Electrode Coating . This coated electrodes must satisfy the required. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. The basic electrode coating is made up of calcium carbonates and fluorite. Discover the four main types of electrode flux coatings and their impact on welding performance. The coating acts as an arc stabilizer, protecting the electrode from oxidation, enhancing its electrical properties, and providing a slag. From rutile and cellulosic to basic and acid. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. They are ideal for deep penetration and. Some common welding electrode coating types include. Electrode coatings should provide gas shielding for the arc, easy striking and arc stability, a protective slag, good weld shape, and most. The coating provides protection for the molten metal, influences the weld’s characteristics, and stabilizes the arc.

from www.durr.com

The coating provides protection for the molten metal, influences the weld’s characteristics, and stabilizes the arc. From rutile and cellulosic to basic and acid. They are ideal for deep penetration and. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. The coating acts as an arc stabilizer, protecting the electrode from oxidation, enhancing its electrical properties, and providing a slag. Electrode coatings should provide gas shielding for the arc, easy striking and arc stability, a protective slag, good weld shape, and most. Discover the four main types of electrode flux coatings and their impact on welding performance. The basic electrode coating is made up of calcium carbonates and fluorite. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. Some common welding electrode coating types include.

Electrode Coating Dürr

Electrode Coating From rutile and cellulosic to basic and acid. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. They are ideal for deep penetration and. Electrode coatings should provide gas shielding for the arc, easy striking and arc stability, a protective slag, good weld shape, and most. This coated electrodes must satisfy the required. The basic electrode coating is made up of calcium carbonates and fluorite. The coating acts as an arc stabilizer, protecting the electrode from oxidation, enhancing its electrical properties, and providing a slag. Discover the four main types of electrode flux coatings and their impact on welding performance. Some common welding electrode coating types include. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. The coating provides protection for the molten metal, influences the weld’s characteristics, and stabilizes the arc. From rutile and cellulosic to basic and acid.

From www.weldinghandbook.com

Welding Electrodes Coatings and Classifications The Welding Handbook Electrode Coating Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. From rutile and cellulosic to basic and acid. The basic electrode coating is made up of calcium carbonates and fluorite. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things.. Electrode Coating.

From www.electricmotorengineering.com

Energy storage for the electric car. Dry electrode coating technology Electric Motor Engineering Electrode Coating They are ideal for deep penetration and. The coating provides protection for the molten metal, influences the weld’s characteristics, and stabilizes the arc. This coated electrodes must satisfy the required. The coating acts as an arc stabilizer, protecting the electrode from oxidation, enhancing its electrical properties, and providing a slag. Some common welding electrode coating types include. Electrode coatings should. Electrode Coating.

From beginnerweldingguide.com

Why Welding Electrodes are Coated? Beginner Welding Guide Electrode Coating Electrode coatings should provide gas shielding for the arc, easy striking and arc stability, a protective slag, good weld shape, and most. The coating provides protection for the molten metal, influences the weld’s characteristics, and stabilizes the arc. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. This coated. Electrode Coating.

From connect2india.com

Electrode Coating Suppliers Electrode Coating विक्रेता and आपूर्तिकर्ता Suppliers of Electrode Coating They are ideal for deep penetration and. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. Some common welding electrode coating types include. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. The coating acts as an arc. Electrode Coating.

From www.indiamart.com

noble electrode Electrode Coating Flux at best price in Gandhinagar ID 4671407491 Electrode Coating They are ideal for deep penetration and. Some common welding electrode coating types include. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. Electrode coatings should provide gas shielding for the arc, easy striking and arc stability, a protective slag, good weld shape, and most. From rutile and cellulosic. Electrode Coating.

From www.researchgate.net

of steps of electrode surface preparations and composite coatings... Download Scientific Diagram Electrode Coating They are ideal for deep penetration and. The basic electrode coating is made up of calcium carbonates and fluorite. This coated electrodes must satisfy the required. The coating acts as an arc stabilizer, protecting the electrode from oxidation, enhancing its electrical properties, and providing a slag. From rutile and cellulosic to basic and acid. The coating provides protection for the. Electrode Coating.

From www.durr.com

Electrode Coating Dürr Electrode Coating The coating provides protection for the molten metal, influences the weld’s characteristics, and stabilizes the arc. They are ideal for deep penetration and. The basic electrode coating is made up of calcium carbonates and fluorite. The coating acts as an arc stabilizer, protecting the electrode from oxidation, enhancing its electrical properties, and providing a slag. The electrode coating can help. Electrode Coating.

