Pinion Bearing Preload Torque Spec . Once pinion depth is achieved using a new crush collar, set pinion bearing preload (see specification chart on page 4). Also, you should not reuse the same. To install your ring and pinion gears and/or differential correctly, it is critical to torque your bolts and set your preload and backlash correctly. The problem is, to correctly get the preload set, you have to measure the torque at the pinion. The following table contains the proper. For accurate reading use dial or beam type. Pinion preload is verified by rotating the pinion with an inch lb torque wrench. Take frequent cone and roller bearing torque preload readings until the original recorded preload reading is obtained by rotating. Pinion bearing preload (used) (inch/lbs)

from shop.broncograveyard.com

The following table contains the proper. Once pinion depth is achieved using a new crush collar, set pinion bearing preload (see specification chart on page 4). To install your ring and pinion gears and/or differential correctly, it is critical to torque your bolts and set your preload and backlash correctly. Also, you should not reuse the same. Take frequent cone and roller bearing torque preload readings until the original recorded preload reading is obtained by rotating. Pinion bearing preload (used) (inch/lbs) Pinion preload is verified by rotating the pinion with an inch lb torque wrench. The problem is, to correctly get the preload set, you have to measure the torque at the pinion. For accurate reading use dial or beam type.

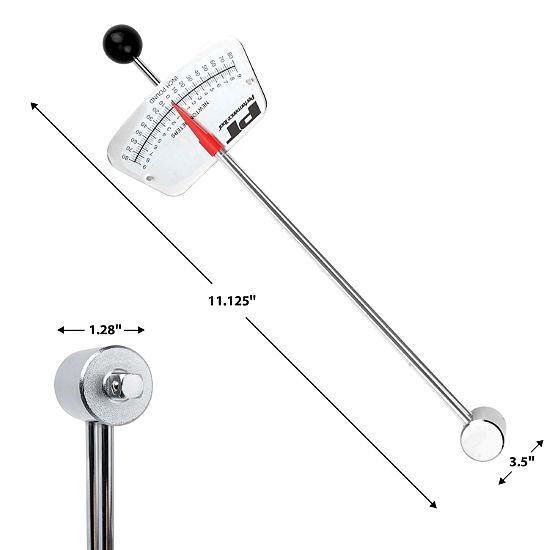

Pinion bearing inch/lb torque wrench for setting pinion bear

Pinion Bearing Preload Torque Spec The problem is, to correctly get the preload set, you have to measure the torque at the pinion. The following table contains the proper. Pinion bearing preload (used) (inch/lbs) For accurate reading use dial or beam type. Pinion preload is verified by rotating the pinion with an inch lb torque wrench. Once pinion depth is achieved using a new crush collar, set pinion bearing preload (see specification chart on page 4). To install your ring and pinion gears and/or differential correctly, it is critical to torque your bolts and set your preload and backlash correctly. Also, you should not reuse the same. The problem is, to correctly get the preload set, you have to measure the torque at the pinion. Take frequent cone and roller bearing torque preload readings until the original recorded preload reading is obtained by rotating.

From www.randysworldwide.com

How It Works Pinion Bearing Preload Pinion Bearing Preload Torque Spec Also, you should not reuse the same. To install your ring and pinion gears and/or differential correctly, it is critical to torque your bolts and set your preload and backlash correctly. Pinion bearing preload (used) (inch/lbs) Take frequent cone and roller bearing torque preload readings until the original recorded preload reading is obtained by rotating. The following table contains the. Pinion Bearing Preload Torque Spec.

From bernardembden.com

Differential Pinion PreLoad Adjustment. Pinion Bearing Preload Torque Spec Pinion bearing preload (used) (inch/lbs) Take frequent cone and roller bearing torque preload readings until the original recorded preload reading is obtained by rotating. The following table contains the proper. To install your ring and pinion gears and/or differential correctly, it is critical to torque your bolts and set your preload and backlash correctly. Pinion preload is verified by rotating. Pinion Bearing Preload Torque Spec.

