Zinc Primer On Galvanized Steel . There are various methods of providing galvanic protection by using protective coatings; Two of the most effective methods are hot dip galvanizing and application of an inorganic zinc rich primer. Painting galvanized steel requires careful preparation and a good understanding of both painting and galvanizing. Many products have been galvanized and painted successfully for. Zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; Both provide an amount of zinc needed to promote electrical. To help architects, engineers, and other specifiers assess and select the most. This article presents a comparison of the application processes and performance properties of these two sacrificial coatings.

from galvanizeit.org

Painting galvanized steel requires careful preparation and a good understanding of both painting and galvanizing. There are various methods of providing galvanic protection by using protective coatings; Zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; Both provide an amount of zinc needed to promote electrical. Two of the most effective methods are hot dip galvanizing and application of an inorganic zinc rich primer. This article presents a comparison of the application processes and performance properties of these two sacrificial coatings. Many products have been galvanized and painted successfully for. To help architects, engineers, and other specifiers assess and select the most.

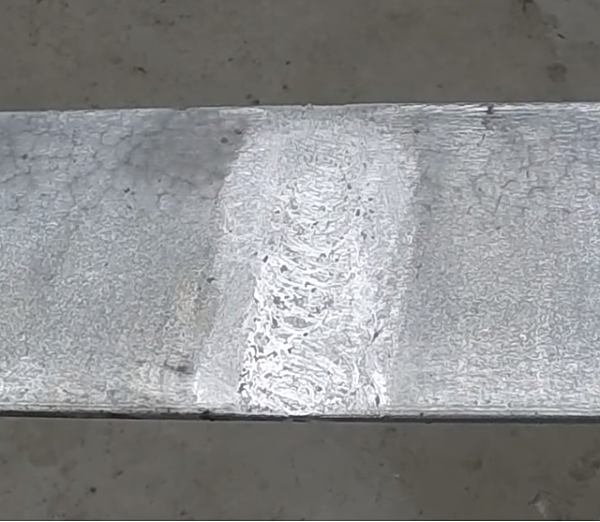

Natural Weathering & Zinc Repairs American Galvanizers Association

Zinc Primer On Galvanized Steel There are various methods of providing galvanic protection by using protective coatings; Both provide an amount of zinc needed to promote electrical. Painting galvanized steel requires careful preparation and a good understanding of both painting and galvanizing. This article presents a comparison of the application processes and performance properties of these two sacrificial coatings. To help architects, engineers, and other specifiers assess and select the most. Many products have been galvanized and painted successfully for. There are various methods of providing galvanic protection by using protective coatings; Zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; Two of the most effective methods are hot dip galvanizing and application of an inorganic zinc rich primer.

From www.duluxprotectivecoatings.com.au

Zinc Rich 1P Zinc Primer On Galvanized Steel Many products have been galvanized and painted successfully for. This article presents a comparison of the application processes and performance properties of these two sacrificial coatings. Both provide an amount of zinc needed to promote electrical. Two of the most effective methods are hot dip galvanizing and application of an inorganic zinc rich primer. Painting galvanized steel requires careful preparation. Zinc Primer On Galvanized Steel.

From www.alibaba.com

Galvanized Iron Zinc Coated Roofing Sheet Corrugated Steel Plate Buy Zinc Primer On Galvanized Steel Two of the most effective methods are hot dip galvanizing and application of an inorganic zinc rich primer. Many products have been galvanized and painted successfully for. There are various methods of providing galvanic protection by using protective coatings; Painting galvanized steel requires careful preparation and a good understanding of both painting and galvanizing. Zinc painting, zinc spray metallizing, mechanical. Zinc Primer On Galvanized Steel.

From www.bmsteel.co.uk

2.5L Zinc Rich Galvanized Coating ? Primer BM Steel Zinc Primer On Galvanized Steel There are various methods of providing galvanic protection by using protective coatings; Both provide an amount of zinc needed to promote electrical. Two of the most effective methods are hot dip galvanizing and application of an inorganic zinc rich primer. Many products have been galvanized and painted successfully for. This article presents a comparison of the application processes and performance. Zinc Primer On Galvanized Steel.

From aaasupply.com

Valspar Valspar Professional Galvanized Metal Primer Zinc Primer On Galvanized Steel Zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; This article presents a comparison of the application processes and performance properties of these two sacrificial coatings. Two of the most effective methods are hot dip galvanizing and application of an inorganic zinc rich primer. To help architects, engineers, and other specifiers assess and select the most. Both provide. Zinc Primer On Galvanized Steel.

