Pipeline Testing Methods . It ensures that the pipelines can safely operate at their maximum operating pressure. These inspections are of utmost importance as they help identify any flaws, weaknesses, or susceptibilities that could lead to pipeline failures. In this article, we will. Read about the 4 common methods Pipeline integrity testing maintains safe & reliable operation of pipelines, protecting from lost profits and the environment. What are the different types of pipe testing methods? During pipeline inspections, specialized equipment and techniques evaluate factors like structural integrity, corrosion levels, leaks, and overall pipeline health. Up to now, only based on ultrasonic and electromagnetic ultrasonic, magnetic flux leakage, eddy current testing methods have successfully developed. Pipeline testing methods play a crucial role in maintaining the reliability and safety of these essential conduits. From magnetic flux tools to pipeline pressure testing equipment, here are the resources and methods pipeline operators can use to evaluate the integrity of their pipelines and promote better preventative maintenance.

from lmats.com.au

These inspections are of utmost importance as they help identify any flaws, weaknesses, or susceptibilities that could lead to pipeline failures. From magnetic flux tools to pipeline pressure testing equipment, here are the resources and methods pipeline operators can use to evaluate the integrity of their pipelines and promote better preventative maintenance. It ensures that the pipelines can safely operate at their maximum operating pressure. Read about the 4 common methods During pipeline inspections, specialized equipment and techniques evaluate factors like structural integrity, corrosion levels, leaks, and overall pipeline health. What are the different types of pipe testing methods? Pipeline integrity testing maintains safe & reliable operation of pipelines, protecting from lost profits and the environment. Pipeline testing methods play a crucial role in maintaining the reliability and safety of these essential conduits. In this article, we will. Up to now, only based on ultrasonic and electromagnetic ultrasonic, magnetic flux leakage, eddy current testing methods have successfully developed.

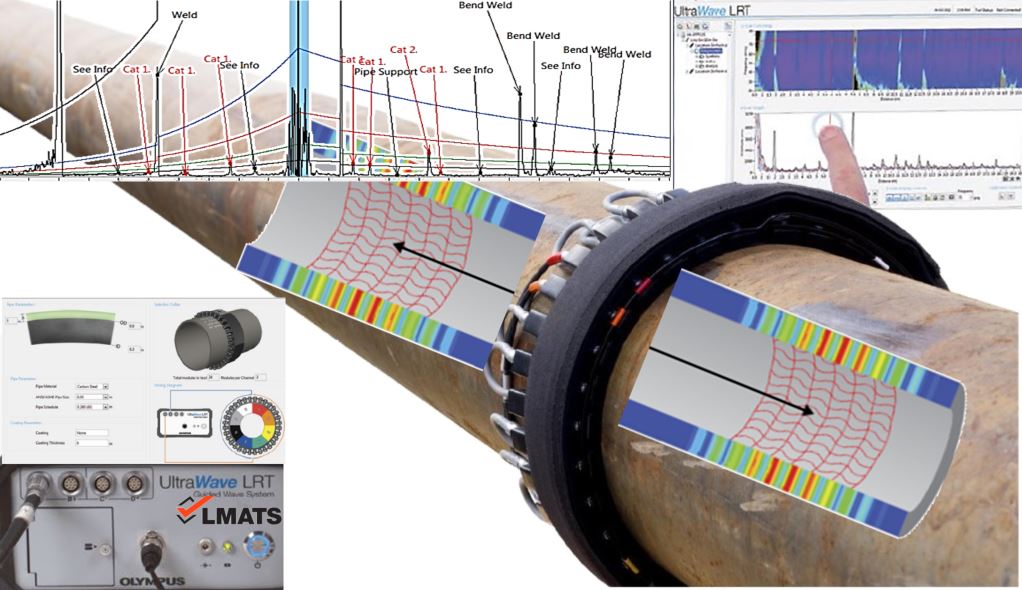

Long range ultrasonic testing ( LRUT ) LMATS

Pipeline Testing Methods During pipeline inspections, specialized equipment and techniques evaluate factors like structural integrity, corrosion levels, leaks, and overall pipeline health. These inspections are of utmost importance as they help identify any flaws, weaknesses, or susceptibilities that could lead to pipeline failures. It ensures that the pipelines can safely operate at their maximum operating pressure. During pipeline inspections, specialized equipment and techniques evaluate factors like structural integrity, corrosion levels, leaks, and overall pipeline health. Up to now, only based on ultrasonic and electromagnetic ultrasonic, magnetic flux leakage, eddy current testing methods have successfully developed. Pipeline integrity testing maintains safe & reliable operation of pipelines, protecting from lost profits and the environment. Pipeline testing methods play a crucial role in maintaining the reliability and safety of these essential conduits. Read about the 4 common methods In this article, we will. What are the different types of pipe testing methods? From magnetic flux tools to pipeline pressure testing equipment, here are the resources and methods pipeline operators can use to evaluate the integrity of their pipelines and promote better preventative maintenance.