From www.researchgate.net

Schematic diagrams of the electrodes with coating defects. a) Slurry... Download Scientific Electrode Coating Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. The coating provides protection for the molten metal, influences the weld’s characteristics, and stabilizes the arc. This coated electrodes must. Electrode Coating.

From www.chinabatterymachine.com

Automatic Roll To Roll Electrode Coating Machine For Liion Cell Manufacturing Electrode Coating Electrode coatings should provide gas shielding for the arc, easy striking and arc stability, a protective slag, good weld shape, and most. This coated electrodes must satisfy the required. From rutile and cellulosic to basic and acid. The basic electrode coating is made up of calcium carbonates and fluorite. Discover the four main types of electrode flux coatings and their. Electrode Coating.

From www.weldingandndt.com

Welding electrodes Understanding the SMAW electrode symbols Welding and NDT Electrode Coating The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. From rutile and cellulosic to basic and acid. They are ideal for deep penetration and. Some common welding electrode coating. Electrode Coating.

From www.rywal.com.pl

MOST 307 B Coated electrode for welding of highalloyed steels RYWALRHC Electrode Coating The basic electrode coating is made up of calcium carbonates and fluorite. This coated electrodes must satisfy the required. They are ideal for deep penetration and. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. From rutile and cellulosic to basic and acid. Electrode coatings should provide gas shielding. Electrode Coating.

From weldingtrends.com

Why Welding Electrodes Are Coated? Electrode Coating They are ideal for deep penetration and. This coated electrodes must satisfy the required. Discover the four main types of electrode flux coatings and their impact on welding performance. The coating provides protection for the molten metal, influences the weld’s characteristics, and stabilizes the arc. Electrode coatings should provide gas shielding for the arc, easy striking and arc stability, a. Electrode Coating.

From www.global.toshiba

SkinCoated Electrode SCiB™ Rechargeable battery Toshiba Electrode Coating Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. The coating provides protection for the molten metal, influences the weld’s characteristics, and stabilizes the arc. Discover the four main types of electrode flux coatings and their impact on welding performance. Some common welding electrode coating types include. This coated. Electrode Coating.

From www.epnt.co.kr

Electrode Coating Machine Products PNT (People and Technology Inc.) Electrode Coating This coated electrodes must satisfy the required. Discover the four main types of electrode flux coatings and their impact on welding performance. From rutile and cellulosic to basic and acid. Electrode coatings should provide gas shielding for the arc, easy striking and arc stability, a protective slag, good weld shape, and most. Electrode welding, or stick welding, uses electrode rods. Electrode Coating.

From www.durr.com

Electrode Coating Dürr Electrode Coating Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. Some common welding electrode coating types include. From rutile and cellulosic to basic and acid. The basic electrode coating is made up of calcium carbonates and fluorite. The coating provides protection for the molten metal, influences the weld’s characteristics, and. Electrode Coating.

From blog.thepipingmart.com

3 Types of Electrode Coating Electrode Coating The coating provides protection for the molten metal, influences the weld’s characteristics, and stabilizes the arc. Discover the four main types of electrode flux coatings and their impact on welding performance. Some common welding electrode coating types include. This coated electrodes must satisfy the required. The coating acts as an arc stabilizer, protecting the electrode from oxidation, enhancing its electrical. Electrode Coating.

From www.durr.com

Electrode Coating Dürr Electrode Coating Electrode coatings should provide gas shielding for the arc, easy striking and arc stability, a protective slag, good weld shape, and most. They are ideal for deep penetration and. Some common welding electrode coating types include. This coated electrodes must satisfy the required. The coating acts as an arc stabilizer, protecting the electrode from oxidation, enhancing its electrical properties, and. Electrode Coating.

From www.youtube.com

Dry Electrode Coating Technology YouTube Electrode Coating They are ideal for deep penetration and. From rutile and cellulosic to basic and acid. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. This coated electrodes must satisfy. Electrode Coating.

From www.canadianmetalworking.com

Mastering stainless SMAW electrodes Electrode Coating The basic electrode coating is made up of calcium carbonates and fluorite. This coated electrodes must satisfy the required. From rutile and cellulosic to basic and acid. They are ideal for deep penetration and. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. Discover the four main types of. Electrode Coating.