From galvanizeit.org

Natural Weathering & Zinc Repairs American Galvanizers Association Zinc Primer On Galvanized Steel Many products have been galvanized and painted successfully for. Painting galvanized steel requires careful preparation and a good understanding of both painting and galvanizing. To help architects, engineers, and other specifiers assess and select the most. Zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; Two of the most effective methods are hot dip galvanizing and application of. Zinc Primer On Galvanized Steel.

From www.wikihow.com

How to Weld Galvanized Steel 10 Steps (with Pictures) wikiHow Zinc Primer On Galvanized Steel Zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; Painting galvanized steel requires careful preparation and a good understanding of both painting and galvanizing. Many products have been galvanized and painted successfully for. To help architects, engineers, and other specifiers assess and select the most. Both provide an amount of zinc needed to promote electrical. There are various. Zinc Primer On Galvanized Steel.

From www.rapidonline.com

Rustins GALP1000 Quick Dry Galvanized Metal Primer 1 Litre Rapid Online Zinc Primer On Galvanized Steel To help architects, engineers, and other specifiers assess and select the most. Painting galvanized steel requires careful preparation and a good understanding of both painting and galvanizing. Two of the most effective methods are hot dip galvanizing and application of an inorganic zinc rich primer. Many products have been galvanized and painted successfully for. Both provide an amount of zinc. Zinc Primer On Galvanized Steel.

From www.prweb.com

NEI Introduces Selfhealing Anticorrosion Coating for ZincPlated and Zinc Primer On Galvanized Steel Painting galvanized steel requires careful preparation and a good understanding of both painting and galvanizing. Both provide an amount of zinc needed to promote electrical. This article presents a comparison of the application processes and performance properties of these two sacrificial coatings. To help architects, engineers, and other specifiers assess and select the most. There are various methods of providing. Zinc Primer On Galvanized Steel.

From techniqpro.com

CAR REP Zinc PRIMER 400ml Zinc Cold Galvanized Spray Welding seams Zinc Primer On Galvanized Steel This article presents a comparison of the application processes and performance properties of these two sacrificial coatings. Two of the most effective methods are hot dip galvanizing and application of an inorganic zinc rich primer. Many products have been galvanized and painted successfully for. To help architects, engineers, and other specifiers assess and select the most. Both provide an amount. Zinc Primer On Galvanized Steel.

From www.metalsteelpipe.com

Hot Dipped Galvanized Steel Plates Zinc Coating SPCC G90 GI Galvanised Zinc Primer On Galvanized Steel To help architects, engineers, and other specifiers assess and select the most. Both provide an amount of zinc needed to promote electrical. This article presents a comparison of the application processes and performance properties of these two sacrificial coatings. Zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; Many products have been galvanized and painted successfully for. Two. Zinc Primer On Galvanized Steel.

From shop.ehayes.co.nz

Corrodex Cold Galv Zinc Rich Metal Primer Zinc Primer On Galvanized Steel Painting galvanized steel requires careful preparation and a good understanding of both painting and galvanizing. To help architects, engineers, and other specifiers assess and select the most. This article presents a comparison of the application processes and performance properties of these two sacrificial coatings. Zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; Both provide an amount of. Zinc Primer On Galvanized Steel.

From www.sturdybuiltonline.com

1 Quart Zinc Rich Cold Galvanized Paint Zinc Primer On Galvanized Steel Painting galvanized steel requires careful preparation and a good understanding of both painting and galvanizing. To help architects, engineers, and other specifiers assess and select the most. Both provide an amount of zinc needed to promote electrical. Zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; There are various methods of providing galvanic protection by using protective coatings;. Zinc Primer On Galvanized Steel.

From www.pinterest.co.kr

Galvanized sheet of metal. Zinc galvanized sheet of metal. Can be used Zinc Primer On Galvanized Steel To help architects, engineers, and other specifiers assess and select the most. Zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; Two of the most effective methods are hot dip galvanizing and application of an inorganic zinc rich primer. Many products have been galvanized and painted successfully for. Both provide an amount of zinc needed to promote electrical.. Zinc Primer On Galvanized Steel.

From www.animalia-life.club

Zinc Metal Products Zinc Primer On Galvanized Steel Both provide an amount of zinc needed to promote electrical. Many products have been galvanized and painted successfully for. There are various methods of providing galvanic protection by using protective coatings; Zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; To help architects, engineers, and other specifiers assess and select the most. Painting galvanized steel requires careful preparation. Zinc Primer On Galvanized Steel.

From burkeindustrialcoatings.com

Stainless Steel Gray Epoxy Metal Primer Coating DuraSteel 316™ Zinc Primer On Galvanized Steel Zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; Two of the most effective methods are hot dip galvanizing and application of an inorganic zinc rich primer. Both provide an amount of zinc needed to promote electrical. This article presents a comparison of the application processes and performance properties of these two sacrificial coatings. To help architects, engineers,. Zinc Primer On Galvanized Steel.

