Welding Wire Melting Point . Er4043 has a lower melting point and higher fluidity compared to er5356. another key distinction between these two types of welding wire is their melting points. From silicon to vanadium, each element plays a unique role in the welding. Carbon steel has a much higher melting point than mild steel; This makes it ideal for welding thin metal. in this welding process, more popularly known as mig, a gas tank (typically co2 or argon) provides the shielding while. learn how the melting point of a material influences your welding process, from controlling heat and thermal expansion to understanding molecular changes. mild steel welding wire has a higher melting point than other welding wires so that it can withstand higher temperatures while welding. how do the various metal elements in welding wire impact the final weld quality? get to grips with the influential factors of welding wire melting to refine your welding skills and output quality.

from www.aliexpress.com

Er4043 has a lower melting point and higher fluidity compared to er5356. Carbon steel has a much higher melting point than mild steel; mild steel welding wire has a higher melting point than other welding wires so that it can withstand higher temperatures while welding. From silicon to vanadium, each element plays a unique role in the welding. another key distinction between these two types of welding wire is their melting points. learn how the melting point of a material influences your welding process, from controlling heat and thermal expansion to understanding molecular changes. get to grips with the influential factors of welding wire melting to refine your welding skills and output quality. This makes it ideal for welding thin metal. in this welding process, more popularly known as mig, a gas tank (typically co2 or argon) provides the shielding while. how do the various metal elements in welding wire impact the final weld quality?

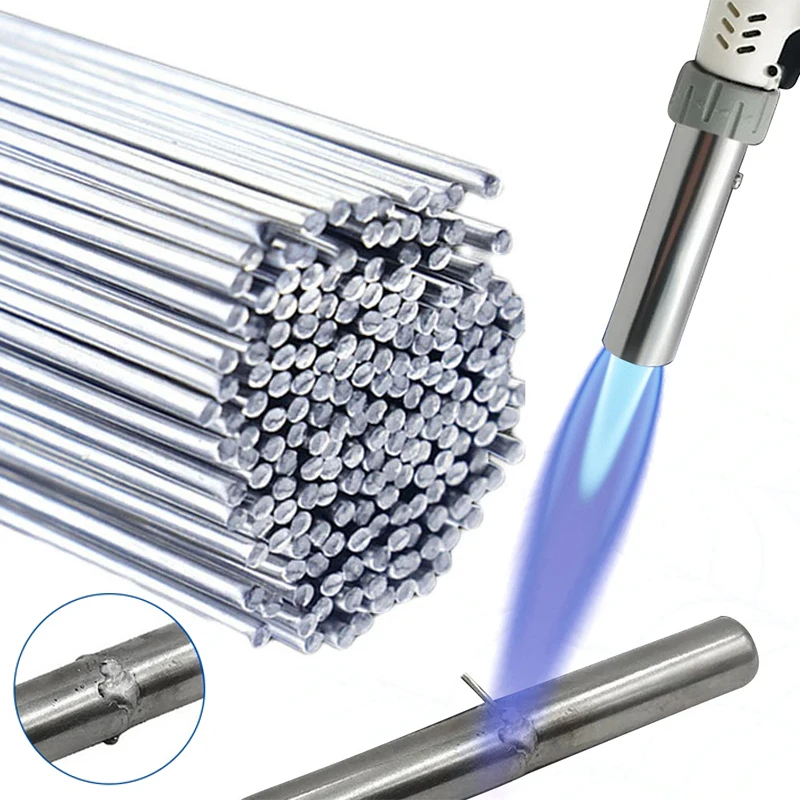

5/10/20Pcs Low Temperature Easy Melt Aluminum Universal Silver Welding

Welding Wire Melting Point From silicon to vanadium, each element plays a unique role in the welding. Carbon steel has a much higher melting point than mild steel; Er4043 has a lower melting point and higher fluidity compared to er5356. how do the various metal elements in welding wire impact the final weld quality? This makes it ideal for welding thin metal. From silicon to vanadium, each element plays a unique role in the welding. mild steel welding wire has a higher melting point than other welding wires so that it can withstand higher temperatures while welding. learn how the melting point of a material influences your welding process, from controlling heat and thermal expansion to understanding molecular changes. another key distinction between these two types of welding wire is their melting points. in this welding process, more popularly known as mig, a gas tank (typically co2 or argon) provides the shielding while. get to grips with the influential factors of welding wire melting to refine your welding skills and output quality.

From www.aliexpress.com

Solder Low Melting Point Welding Repair Tool Welding Wire Welding Welding Wire Melting Point get to grips with the influential factors of welding wire melting to refine your welding skills and output quality. another key distinction between these two types of welding wire is their melting points. how do the various metal elements in welding wire impact the final weld quality? learn how the melting point of a material influences. Welding Wire Melting Point.

From xinqichain.en.made-in-china.com

Rosin Core LeadFree Melting Point Solder Wire Welding Flux China Welding Wire Melting Point Er4043 has a lower melting point and higher fluidity compared to er5356. From silicon to vanadium, each element plays a unique role in the welding. mild steel welding wire has a higher melting point than other welding wires so that it can withstand higher temperatures while welding. how do the various metal elements in welding wire impact the. Welding Wire Melting Point.

From alexnld.com

MECHANIC HXT100 0.6mm Low Melting Point Welding Tin Wire Welding Wire Melting Point mild steel welding wire has a higher melting point than other welding wires so that it can withstand higher temperatures while welding. Carbon steel has a much higher melting point than mild steel; This makes it ideal for welding thin metal. another key distinction between these two types of welding wire is their melting points. learn how. Welding Wire Melting Point.

