Hydraulic Cylinder Adjustment . Tie rod and welded body cylinders. — when synchronizing hydraulic cylinders, the cylinders must be properly sized and matched to enable precise. Finally, cylinders can be slowed down by storing the kinetic energy in viscous fluids such as oil. there are primarily two styles of hydraulic cylinder construction used in industry: Enhance control and reduce impact in your systems. every component in a hydraulic cylinder is vital, including pivot pins, clevises, and accessories. — discover techniques for cushioning and decelerating hydraulic cylinders. Worn or damaged pivot pins and clevises can introduce play and slop into cylinder joints, causing misalignment and wear. to adjust the piston velocity, you need to know the cylinder characteristics, specified load mass and the operating pressure specified by the manufacturer.

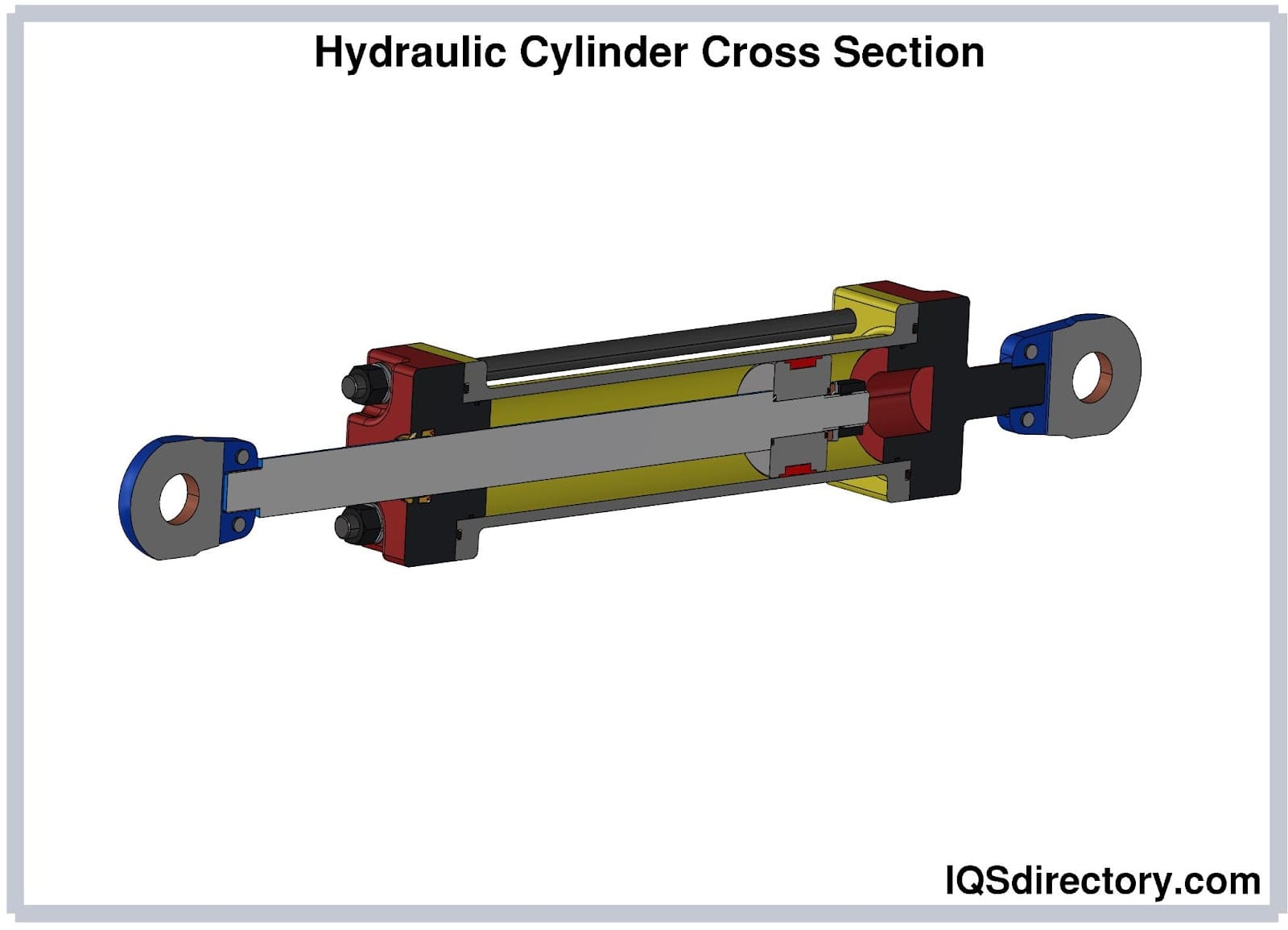

from www.iqsdirectory.com

every component in a hydraulic cylinder is vital, including pivot pins, clevises, and accessories. — discover techniques for cushioning and decelerating hydraulic cylinders. Enhance control and reduce impact in your systems. Worn or damaged pivot pins and clevises can introduce play and slop into cylinder joints, causing misalignment and wear. Finally, cylinders can be slowed down by storing the kinetic energy in viscous fluids such as oil. to adjust the piston velocity, you need to know the cylinder characteristics, specified load mass and the operating pressure specified by the manufacturer. there are primarily two styles of hydraulic cylinder construction used in industry: — when synchronizing hydraulic cylinders, the cylinders must be properly sized and matched to enable precise. Tie rod and welded body cylinders.

Hydraulic Cylinders Types, Configurations & Applications

Hydraulic Cylinder Adjustment Finally, cylinders can be slowed down by storing the kinetic energy in viscous fluids such as oil. — discover techniques for cushioning and decelerating hydraulic cylinders. Enhance control and reduce impact in your systems. Tie rod and welded body cylinders. Worn or damaged pivot pins and clevises can introduce play and slop into cylinder joints, causing misalignment and wear. — when synchronizing hydraulic cylinders, the cylinders must be properly sized and matched to enable precise. there are primarily two styles of hydraulic cylinder construction used in industry: every component in a hydraulic cylinder is vital, including pivot pins, clevises, and accessories. Finally, cylinders can be slowed down by storing the kinetic energy in viscous fluids such as oil. to adjust the piston velocity, you need to know the cylinder characteristics, specified load mass and the operating pressure specified by the manufacturer.