From www.meesenburg.kz

Wash Primer For Galvanized Steel Outlet Stores www.meesenburg.kz Zinc Primer On Galvanized Steel Two of the most effective methods are hot dip galvanizing and application of an inorganic zinc rich primer. Painting galvanized steel requires careful preparation and a good understanding of both painting and galvanizing. To help architects, engineers, and other specifiers assess and select the most. Many products have been galvanized and painted successfully for. Both provide an amount of zinc. Zinc Primer On Galvanized Steel.

From www.pwmag.com

Organic ZincRich Epoxy Coating Public Works Magazine Coatings and Zinc Primer On Galvanized Steel Zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; To help architects, engineers, and other specifiers assess and select the most. This article presents a comparison of the application processes and performance properties of these two sacrificial coatings. Many products have been galvanized and painted successfully for. Both provide an amount of zinc needed to promote electrical. There. Zinc Primer On Galvanized Steel.

From www.buzzweld.co.uk

Zinc Rich Primer Paint Testing on Blasted steel, and rusty metal Zinc Primer On Galvanized Steel To help architects, engineers, and other specifiers assess and select the most. Many products have been galvanized and painted successfully for. Painting galvanized steel requires careful preparation and a good understanding of both painting and galvanizing. Both provide an amount of zinc needed to promote electrical. Zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; There are various. Zinc Primer On Galvanized Steel.

From www.soselectronic.com

Zinc Primer 500ml CRC Corrosion protective easy to paint over 292709 Zinc Primer On Galvanized Steel This article presents a comparison of the application processes and performance properties of these two sacrificial coatings. There are various methods of providing galvanic protection by using protective coatings; Many products have been galvanized and painted successfully for. Two of the most effective methods are hot dip galvanizing and application of an inorganic zinc rich primer. Painting galvanized steel requires. Zinc Primer On Galvanized Steel.

From www.protectivepaints.co.nz

01.55 Epoxy Zinc Primer 31 Protective Paints Zinc Primer On Galvanized Steel Both provide an amount of zinc needed to promote electrical. This article presents a comparison of the application processes and performance properties of these two sacrificial coatings. Zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; Two of the most effective methods are hot dip galvanizing and application of an inorganic zinc rich primer. Many products have been. Zinc Primer On Galvanized Steel.

From www.southpacificsupplies.co.nz

Bright Galvanise Coating 65 Zinc Rich South Pacific Supplies Ltd Zinc Primer On Galvanized Steel Zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; Painting galvanized steel requires careful preparation and a good understanding of both painting and galvanizing. Two of the most effective methods are hot dip galvanizing and application of an inorganic zinc rich primer. This article presents a comparison of the application processes and performance properties of these two sacrificial. Zinc Primer On Galvanized Steel.

From www.galvanizeit.org

ZincRich Paint American Galvanizers Association Zinc Primer On Galvanized Steel Many products have been galvanized and painted successfully for. To help architects, engineers, and other specifiers assess and select the most. There are various methods of providing galvanic protection by using protective coatings; Zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; This article presents a comparison of the application processes and performance properties of these two sacrificial. Zinc Primer On Galvanized Steel.

From www.bigstockphoto.com

Zinc Galvanized Grunge Image & Photo (Free Trial) Bigstock Zinc Primer On Galvanized Steel This article presents a comparison of the application processes and performance properties of these two sacrificial coatings. Two of the most effective methods are hot dip galvanizing and application of an inorganic zinc rich primer. Both provide an amount of zinc needed to promote electrical. Painting galvanized steel requires careful preparation and a good understanding of both painting and galvanizing.. Zinc Primer On Galvanized Steel.

From mrslja.com

Pat yarn spray primer for galvanized metal effective Bank Zinc Primer On Galvanized Steel This article presents a comparison of the application processes and performance properties of these two sacrificial coatings. There are various methods of providing galvanic protection by using protective coatings; To help architects, engineers, and other specifiers assess and select the most. Painting galvanized steel requires careful preparation and a good understanding of both painting and galvanizing. Both provide an amount. Zinc Primer On Galvanized Steel.

From www.sonalog.com

Agriculture Zinc Primer Galvanized Steel Coil By Hot Dip Galvanization Zinc Primer On Galvanized Steel Many products have been galvanized and painted successfully for. Two of the most effective methods are hot dip galvanizing and application of an inorganic zinc rich primer. Painting galvanized steel requires careful preparation and a good understanding of both painting and galvanizing. Zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; Both provide an amount of zinc needed. Zinc Primer On Galvanized Steel.

