Blade Shear Cut . We use rotary shearing at shengen for specific applications where its unique. They're tasked with the demanding job. Shearing is a simple process whereby a sheet of metal is cut into smaller pieces by two knives which are positioned at an angle relative to each other. Shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. In this section, we will dive into the 4 geometrical relationships that. Click here to read the first part of “the 2 types of shear cutting and the 4 relations that impact quality”. The lower knife is firmly attached. The drive system powers the moving blade through the material to make a cut. Shear cutting (also known as shear slitting) is the type of slitting that uses a combination of top and bottom knives. This shearing type can cut metal into strips or trim edges. Drive systems can be categorized into five. With the defined geometries introduced later in. To cut sheet metal, we use blades that rotate.

from www.youtube.com

Shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. Shear cutting (also known as shear slitting) is the type of slitting that uses a combination of top and bottom knives. They're tasked with the demanding job. This shearing type can cut metal into strips or trim edges. With the defined geometries introduced later in. The drive system powers the moving blade through the material to make a cut. The lower knife is firmly attached. Drive systems can be categorized into five. To cut sheet metal, we use blades that rotate. In this section, we will dive into the 4 geometrical relationships that.

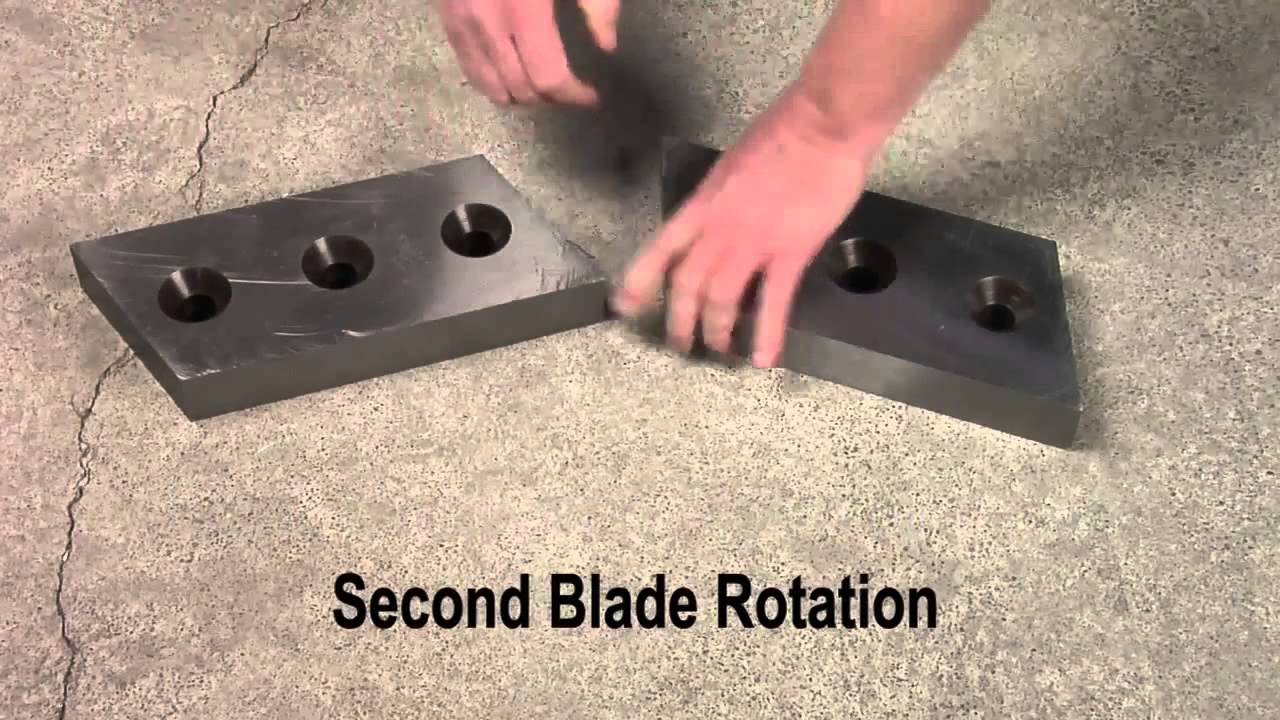

Genesis Mobile Shear Cutting Blade Rotation YouTube 720p YouTube

Blade Shear Cut They're tasked with the demanding job. The drive system powers the moving blade through the material to make a cut. In this section, we will dive into the 4 geometrical relationships that. Shearing is a simple process whereby a sheet of metal is cut into smaller pieces by two knives which are positioned at an angle relative to each other. They're tasked with the demanding job. Click here to read the first part of “the 2 types of shear cutting and the 4 relations that impact quality”. This shearing type can cut metal into strips or trim edges. We use rotary shearing at shengen for specific applications where its unique. With the defined geometries introduced later in. The lower knife is firmly attached. To cut sheet metal, we use blades that rotate. Shear cutting (also known as shear slitting) is the type of slitting that uses a combination of top and bottom knives. Shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. Drive systems can be categorized into five.