From www.youtube.com

Hydraulic cylinder design. How does the hydraulic cylinder work? YouTube Hydraulic Cylinder Adjustment Enhance control and reduce impact in your systems. every component in a hydraulic cylinder is vital, including pivot pins, clevises, and accessories. Tie rod and welded body cylinders. Worn or damaged pivot pins and clevises can introduce play and slop into cylinder joints, causing misalignment and wear. Finally, cylinders can be slowed down by storing the kinetic energy in. Hydraulic Cylinder Adjustment.

From eureka.patsnap.com

Hydraulic cylinder adjustment device of eighteen rolling mill working Hydraulic Cylinder Adjustment — when synchronizing hydraulic cylinders, the cylinders must be properly sized and matched to enable precise. to adjust the piston velocity, you need to know the cylinder characteristics, specified load mass and the operating pressure specified by the manufacturer. there are primarily two styles of hydraulic cylinder construction used in industry: every component in a hydraulic. Hydraulic Cylinder Adjustment.

From pto-shaft.en.made-in-china.com

Various Good Quality 15MPa 13kg Forklift Distance Adjustment Hydraulic Hydraulic Cylinder Adjustment Enhance control and reduce impact in your systems. to adjust the piston velocity, you need to know the cylinder characteristics, specified load mass and the operating pressure specified by the manufacturer. — when synchronizing hydraulic cylinders, the cylinders must be properly sized and matched to enable precise. Tie rod and welded body cylinders. there are primarily two. Hydraulic Cylinder Adjustment.

From www.iqsdirectory.com

Hydraulic Cylinders Types, Configurations & Applications Hydraulic Cylinder Adjustment to adjust the piston velocity, you need to know the cylinder characteristics, specified load mass and the operating pressure specified by the manufacturer. Tie rod and welded body cylinders. Finally, cylinders can be slowed down by storing the kinetic energy in viscous fluids such as oil. — when synchronizing hydraulic cylinders, the cylinders must be properly sized and. Hydraulic Cylinder Adjustment.