From www.duluxprotectivecoatings.com.au

Metalshield Cold Galv Primer Zinc Primer On Galvanized Steel This article presents a comparison of the application processes and performance properties of these two sacrificial coatings. Painting galvanized steel requires careful preparation and a good understanding of both painting and galvanizing. Both provide an amount of zinc needed to promote electrical. Two of the most effective methods are hot dip galvanizing and application of an inorganic zinc rich primer.. Zinc Primer On Galvanized Steel.

From www.steelpanels.co.uk

FROST WELDTHRU ZINC GALVANIZED RICH PRIMER 500ML ExPressed Steel Zinc Primer On Galvanized Steel Two of the most effective methods are hot dip galvanizing and application of an inorganic zinc rich primer. Painting galvanized steel requires careful preparation and a good understanding of both painting and galvanizing. Zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; To help architects, engineers, and other specifiers assess and select the most. This article presents a. Zinc Primer On Galvanized Steel.

From www.buzzweld.co.uk

Zinc Rich Primer Paint Testing on Blasted steel, and rusty metal Zinc Primer On Galvanized Steel Painting galvanized steel requires careful preparation and a good understanding of both painting and galvanizing. Many products have been galvanized and painted successfully for. Two of the most effective methods are hot dip galvanizing and application of an inorganic zinc rich primer. To help architects, engineers, and other specifiers assess and select the most. There are various methods of providing. Zinc Primer On Galvanized Steel.

From www.isocolor.co.uk

Primer for galvanized sheet and surfaces with difficult adhesion Zinc Primer On Galvanized Steel Many products have been galvanized and painted successfully for. Two of the most effective methods are hot dip galvanizing and application of an inorganic zinc rich primer. To help architects, engineers, and other specifiers assess and select the most. Zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; This article presents a comparison of the application processes and. Zinc Primer On Galvanized Steel.

From www.rolledsteelsheet.com

Building Zinc Coated Hot Dipped Galvanized Steel Coil GI ID 508mm Zinc Primer On Galvanized Steel This article presents a comparison of the application processes and performance properties of these two sacrificial coatings. Zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; Both provide an amount of zinc needed to promote electrical. Many products have been galvanized and painted successfully for. Two of the most effective methods are hot dip galvanizing and application of. Zinc Primer On Galvanized Steel.

From www.homedepot.com

Zinsser 1 gal. Flat Red Interior/Exterior 400 VOC Metal Primer (2Pack Zinc Primer On Galvanized Steel Zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; Painting galvanized steel requires careful preparation and a good understanding of both painting and galvanizing. This article presents a comparison of the application processes and performance properties of these two sacrificial coatings. Two of the most effective methods are hot dip galvanizing and application of an inorganic zinc rich. Zinc Primer On Galvanized Steel.

From www.pinterest.com

Zinc vs. Galvanized Steel US Coatings Galvanized, Galvanized steel Zinc Primer On Galvanized Steel To help architects, engineers, and other specifiers assess and select the most. Two of the most effective methods are hot dip galvanizing and application of an inorganic zinc rich primer. Both provide an amount of zinc needed to promote electrical. Painting galvanized steel requires careful preparation and a good understanding of both painting and galvanizing. There are various methods of. Zinc Primer On Galvanized Steel.

From www.rlapolymers.com.au

Zinc Primer RLA Polymers Zinc Primer On Galvanized Steel Zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; To help architects, engineers, and other specifiers assess and select the most. Painting galvanized steel requires careful preparation and a good understanding of both painting and galvanizing. There are various methods of providing galvanic protection by using protective coatings; This article presents a comparison of the application processes and. Zinc Primer On Galvanized Steel.

From www.sonalog.com

Agriculture Zinc Primer Galvanized Steel Coil By Hot Dip Galvanization Zinc Primer On Galvanized Steel Painting galvanized steel requires careful preparation and a good understanding of both painting and galvanizing. Both provide an amount of zinc needed to promote electrical. Two of the most effective methods are hot dip galvanizing and application of an inorganic zinc rich primer. This article presents a comparison of the application processes and performance properties of these two sacrificial coatings.. Zinc Primer On Galvanized Steel.

From medium.com

4S Zinc Galvanizing Spray is a highly effective Zincrich touchup Zinc Primer On Galvanized Steel This article presents a comparison of the application processes and performance properties of these two sacrificial coatings. Both provide an amount of zinc needed to promote electrical. There are various methods of providing galvanic protection by using protective coatings; Zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; Two of the most effective methods are hot dip galvanizing. Zinc Primer On Galvanized Steel.