Fail Lock For Control Valve . A fail safety status is how the valve should operate when there is a loss of power or signal. “fail locked” means when the control valve loses power, the valve stem stays in the last position and it must be secured in its. Failed locked / drift open or close will work based on fisher lock up relay, which is a pneumatic relay by function. This is frequently called out as fail last position, fail in place, or fail freeze. There are many industrial control valve applications that require the valve to stay at the last set point as a failure state. In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure in the actuator’s diaphragm or piston chamber in the event of supply pressure loss. These terms are interchangeable, so we will use fail freeze for the rest of this article.

from supriyaprototech.com

These terms are interchangeable, so we will use fail freeze for the rest of this article. In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure in the actuator’s diaphragm or piston chamber in the event of supply pressure loss. “fail locked” means when the control valve loses power, the valve stem stays in the last position and it must be secured in its. There are many industrial control valve applications that require the valve to stay at the last set point as a failure state. This is frequently called out as fail last position, fail in place, or fail freeze. A fail safety status is how the valve should operate when there is a loss of power or signal. Failed locked / drift open or close will work based on fisher lock up relay, which is a pneumatic relay by function.

Supriya Prototech

Fail Lock For Control Valve This is frequently called out as fail last position, fail in place, or fail freeze. Failed locked / drift open or close will work based on fisher lock up relay, which is a pneumatic relay by function. This is frequently called out as fail last position, fail in place, or fail freeze. A fail safety status is how the valve should operate when there is a loss of power or signal. “fail locked” means when the control valve loses power, the valve stem stays in the last position and it must be secured in its. There are many industrial control valve applications that require the valve to stay at the last set point as a failure state. These terms are interchangeable, so we will use fail freeze for the rest of this article. In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure in the actuator’s diaphragm or piston chamber in the event of supply pressure loss.

From www.youtube.com

What is Fail safe modes in Actuator? Learn Instrumentation Engineering YouTube Fail Lock For Control Valve “fail locked” means when the control valve loses power, the valve stem stays in the last position and it must be secured in its. These terms are interchangeable, so we will use fail freeze for the rest of this article. Failed locked / drift open or close will work based on fisher lock up relay, which is a pneumatic relay. Fail Lock For Control Valve.

From boostrand.com

What if a Control Valve Failed in a Process Plant? Boostrand Fail Lock For Control Valve There are many industrial control valve applications that require the valve to stay at the last set point as a failure state. A fail safety status is how the valve should operate when there is a loss of power or signal. These terms are interchangeable, so we will use fail freeze for the rest of this article. Failed locked /. Fail Lock For Control Valve.

From instrumentationtools.com

How to Select Control Valve Failure Mode Instrumentation Tools Fail Lock For Control Valve Failed locked / drift open or close will work based on fisher lock up relay, which is a pneumatic relay by function. This is frequently called out as fail last position, fail in place, or fail freeze. “fail locked” means when the control valve loses power, the valve stem stays in the last position and it must be secured in. Fail Lock For Control Valve.

From supriyaprototech.com

Supriya Prototech Fail Lock For Control Valve There are many industrial control valve applications that require the valve to stay at the last set point as a failure state. This is frequently called out as fail last position, fail in place, or fail freeze. A fail safety status is how the valve should operate when there is a loss of power or signal. Failed locked / drift. Fail Lock For Control Valve.

From www.grainger.com

Fail Safe Valve, Locking Valve Kit 28VZ97OFSV004 Grainger Fail Lock For Control Valve There are many industrial control valve applications that require the valve to stay at the last set point as a failure state. This is frequently called out as fail last position, fail in place, or fail freeze. Failed locked / drift open or close will work based on fisher lock up relay, which is a pneumatic relay by function. A. Fail Lock For Control Valve.

From www.youtube.com

FailSafe System for Control Valves Series FCS YouTube Fail Lock For Control Valve “fail locked” means when the control valve loses power, the valve stem stays in the last position and it must be secured in its. A fail safety status is how the valve should operate when there is a loss of power or signal. In order for a pneumatic or hydraulic valve to fail in the locked state, an external device. Fail Lock For Control Valve.

From www.youtube.com

fail to open, fail to close & fail to lock control valve YouTube Fail Lock For Control Valve These terms are interchangeable, so we will use fail freeze for the rest of this article. In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure in the actuator’s diaphragm or piston chamber in the event of supply pressure loss. This is frequently called out as fail last position,. Fail Lock For Control Valve.