From www.petersenproducts.com

3 Different Pipeline Integrity Testing Methods Petersen Pipeline Testing Methods During pipeline inspections, specialized equipment and techniques evaluate factors like structural integrity, corrosion levels, leaks, and overall pipeline health. In this article, we will. What are the different types of pipe testing methods? It ensures that the pipelines can safely operate at their maximum operating pressure. From magnetic flux tools to pipeline pressure testing equipment, here are the resources and. Pipeline Testing Methods.

From engtechservices.com

Hydrostatic Pressure Testing (Ireland). Watermain & Pipeline Pressure Pipeline Testing Methods Read about the 4 common methods It ensures that the pipelines can safely operate at their maximum operating pressure. In this article, we will. Pipeline testing methods play a crucial role in maintaining the reliability and safety of these essential conduits. During pipeline inspections, specialized equipment and techniques evaluate factors like structural integrity, corrosion levels, leaks, and overall pipeline health.. Pipeline Testing Methods.

From www.pp-ts.com

General 6 — Piping & Pipeline Testing Services Pipeline Testing Methods From magnetic flux tools to pipeline pressure testing equipment, here are the resources and methods pipeline operators can use to evaluate the integrity of their pipelines and promote better preventative maintenance. It ensures that the pipelines can safely operate at their maximum operating pressure. These inspections are of utmost importance as they help identify any flaws, weaknesses, or susceptibilities that. Pipeline Testing Methods.

From www.youtube.com

TechCorr Realtime Radiography (RTR) for Pipeline Weld Inspection Pipeline Testing Methods It ensures that the pipelines can safely operate at their maximum operating pressure. From magnetic flux tools to pipeline pressure testing equipment, here are the resources and methods pipeline operators can use to evaluate the integrity of their pipelines and promote better preventative maintenance. Up to now, only based on ultrasonic and electromagnetic ultrasonic, magnetic flux leakage, eddy current testing. Pipeline Testing Methods.

From www.youtube.com

Hydrostatic Testing Atlantic Coast Pipeline YouTube Pipeline Testing Methods During pipeline inspections, specialized equipment and techniques evaluate factors like structural integrity, corrosion levels, leaks, and overall pipeline health. Up to now, only based on ultrasonic and electromagnetic ultrasonic, magnetic flux leakage, eddy current testing methods have successfully developed. In this article, we will. From magnetic flux tools to pipeline pressure testing equipment, here are the resources and methods pipeline. Pipeline Testing Methods.

From engtechservices.com

Hydrostatic Pressure Testing (Ireland). Watermain & Pipeline Pressure Pipeline Testing Methods What are the different types of pipe testing methods? These inspections are of utmost importance as they help identify any flaws, weaknesses, or susceptibilities that could lead to pipeline failures. During pipeline inspections, specialized equipment and techniques evaluate factors like structural integrity, corrosion levels, leaks, and overall pipeline health. Read about the 4 common methods Up to now, only based. Pipeline Testing Methods.

From www.slideteam.net

Pipeline Testing Methods Ppt Powerpoint Presentation Slides Samples Cpb Pipeline Testing Methods During pipeline inspections, specialized equipment and techniques evaluate factors like structural integrity, corrosion levels, leaks, and overall pipeline health. It ensures that the pipelines can safely operate at their maximum operating pressure. These inspections are of utmost importance as they help identify any flaws, weaknesses, or susceptibilities that could lead to pipeline failures. In this article, we will. Read about. Pipeline Testing Methods.

From pipelinetesting.co.uk

Pipeline Testing Consultants Ltd. Pipeline Testing Methods Read about the 4 common methods Pipeline integrity testing maintains safe & reliable operation of pipelines, protecting from lost profits and the environment. These inspections are of utmost importance as they help identify any flaws, weaknesses, or susceptibilities that could lead to pipeline failures. It ensures that the pipelines can safely operate at their maximum operating pressure. From magnetic flux. Pipeline Testing Methods.

