsz, twas): Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. Spray arc welding is an efficient and economical method for joining two pieces of metal together, resulting in stronger bonds than other traditional fusion processes. Tiny droplets of molten metal travel.

Arc Spraying Arc Spray Engineering

Spray Arc Tig Welding Flame and arc welding (also called tsa, tsz, twas): Spray arc welding is an efficient and economical method for joining two pieces of metal together, resulting in stronger bonds than other traditional fusion processes. Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. Tiny droplets of molten metal travel. The arc spray process utilizes a dc power source at high amps (usually 650 amp) to energize negative and positive wires. Flame and arc welding (also called tsa, tsz, twas): Uses fuel such as acetylene or an electric arc to create required heat.

From bangshift.com

InDepth Look At Using Spray Welding To Repair A Large Spray Arc Tig Welding Flame and arc welding (also called tsa, tsz, twas): Tiny droplets of molten metal travel. Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. Uses fuel such as acetylene or an electric arc to create required heat. The arc spray process utilizes a dc power source at high amps (usually 650. Spray Arc Tig Welding.

From www.youtube.com

MIG Welding Basics What is Spray Arc Transfer? YouTube Spray Arc Tig Welding Spray arc welding is an efficient and economical method for joining two pieces of metal together, resulting in stronger bonds than other traditional fusion processes. Flame and arc welding (also called tsa, tsz, twas): The arc spray process utilizes a dc power source at high amps (usually 650 amp) to energize negative and positive wires. Spray transfer is named for. Spray Arc Tig Welding.

From www.walter.com

TIG Welding Walter Surface Technologies Spray Arc Tig Welding The arc spray process utilizes a dc power source at high amps (usually 650 amp) to energize negative and positive wires. Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. Uses fuel such as acetylene or an electric arc to create required heat. Tiny droplets of molten metal travel. Flame and. Spray Arc Tig Welding.

From www.pinterest.com

Practicing for a spray arc cert in July. Any advice would be Spray Arc Tig Welding Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. Spray arc welding is an efficient and economical method for joining two pieces of metal together, resulting in stronger bonds than other traditional fusion processes. Tiny droplets of molten metal travel. Flame and arc welding (also called tsa, tsz, twas): Uses fuel. Spray Arc Tig Welding.

From weldingpros.net

Spray Welding Methods & Types Advantages & Drawbacks Spray Arc Tig Welding Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. The arc spray process utilizes a dc power source at high amps (usually 650 amp) to energize negative and positive wires. Uses fuel such as acetylene or an electric arc to create required heat. Spray arc welding is an efficient and economical. Spray Arc Tig Welding.

From www.beltecno-global.com

Laser Focus on TIG Welding Spray Arc Tig Welding The arc spray process utilizes a dc power source at high amps (usually 650 amp) to energize negative and positive wires. Spray arc welding is an efficient and economical method for joining two pieces of metal together, resulting in stronger bonds than other traditional fusion processes. Uses fuel such as acetylene or an electric arc to create required heat. Flame. Spray Arc Tig Welding.

From captionsblogau.blogspot.com

What Is Spray Arc Welding Captions Blog Spray Arc Tig Welding The arc spray process utilizes a dc power source at high amps (usually 650 amp) to energize negative and positive wires. Tiny droplets of molten metal travel. Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. Flame and arc welding (also called tsa, tsz, twas): Uses fuel such as acetylene or. Spray Arc Tig Welding.

From streetlink.org.uk

😝 Difference between arc mig and tig welding. The Different Types of Spray Arc Tig Welding Tiny droplets of molten metal travel. The arc spray process utilizes a dc power source at high amps (usually 650 amp) to energize negative and positive wires. Flame and arc welding (also called tsa, tsz, twas): Spray arc welding is an efficient and economical method for joining two pieces of metal together, resulting in stronger bonds than other traditional fusion. Spray Arc Tig Welding.

From weldguru.com

Welding Transfer Modes Spray, Global & Short Circuiting Spray Arc Tig Welding Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. Spray arc welding is an efficient and economical method for joining two pieces of metal together, resulting in stronger bonds than other traditional fusion processes. Flame and arc welding (also called tsa, tsz, twas): Uses fuel such as acetylene or an electric. Spray Arc Tig Welding.

From techslana.weebly.com

Tig welding technics manual techslana Spray Arc Tig Welding Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. Tiny droplets of molten metal travel. The arc spray process utilizes a dc power source at high amps (usually 650 amp) to energize negative and positive wires. Uses fuel such as acetylene or an electric arc to create required heat. Spray arc. Spray Arc Tig Welding.

From weldguru.com

Welding Transfer Modes Spray, Global & Short Circuiting Spray Arc Tig Welding Tiny droplets of molten metal travel. Spray arc welding is an efficient and economical method for joining two pieces of metal together, resulting in stronger bonds than other traditional fusion processes. Flame and arc welding (also called tsa, tsz, twas): The arc spray process utilizes a dc power source at high amps (usually 650 amp) to energize negative and positive. Spray Arc Tig Welding.

