Pressure Control Valve Failure Modes . Some of the common control valve failure modes are: In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure in the actuator’s diaphragm or piston chamber. In the event of power or pressure loss, a kimray high pressure control valve actuator will cause the control valve to “fail,” or stop, in one of two positions: Understand the causes, effects, and importance of quality in pressure systems. One of the most common failure modes is when the valve stem or actuator becomes stuck or binds. Today we will look at. These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. As you know control valves play. Explore the various failure modes of valves, from leakage to design flaws. An important design parameter for control valves is the position to which the valve will fail if power or signal is lost.

from automationforum.co

An important design parameter for control valves is the position to which the valve will fail if power or signal is lost. Explore the various failure modes of valves, from leakage to design flaws. Understand the causes, effects, and importance of quality in pressure systems. One of the most common failure modes is when the valve stem or actuator becomes stuck or binds. Some of the common control valve failure modes are: As you know control valves play. In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure in the actuator’s diaphragm or piston chamber. These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. Today we will look at. In the event of power or pressure loss, a kimray high pressure control valve actuator will cause the control valve to “fail,” or stop, in one of two positions:

Failure modes in Control valve actuators AutomationForum

Pressure Control Valve Failure Modes In the event of power or pressure loss, a kimray high pressure control valve actuator will cause the control valve to “fail,” or stop, in one of two positions: These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. Some of the common control valve failure modes are: As you know control valves play. An important design parameter for control valves is the position to which the valve will fail if power or signal is lost. Understand the causes, effects, and importance of quality in pressure systems. In the event of power or pressure loss, a kimray high pressure control valve actuator will cause the control valve to “fail,” or stop, in one of two positions: Today we will look at. Explore the various failure modes of valves, from leakage to design flaws. In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure in the actuator’s diaphragm or piston chamber. One of the most common failure modes is when the valve stem or actuator becomes stuck or binds.

From control.com

Common Control Valve Problems Basic Principles of Control Valves and Actuators Automation Pressure Control Valve Failure Modes Some of the common control valve failure modes are: As you know control valves play. Today we will look at. One of the most common failure modes is when the valve stem or actuator becomes stuck or binds. In the event of power or pressure loss, a kimray high pressure control valve actuator will cause the control valve to “fail,”. Pressure Control Valve Failure Modes.

From www.slideserve.com

PPT Important Practical Valve and Controller Issues PowerPoint Presentation ID4539752 Pressure Control Valve Failure Modes In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure in the actuator’s diaphragm or piston chamber. In the event of power or pressure loss, a kimray high pressure control valve actuator will cause the control valve to “fail,” or stop, in one of two positions: Some of the. Pressure Control Valve Failure Modes.

From control.com

Instrument and Process Equipment Symbols Control and Instrumentation Documentation Textbook Pressure Control Valve Failure Modes Understand the causes, effects, and importance of quality in pressure systems. Today we will look at. One of the most common failure modes is when the valve stem or actuator becomes stuck or binds. These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. In order for a pneumatic or hydraulic valve to fail. Pressure Control Valve Failure Modes.

From instrumentationtools.com

How to Select Control Valve Failure Mode Instrumentation Tools Pressure Control Valve Failure Modes In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure in the actuator’s diaphragm or piston chamber. As you know control valves play. In the event of power or pressure loss, a kimray high pressure control valve actuator will cause the control valve to “fail,” or stop, in one. Pressure Control Valve Failure Modes.

From mavink.com

Types Of Pressure Control Valves Pressure Control Valve Failure Modes Today we will look at. Understand the causes, effects, and importance of quality in pressure systems. Explore the various failure modes of valves, from leakage to design flaws. One of the most common failure modes is when the valve stem or actuator becomes stuck or binds. As you know control valves play. In order for a pneumatic or hydraulic valve. Pressure Control Valve Failure Modes.

From www.slideserve.com

PPT Control Valve Actuators Types and Failure Modes PowerPoint Presentation ID11015353 Pressure Control Valve Failure Modes As you know control valves play. One of the most common failure modes is when the valve stem or actuator becomes stuck or binds. Some of the common control valve failure modes are: In the event of power or pressure loss, a kimray high pressure control valve actuator will cause the control valve to “fail,” or stop, in one of. Pressure Control Valve Failure Modes.

From control.com

Common Control Valve Problems Basic Principles of Control Valves and Actuators Textbook Pressure Control Valve Failure Modes Explore the various failure modes of valves, from leakage to design flaws. In the event of power or pressure loss, a kimray high pressure control valve actuator will cause the control valve to “fail,” or stop, in one of two positions: An important design parameter for control valves is the position to which the valve will fail if power or. Pressure Control Valve Failure Modes.