From www.usastandardgear.com

Pinion bearing inch/lb torque wrench for setting pinion bearing preload Pinion Bearing Preload Torque Spec The problem is, to correctly get the preload set, you have to measure the torque at the pinion. For accurate reading use dial or beam type. Pinion preload is verified by rotating the pinion with an inch lb torque wrench. Once pinion depth is achieved using a new crush collar, set pinion bearing preload (see specification chart on page 4).. Pinion Bearing Preload Torque Spec.

From www.autozone.com

Repair Guides Rear Axle Pinion Seal Pinion Bearing Preload Torque Spec The following table contains the proper. To install your ring and pinion gears and/or differential correctly, it is critical to torque your bolts and set your preload and backlash correctly. The problem is, to correctly get the preload set, you have to measure the torque at the pinion. Pinion bearing preload (used) (inch/lbs) Take frequent cone and roller bearing torque. Pinion Bearing Preload Torque Spec.

From www.youtube.com

pinion preload YouTube Pinion Bearing Preload Torque Spec Take frequent cone and roller bearing torque preload readings until the original recorded preload reading is obtained by rotating. To install your ring and pinion gears and/or differential correctly, it is critical to torque your bolts and set your preload and backlash correctly. The following table contains the proper. For accurate reading use dial or beam type. Also, you should. Pinion Bearing Preload Torque Spec.

From www.miataturbo.net

Pinion bearing preload (used) Miata Turbo Forum Boost cars, acquire Pinion Bearing Preload Torque Spec Take frequent cone and roller bearing torque preload readings until the original recorded preload reading is obtained by rotating. The problem is, to correctly get the preload set, you have to measure the torque at the pinion. To install your ring and pinion gears and/or differential correctly, it is critical to torque your bolts and set your preload and backlash. Pinion Bearing Preload Torque Spec.

From innovationdiscoveries.space

KnowHow To Read Bearings Specification Pinion Bearing Preload Torque Spec Take frequent cone and roller bearing torque preload readings until the original recorded preload reading is obtained by rotating. Pinion bearing preload (used) (inch/lbs) Pinion preload is verified by rotating the pinion with an inch lb torque wrench. Also, you should not reuse the same. For accurate reading use dial or beam type. The problem is, to correctly get the. Pinion Bearing Preload Torque Spec.

From www.justanswer.com

02 f150 4wd 5.4l 9.75 ring gear, replacing pinion shaft bearings, crush Pinion Bearing Preload Torque Spec Once pinion depth is achieved using a new crush collar, set pinion bearing preload (see specification chart on page 4). Take frequent cone and roller bearing torque preload readings until the original recorded preload reading is obtained by rotating. The problem is, to correctly get the preload set, you have to measure the torque at the pinion. Pinion bearing preload. Pinion Bearing Preload Torque Spec.

From www.bernardembden.com

Differential Pinion PreLoad Adjustment. Pinion Bearing Preload Torque Spec For accurate reading use dial or beam type. Also, you should not reuse the same. Take frequent cone and roller bearing torque preload readings until the original recorded preload reading is obtained by rotating. Once pinion depth is achieved using a new crush collar, set pinion bearing preload (see specification chart on page 4). To install your ring and pinion. Pinion Bearing Preload Torque Spec.

From shop.broncograveyard.com

Pinion bearing inch/lb torque wrench for setting pinion bear Pinion Bearing Preload Torque Spec Take frequent cone and roller bearing torque preload readings until the original recorded preload reading is obtained by rotating. Also, you should not reuse the same. The following table contains the proper. To install your ring and pinion gears and/or differential correctly, it is critical to torque your bolts and set your preload and backlash correctly. The problem is, to. Pinion Bearing Preload Torque Spec.