From instrumentationtools.com

What is a FailClose Valve? Advantages and Disadvantages Fail Lock For Control Valve Failed locked / drift open or close will work based on fisher lock up relay, which is a pneumatic relay by function. In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure in the actuator’s diaphragm or piston chamber in the event of supply pressure loss. This is frequently. Fail Lock For Control Valve.

From www.scribd.com

Fail To Open and Fail To Close Control Valve PDF Fail Lock For Control Valve “fail locked” means when the control valve loses power, the valve stem stays in the last position and it must be secured in its. This is frequently called out as fail last position, fail in place, or fail freeze. In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure. Fail Lock For Control Valve.

From www.hafner-pneumatik.com

Failsafe position for double acting actuators Fail Lock For Control Valve There are many industrial control valve applications that require the valve to stay at the last set point as a failure state. This is frequently called out as fail last position, fail in place, or fail freeze. “fail locked” means when the control valve loses power, the valve stem stays in the last position and it must be secured in. Fail Lock For Control Valve.

From www.youtube.com

Types of Control Valve Air Fail to Open & Air Fail to Close Control Valve Pneumatic Valve Fail Lock For Control Valve A fail safety status is how the valve should operate when there is a loss of power or signal. There are many industrial control valve applications that require the valve to stay at the last set point as a failure state. This is frequently called out as fail last position, fail in place, or fail freeze. In order for a. Fail Lock For Control Valve.

From www.youtube.com

Control Valve Failure Mode (Fail Lock Fail last DC Fail Last DO FC FO Modes included Fail Lock For Control Valve “fail locked” means when the control valve loses power, the valve stem stays in the last position and it must be secured in its. A fail safety status is how the valve should operate when there is a loss of power or signal. This is frequently called out as fail last position, fail in place, or fail freeze. In order. Fail Lock For Control Valve.

From automationforum.co

Fail Open Vs Fail Close valves Fail Lock For Control Valve There are many industrial control valve applications that require the valve to stay at the last set point as a failure state. A fail safety status is how the valve should operate when there is a loss of power or signal. This is frequently called out as fail last position, fail in place, or fail freeze. “fail locked” means when. Fail Lock For Control Valve.

From automationforum.co

Control valve Air Lock Instrumentation and Control Engineering Fail Lock For Control Valve These terms are interchangeable, so we will use fail freeze for the rest of this article. A fail safety status is how the valve should operate when there is a loss of power or signal. In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure in the actuator’s diaphragm. Fail Lock For Control Valve.

From automationforum.co

Failure modes in Control valve actuators AutomationForum Fail Lock For Control Valve There are many industrial control valve applications that require the valve to stay at the last set point as a failure state. In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure in the actuator’s diaphragm or piston chamber in the event of supply pressure loss. “fail locked” means. Fail Lock For Control Valve.

From www.youtube.com

FAIL SAFE POSITION IN ENGLISH FAIL TO OPEN FAIL TO CLOSE CONTROL VALVE FAIL SAFE POSITION Fail Lock For Control Valve These terms are interchangeable, so we will use fail freeze for the rest of this article. This is frequently called out as fail last position, fail in place, or fail freeze. A fail safety status is how the valve should operate when there is a loss of power or signal. “fail locked” means when the control valve loses power, the. Fail Lock For Control Valve.

From en.ppt-online.org

Control valves online presentation Fail Lock For Control Valve These terms are interchangeable, so we will use fail freeze for the rest of this article. This is frequently called out as fail last position, fail in place, or fail freeze. Failed locked / drift open or close will work based on fisher lock up relay, which is a pneumatic relay by function. “fail locked” means when the control valve. Fail Lock For Control Valve.

From www.youtube.com

Control Valve FailSafe & Automation with Pneumatic Manifold CPAC Module® YouTube Fail Lock For Control Valve This is frequently called out as fail last position, fail in place, or fail freeze. These terms are interchangeable, so we will use fail freeze for the rest of this article. Failed locked / drift open or close will work based on fisher lock up relay, which is a pneumatic relay by function. In order for a pneumatic or hydraulic. Fail Lock For Control Valve.

From cncontrolvalve.com

Control Valve Failure Position 101 THINKTANK Fail Lock For Control Valve A fail safety status is how the valve should operate when there is a loss of power or signal. This is frequently called out as fail last position, fail in place, or fail freeze. Failed locked / drift open or close will work based on fisher lock up relay, which is a pneumatic relay by function. These terms are interchangeable,. Fail Lock For Control Valve.