From www.dallasthydraulics.com

How to adjust the speed of the hydraulic cylinder? Hydraulic Cylinder Adjustment every component in a hydraulic cylinder is vital, including pivot pins, clevises, and accessories. — discover techniques for cushioning and decelerating hydraulic cylinders. Enhance control and reduce impact in your systems. to adjust the piston velocity, you need to know the cylinder characteristics, specified load mass and the operating pressure specified by the manufacturer. Tie rod and. Hydraulic Cylinder Adjustment.

From www.e-pneumatic.com

How Pneumatic Cylinder Work? Described Instructions EPneumatic Blog Hydraulic Cylinder Adjustment there are primarily two styles of hydraulic cylinder construction used in industry: Worn or damaged pivot pins and clevises can introduce play and slop into cylinder joints, causing misalignment and wear. Enhance control and reduce impact in your systems. Tie rod and welded body cylinders. — discover techniques for cushioning and decelerating hydraulic cylinders. Finally, cylinders can be. Hydraulic Cylinder Adjustment.

From dxoyjwwao.blob.core.windows.net

Hydraulic Actuator Design Calculations at Walter Ford blog Hydraulic Cylinder Adjustment every component in a hydraulic cylinder is vital, including pivot pins, clevises, and accessories. Enhance control and reduce impact in your systems. Finally, cylinders can be slowed down by storing the kinetic energy in viscous fluids such as oil. there are primarily two styles of hydraulic cylinder construction used in industry: to adjust the piston velocity, you. Hydraulic Cylinder Adjustment.

From www.youtube.com

Rocker Arm/Hydraulic Lifter Adjustment YouTube Hydraulic Cylinder Adjustment to adjust the piston velocity, you need to know the cylinder characteristics, specified load mass and the operating pressure specified by the manufacturer. — discover techniques for cushioning and decelerating hydraulic cylinders. — when synchronizing hydraulic cylinders, the cylinders must be properly sized and matched to enable precise. Tie rod and welded body cylinders. Finally, cylinders can. Hydraulic Cylinder Adjustment.

From www.youtube.com

Part 1 Rebuilding Wheel Horse Hydraulic Cylinder YouTube Hydraulic Cylinder Adjustment — discover techniques for cushioning and decelerating hydraulic cylinders. Enhance control and reduce impact in your systems. — when synchronizing hydraulic cylinders, the cylinders must be properly sized and matched to enable precise. there are primarily two styles of hydraulic cylinder construction used in industry: to adjust the piston velocity, you need to know the cylinder. Hydraulic Cylinder Adjustment.

From www.ametekfactoryautomation.com

Cylinder Position Sensor for Hydraulic Cylinders AMETEK Factory Hydraulic Cylinder Adjustment there are primarily two styles of hydraulic cylinder construction used in industry: Worn or damaged pivot pins and clevises can introduce play and slop into cylinder joints, causing misalignment and wear. every component in a hydraulic cylinder is vital, including pivot pins, clevises, and accessories. Finally, cylinders can be slowed down by storing the kinetic energy in viscous. Hydraulic Cylinder Adjustment.

From www.hmbhydraulicbreaker.com

News How to adjust the hydraulic breaker? Hydraulic Cylinder Adjustment there are primarily two styles of hydraulic cylinder construction used in industry: — when synchronizing hydraulic cylinders, the cylinders must be properly sized and matched to enable precise. to adjust the piston velocity, you need to know the cylinder characteristics, specified load mass and the operating pressure specified by the manufacturer. Worn or damaged pivot pins and. Hydraulic Cylinder Adjustment.

From www.youtube.com

Hydraulic cylinder working animation How does a Hydraulic cylinder Hydraulic Cylinder Adjustment Finally, cylinders can be slowed down by storing the kinetic energy in viscous fluids such as oil. there are primarily two styles of hydraulic cylinder construction used in industry: to adjust the piston velocity, you need to know the cylinder characteristics, specified load mass and the operating pressure specified by the manufacturer. Worn or damaged pivot pins and. Hydraulic Cylinder Adjustment.