From techblog.ctgclean.com

Valves Backpressure Regulating Valves CTG Technical Blog Pressure Control Valve Failure Modes As you know control valves play. Some of the common control valve failure modes are: One of the most common failure modes is when the valve stem or actuator becomes stuck or binds. In the event of power or pressure loss, a kimray high pressure control valve actuator will cause the control valve to “fail,” or stop, in one of. Pressure Control Valve Failure Modes.

From www.researchgate.net

What are the causes of failure of pressure safety valve springs Pressure Control Valve Failure Modes Today we will look at. As you know control valves play. Some of the common control valve failure modes are: An important design parameter for control valves is the position to which the valve will fail if power or signal is lost. These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. Understand the. Pressure Control Valve Failure Modes.

From instrumentationtools.com

Troubleshooting Common Control Valve Problems Inst Tools Pressure Control Valve Failure Modes Explore the various failure modes of valves, from leakage to design flaws. Some of the common control valve failure modes are: One of the most common failure modes is when the valve stem or actuator becomes stuck or binds. In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure. Pressure Control Valve Failure Modes.

From www.youtube.com

Control Valve Failure Mode (Fail Lock Fail last DC Fail Last DO FC FO Modes included Pressure Control Valve Failure Modes Today we will look at. These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. As you know control valves play. Understand the causes, effects, and importance of quality in pressure systems. One of the most common failure modes is when the valve stem or actuator becomes stuck or binds. Some of the common. Pressure Control Valve Failure Modes.

From automation-renew.blogspot.com

Automation and Instrumentation Process and Instrument Diagrams Valve Failure Mode Pressure Control Valve Failure Modes In the event of power or pressure loss, a kimray high pressure control valve actuator will cause the control valve to “fail,” or stop, in one of two positions: Understand the causes, effects, and importance of quality in pressure systems. In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid. Pressure Control Valve Failure Modes.

From www.cooneybrothers.com

Top 5 Steam Pressure Reducing Valve Failure Symptoms (Spirax Sarco 25 Series PRVs) Cooney Brothers Pressure Control Valve Failure Modes In the event of power or pressure loss, a kimray high pressure control valve actuator will cause the control valve to “fail,” or stop, in one of two positions: Today we will look at. Some of the common control valve failure modes are: Explore the various failure modes of valves, from leakage to design flaws. Understand the causes, effects, and. Pressure Control Valve Failure Modes.

From www.controlglobal.com

How valve failure modes interact with controller actions and process loads Control Global Pressure Control Valve Failure Modes As you know control valves play. One of the most common failure modes is when the valve stem or actuator becomes stuck or binds. In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure in the actuator’s diaphragm or piston chamber. Explore the various failure modes of valves, from. Pressure Control Valve Failure Modes.

From www.pinterest.com

Control Valve Actuators Different Types and Failure Modes Discussed Control valves, Actuator Pressure Control Valve Failure Modes One of the most common failure modes is when the valve stem or actuator becomes stuck or binds. As you know control valves play. Understand the causes, effects, and importance of quality in pressure systems. Today we will look at. These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. In the event of. Pressure Control Valve Failure Modes.

From www.redriver.team

Common Failure Modes of Valves A Comprehensive Guide Pressure Control Valve Failure Modes Some of the common control valve failure modes are: These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. Today we will look at. In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure in the actuator’s diaphragm or piston chamber. In the. Pressure Control Valve Failure Modes.

From theinstrumentguru.com

Control Valve Problems THE INSTRUMENT GURU Pressure Control Valve Failure Modes Today we will look at. As you know control valves play. Some of the common control valve failure modes are: Understand the causes, effects, and importance of quality in pressure systems. In the event of power or pressure loss, a kimray high pressure control valve actuator will cause the control valve to “fail,” or stop, in one of two positions:. Pressure Control Valve Failure Modes.

From www.vppparegion2.org

Valve Failure Pressure Control Valve Failure Modes Some of the common control valve failure modes are: In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure in the actuator’s diaphragm or piston chamber. In the event of power or pressure loss, a kimray high pressure control valve actuator will cause the control valve to “fail,” or. Pressure Control Valve Failure Modes.

From control.com

Valve Failure Modes Basic Principles of Control Valves and Actuators Textbook Pressure Control Valve Failure Modes Some of the common control valve failure modes are: One of the most common failure modes is when the valve stem or actuator becomes stuck or binds. An important design parameter for control valves is the position to which the valve will fail if power or signal is lost. As you know control valves play. In the event of power. Pressure Control Valve Failure Modes.