From www.youtube.com

Setting Pinion Bearing Preload / Rotating Torque / Chrysler 8.25 Pinion Bearing Preload Torque Spec The following table contains the proper. Pinion bearing preload (used) (inch/lbs) Also, you should not reuse the same. The problem is, to correctly get the preload set, you have to measure the torque at the pinion. Once pinion depth is achieved using a new crush collar, set pinion bearing preload (see specification chart on page 4). Take frequent cone and. Pinion Bearing Preload Torque Spec.

From www.pinnaxis.com

Dana 30 Yoke Torque Spec Compare Price Pinion Bearing Preload Torque Spec The following table contains the proper. For accurate reading use dial or beam type. Once pinion depth is achieved using a new crush collar, set pinion bearing preload (see specification chart on page 4). Pinion bearing preload (used) (inch/lbs) Pinion preload is verified by rotating the pinion with an inch lb torque wrench. Also, you should not reuse the same.. Pinion Bearing Preload Torque Spec.

From engineersfield.com

Preload force ad tightening torque Engineersfield Pinion Bearing Preload Torque Spec The following table contains the proper. For accurate reading use dial or beam type. Once pinion depth is achieved using a new crush collar, set pinion bearing preload (see specification chart on page 4). The problem is, to correctly get the preload set, you have to measure the torque at the pinion. Take frequent cone and roller bearing torque preload. Pinion Bearing Preload Torque Spec.

From www.youtube.com

How to Measure Differential Preload YouTube Pinion Bearing Preload Torque Spec For accurate reading use dial or beam type. The problem is, to correctly get the preload set, you have to measure the torque at the pinion. Pinion preload is verified by rotating the pinion with an inch lb torque wrench. Take frequent cone and roller bearing torque preload readings until the original recorded preload reading is obtained by rotating. Pinion. Pinion Bearing Preload Torque Spec.

From forums.tdiclub.com

Achieving spec axle bolt torque. Forums Pinion Bearing Preload Torque Spec Once pinion depth is achieved using a new crush collar, set pinion bearing preload (see specification chart on page 4). Also, you should not reuse the same. To install your ring and pinion gears and/or differential correctly, it is critical to torque your bolts and set your preload and backlash correctly. The problem is, to correctly get the preload set,. Pinion Bearing Preload Torque Spec.

From repairfixdefender.z13.web.core.windows.net

Ford F150 Pinion Nut Torque Specs Pinion Bearing Preload Torque Spec For accurate reading use dial or beam type. Also, you should not reuse the same. The problem is, to correctly get the preload set, you have to measure the torque at the pinion. Take frequent cone and roller bearing torque preload readings until the original recorded preload reading is obtained by rotating. Pinion bearing preload (used) (inch/lbs) The following table. Pinion Bearing Preload Torque Spec.

From www.autozone.com

Repair Guides Fasteners, Measurements And Conversions Measuring Pinion Bearing Preload Torque Spec Also, you should not reuse the same. Once pinion depth is achieved using a new crush collar, set pinion bearing preload (see specification chart on page 4). The problem is, to correctly get the preload set, you have to measure the torque at the pinion. Pinion preload is verified by rotating the pinion with an inch lb torque wrench. Pinion. Pinion Bearing Preload Torque Spec.

From www.youtube.com

How to set pinion bearing preload 8" Ford 65 Mustang Fastback Pinion Bearing Preload Torque Spec Pinion preload is verified by rotating the pinion with an inch lb torque wrench. Once pinion depth is achieved using a new crush collar, set pinion bearing preload (see specification chart on page 4). The problem is, to correctly get the preload set, you have to measure the torque at the pinion. Also, you should not reuse the same. For. Pinion Bearing Preload Torque Spec.