From beginnerweldingguide.com

Why Welding Electrodes are Coated? Beginner Welding Guide Electrode Coating Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. From rutile and cellulosic to basic and acid. Discover the four main types of electrode flux coatings and their impact on welding performance. Electrode coatings should provide gas shielding for the arc, easy striking and arc stability, a protective slag,. Electrode Coating.

From www.theweldingmaster.com

Types of Welding Electrodes Complete Guide Electrode Coating The coating provides protection for the molten metal, influences the weld’s characteristics, and stabilizes the arc. The basic electrode coating is made up of calcium carbonates and fluorite. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. The coating acts as an arc stabilizer, protecting the electrode from oxidation,. Electrode Coating.

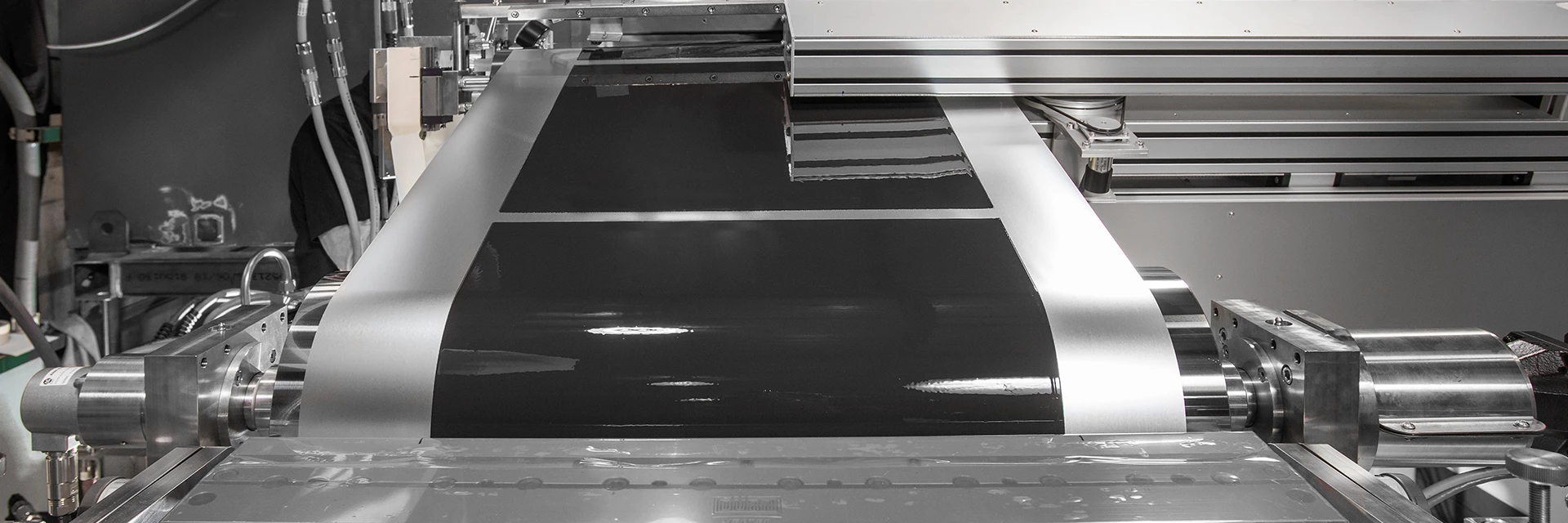

From www.durr.com

Simultaneous twosided electrode coating and drying Dürr Electrode Coating Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. The basic electrode coating is made up of calcium carbonates and fluorite. The coating provides protection for the molten metal, influences the weld’s characteristics, and stabilizes the arc. This coated electrodes must satisfy the required. Electrode coatings should provide gas. Electrode Coating.

From darkfield.com

Electrode Coating, Compression & Drying Dark Field Technologies Electrode Coating Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. From rutile and cellulosic to basic and acid. Electrode coatings should provide gas shielding for the arc, easy striking and arc stability, a protective slag, good weld shape, and most. This coated electrodes must satisfy the required. The coating acts. Electrode Coating.

From www.durr.com

Simultaneous twosided electrode coating and drying Dürr Electrode Coating Discover the four main types of electrode flux coatings and their impact on welding performance. Electrode coatings should provide gas shielding for the arc, easy striking and arc stability, a protective slag, good weld shape, and most. From rutile and cellulosic to basic and acid. The coating provides protection for the molten metal, influences the weld’s characteristics, and stabilizes the. Electrode Coating.