From www.youtube.com

PIPELINE HYDROTEST HOW TO CHECK PIPELINE SYSTEM INTEGRITY? YouTube Pipeline Testing Methods It ensures that the pipelines can safely operate at their maximum operating pressure. Up to now, only based on ultrasonic and electromagnetic ultrasonic, magnetic flux leakage, eddy current testing methods have successfully developed. Pipeline integrity testing maintains safe & reliable operation of pipelines, protecting from lost profits and the environment. During pipeline inspections, specialized equipment and techniques evaluate factors like. Pipeline Testing Methods.

From www.britewater.ie

Hydrostatic PE Pipeline Pressure Testing Type 2 Britewater Pipeline Testing Methods Read about the 4 common methods Pipeline integrity testing maintains safe & reliable operation of pipelines, protecting from lost profits and the environment. It ensures that the pipelines can safely operate at their maximum operating pressure. These inspections are of utmost importance as they help identify any flaws, weaknesses, or susceptibilities that could lead to pipeline failures. Pipeline testing methods. Pipeline Testing Methods.

From www.creaform3d.com

3D measurement technologies The new frontier in NDT solutions for Pipeline Testing Methods Up to now, only based on ultrasonic and electromagnetic ultrasonic, magnetic flux leakage, eddy current testing methods have successfully developed. Pipeline integrity testing maintains safe & reliable operation of pipelines, protecting from lost profits and the environment. In this article, we will. Pipeline testing methods play a crucial role in maintaining the reliability and safety of these essential conduits. Read. Pipeline Testing Methods.

From www.americanpipelinesolutions.com

Pipeline Inspection & Condition Analysis APS American Pipeline Pipeline Testing Methods Read about the 4 common methods It ensures that the pipelines can safely operate at their maximum operating pressure. From magnetic flux tools to pipeline pressure testing equipment, here are the resources and methods pipeline operators can use to evaluate the integrity of their pipelines and promote better preventative maintenance. Up to now, only based on ultrasonic and electromagnetic ultrasonic,. Pipeline Testing Methods.

From bluelinetesting.ie

Pipeline Pressure Testing Blue Line Testing Pipeline Testing Methods Read about the 4 common methods Pipeline testing methods play a crucial role in maintaining the reliability and safety of these essential conduits. During pipeline inspections, specialized equipment and techniques evaluate factors like structural integrity, corrosion levels, leaks, and overall pipeline health. These inspections are of utmost importance as they help identify any flaws, weaknesses, or susceptibilities that could lead. Pipeline Testing Methods.

From 2020ndt.com

Pipeline Testing NDE & NDT 20/20NDT Pipeline Testing Methods During pipeline inspections, specialized equipment and techniques evaluate factors like structural integrity, corrosion levels, leaks, and overall pipeline health. Pipeline integrity testing maintains safe & reliable operation of pipelines, protecting from lost profits and the environment. These inspections are of utmost importance as they help identify any flaws, weaknesses, or susceptibilities that could lead to pipeline failures. It ensures that. Pipeline Testing Methods.

From www.americanpipelinesolutions.com

Guide to Pipeline Hydrostatic Testing American Pipeline Solutions Pipeline Testing Methods During pipeline inspections, specialized equipment and techniques evaluate factors like structural integrity, corrosion levels, leaks, and overall pipeline health. Pipeline integrity testing maintains safe & reliable operation of pipelines, protecting from lost profits and the environment. Up to now, only based on ultrasonic and electromagnetic ultrasonic, magnetic flux leakage, eddy current testing methods have successfully developed. In this article, we. Pipeline Testing Methods.

From engtechservices.com

Hydrostatic Pressure Testing (Ireland). Watermain & Pipeline Pressure Pipeline Testing Methods From magnetic flux tools to pipeline pressure testing equipment, here are the resources and methods pipeline operators can use to evaluate the integrity of their pipelines and promote better preventative maintenance. What are the different types of pipe testing methods? It ensures that the pipelines can safely operate at their maximum operating pressure. Read about the 4 common methods Up. Pipeline Testing Methods.

From blog.thepipingmart.com

Procedure For Hydrotesting A Piping System Pipeline Testing Methods Pipeline integrity testing maintains safe & reliable operation of pipelines, protecting from lost profits and the environment. These inspections are of utmost importance as they help identify any flaws, weaknesses, or susceptibilities that could lead to pipeline failures. Up to now, only based on ultrasonic and electromagnetic ultrasonic, magnetic flux leakage, eddy current testing methods have successfully developed. From magnetic. Pipeline Testing Methods.

