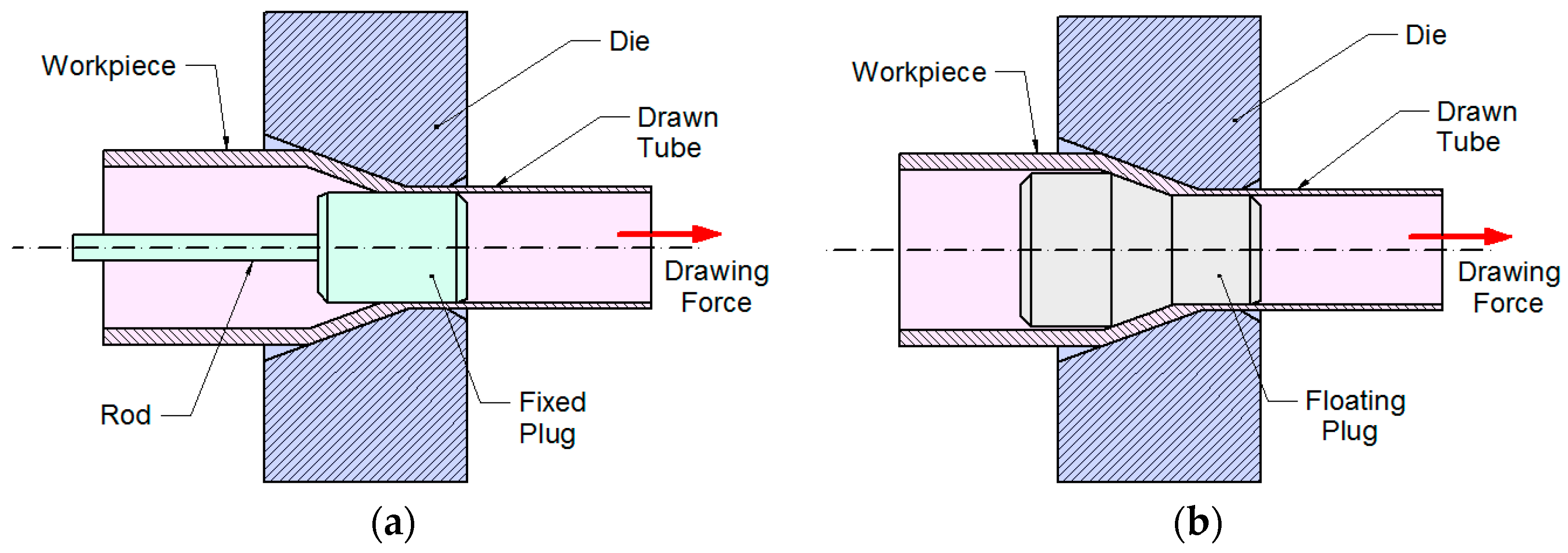

Steel Tube Drawing Process . Metal drawing is a manufacturing process that forms metal work stock by reducing its cross section. The process has two main steps: Drawing without a mandrel (tube sinking) the tube is pulled through the drawing die hole with no support from inside. When the process is finished, the tube’s od matches the die’s id. The basic tube shell is normally hot. Table 11.1 tube drawing processes. When a hollow tube is drawn through a die, generally a mandrel or plug is used to support the inside diameter of the tube, this process is called tube. Crushing one end (also known as pointing the tube), then drawing it through a die that has the correct id. While the tube can be of almost any metal, the most common are copper, brass, cupronickel, aluminum, carbon steel, alloy steel, and stainless steel. This is accomplished by forcing the work through a mold, (die), of smaller cross sectional area than.

from www.mdpi.com

Table 11.1 tube drawing processes. When a hollow tube is drawn through a die, generally a mandrel or plug is used to support the inside diameter of the tube, this process is called tube. Drawing without a mandrel (tube sinking) the tube is pulled through the drawing die hole with no support from inside. When the process is finished, the tube’s od matches the die’s id. The basic tube shell is normally hot. The process has two main steps: While the tube can be of almost any metal, the most common are copper, brass, cupronickel, aluminum, carbon steel, alloy steel, and stainless steel. Crushing one end (also known as pointing the tube), then drawing it through a die that has the correct id. Metal drawing is a manufacturing process that forms metal work stock by reducing its cross section. This is accomplished by forcing the work through a mold, (die), of smaller cross sectional area than.