From www.magisterhyd.com

2.5 bore x 26 stroke hydraulic cylinder, welded tang double acting Hydraulic Cylinder Adjustment — discover techniques for cushioning and decelerating hydraulic cylinders. Finally, cylinders can be slowed down by storing the kinetic energy in viscous fluids such as oil. to adjust the piston velocity, you need to know the cylinder characteristics, specified load mass and the operating pressure specified by the manufacturer. every component in a hydraulic cylinder is vital,. Hydraulic Cylinder Adjustment.

From www.youtube.com

How to adjust cushion on air cylinder YouTube Hydraulic Cylinder Adjustment Tie rod and welded body cylinders. Finally, cylinders can be slowed down by storing the kinetic energy in viscous fluids such as oil. Worn or damaged pivot pins and clevises can introduce play and slop into cylinder joints, causing misalignment and wear. every component in a hydraulic cylinder is vital, including pivot pins, clevises, and accessories. — when. Hydraulic Cylinder Adjustment.

From repairfixmielsdorfa8.z13.web.core.windows.net

How To Install A Lippert Hydraulic Cylinder Hydraulic Cylinder Adjustment Finally, cylinders can be slowed down by storing the kinetic energy in viscous fluids such as oil. Worn or damaged pivot pins and clevises can introduce play and slop into cylinder joints, causing misalignment and wear. Tie rod and welded body cylinders. Enhance control and reduce impact in your systems. — when synchronizing hydraulic cylinders, the cylinders must be. Hydraulic Cylinder Adjustment.

From pto-shaft.en.made-in-china.com

Pump Forklift Hydraulic Cylinder for Tilt Lifting Steering Distance Hydraulic Cylinder Adjustment there are primarily two styles of hydraulic cylinder construction used in industry: Finally, cylinders can be slowed down by storing the kinetic energy in viscous fluids such as oil. — when synchronizing hydraulic cylinders, the cylinders must be properly sized and matched to enable precise. every component in a hydraulic cylinder is vital, including pivot pins, clevises,. Hydraulic Cylinder Adjustment.

From www.heiss.de

HYDRAULIC CYLINDER WITH INTERNAL STROKE ADJUSTMENT Heiss Hydraulik Hydraulic Cylinder Adjustment — discover techniques for cushioning and decelerating hydraulic cylinders. Worn or damaged pivot pins and clevises can introduce play and slop into cylinder joints, causing misalignment and wear. to adjust the piston velocity, you need to know the cylinder characteristics, specified load mass and the operating pressure specified by the manufacturer. Enhance control and reduce impact in your. Hydraulic Cylinder Adjustment.

From www.onallcylinders.com

The Basics of Setting and Adjusting Valve Lash Hydraulic Cylinder Adjustment Worn or damaged pivot pins and clevises can introduce play and slop into cylinder joints, causing misalignment and wear. to adjust the piston velocity, you need to know the cylinder characteristics, specified load mass and the operating pressure specified by the manufacturer. Tie rod and welded body cylinders. there are primarily two styles of hydraulic cylinder construction used. Hydraulic Cylinder Adjustment.

From www.peninsularcylinders.com

Peninsular Cylinder Co. cylinder repair, hydraulic cylinder repair Hydraulic Cylinder Adjustment Finally, cylinders can be slowed down by storing the kinetic energy in viscous fluids such as oil. there are primarily two styles of hydraulic cylinder construction used in industry: Tie rod and welded body cylinders. every component in a hydraulic cylinder is vital, including pivot pins, clevises, and accessories. — when synchronizing hydraulic cylinders, the cylinders must. Hydraulic Cylinder Adjustment.