From kimray.com

Should My Valve Fail Open or Closed? Kimray Fail Lock For Control Valve There are many industrial control valve applications that require the valve to stay at the last set point as a failure state. A fail safety status is how the valve should operate when there is a loss of power or signal. These terms are interchangeable, so we will use fail freeze for the rest of this article. This is frequently. Fail Lock For Control Valve.

From control.com

Valve Failure Modes Basic Principles of Control Valves and Actuators Textbook Fail Lock For Control Valve This is frequently called out as fail last position, fail in place, or fail freeze. In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure in the actuator’s diaphragm or piston chamber in the event of supply pressure loss. There are many industrial control valve applications that require the. Fail Lock For Control Valve.

From instrumentationtools.com

Control Valve Air Lock Relay Working Principle Instrumentation Tools Fail Lock For Control Valve In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure in the actuator’s diaphragm or piston chamber in the event of supply pressure loss. These terms are interchangeable, so we will use fail freeze for the rest of this article. There are many industrial control valve applications that require. Fail Lock For Control Valve.

From automationforum.co

Fail Open Vs Fail Close valves Fail Lock For Control Valve “fail locked” means when the control valve loses power, the valve stem stays in the last position and it must be secured in its. This is frequently called out as fail last position, fail in place, or fail freeze. There are many industrial control valve applications that require the valve to stay at the last set point as a failure. Fail Lock For Control Valve.

From www.vppparegion2.org

Valve Failure Fail Lock For Control Valve Failed locked / drift open or close will work based on fisher lock up relay, which is a pneumatic relay by function. In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure in the actuator’s diaphragm or piston chamber in the event of supply pressure loss. A fail safety. Fail Lock For Control Valve.

From www.youtube.com

What Is Fail Open Valve And Fail Close Valve ? Why we need it ? YouTube Fail Lock For Control Valve “fail locked” means when the control valve loses power, the valve stem stays in the last position and it must be secured in its. Failed locked / drift open or close will work based on fisher lock up relay, which is a pneumatic relay by function. There are many industrial control valve applications that require the valve to stay at. Fail Lock For Control Valve.

From www.slideserve.com

PPT Control Valves PowerPoint Presentation, free download ID832947 Fail Lock For Control Valve These terms are interchangeable, so we will use fail freeze for the rest of this article. In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure in the actuator’s diaphragm or piston chamber in the event of supply pressure loss. “fail locked” means when the control valve loses power,. Fail Lock For Control Valve.

From www.realpars.com

What is a Control Valve? RealPars Fail Lock For Control Valve “fail locked” means when the control valve loses power, the valve stem stays in the last position and it must be secured in its. This is frequently called out as fail last position, fail in place, or fail freeze. In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure. Fail Lock For Control Valve.

From vacaccessories.com

Tech Tip Fail Last, Fail In Place, Fail Freeze VAC Fail Lock For Control Valve Failed locked / drift open or close will work based on fisher lock up relay, which is a pneumatic relay by function. “fail locked” means when the control valve loses power, the valve stem stays in the last position and it must be secured in its. A fail safety status is how the valve should operate when there is a. Fail Lock For Control Valve.

From www.specsvalve.com

What Is FC FO and FL Fail Lock For Control Valve There are many industrial control valve applications that require the valve to stay at the last set point as a failure state. In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure in the actuator’s diaphragm or piston chamber in the event of supply pressure loss. This is frequently. Fail Lock For Control Valve.