Metals Free FullText Guidelines for Selecting Plugs Used in Thin

Steel Tube Drawing Process Metal drawing is a manufacturing process that forms metal work stock by reducing its cross section. Crushing one end (also known as pointing the tube), then drawing it through a die that has the correct id. This is accomplished by forcing the work through a mold, (die), of smaller cross sectional area than. When the process is finished, the tube’s od matches the die’s id. The process has two main steps: Table 11.1 tube drawing processes. Drawing without a mandrel (tube sinking) the tube is pulled through the drawing die hole with no support from inside. The basic tube shell is normally hot. When a hollow tube is drawn through a die, generally a mandrel or plug is used to support the inside diameter of the tube, this process is called tube. While the tube can be of almost any metal, the most common are copper, brass, cupronickel, aluminum, carbon steel, alloy steel, and stainless steel. Metal drawing is a manufacturing process that forms metal work stock by reducing its cross section.

From www.mdpi.com

Metals Free FullText Guidelines for Selecting Plugs Used in Thin Steel Tube Drawing Process When the process is finished, the tube’s od matches the die’s id. Table 11.1 tube drawing processes. When a hollow tube is drawn through a die, generally a mandrel or plug is used to support the inside diameter of the tube, this process is called tube. This is accomplished by forcing the work through a mold, (die), of smaller cross. Steel Tube Drawing Process.

From www.youtube.com

Simplified Tube Drawing Process in Metal Forming Gate Production Steel Tube Drawing Process The process has two main steps: Table 11.1 tube drawing processes. While the tube can be of almost any metal, the most common are copper, brass, cupronickel, aluminum, carbon steel, alloy steel, and stainless steel. Drawing without a mandrel (tube sinking) the tube is pulled through the drawing die hole with no support from inside. This is accomplished by forcing. Steel Tube Drawing Process.

From www.union-steels.com

Piling Pipe,Steel Tubular Piles,Tube Piles Steel Tube Drawing Process The process has two main steps: When the process is finished, the tube’s od matches the die’s id. The basic tube shell is normally hot. While the tube can be of almost any metal, the most common are copper, brass, cupronickel, aluminum, carbon steel, alloy steel, and stainless steel. Metal drawing is a manufacturing process that forms metal work stock. Steel Tube Drawing Process.

From www.manufacturingguide.com

Tube drawing Find suppliers, processes & material Steel Tube Drawing Process Table 11.1 tube drawing processes. When the process is finished, the tube’s od matches the die’s id. The basic tube shell is normally hot. The process has two main steps: Drawing without a mandrel (tube sinking) the tube is pulled through the drawing die hole with no support from inside. When a hollow tube is drawn through a die, generally. Steel Tube Drawing Process.

From ahssinsights.org

High Frequency Tube/Pipe Welding AHSS Guidelines Steel Tube Drawing Process When the process is finished, the tube’s od matches the die’s id. Crushing one end (also known as pointing the tube), then drawing it through a die that has the correct id. This is accomplished by forcing the work through a mold, (die), of smaller cross sectional area than. While the tube can be of almost any metal, the most. Steel Tube Drawing Process.

From www.thelibraryofmanufacturing.com

Metal Drawing Steel Tube Drawing Process Drawing without a mandrel (tube sinking) the tube is pulled through the drawing die hole with no support from inside. The basic tube shell is normally hot. This is accomplished by forcing the work through a mold, (die), of smaller cross sectional area than. Crushing one end (also known as pointing the tube), then drawing it through a die that. Steel Tube Drawing Process.

From www.youtube.com

Tube drawing process and different method explained 3D animaiton YouTube Steel Tube Drawing Process While the tube can be of almost any metal, the most common are copper, brass, cupronickel, aluminum, carbon steel, alloy steel, and stainless steel. Table 11.1 tube drawing processes. When a hollow tube is drawn through a die, generally a mandrel or plug is used to support the inside diameter of the tube, this process is called tube. When the. Steel Tube Drawing Process.