From lasoparail602.weebly.com

Mig welder does not arc lasoparail Spray Arc Tig Welding Flame and arc welding (also called tsa, tsz, twas): Uses fuel such as acetylene or an electric arc to create required heat. The arc spray process utilizes a dc power source at high amps (usually 650 amp) to energize negative and positive wires. Tiny droplets of molten metal travel. Spray transfer is named for the spray of tiny molten droplets. Spray Arc Tig Welding.

From www.youtube.com

Spray Arc MIG Welding YouTube Spray Arc Tig Welding Uses fuel such as acetylene or an electric arc to create required heat. The arc spray process utilizes a dc power source at high amps (usually 650 amp) to energize negative and positive wires. Spray arc welding is an efficient and economical method for joining two pieces of metal together, resulting in stronger bonds than other traditional fusion processes. Tiny. Spray Arc Tig Welding.

From www.westweld.com

WS(M)315/400IGBT Pro Inverter Pulse Argon Arc TIG Welding Machine Spray Arc Tig Welding Spray arc welding is an efficient and economical method for joining two pieces of metal together, resulting in stronger bonds than other traditional fusion processes. Flame and arc welding (also called tsa, tsz, twas): Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. Tiny droplets of molten metal travel. The arc. Spray Arc Tig Welding.

From www.reddit.com

Saturday morning Spray Arc r/Welding Spray Arc Tig Welding Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. Flame and arc welding (also called tsa, tsz, twas): Tiny droplets of molten metal travel. The arc spray process utilizes a dc power source at high amps (usually 650 amp) to energize negative and positive wires. Spray arc welding is an efficient. Spray Arc Tig Welding.

From weldguru.com

TIG Welding Filler Rods Selection Size With Chart Weld Guru Spray Arc Tig Welding Uses fuel such as acetylene or an electric arc to create required heat. Flame and arc welding (also called tsa, tsz, twas): Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. Spray arc welding is an efficient and economical method for joining two pieces of metal together, resulting in stronger bonds. Spray Arc Tig Welding.

From www.arcsprayengineering.com.au

Arc Spraying Arc Spray Engineering Spray Arc Tig Welding Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. Flame and arc welding (also called tsa, tsz, twas): Tiny droplets of molten metal travel. Spray arc welding is an efficient and economical method for joining two pieces of metal together, resulting in stronger bonds than other traditional fusion processes. The arc. Spray Arc Tig Welding.

From blog.thepipingmart.com

Advantages and Disadvantages of Spray Arc MIG Welding Spray Arc Tig Welding Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. Spray arc welding is an efficient and economical method for joining two pieces of metal together, resulting in stronger bonds than other traditional fusion processes. Tiny droplets of molten metal travel. The arc spray process utilizes a dc power source at high. Spray Arc Tig Welding.

From onsitemachiningsolutions.com

Spray Welding Onsite Machining Solutions Spray Arc Tig Welding Flame and arc welding (also called tsa, tsz, twas): The arc spray process utilizes a dc power source at high amps (usually 650 amp) to energize negative and positive wires. Uses fuel such as acetylene or an electric arc to create required heat. Tiny droplets of molten metal travel. Spray arc welding is an efficient and economical method for joining. Spray Arc Tig Welding.

From weldguru.com

MIG vs TIG Welding The Main Differences Weld Guru Spray Arc Tig Welding The arc spray process utilizes a dc power source at high amps (usually 650 amp) to energize negative and positive wires. Flame and arc welding (also called tsa, tsz, twas): Uses fuel such as acetylene or an electric arc to create required heat. Spray arc welding is an efficient and economical method for joining two pieces of metal together, resulting. Spray Arc Tig Welding.

From blog.thepipingmart.com

Arc Welding vs TIG Welding What's the Difference Spray Arc Tig Welding Flame and arc welding (also called tsa, tsz, twas): The arc spray process utilizes a dc power source at high amps (usually 650 amp) to energize negative and positive wires. Tiny droplets of molten metal travel. Spray arc welding is an efficient and economical method for joining two pieces of metal together, resulting in stronger bonds than other traditional fusion. Spray Arc Tig Welding.

From weldingclarity.com

What is Spray Arc Welding? A Comprehensive Guide Procedure Spray Arc Tig Welding Flame and arc welding (also called tsa, tsz, twas): Uses fuel such as acetylene or an electric arc to create required heat. Tiny droplets of molten metal travel. Spray arc welding is an efficient and economical method for joining two pieces of metal together, resulting in stronger bonds than other traditional fusion processes. The arc spray process utilizes a dc. Spray Arc Tig Welding.

From blog.thepipingmart.com

TIG Welding vs Arc Welding What's the Difference Spray Arc Tig Welding Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. Tiny droplets of molten metal travel. Flame and arc welding (also called tsa, tsz, twas): Uses fuel such as acetylene or an electric arc to create required heat. The arc spray process utilizes a dc power source at high amps (usually 650. Spray Arc Tig Welding.