From washiscissor.com

Shear Knowledge Shear Quality, Steel Types, Blade Types and more.. Blade Shear Cut To cut sheet metal, we use blades that rotate. In this section, we will dive into the 4 geometrical relationships that. Click here to read the first part of “the 2 types of shear cutting and the 4 relations that impact quality”. The lower knife is firmly attached. Shear cutting (also known as shear slitting) is the type of slitting. Blade Shear Cut.

From masshenlite.en.made-in-china.com

Rolling Shear Slitting Blade, Longitudinal Shear Round Blade, Cutting Blade Shear Cut Shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. This shearing type can cut metal into strips or trim edges. The drive system powers the moving blade through the material to make a cut. Drive systems can be categorized into five. To cut sheet metal, we use blades. Blade Shear Cut.

From havencut.com

Servo Controlled Dualblade Shear Cutoff from Haven Manufacturing Blade Shear Cut With the defined geometries introduced later in. In this section, we will dive into the 4 geometrical relationships that. This shearing type can cut metal into strips or trim edges. Shear cutting (also known as shear slitting) is the type of slitting that uses a combination of top and bottom knives. The drive system powers the moving blade through the. Blade Shear Cut.

From toolnotes.com

Sheet Metal Shearing ToolNotes Blade Shear Cut The drive system powers the moving blade through the material to make a cut. In this section, we will dive into the 4 geometrical relationships that. Shearing is a simple process whereby a sheet of metal is cut into smaller pieces by two knives which are positioned at an angle relative to each other. This shearing type can cut metal. Blade Shear Cut.

From havencut.com

DualAxis / DualBlade Shear Cutoff from Coil Videos Blade Shear Cut We use rotary shearing at shengen for specific applications where its unique. With the defined geometries introduced later in. The lower knife is firmly attached. Shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. Click here to read the first part of “the 2 types of shear cutting. Blade Shear Cut.

From boyutcnc.com

Shear CutOff Blades & Machine Knives BoyutCNC Blade Shear Cut Drive systems can be categorized into five. This shearing type can cut metal into strips or trim edges. Click here to read the first part of “the 2 types of shear cutting and the 4 relations that impact quality”. Shear cutting (also known as shear slitting) is the type of slitting that uses a combination of top and bottom knives.. Blade Shear Cut.

From havencut.com

Haven's DualBlade Shear Cutting Technology Haven Manufacturing Blade Shear Cut Shear cutting (also known as shear slitting) is the type of slitting that uses a combination of top and bottom knives. Drive systems can be categorized into five. We use rotary shearing at shengen for specific applications where its unique. They're tasked with the demanding job. With the defined geometries introduced later in. Shearing is a simple process whereby a. Blade Shear Cut.

From havencut.com

DualBlade Shear Cutting Tube Recut Machines Finishing Blade Shear Cut Click here to read the first part of “the 2 types of shear cutting and the 4 relations that impact quality”. The drive system powers the moving blade through the material to make a cut. Drive systems can be categorized into five. This shearing type can cut metal into strips or trim edges. We use rotary shearing at shengen for. Blade Shear Cut.

From www.youtube.com

Genesis Mobile Shear Cutting Blade Rotation YouTube 720p YouTube Blade Shear Cut Shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. The lower knife is firmly attached. In this section, we will dive into the 4 geometrical relationships that. To cut sheet metal, we use blades that rotate. This shearing type can cut metal into strips or trim edges. They're. Blade Shear Cut.

From havencut.com

Haven Designs Unique 873 DualBlade Shear Solution Blade Shear Cut In this section, we will dive into the 4 geometrical relationships that. Shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. They're tasked with the demanding job. Click here to read the first part of “the 2 types of shear cutting and the 4 relations that impact quality”.. Blade Shear Cut.

From federalknife.com

Metal cutting Shear blades for most machines makes and models • Federal Blade Shear Cut This shearing type can cut metal into strips or trim edges. The lower knife is firmly attached. We use rotary shearing at shengen for specific applications where its unique. Shearing is a simple process whereby a sheet of metal is cut into smaller pieces by two knives which are positioned at an angle relative to each other. Click here to. Blade Shear Cut.