From www.abtersteel.com

Processus de fabrication de tuyaux fabricant de tuyaux en acier abter Steel Tube Drawing Process While the tube can be of almost any metal, the most common are copper, brass, cupronickel, aluminum, carbon steel, alloy steel, and stainless steel. The basic tube shell is normally hot. Metal drawing is a manufacturing process that forms metal work stock by reducing its cross section. The process has two main steps: This is accomplished by forcing the work. Steel Tube Drawing Process.

From www.researchgate.net

Drawbench used for tube drawing process Download Scientific Diagram Steel Tube Drawing Process Metal drawing is a manufacturing process that forms metal work stock by reducing its cross section. While the tube can be of almost any metal, the most common are copper, brass, cupronickel, aluminum, carbon steel, alloy steel, and stainless steel. This is accomplished by forcing the work through a mold, (die), of smaller cross sectional area than. Drawing without a. Steel Tube Drawing Process.

From www.youtube.com

Abaqus Steel Tube Drawing Process YouTube Steel Tube Drawing Process Table 11.1 tube drawing processes. This is accomplished by forcing the work through a mold, (die), of smaller cross sectional area than. Metal drawing is a manufacturing process that forms metal work stock by reducing its cross section. Crushing one end (also known as pointing the tube), then drawing it through a die that has the correct id. The basic. Steel Tube Drawing Process.

From www.doublestonesteel.com

How the simple industrial process of tube drawing allows for the Steel Tube Drawing Process When the process is finished, the tube’s od matches the die’s id. Table 11.1 tube drawing processes. When a hollow tube is drawn through a die, generally a mandrel or plug is used to support the inside diameter of the tube, this process is called tube. While the tube can be of almost any metal, the most common are copper,. Steel Tube Drawing Process.

From www.rapiddirect.com

Bending Stainless Steel Tubing Effective Processes and Considerations Steel Tube Drawing Process Metal drawing is a manufacturing process that forms metal work stock by reducing its cross section. When a hollow tube is drawn through a die, generally a mandrel or plug is used to support the inside diameter of the tube, this process is called tube. The basic tube shell is normally hot. When the process is finished, the tube’s od. Steel Tube Drawing Process.

From pearlitesteel.com

Stainless Steel Pipe and Tube Manufacturing Process Pearlite Steel Steel Tube Drawing Process This is accomplished by forcing the work through a mold, (die), of smaller cross sectional area than. Drawing without a mandrel (tube sinking) the tube is pulled through the drawing die hole with no support from inside. The basic tube shell is normally hot. When a hollow tube is drawn through a die, generally a mandrel or plug is used. Steel Tube Drawing Process.

From ar.inspiredpencil.com

How To Draw A Pipe Step By Step Steel Tube Drawing Process Crushing one end (also known as pointing the tube), then drawing it through a die that has the correct id. When the process is finished, the tube’s od matches the die’s id. While the tube can be of almost any metal, the most common are copper, brass, cupronickel, aluminum, carbon steel, alloy steel, and stainless steel. The basic tube shell. Steel Tube Drawing Process.

From www.youtube.com

Tube Drawing Process In English YouTube Steel Tube Drawing Process The process has two main steps: Table 11.1 tube drawing processes. The basic tube shell is normally hot. Metal drawing is a manufacturing process that forms metal work stock by reducing its cross section. Crushing one end (also known as pointing the tube), then drawing it through a die that has the correct id. This is accomplished by forcing the. Steel Tube Drawing Process.

From thelibraryofmanufacturing.com

Metal Drawing Steel Tube Drawing Process When the process is finished, the tube’s od matches the die’s id. The process has two main steps: When a hollow tube is drawn through a die, generally a mandrel or plug is used to support the inside diameter of the tube, this process is called tube. Metal drawing is a manufacturing process that forms metal work stock by reducing. Steel Tube Drawing Process.