From disorderbnews.blogspot.com

Pipeline Equipment Pipe Handling Systems You seek to supply your Pipeline Testing Methods Up to now, only based on ultrasonic and electromagnetic ultrasonic, magnetic flux leakage, eddy current testing methods have successfully developed. Pipeline integrity testing maintains safe & reliable operation of pipelines, protecting from lost profits and the environment. Read about the 4 common methods Pipeline testing methods play a crucial role in maintaining the reliability and safety of these essential conduits.. Pipeline Testing Methods.

From www.pipeline-engineer.com

Hot Tapping (Pressure Tapping) and Freezing A. Keith Escoe, in Piping Pipeline Testing Methods It ensures that the pipelines can safely operate at their maximum operating pressure. Pipeline testing methods play a crucial role in maintaining the reliability and safety of these essential conduits. What are the different types of pipe testing methods? During pipeline inspections, specialized equipment and techniques evaluate factors like structural integrity, corrosion levels, leaks, and overall pipeline health. These inspections. Pipeline Testing Methods.

From www.metalogicinspection.com

Pipeline Metalogic Inspection Services Pipeline Testing Methods These inspections are of utmost importance as they help identify any flaws, weaknesses, or susceptibilities that could lead to pipeline failures. Read about the 4 common methods During pipeline inspections, specialized equipment and techniques evaluate factors like structural integrity, corrosion levels, leaks, and overall pipeline health. It ensures that the pipelines can safely operate at their maximum operating pressure. In. Pipeline Testing Methods.

From blog.eddyfi.com

Unpiggable Pipelines Require Better Understanding Under PHMSA Gas Mega Rule Pipeline Testing Methods These inspections are of utmost importance as they help identify any flaws, weaknesses, or susceptibilities that could lead to pipeline failures. From magnetic flux tools to pipeline pressure testing equipment, here are the resources and methods pipeline operators can use to evaluate the integrity of their pipelines and promote better preventative maintenance. In this article, we will. Read about the. Pipeline Testing Methods.

From www.pipelinetesting.com.au

Water and Sewage Pipeline Testing Solutions in SEQ Pipeline Testing Pipeline Testing Methods These inspections are of utmost importance as they help identify any flaws, weaknesses, or susceptibilities that could lead to pipeline failures. Up to now, only based on ultrasonic and electromagnetic ultrasonic, magnetic flux leakage, eddy current testing methods have successfully developed. It ensures that the pipelines can safely operate at their maximum operating pressure. During pipeline inspections, specialized equipment and. Pipeline Testing Methods.

From lmats.com.au

Long range ultrasonic testing ( LRUT ) LMATS Pipeline Testing Methods Pipeline integrity testing maintains safe & reliable operation of pipelines, protecting from lost profits and the environment. During pipeline inspections, specialized equipment and techniques evaluate factors like structural integrity, corrosion levels, leaks, and overall pipeline health. From magnetic flux tools to pipeline pressure testing equipment, here are the resources and methods pipeline operators can use to evaluate the integrity of. Pipeline Testing Methods.

From tiat.nl

NDT Pipeline Testing Tiat Europe B.V. Pipeline Testing Methods Read about the 4 common methods Pipeline testing methods play a crucial role in maintaining the reliability and safety of these essential conduits. During pipeline inspections, specialized equipment and techniques evaluate factors like structural integrity, corrosion levels, leaks, and overall pipeline health. It ensures that the pipelines can safely operate at their maximum operating pressure. From magnetic flux tools to. Pipeline Testing Methods.

From metalexponents.com

4 Types of Pipe Testing Methods Pipeline Testing Methods Up to now, only based on ultrasonic and electromagnetic ultrasonic, magnetic flux leakage, eddy current testing methods have successfully developed. These inspections are of utmost importance as they help identify any flaws, weaknesses, or susceptibilities that could lead to pipeline failures. What are the different types of pipe testing methods? Pipeline testing methods play a crucial role in maintaining the. Pipeline Testing Methods.

From www.inpipeproducts.com

Pipeline Testing iNPIPE Products™ Pipeline Testing Methods What are the different types of pipe testing methods? It ensures that the pipelines can safely operate at their maximum operating pressure. These inspections are of utmost importance as they help identify any flaws, weaknesses, or susceptibilities that could lead to pipeline failures. During pipeline inspections, specialized equipment and techniques evaluate factors like structural integrity, corrosion levels, leaks, and overall. Pipeline Testing Methods.