From blog.thepipingmart.com

What is Spray Arc Welding? Uses and Working Spray Arc Tig Welding Tiny droplets of molten metal travel. Spray arc welding is an efficient and economical method for joining two pieces of metal together, resulting in stronger bonds than other traditional fusion processes. Flame and arc welding (also called tsa, tsz, twas): Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. The arc. Spray Arc Tig Welding.

From weldingheadquarters.com

What is Spray Arc Welding? Welding Headquarters Spray Arc Tig Welding Spray arc welding is an efficient and economical method for joining two pieces of metal together, resulting in stronger bonds than other traditional fusion processes. Tiny droplets of molten metal travel. Uses fuel such as acetylene or an electric arc to create required heat. The arc spray process utilizes a dc power source at high amps (usually 650 amp) to. Spray Arc Tig Welding.

From slidetodoc.com

CHAPTER 10 Gas Metal Arc Welding Equipment Setup Spray Arc Tig Welding Spray arc welding is an efficient and economical method for joining two pieces of metal together, resulting in stronger bonds than other traditional fusion processes. Flame and arc welding (also called tsa, tsz, twas): The arc spray process utilizes a dc power source at high amps (usually 650 amp) to energize negative and positive wires. Tiny droplets of molten metal. Spray Arc Tig Welding.

From socalweldtrainingschool.org

Gas Tungsten Arc Welding (TIG) III Weld on Stainless Steel Spray Arc Tig Welding Tiny droplets of molten metal travel. The arc spray process utilizes a dc power source at high amps (usually 650 amp) to energize negative and positive wires. Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. Flame and arc welding (also called tsa, tsz, twas): Uses fuel such as acetylene or. Spray Arc Tig Welding.

From www.technoxmachine.com

MIG vs TIG Welding Types, Materials, and Applications A Guide Spray Arc Tig Welding Tiny droplets of molten metal travel. Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. The arc spray process utilizes a dc power source at high amps (usually 650 amp) to energize negative and positive wires. Spray arc welding is an efficient and economical method for joining two pieces of metal. Spray Arc Tig Welding.

From www.perfectwelders.com

What Do You Need To Achieve Spray Arc Welding? PERFECT POWER Spray Arc Tig Welding The arc spray process utilizes a dc power source at high amps (usually 650 amp) to energize negative and positive wires. Tiny droplets of molten metal travel. Uses fuel such as acetylene or an electric arc to create required heat. Flame and arc welding (also called tsa, tsz, twas): Spray arc welding is an efficient and economical method for joining. Spray Arc Tig Welding.

From www.thefabricator.com

TIG welding stainless steel? Investing in three areas may help Spray Arc Tig Welding Tiny droplets of molten metal travel. Flame and arc welding (also called tsa, tsz, twas): Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. Spray arc welding is an efficient and economical method for joining two pieces of metal together, resulting in stronger bonds than other traditional fusion processes. The arc. Spray Arc Tig Welding.

From blog.thepipingmart.com

Plasma Arc Welding vs TIG Welding What's the Difference Spray Arc Tig Welding Tiny droplets of molten metal travel. Flame and arc welding (also called tsa, tsz, twas): Spray arc welding is an efficient and economical method for joining two pieces of metal together, resulting in stronger bonds than other traditional fusion processes. The arc spray process utilizes a dc power source at high amps (usually 650 amp) to energize negative and positive. Spray Arc Tig Welding.

From ar.inspiredpencil.com

Arc Welding Process Spray Arc Tig Welding The arc spray process utilizes a dc power source at high amps (usually 650 amp) to energize negative and positive wires. Tiny droplets of molten metal travel. Spray arc welding is an efficient and economical method for joining two pieces of metal together, resulting in stronger bonds than other traditional fusion processes. Spray transfer is named for the spray of. Spray Arc Tig Welding.

From www.basicwelding.co.uk

What Is Spray Arc Welding? How It Works BWS Ltd Spray Arc Tig Welding Uses fuel such as acetylene or an electric arc to create required heat. Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. The arc spray process utilizes a dc power source at high amps (usually 650 amp) to energize negative and positive wires. Tiny droplets of molten metal travel. Spray arc. Spray Arc Tig Welding.

From www.topwellwelders.com

Pulse MIG(sprayarc transfer) for welding aluminum by Portable MIG Spray Arc Tig Welding Spray arc welding is an efficient and economical method for joining two pieces of metal together, resulting in stronger bonds than other traditional fusion processes. Tiny droplets of molten metal travel. Spray transfer is named for the spray of tiny molten droplets across the arc, similar to spray coming. The arc spray process utilizes a dc power source at high. Spray Arc Tig Welding.

From www.alloy-wires.com

TIG MIG Submerged Arc Welding Metal Spray Wire 308LSi Spray Arc Tig Welding Flame and arc welding (also called tsa, tsz, twas): Tiny droplets of molten metal travel. Uses fuel such as acetylene or an electric arc to create required heat. Spray arc welding is an efficient and economical method for joining two pieces of metal together, resulting in stronger bonds than other traditional fusion processes. Spray transfer is named for the spray. Spray Arc Tig Welding.