From www.aggressivehydraulics.com

Preventing Mechanical Shock Hydraulic Cylinder Cushioning Hydraulic Cylinder Adjustment every component in a hydraulic cylinder is vital, including pivot pins, clevises, and accessories. to adjust the piston velocity, you need to know the cylinder characteristics, specified load mass and the operating pressure specified by the manufacturer. there are primarily two styles of hydraulic cylinder construction used in industry: — discover techniques for cushioning and decelerating. Hydraulic Cylinder Adjustment.

From www.youtube.com

Adjusting the Hydraulic Cylinder by Prime Design YouTube Hydraulic Cylinder Adjustment Tie rod and welded body cylinders. Finally, cylinders can be slowed down by storing the kinetic energy in viscous fluids such as oil. every component in a hydraulic cylinder is vital, including pivot pins, clevises, and accessories. — discover techniques for cushioning and decelerating hydraulic cylinders. Enhance control and reduce impact in your systems. there are primarily. Hydraulic Cylinder Adjustment.

From korean.electricalcylinder.com

Lifting Tools 300 Ton Telescopic Hydraulic Adjust Cylinder Double Hydraulic Cylinder Adjustment every component in a hydraulic cylinder is vital, including pivot pins, clevises, and accessories. there are primarily two styles of hydraulic cylinder construction used in industry: — when synchronizing hydraulic cylinders, the cylinders must be properly sized and matched to enable precise. Tie rod and welded body cylinders. Worn or damaged pivot pins and clevises can introduce. Hydraulic Cylinder Adjustment.

From exonaxgyi.blob.core.windows.net

Pneumatic Cylinder System Design at Robert Squires blog Hydraulic Cylinder Adjustment to adjust the piston velocity, you need to know the cylinder characteristics, specified load mass and the operating pressure specified by the manufacturer. — discover techniques for cushioning and decelerating hydraulic cylinders. Enhance control and reduce impact in your systems. Finally, cylinders can be slowed down by storing the kinetic energy in viscous fluids such as oil. . Hydraulic Cylinder Adjustment.

From circuitdbseriatim.z13.web.core.windows.net

Double Acting Hydraulic Cylinder Diagram Hydraulic Cylinder Adjustment every component in a hydraulic cylinder is vital, including pivot pins, clevises, and accessories. Finally, cylinders can be slowed down by storing the kinetic energy in viscous fluids such as oil. — discover techniques for cushioning and decelerating hydraulic cylinders. Enhance control and reduce impact in your systems. — when synchronizing hydraulic cylinders, the cylinders must be. Hydraulic Cylinder Adjustment.

From blog.enerpac.com

How to SetUp Your Single or MultiPoint Hydraulic System Enerpac Blog Hydraulic Cylinder Adjustment Enhance control and reduce impact in your systems. there are primarily two styles of hydraulic cylinder construction used in industry: Finally, cylinders can be slowed down by storing the kinetic energy in viscous fluids such as oil. — when synchronizing hydraulic cylinders, the cylinders must be properly sized and matched to enable precise. — discover techniques for. Hydraulic Cylinder Adjustment.

From www.eastern-triangle.com

Eastern Triangle Enterprises LLC EStore. Kubota 6C12037220 Hydraulic Hydraulic Cylinder Adjustment Tie rod and welded body cylinders. to adjust the piston velocity, you need to know the cylinder characteristics, specified load mass and the operating pressure specified by the manufacturer. — discover techniques for cushioning and decelerating hydraulic cylinders. Finally, cylinders can be slowed down by storing the kinetic energy in viscous fluids such as oil. — when. Hydraulic Cylinder Adjustment.

From slidetodoc.com

Hydraulic Cylinders and Cushioning Devices Introduction Hydraulic cylinders Hydraulic Cylinder Adjustment Worn or damaged pivot pins and clevises can introduce play and slop into cylinder joints, causing misalignment and wear. Tie rod and welded body cylinders. Finally, cylinders can be slowed down by storing the kinetic energy in viscous fluids such as oil. — discover techniques for cushioning and decelerating hydraulic cylinders. there are primarily two styles of hydraulic. Hydraulic Cylinder Adjustment.