From www.researchgate.net

Tube drawing setup (a) CAD model (b) Simplified meshed model Steel Tube Drawing Process The process has two main steps: When the process is finished, the tube’s od matches the die’s id. Table 11.1 tube drawing processes. Crushing one end (also known as pointing the tube), then drawing it through a die that has the correct id. Metal drawing is a manufacturing process that forms metal work stock by reducing its cross section. The. Steel Tube Drawing Process.

From www.eastern-steels.com

Seamless steel pipe production process Steel Tube Drawing Process Table 11.1 tube drawing processes. Drawing without a mandrel (tube sinking) the tube is pulled through the drawing die hole with no support from inside. Crushing one end (also known as pointing the tube), then drawing it through a die that has the correct id. When a hollow tube is drawn through a die, generally a mandrel or plug is. Steel Tube Drawing Process.

From www.mdpi.com

Metals Free FullText Tube Drawing Process with Diameter Expansion Steel Tube Drawing Process When the process is finished, the tube’s od matches the die’s id. Crushing one end (also known as pointing the tube), then drawing it through a die that has the correct id. Drawing without a mandrel (tube sinking) the tube is pulled through the drawing die hole with no support from inside. The process has two main steps: This is. Steel Tube Drawing Process.

From www.researchgate.net

Schematic of tube drawing process with a fixed mandrel Download Steel Tube Drawing Process Crushing one end (also known as pointing the tube), then drawing it through a die that has the correct id. The basic tube shell is normally hot. Metal drawing is a manufacturing process that forms metal work stock by reducing its cross section. While the tube can be of almost any metal, the most common are copper, brass, cupronickel, aluminum,. Steel Tube Drawing Process.

From www.mdpi.com

Metals Free FullText Tube Drawing Process with Diameter Expansion Steel Tube Drawing Process Table 11.1 tube drawing processes. Drawing without a mandrel (tube sinking) the tube is pulled through the drawing die hole with no support from inside. Crushing one end (also known as pointing the tube), then drawing it through a die that has the correct id. This is accomplished by forcing the work through a mold, (die), of smaller cross sectional. Steel Tube Drawing Process.

From www.scribd.com

Tube Drawing Process PDF Annealing (Metallurgy) Rolling Steel Tube Drawing Process The process has two main steps: Table 11.1 tube drawing processes. Drawing without a mandrel (tube sinking) the tube is pulled through the drawing die hole with no support from inside. When a hollow tube is drawn through a die, generally a mandrel or plug is used to support the inside diameter of the tube, this process is called tube.. Steel Tube Drawing Process.

From www.iqsdirectory.com

Stainless Steel Tubing Types, Uses, Benefits, Manufacturing Steel Tube Drawing Process The basic tube shell is normally hot. When the process is finished, the tube’s od matches the die’s id. This is accomplished by forcing the work through a mold, (die), of smaller cross sectional area than. Crushing one end (also known as pointing the tube), then drawing it through a die that has the correct id. When a hollow tube. Steel Tube Drawing Process.

From www.researchgate.net

Schematic of tube drawing process with a fixed mandrel Download Steel Tube Drawing Process When a hollow tube is drawn through a die, generally a mandrel or plug is used to support the inside diameter of the tube, this process is called tube. Crushing one end (also known as pointing the tube), then drawing it through a die that has the correct id. When the process is finished, the tube’s od matches the die’s. Steel Tube Drawing Process.

From www.mech4study.com

Types of Drawing Process Wire Drawing, Rod Drawing and Tube Drawing Steel Tube Drawing Process Crushing one end (also known as pointing the tube), then drawing it through a die that has the correct id. The process has two main steps: Metal drawing is a manufacturing process that forms metal work stock by reducing its cross section. When the process is finished, the tube’s od matches the die’s id. Table 11.1 tube drawing processes. This. Steel Tube Drawing Process.

From learnmech.com

Types Of Extrusion And Advantages of Extrusion Steel Tube Drawing Process This is accomplished by forcing the work through a mold, (die), of smaller cross sectional area than. Crushing one end (also known as pointing the tube), then drawing it through a die that has the correct id. While the tube can be of almost any metal, the most common are copper, brass, cupronickel, aluminum, carbon steel, alloy steel, and stainless. Steel Tube Drawing Process.