From instrumentationtools.com

How to Select Control Valve Failure Mode Instrumentation Tools Pressure Control Valve Failure Modes Some of the common control valve failure modes are: As you know control valves play. Today we will look at. In the event of power or pressure loss, a kimray high pressure control valve actuator will cause the control valve to “fail,” or stop, in one of two positions: In order for a pneumatic or hydraulic valve to fail in. Pressure Control Valve Failure Modes.

From boostrand.com

What if a Control Valve Failed in a Process Plant? Boostrand Pressure Control Valve Failure Modes One of the most common failure modes is when the valve stem or actuator becomes stuck or binds. Understand the causes, effects, and importance of quality in pressure systems. As you know control valves play. In the event of power or pressure loss, a kimray high pressure control valve actuator will cause the control valve to “fail,” or stop, in. Pressure Control Valve Failure Modes.

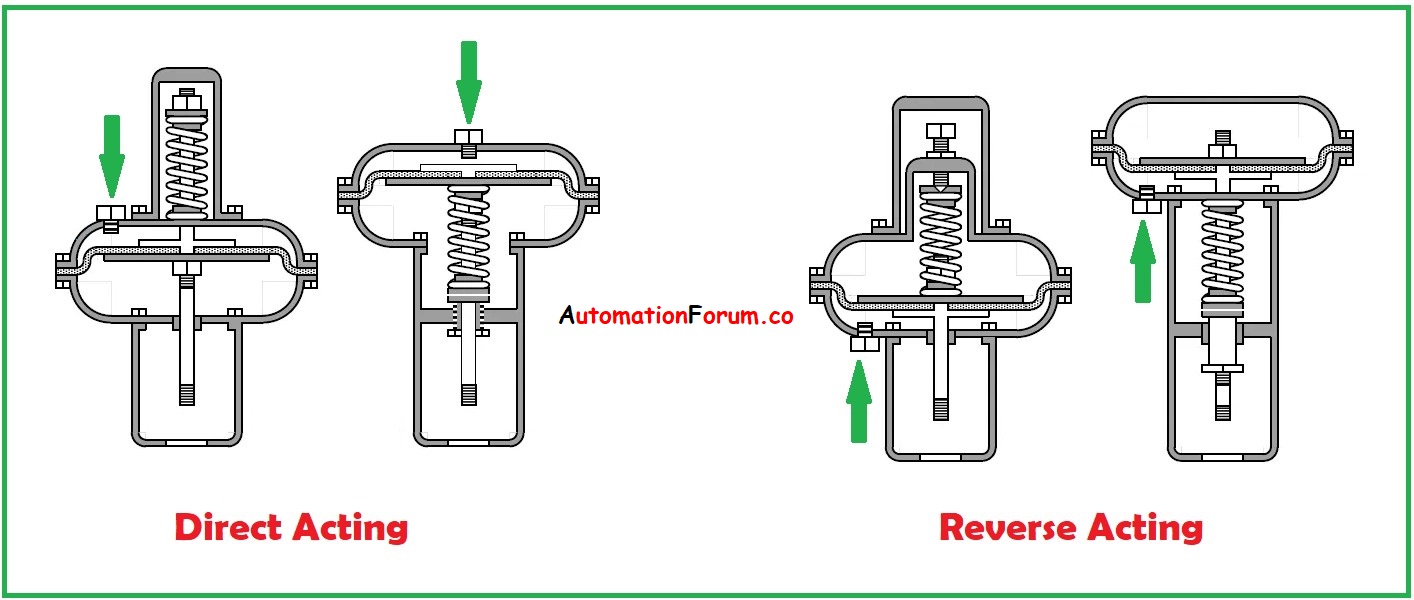

From automationforum.co

Failure modes in Control valve actuators AutomationForum Pressure Control Valve Failure Modes One of the most common failure modes is when the valve stem or actuator becomes stuck or binds. An important design parameter for control valves is the position to which the valve will fail if power or signal is lost. In the event of power or pressure loss, a kimray high pressure control valve actuator will cause the control valve. Pressure Control Valve Failure Modes.

From automationforum.co

Failure modes in Control valve actuators AutomationForum Pressure Control Valve Failure Modes Understand the causes, effects, and importance of quality in pressure systems. Explore the various failure modes of valves, from leakage to design flaws. As you know control valves play. In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure in the actuator’s diaphragm or piston chamber. An important design. Pressure Control Valve Failure Modes.

From catalog.udlvirtual.edu.pe

Pressure Safety Valve Failure Modes Catalog Library Pressure Control Valve Failure Modes An important design parameter for control valves is the position to which the valve will fail if power or signal is lost. Explore the various failure modes of valves, from leakage to design flaws. In the event of power or pressure loss, a kimray high pressure control valve actuator will cause the control valve to “fail,” or stop, in one. Pressure Control Valve Failure Modes.