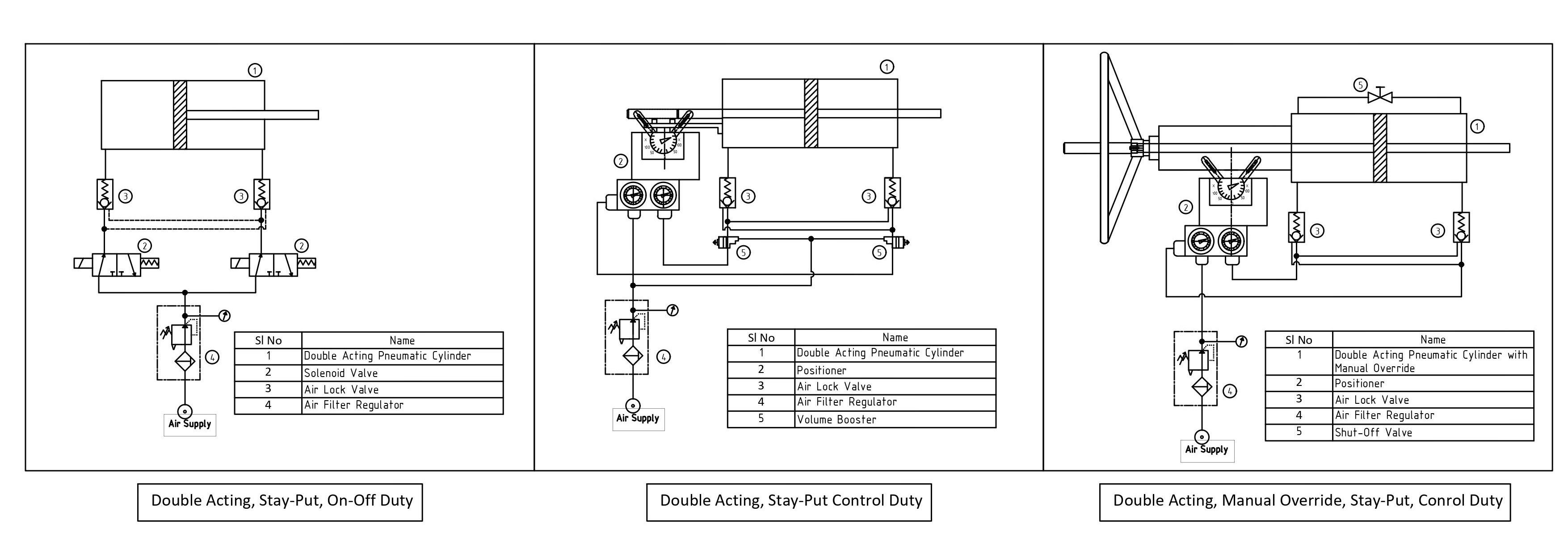

From instrumentationandcontroltoday.blogspot.com

Instrumentation Today CONTROL VALVE PNEUMATIC SKETCH Fail Lock For Control Valve These terms are interchangeable, so we will use fail freeze for the rest of this article. Failed locked / drift open or close will work based on fisher lock up relay, which is a pneumatic relay by function. This is frequently called out as fail last position, fail in place, or fail freeze. “fail locked” means when the control valve. Fail Lock For Control Valve.

From www.youtube.com

Process Instrumentation Control Valves & ON/OFF Valves (part1) Tips And Tricks YouTube Fail Lock For Control Valve Failed locked / drift open or close will work based on fisher lock up relay, which is a pneumatic relay by function. “fail locked” means when the control valve loses power, the valve stem stays in the last position and it must be secured in its. There are many industrial control valve applications that require the valve to stay at. Fail Lock For Control Valve.

From cncontrolvalve.com

Control Valve Failure Modes THINKTANK Fail Lock For Control Valve In order for a pneumatic or hydraulic valve to fail in the locked state, an external device must trap fluid pressure in the actuator’s diaphragm or piston chamber in the event of supply pressure loss. Failed locked / drift open or close will work based on fisher lock up relay, which is a pneumatic relay by function. “fail locked” means. Fail Lock For Control Valve.

From supriyaprototech.com

Supriya Prototech Fail Lock For Control Valve This is frequently called out as fail last position, fail in place, or fail freeze. These terms are interchangeable, so we will use fail freeze for the rest of this article. Failed locked / drift open or close will work based on fisher lock up relay, which is a pneumatic relay by function. There are many industrial control valve applications. Fail Lock For Control Valve.

From ppt-online.org

Control valves презентация онлайн Fail Lock For Control Valve Failed locked / drift open or close will work based on fisher lock up relay, which is a pneumatic relay by function. A fail safety status is how the valve should operate when there is a loss of power or signal. “fail locked” means when the control valve loses power, the valve stem stays in the last position and it. Fail Lock For Control Valve.

From mart.ecer.com

Intelligent Valve Positioner Explosion Proof Smart Valve Positioner Single Acting Fail Lock Fail Lock For Control Valve This is frequently called out as fail last position, fail in place, or fail freeze. A fail safety status is how the valve should operate when there is a loss of power or signal. These terms are interchangeable, so we will use fail freeze for the rest of this article. Failed locked / drift open or close will work based. Fail Lock For Control Valve.