From www.youtube.com

Seamless steel tube manufacturing companycold drawing process YouTube Steel Tube Drawing Process This is accomplished by forcing the work through a mold, (die), of smaller cross sectional area than. The process has two main steps: Table 11.1 tube drawing processes. The basic tube shell is normally hot. When the process is finished, the tube’s od matches the die’s id. When a hollow tube is drawn through a die, generally a mandrel or. Steel Tube Drawing Process.

From www.youtube.com

Tube Drawing & Types of Tube Drawing YouTube Steel Tube Drawing Process Table 11.1 tube drawing processes. While the tube can be of almost any metal, the most common are copper, brass, cupronickel, aluminum, carbon steel, alloy steel, and stainless steel. The process has two main steps: When the process is finished, the tube’s od matches the die’s id. This is accomplished by forcing the work through a mold, (die), of smaller. Steel Tube Drawing Process.

From www.ashtapadoverseas.com

Stainless Steel welded pipe & tubes manufacturing process Steel Tube Drawing Process The process has two main steps: While the tube can be of almost any metal, the most common are copper, brass, cupronickel, aluminum, carbon steel, alloy steel, and stainless steel. When a hollow tube is drawn through a die, generally a mandrel or plug is used to support the inside diameter of the tube, this process is called tube. When. Steel Tube Drawing Process.

From www.youtube.com

Tube Drawing Process YouTube Steel Tube Drawing Process Metal drawing is a manufacturing process that forms metal work stock by reducing its cross section. The basic tube shell is normally hot. Drawing without a mandrel (tube sinking) the tube is pulled through the drawing die hole with no support from inside. When the process is finished, the tube’s od matches the die’s id. This is accomplished by forcing. Steel Tube Drawing Process.

From www.mdpi.com

Metals Free FullText Tube Drawing Process with Diameter Expansion Steel Tube Drawing Process Crushing one end (also known as pointing the tube), then drawing it through a die that has the correct id. When the process is finished, the tube’s od matches the die’s id. Drawing without a mandrel (tube sinking) the tube is pulled through the drawing die hole with no support from inside. The basic tube shell is normally hot. While. Steel Tube Drawing Process.

From www.cnspipes.com

Simple understanding of spiral steel tube manufacturing process Steel Tube Drawing Process Table 11.1 tube drawing processes. Drawing without a mandrel (tube sinking) the tube is pulled through the drawing die hole with no support from inside. When the process is finished, the tube’s od matches the die’s id. This is accomplished by forcing the work through a mold, (die), of smaller cross sectional area than. The basic tube shell is normally. Steel Tube Drawing Process.

From www.mdpi.com

Metals Free FullText Tube Drawing Process with Diameter Expansion Steel Tube Drawing Process When a hollow tube is drawn through a die, generally a mandrel or plug is used to support the inside diameter of the tube, this process is called tube. Table 11.1 tube drawing processes. Crushing one end (also known as pointing the tube), then drawing it through a die that has the correct id. Metal drawing is a manufacturing process. Steel Tube Drawing Process.

From www.prudentstainless.com

Seamless Pipe and Tube Manufacturing Process Steel Tube Drawing Process When the process is finished, the tube’s od matches the die’s id. The process has two main steps: Table 11.1 tube drawing processes. The basic tube shell is normally hot. Metal drawing is a manufacturing process that forms metal work stock by reducing its cross section. While the tube can be of almost any metal, the most common are copper,. Steel Tube Drawing Process.

From tubingchina.com

Cold Finished Stainless Steel Tube Technology Flow Chart Tubing China Steel Tube Drawing Process Crushing one end (also known as pointing the tube), then drawing it through a die that has the correct id. The process has two main steps: While the tube can be of almost any metal, the most common are copper, brass, cupronickel, aluminum, carbon steel, alloy steel, and stainless steel. Drawing without a mandrel (tube sinking) the tube is pulled. Steel Tube Drawing Process.