From www.youtube.com

Double Acting Hydraulic Cylinder Working Animation YouTube Hydraulic Cylinder Adjustment — discover techniques for cushioning and decelerating hydraulic cylinders. to adjust the piston velocity, you need to know the cylinder characteristics, specified load mass and the operating pressure specified by the manufacturer. there are primarily two styles of hydraulic cylinder construction used in industry: Finally, cylinders can be slowed down by storing the kinetic energy in viscous. Hydraulic Cylinder Adjustment.

From schematicmanualwilliam.z13.web.core.windows.net

Hydraulic Valve Detent Adjustment Hydraulic Cylinder Adjustment Finally, cylinders can be slowed down by storing the kinetic energy in viscous fluids such as oil. there are primarily two styles of hydraulic cylinder construction used in industry: to adjust the piston velocity, you need to know the cylinder characteristics, specified load mass and the operating pressure specified by the manufacturer. Tie rod and welded body cylinders.. Hydraulic Cylinder Adjustment.

From www.hydrauliccylindersinc.com

StepByStep Hydraulic Cylinder Installation Guide Hydraulic Cylinder Adjustment there are primarily two styles of hydraulic cylinder construction used in industry: — when synchronizing hydraulic cylinders, the cylinders must be properly sized and matched to enable precise. Worn or damaged pivot pins and clevises can introduce play and slop into cylinder joints, causing misalignment and wear. Enhance control and reduce impact in your systems. to adjust. Hydraulic Cylinder Adjustment.

From blog.enerpac.com

How to SetUp Your Single or MultiPoint Hydraulic System Enerpac Blog Hydraulic Cylinder Adjustment Worn or damaged pivot pins and clevises can introduce play and slop into cylinder joints, causing misalignment and wear. every component in a hydraulic cylinder is vital, including pivot pins, clevises, and accessories. — discover techniques for cushioning and decelerating hydraulic cylinders. to adjust the piston velocity, you need to know the cylinder characteristics, specified load mass. Hydraulic Cylinder Adjustment.

From www.hkdivedi.com

CUSHIONING HYDRAULIC CYLINDER WORKING PRINCIPLE ENGINEERING APPLICATIONS Hydraulic Cylinder Adjustment to adjust the piston velocity, you need to know the cylinder characteristics, specified load mass and the operating pressure specified by the manufacturer. every component in a hydraulic cylinder is vital, including pivot pins, clevises, and accessories. Worn or damaged pivot pins and clevises can introduce play and slop into cylinder joints, causing misalignment and wear. —. Hydraulic Cylinder Adjustment.

From www.hopetech.com.tw

SCC mold adjustment hydraulic cylinder HOPETECH Hydraulic Cylinder Adjustment Finally, cylinders can be slowed down by storing the kinetic energy in viscous fluids such as oil. — when synchronizing hydraulic cylinders, the cylinders must be properly sized and matched to enable precise. to adjust the piston velocity, you need to know the cylinder characteristics, specified load mass and the operating pressure specified by the manufacturer. there. Hydraulic Cylinder Adjustment.

From dxovfhiio.blob.core.windows.net

Hydraulic Cylinder Definition Engineering at Rebecca Coon blog Hydraulic Cylinder Adjustment there are primarily two styles of hydraulic cylinder construction used in industry: Finally, cylinders can be slowed down by storing the kinetic energy in viscous fluids such as oil. Enhance control and reduce impact in your systems. — when synchronizing hydraulic cylinders, the cylinders must be properly sized and matched to enable precise. Tie rod and welded body. Hydraulic Cylinder Adjustment.

From www.dreamstime.com

Spring Gaskets To Adjust the Stroke of the Hydraulic Cylinder Stock Hydraulic Cylinder Adjustment Enhance control and reduce impact in your systems. — discover techniques for cushioning and decelerating hydraulic cylinders. Finally, cylinders can be slowed down by storing the kinetic energy in viscous fluids such as oil. Worn or damaged pivot pins and clevises can introduce play and slop into cylinder joints, causing misalignment and wear. — when synchronizing hydraulic cylinders,. Hydraulic Cylinder Adjustment.