From eanswer.com

Jeep Grand Cherokee 4x4 What is the torque specs on a pinion Pinion Bearing Preload Torque Spec The following table contains the proper. Take frequent cone and roller bearing torque preload readings until the original recorded preload reading is obtained by rotating. Also, you should not reuse the same. To install your ring and pinion gears and/or differential correctly, it is critical to torque your bolts and set your preload and backlash correctly. For accurate reading use. Pinion Bearing Preload Torque Spec.

From www.classiczcars.com

r200 pinion nut torque Engine & Drivetrain The Classic Zcar Club Pinion Bearing Preload Torque Spec Also, you should not reuse the same. Take frequent cone and roller bearing torque preload readings until the original recorded preload reading is obtained by rotating. The following table contains the proper. For accurate reading use dial or beam type. Pinion preload is verified by rotating the pinion with an inch lb torque wrench. Once pinion depth is achieved using. Pinion Bearing Preload Torque Spec.

From www.slideserve.com

PPT Ring and Pinion Adjustments PowerPoint Presentation ID351877 Pinion Bearing Preload Torque Spec For accurate reading use dial or beam type. Pinion preload is verified by rotating the pinion with an inch lb torque wrench. The problem is, to correctly get the preload set, you have to measure the torque at the pinion. To install your ring and pinion gears and/or differential correctly, it is critical to torque your bolts and set your. Pinion Bearing Preload Torque Spec.

From www.pirate4x4.com

Figure 26 Measuring pinionbearing preload Pinion Bearing Preload Torque Spec Pinion bearing preload (used) (inch/lbs) The problem is, to correctly get the preload set, you have to measure the torque at the pinion. Also, you should not reuse the same. Once pinion depth is achieved using a new crush collar, set pinion bearing preload (see specification chart on page 4). Take frequent cone and roller bearing torque preload readings until. Pinion Bearing Preload Torque Spec.

From sophiegould.z21.web.core.windows.net

Wheel Bearing Torque Chart Pinion Bearing Preload Torque Spec Pinion preload is verified by rotating the pinion with an inch lb torque wrench. The following table contains the proper. To install your ring and pinion gears and/or differential correctly, it is critical to torque your bolts and set your preload and backlash correctly. The problem is, to correctly get the preload set, you have to measure the torque at. Pinion Bearing Preload Torque Spec.

From www.youtube.com

How to set your pinion bearing preload on a 9" Ford differential YouTube Pinion Bearing Preload Torque Spec Once pinion depth is achieved using a new crush collar, set pinion bearing preload (see specification chart on page 4). Pinion bearing preload (used) (inch/lbs) For accurate reading use dial or beam type. The problem is, to correctly get the preload set, you have to measure the torque at the pinion. Also, you should not reuse the same. The following. Pinion Bearing Preload Torque Spec.

From www.bearingtips.com

Why is preload necessary in some bearing applications? Bearing Tips Pinion Bearing Preload Torque Spec The problem is, to correctly get the preload set, you have to measure the torque at the pinion. Pinion preload is verified by rotating the pinion with an inch lb torque wrench. To install your ring and pinion gears and/or differential correctly, it is critical to torque your bolts and set your preload and backlash correctly. Once pinion depth is. Pinion Bearing Preload Torque Spec.

From blazerforum.com

Torque Blazer Forum Chevy Blazer Forums Pinion Bearing Preload Torque Spec Once pinion depth is achieved using a new crush collar, set pinion bearing preload (see specification chart on page 4). Pinion preload is verified by rotating the pinion with an inch lb torque wrench. Take frequent cone and roller bearing torque preload readings until the original recorded preload reading is obtained by rotating. The following table contains the proper. Pinion. Pinion Bearing Preload Torque Spec.

From www.youtube.com

How to measure bearing Preload with a Dial Type Inch Pounds Torque Pinion Bearing Preload Torque Spec The problem is, to correctly get the preload set, you have to measure the torque at the pinion. The following table contains the proper. Pinion preload is verified by rotating the pinion with an inch lb torque wrench. Once pinion depth is achieved using a new crush collar, set pinion bearing preload (see specification chart on page 4). Pinion bearing. Pinion Bearing Preload Torque Spec.