From www.dienesusa.com

The 2 Types of Shear Cutting and the 4 Relations that Impact Quality Blade Shear Cut Shear cutting (also known as shear slitting) is the type of slitting that uses a combination of top and bottom knives. The drive system powers the moving blade through the material to make a cut. Shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. They're tasked with the. Blade Shear Cut.

From www.desertcart.ae

Buy Multi Angle Miter Shear Cutter ket Shear 45 Degree to 135 Degree Blade Shear Cut In this section, we will dive into the 4 geometrical relationships that. The drive system powers the moving blade through the material to make a cut. To cut sheet metal, we use blades that rotate. They're tasked with the demanding job. Click here to read the first part of “the 2 types of shear cutting and the 4 relations that. Blade Shear Cut.

From masshenlite.en.made-in-china.com

Blades Shearing Shearing Machine Blade Custom D2 Shear Cutting Blades Blade Shear Cut This shearing type can cut metal into strips or trim edges. We use rotary shearing at shengen for specific applications where its unique. Drive systems can be categorized into five. Click here to read the first part of “the 2 types of shear cutting and the 4 relations that impact quality”. They're tasked with the demanding job. In this section,. Blade Shear Cut.

From federalknife.com

Metal Cutting Blades & Forming Shear Blades,slitter blades Blade Shear Cut With the defined geometries introduced later in. The lower knife is firmly attached. They're tasked with the demanding job. We use rotary shearing at shengen for specific applications where its unique. Drive systems can be categorized into five. This shearing type can cut metal into strips or trim edges. Shear cutting (also known as shear slitting) is the type of. Blade Shear Cut.

From masshenlite.en.made-in-china.com

Custom Hot Rolled Steel Shear Blade Machine Blade for Cutting Line Blade Shear Cut Shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. The drive system powers the moving blade through the material to make a cut. In this section, we will dive into the 4 geometrical relationships that. Click here to read the first part of “the 2 types of shear. Blade Shear Cut.

From amkgroup.en.made-in-china.com

Guillotine Shearing Blade, Shear Cutting Blade China Shear Blades and Blade Shear Cut Click here to read the first part of “the 2 types of shear cutting and the 4 relations that impact quality”. The drive system powers the moving blade through the material to make a cut. The lower knife is firmly attached. Shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy. Blade Shear Cut.

From havencut.com

DualBlade Shear Cutoff as Manufacturer's Best Solution Haven Blade Shear Cut Drive systems can be categorized into five. We use rotary shearing at shengen for specific applications where its unique. The lower knife is firmly attached. In this section, we will dive into the 4 geometrical relationships that. Shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. The drive. Blade Shear Cut.

From federalknife.com

Shear knives for any shear blades application • Federal Knife Blade Shear Cut Shearing is a simple process whereby a sheet of metal is cut into smaller pieces by two knives which are positioned at an angle relative to each other. The lower knife is firmly attached. They're tasked with the demanding job. Drive systems can be categorized into five. With the defined geometries introduced later in. In this section, we will dive. Blade Shear Cut.

From www.cincinnatigeneraltool.com

Milwaukee 263620 M18 Double Cut 14ga Shear Blade Kit, Cincinnati Blade Shear Cut The lower knife is firmly attached. Shear cutting (also known as shear slitting) is the type of slitting that uses a combination of top and bottom knives. They're tasked with the demanding job. In this section, we will dive into the 4 geometrical relationships that. Shearing machine blades serve as the cutting edge in mechanical devices designed to slice through. Blade Shear Cut.

From havencut.com

Unique DualBlade Shear Cutting Solution Videos Haven Blade Shear Cut The lower knife is firmly attached. Shearing is a simple process whereby a sheet of metal is cut into smaller pieces by two knives which are positioned at an angle relative to each other. Shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. In this section, we will. Blade Shear Cut.

From www.cincinnatigeneraltool.com

Milwaukee 685220 M18 Cordless Double Cut 18 gauge Shear Complete Blade Shear Cut Shearing is a simple process whereby a sheet of metal is cut into smaller pieces by two knives which are positioned at an angle relative to each other. In this section, we will dive into the 4 geometrical relationships that. To cut sheet metal, we use blades that rotate. They're tasked with the demanding job. Shear cutting (also known as. Blade Shear Cut.

From hautau.com

Dual Blade Shear Cutting Machine Hautau Blade Shear Cut Shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. With the defined geometries introduced later in. We use rotary shearing at shengen for specific applications where its unique. The lower knife is firmly attached. In this section, we will dive into the 4 geometrical relationships that. They're tasked. Blade Shear Cut.