From www.britewater.ie

Hydrostatic PE Pipeline Pressure Testing Type 2 Britewater Pipeline Testing Methods During pipeline inspections, specialized equipment and techniques evaluate factors like structural integrity, corrosion levels, leaks, and overall pipeline health. What are the different types of pipe testing methods? Read about the 4 common methods Pipeline testing methods play a crucial role in maintaining the reliability and safety of these essential conduits. Up to now, only based on ultrasonic and electromagnetic. Pipeline Testing Methods.

From www.youtube.com

Pipeline Safety Hydrostatic Pressure Testing Short Version YouTube Pipeline Testing Methods Pipeline integrity testing maintains safe & reliable operation of pipelines, protecting from lost profits and the environment. It ensures that the pipelines can safely operate at their maximum operating pressure. Pipeline testing methods play a crucial role in maintaining the reliability and safety of these essential conduits. Read about the 4 common methods During pipeline inspections, specialized equipment and techniques. Pipeline Testing Methods.

From www.vaengineering.com

Cathodic Protection (CP) Testing Methods for Pipelines — V&A Consulting Pipeline Testing Methods During pipeline inspections, specialized equipment and techniques evaluate factors like structural integrity, corrosion levels, leaks, and overall pipeline health. Pipeline testing methods play a crucial role in maintaining the reliability and safety of these essential conduits. Pipeline integrity testing maintains safe & reliable operation of pipelines, protecting from lost profits and the environment. These inspections are of utmost importance as. Pipeline Testing Methods.

From www.slideserve.com

PPT Pipeline Test methods PowerPoint Presentation, free download ID Pipeline Testing Methods What are the different types of pipe testing methods? Pipeline integrity testing maintains safe & reliable operation of pipelines, protecting from lost profits and the environment. Pipeline testing methods play a crucial role in maintaining the reliability and safety of these essential conduits. These inspections are of utmost importance as they help identify any flaws, weaknesses, or susceptibilities that could. Pipeline Testing Methods.

From www.mercurynews.com

PG&E tests pipeline in Mountain View with water pressure The Mercury News Pipeline Testing Methods During pipeline inspections, specialized equipment and techniques evaluate factors like structural integrity, corrosion levels, leaks, and overall pipeline health. It ensures that the pipelines can safely operate at their maximum operating pressure. Pipeline integrity testing maintains safe & reliable operation of pipelines, protecting from lost profits and the environment. From magnetic flux tools to pipeline pressure testing equipment, here are. Pipeline Testing Methods.

From pipelinetesting.co.uk

Pipeline Testing Consultants Ltd. Pipeline Testing Methods What are the different types of pipe testing methods? In this article, we will. Read about the 4 common methods Pipeline integrity testing maintains safe & reliable operation of pipelines, protecting from lost profits and the environment. From magnetic flux tools to pipeline pressure testing equipment, here are the resources and methods pipeline operators can use to evaluate the integrity. Pipeline Testing Methods.

From www.researchgate.net

Pipeline inspection techniques Download Scientific Diagram Pipeline Testing Methods From magnetic flux tools to pipeline pressure testing equipment, here are the resources and methods pipeline operators can use to evaluate the integrity of their pipelines and promote better preventative maintenance. These inspections are of utmost importance as they help identify any flaws, weaknesses, or susceptibilities that could lead to pipeline failures. Up to now, only based on ultrasonic and. Pipeline Testing Methods.

From corrolytics.com

Testing 101 Methods and Strategies for Testing Corrosion in Oil and Pipeline Testing Methods Pipeline integrity testing maintains safe & reliable operation of pipelines, protecting from lost profits and the environment. From magnetic flux tools to pipeline pressure testing equipment, here are the resources and methods pipeline operators can use to evaluate the integrity of their pipelines and promote better preventative maintenance. What are the different types of pipe testing methods? Read about the. Pipeline Testing Methods.

From control.com

Essential Industrial Pipeline and Inspection Tools Industry Articles Pipeline Testing Methods These inspections are of utmost importance as they help identify any flaws, weaknesses, or susceptibilities that could lead to pipeline failures. What are the different types of pipe testing methods? Pipeline testing methods play a crucial role in maintaining the reliability and safety of these essential conduits. During pipeline inspections, specialized equipment and techniques evaluate factors like structural integrity, corrosion. Pipeline Testing Methods.