From shop.broncograveyard.com

Pinion bearing inch/lb torque wrench for setting pinion bear Pinion Bearing Preload Torque Spec To install your ring and pinion gears and/or differential correctly, it is critical to torque your bolts and set your preload and backlash correctly. Pinion bearing preload (used) (inch/lbs) For accurate reading use dial or beam type. Also, you should not reuse the same. The problem is, to correctly get the preload set, you have to measure the torque at. Pinion Bearing Preload Torque Spec.

From www.therangerstation.com

Pinion nut torque versus bearing preload The Ranger Station Pinion Bearing Preload Torque Spec For accurate reading use dial or beam type. To install your ring and pinion gears and/or differential correctly, it is critical to torque your bolts and set your preload and backlash correctly. Also, you should not reuse the same. Pinion preload is verified by rotating the pinion with an inch lb torque wrench. The following table contains the proper. Pinion. Pinion Bearing Preload Torque Spec.

From www.youtube.com

How to adjust pinion bearing preload YouTube Pinion Bearing Preload Torque Spec Pinion bearing preload (used) (inch/lbs) To install your ring and pinion gears and/or differential correctly, it is critical to torque your bolts and set your preload and backlash correctly. For accurate reading use dial or beam type. The following table contains the proper. Pinion preload is verified by rotating the pinion with an inch lb torque wrench. Also, you should. Pinion Bearing Preload Torque Spec.

From svtperformance.com

Pinion Nut Torque With Solid Spacer Pinion Bearing Preload Torque Spec Pinion bearing preload (used) (inch/lbs) The following table contains the proper. Also, you should not reuse the same. Once pinion depth is achieved using a new crush collar, set pinion bearing preload (see specification chart on page 4). Pinion preload is verified by rotating the pinion with an inch lb torque wrench. Take frequent cone and roller bearing torque preload. Pinion Bearing Preload Torque Spec.

From forum.ih8mud.com

Rear diff pinion nut torque IH8MUD Forum Pinion Bearing Preload Torque Spec Also, you should not reuse the same. Pinion preload is verified by rotating the pinion with an inch lb torque wrench. Pinion bearing preload (used) (inch/lbs) The following table contains the proper. For accurate reading use dial or beam type. Take frequent cone and roller bearing torque preload readings until the original recorded preload reading is obtained by rotating. To. Pinion Bearing Preload Torque Spec.

From www.youtube.com

Measuring Pinion bearing preload Ford 8.8 YouTube Pinion Bearing Preload Torque Spec Also, you should not reuse the same. The following table contains the proper. The problem is, to correctly get the preload set, you have to measure the torque at the pinion. Pinion preload is verified by rotating the pinion with an inch lb torque wrench. Pinion bearing preload (used) (inch/lbs) To install your ring and pinion gears and/or differential correctly,. Pinion Bearing Preload Torque Spec.

From www.explorerforum.com

How to Install Ford 8.8" gears Ford Explorer and Ranger Forums Pinion Bearing Preload Torque Spec To install your ring and pinion gears and/or differential correctly, it is critical to torque your bolts and set your preload and backlash correctly. Once pinion depth is achieved using a new crush collar, set pinion bearing preload (see specification chart on page 4). Pinion preload is verified by rotating the pinion with an inch lb torque wrench. Also, you. Pinion Bearing Preload Torque Spec.

From www.racingjunk.com

Setting Pinion Depth and Backlash RacingJunk News Pinion Bearing Preload Torque Spec Pinion bearing preload (used) (inch/lbs) Once pinion depth is achieved using a new crush collar, set pinion bearing preload (see specification chart on page 4). Also, you should not reuse the same. The following table contains the proper. The problem is, to correctly get the preload set, you have to measure the torque at the pinion. Take frequent cone and. Pinion Bearing Preload Torque Spec.