From www.ineos.com

Electrode Coatings & Refurbishment INEOS Electrochemical Solutions Electrode Coating The coating acts as an arc stabilizer, protecting the electrode from oxidation, enhancing its electrical properties, and providing a slag. The basic electrode coating is made up of calcium carbonates and fluorite. Some common welding electrode coating types include. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. From. Electrode Coating.

From weldingzilla.com

Why Welding Electrodes Are Coated With Flux? Electrode Coating From rutile and cellulosic to basic and acid. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. The coating provides protection for the molten metal, influences the weld’s characteristics, and stabilizes the arc. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition. Electrode Coating.

From pubs.acs.org

Soft Printable Electrode Coating for Neural Interfaces ACS Applied Bio Materials Electrode Coating The coating acts as an arc stabilizer, protecting the electrode from oxidation, enhancing its electrical properties, and providing a slag. The coating provides protection for the molten metal, influences the weld’s characteristics, and stabilizes the arc. The basic electrode coating is made up of calcium carbonates and fluorite. Electrode welding, or stick welding, uses electrode rods covered in a flux,. Electrode Coating.

From www.technologynetworks.com

Achieving Coating Uniformity in Battery Electrode Production Technology Networks Electrode Coating The coating acts as an arc stabilizer, protecting the electrode from oxidation, enhancing its electrical properties, and providing a slag. This coated electrodes must satisfy the required. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. The electrode coating can help stabilize the arc, create smooth weld appearance, and. Electrode Coating.

From www.dreamstime.com

Manual Arc Welding with Consumable Electrode with a Coating Stock Image Image of factory Electrode Coating This coated electrodes must satisfy the required. The basic electrode coating is made up of calcium carbonates and fluorite. The coating provides protection for the molten metal, influences the weld’s characteristics, and stabilizes the arc. From rutile and cellulosic to basic and acid. Some common welding electrode coating types include. Electrode coatings should provide gas shielding for the arc, easy. Electrode Coating.

From www.youtube.com

CAN WE SELECT ELECTRODE BY COLOR OF COATING? WHY WE NEED FLUX COATING ? TYPES OF ELECTRODE Electrode Coating This coated electrodes must satisfy the required. From rutile and cellulosic to basic and acid. Electrode coatings should provide gas shielding for the arc, easy striking and arc stability, a protective slag, good weld shape, and most. They are ideal for deep penetration and. The coating acts as an arc stabilizer, protecting the electrode from oxidation, enhancing its electrical properties,. Electrode Coating.

From www.frontiersin.org

Frontiers Organic electrode coatings for nextgeneration neural interfaces Electrode Coating The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. Discover the four main types of electrode flux coatings and their impact on welding performance. They are ideal for deep penetration and. Some common welding electrode coating types include. The basic electrode coating is made up of calcium carbonates and. Electrode Coating.

From www.dreamstime.com

Manual Arc Welding with Consumable Electrode with a Coating Stock Image Image of manufacture Electrode Coating This coated electrodes must satisfy the required. From rutile and cellulosic to basic and acid. The basic electrode coating is made up of calcium carbonates and fluorite. They are ideal for deep penetration and. Electrode coatings should provide gas shielding for the arc, easy striking and arc stability, a protective slag, good weld shape, and most. The coating acts as. Electrode Coating.

From batteriselskab.dk

Uniform electrode coating a visit to Haldor Topsøe A/S Dansk Batteriselskab Electrode Coating The basic electrode coating is made up of calcium carbonates and fluorite. Discover the four main types of electrode flux coatings and their impact on welding performance. Some common welding electrode coating types include. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. From rutile and cellulosic to basic. Electrode Coating.

From weldguru.com

Welding Electrode Chart and Selection Weld Guru Electrode Coating Electrode coatings should provide gas shielding for the arc, easy striking and arc stability, a protective slag, good weld shape, and most. From rutile and cellulosic to basic and acid. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. Discover the four main types of electrode flux coatings and. Electrode Coating.

From weldguru.com

Welding Electrode Chart and Selection Weld Guru Electrode Coating Electrode coatings should provide gas shielding for the arc, easy striking and arc stability, a protective slag, good weld shape, and most. Discover the four main types of electrode flux coatings and their impact on welding performance. The basic electrode coating is made up of calcium carbonates and fluorite. The coating provides protection for the molten metal, influences the weld’s. Electrode Coating.