From www.acra.com.au

The 7 Different Types of Shears Used in Sheet Metal Manufacturing Blade Shear Cut In this section, we will dive into the 4 geometrical relationships that. The drive system powers the moving blade through the material to make a cut. Shear cutting (also known as shear slitting) is the type of slitting that uses a combination of top and bottom knives. To cut sheet metal, we use blades that rotate. Shearing is a simple. Blade Shear Cut.

From www.tfico.com

Shear Blades TFICO Blade Shear Cut We use rotary shearing at shengen for specific applications where its unique. Shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. The drive system powers the moving blade through the material to make a cut. They're tasked with the demanding job. The lower knife is firmly attached. Click. Blade Shear Cut.

From sendaknife.en.made-in-china.com

High Accuracy Flying Shear Cutting Blades Knives for for Matching Blade Shear Cut We use rotary shearing at shengen for specific applications where its unique. Shearing is a simple process whereby a sheet of metal is cut into smaller pieces by two knives which are positioned at an angle relative to each other. This shearing type can cut metal into strips or trim edges. The lower knife is firmly attached. In this section,. Blade Shear Cut.

From www.converteraccessory.com

Slitting Assemblies by CAC Blade Shear Cut Drive systems can be categorized into five. The drive system powers the moving blade through the material to make a cut. Shearing is a simple process whereby a sheet of metal is cut into smaller pieces by two knives which are positioned at an angle relative to each other. We use rotary shearing at shengen for specific applications where its. Blade Shear Cut.

From havencut.com

DualBlade Shear Cutting Tube Recut Machines Finishing Blade Shear Cut Shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. Shearing is a simple process whereby a sheet of metal is cut into smaller pieces by two knives which are positioned at an angle relative to each other. This shearing type can cut metal into strips or trim edges.. Blade Shear Cut.

From www.sparkblades.com

metallurgical shear blades for cutting thick steel plate mills Blade Shear Cut Shear cutting (also known as shear slitting) is the type of slitting that uses a combination of top and bottom knives. The lower knife is firmly attached. We use rotary shearing at shengen for specific applications where its unique. Shearing is a simple process whereby a sheet of metal is cut into smaller pieces by two knives which are positioned. Blade Shear Cut.

From www.kangblade.com

Shear blade/Shear Knife/Straight blade/Shearcutting/Plastic, rubber, Blade Shear Cut In this section, we will dive into the 4 geometrical relationships that. Shearing is a simple process whereby a sheet of metal is cut into smaller pieces by two knives which are positioned at an angle relative to each other. We use rotary shearing at shengen for specific applications where its unique. The drive system powers the moving blade through. Blade Shear Cut.

From www.kangblade.com

Shear blade/Shear Knife/Straight blade/Shearcutting/Plastic, rubber, Blade Shear Cut The drive system powers the moving blade through the material to make a cut. This shearing type can cut metal into strips or trim edges. We use rotary shearing at shengen for specific applications where its unique. To cut sheet metal, we use blades that rotate. Shear cutting (also known as shear slitting) is the type of slitting that uses. Blade Shear Cut.

From hkpowerunion.en.made-in-china.com

HSS Shearing Shear Cutter Custom Hydraulic Cutting Tungsten Knife Blade Blade Shear Cut Shearing is a simple process whereby a sheet of metal is cut into smaller pieces by two knives which are positioned at an angle relative to each other. With the defined geometries introduced later in. Drive systems can be categorized into five. This shearing type can cut metal into strips or trim edges. The drive system powers the moving blade. Blade Shear Cut.

From www.dienesusa.com

The 2 Types of Shear Cutting and the 4 Relations that Impact Quality Blade Shear Cut We use rotary shearing at shengen for specific applications where its unique. Shearing is a simple process whereby a sheet of metal is cut into smaller pieces by two knives which are positioned at an angle relative to each other. To cut sheet metal, we use blades that rotate. Shearing machine blades serve as the cutting edge in mechanical devices. Blade Shear Cut.

From masshenlite.en.made-in-china.com

Shearing Machine Blade / Guillotine Shear Blade / Shear Machine Cut Blade Shear Cut Shearing is a simple process whereby a sheet of metal is cut into smaller pieces by two knives which are positioned at an angle relative to each other. The drive system powers the moving blade through the material to make a cut. They're tasked with the demanding job. The lower knife is firmly attached. In this section, we will dive. Blade Shear Cut.

From sendaknife.en.made-in-china.com

High Quality Industrial Flying Shear Blade Cutting Machine Blade Blade Shear Cut To cut sheet metal, we use blades that rotate. We use rotary shearing at shengen for specific applications where its unique. The lower knife is firmly attached. Drive systems can be categorized into five. With the defined geometries introduced later in. Shearing is a simple process whereby a sheet of metal is cut into smaller pieces by two knives which. Blade Shear Cut.