From inspectapedia.com

How to adjust the water pressure reducing valve, how to find and adjust the water pressure Pressure Control Valve Failure Modes In the event of power or pressure loss, a kimray high pressure control valve actuator will cause the control valve to “fail,” or stop, in one of two positions: Some of the common control valve failure modes are: In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure in. Pressure Control Valve Failure Modes.

From control.com

Common Control Valve Problems Basic Principles of Control Valves and Actuators Textbook Pressure Control Valve Failure Modes In the event of power or pressure loss, a kimray high pressure control valve actuator will cause the control valve to “fail,” or stop, in one of two positions: An important design parameter for control valves is the position to which the valve will fail if power or signal is lost. Understand the causes, effects, and importance of quality in. Pressure Control Valve Failure Modes.

From www.cascadeindustrial.com

3 Signs Of Pressure Relief Valve Failure Cascade Industrial Services Corp Pressure Control Valve Failure Modes In the event of power or pressure loss, a kimray high pressure control valve actuator will cause the control valve to “fail,” or stop, in one of two positions: Explore the various failure modes of valves, from leakage to design flaws. Some of the common control valve failure modes are: As you know control valves play. One of the most. Pressure Control Valve Failure Modes.

From onlyvalves.com

Failure Modes of Pneumatic Actuators Pressure Control Valve Failure Modes As you know control valves play. In the event of power or pressure loss, a kimray high pressure control valve actuator will cause the control valve to “fail,” or stop, in one of two positions: These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. In order for a pneumatic or hydraulic valve to. Pressure Control Valve Failure Modes.

From instrumentationtools.com

How to Troubleshoot Control Valve? Problems and Solutions Pressure Control Valve Failure Modes Today we will look at. As you know control valves play. Understand the causes, effects, and importance of quality in pressure systems. In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure in the actuator’s diaphragm or piston chamber. These problems can include friction sticking, flashing, cavitation, choked flow,. Pressure Control Valve Failure Modes.

From www.youtube.com

Troubleshooting a Pressure Reducing Valve YouTube Pressure Control Valve Failure Modes Today we will look at. Some of the common control valve failure modes are: In the event of power or pressure loss, a kimray high pressure control valve actuator will cause the control valve to “fail,” or stop, in one of two positions: One of the most common failure modes is when the valve stem or actuator becomes stuck or. Pressure Control Valve Failure Modes.

From cncontrolvalve.com

Control Valve Failure Position 101 THINKTANK Pressure Control Valve Failure Modes In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure in the actuator’s diaphragm or piston chamber. One of the most common failure modes is when the valve stem or actuator becomes stuck or binds. Understand the causes, effects, and importance of quality in pressure systems. As you know. Pressure Control Valve Failure Modes.

From www.scribd.com

Diaphragm Valves Typical Failure Modes PDF Valve Corrosion Pressure Control Valve Failure Modes Today we will look at. Explore the various failure modes of valves, from leakage to design flaws. As you know control valves play. In the event of power or pressure loss, a kimray high pressure control valve actuator will cause the control valve to “fail,” or stop, in one of two positions: Understand the causes, effects, and importance of quality. Pressure Control Valve Failure Modes.

From techblog.ctgclean.com

Valves Pressure Reducing Valves CTG Technical Blog Pressure Control Valve Failure Modes As you know control valves play. Today we will look at. An important design parameter for control valves is the position to which the valve will fail if power or signal is lost. In the event of power or pressure loss, a kimray high pressure control valve actuator will cause the control valve to “fail,” or stop, in one of. Pressure Control Valve Failure Modes.

From www.slideserve.com

PPT Introduction to Power Brakes PowerPoint Presentation, free download ID3863806 Pressure Control Valve Failure Modes Understand the causes, effects, and importance of quality in pressure systems. In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure in the actuator’s diaphragm or piston chamber. One of the most common failure modes is when the valve stem or actuator becomes stuck or binds. Some of the. Pressure Control Valve Failure Modes.

From control.com

Common Control Valve Problems Basic Principles of Control Valves and Actuators Automation Pressure Control Valve Failure Modes These problems can include friction sticking, flashing, cavitation, choked flow, acoustic noise, erosion, and chemical corrosion. One of the most common failure modes is when the valve stem or actuator becomes stuck or binds. Explore the various failure modes of valves, from leakage to design flaws. As you know control valves play. Understand the causes, effects, and importance of quality. Pressure Control Valve Failure Modes.