From www.amazon.com

20pcs Metal Universal Welding Wire 1.6mma, Flux Core Welding Wire Welding Wire Melting Point how do the various metal elements in welding wire impact the final weld quality? Carbon steel has a much higher melting point than mild steel; From silicon to vanadium, each element plays a unique role in the welding. This makes it ideal for welding thin metal. mild steel welding wire has a higher melting point than other welding. Welding Wire Melting Point.

From www.aliexpress.com

YIHUA Wire low melting point environmentally friendly solder solder Welding Wire Melting Point This makes it ideal for welding thin metal. in this welding process, more popularly known as mig, a gas tank (typically co2 or argon) provides the shielding while. From silicon to vanadium, each element plays a unique role in the welding. Carbon steel has a much higher melting point than mild steel; Er4043 has a lower melting point and. Welding Wire Melting Point.

From www.aliexpress.com

63/37 B 1 350g Low Melting Point 1.5mm Tin Fine Wire Core Rosin Solder Welding Wire Melting Point This makes it ideal for welding thin metal. how do the various metal elements in welding wire impact the final weld quality? From silicon to vanadium, each element plays a unique role in the welding. learn how the melting point of a material influences your welding process, from controlling heat and thermal expansion to understanding molecular changes. . Welding Wire Melting Point.

From www.aliexpress.com

Jelbo 0.8mm 102g Lead Welding Wire Rosin Type Low Melting Point Solder Welding Wire Melting Point From silicon to vanadium, each element plays a unique role in the welding. learn how the melting point of a material influences your welding process, from controlling heat and thermal expansion to understanding molecular changes. in this welding process, more popularly known as mig, a gas tank (typically co2 or argon) provides the shielding while. get to. Welding Wire Melting Point.

From www.aliexpress.com

Low Melting Point 60/40 B 1 500g 0.5mm No clean Rosin Core Solder Wire Welding Wire Melting Point how do the various metal elements in welding wire impact the final weld quality? another key distinction between these two types of welding wire is their melting points. From silicon to vanadium, each element plays a unique role in the welding. Er4043 has a lower melting point and higher fluidity compared to er5356. mild steel welding wire. Welding Wire Melting Point.

From www.tradeindia.com

Silver 2750a C Melting Point Nickel Plated Stainless Steel Mig Welding Welding Wire Melting Point how do the various metal elements in welding wire impact the final weld quality? in this welding process, more popularly known as mig, a gas tank (typically co2 or argon) provides the shielding while. From silicon to vanadium, each element plays a unique role in the welding. learn how the melting point of a material influences your. Welding Wire Melting Point.

From www.aliexpress.com

Kaisi 0.3mm 0.4mm 0.5mm 0.6mm Low Melting Point Solder Wire Repair Welding Wire Melting Point From silicon to vanadium, each element plays a unique role in the welding. how do the various metal elements in welding wire impact the final weld quality? in this welding process, more popularly known as mig, a gas tank (typically co2 or argon) provides the shielding while. Carbon steel has a much higher melting point than mild steel;. Welding Wire Melting Point.

From bd5909067e654342.en.made-in-china.com

Welding Wire 70s6 1.0mm 1.2mm Electrical Soldering Wire Low Melting Welding Wire Melting Point learn how the melting point of a material influences your welding process, from controlling heat and thermal expansion to understanding molecular changes. how do the various metal elements in welding wire impact the final weld quality? From silicon to vanadium, each element plays a unique role in the welding. another key distinction between these two types of. Welding Wire Melting Point.

From www.aliexpress.com

Free clean rosin core solder wire 0.8mm 500G 63/37 low melting point Welding Wire Melting Point in this welding process, more popularly known as mig, a gas tank (typically co2 or argon) provides the shielding while. Er4043 has a lower melting point and higher fluidity compared to er5356. This makes it ideal for welding thin metal. Carbon steel has a much higher melting point than mild steel; learn how the melting point of a. Welding Wire Melting Point.

From www.aliexpress.com

Free shipping!! Low melting point Leaded Soldering Wire 0.3mm 100g Welding Wire Melting Point Carbon steel has a much higher melting point than mild steel; mild steel welding wire has a higher melting point than other welding wires so that it can withstand higher temperatures while welding. in this welding process, more popularly known as mig, a gas tank (typically co2 or argon) provides the shielding while. From silicon to vanadium, each. Welding Wire Melting Point.

From www.aliexpress.com

60/40 Low Melting Point 100g 1.5mm Tin Fine Wire Core 2 Flux Welding Welding Wire Melting Point how do the various metal elements in welding wire impact the final weld quality? This makes it ideal for welding thin metal. get to grips with the influential factors of welding wire melting to refine your welding skills and output quality. mild steel welding wire has a higher melting point than other welding wires so that it. Welding Wire Melting Point.

From www.aliexpress.com

Solder Wire 1.0mm Welding Wire Free Clean Rosin Core Low Welding Wire Melting Point Er4043 has a lower melting point and higher fluidity compared to er5356. get to grips with the influential factors of welding wire melting to refine your welding skills and output quality. This makes it ideal for welding thin metal. From silicon to vanadium, each element plays a unique role in the welding. learn how the melting point of. Welding Wire Melting Point.

From www.aliexpress.com

Free Shipping 0.8mm Lead free low melting point Solder wire Electronic Welding Wire Melting Point learn how the melting point of a material influences your welding process, from controlling heat and thermal expansion to understanding molecular changes. From silicon to vanadium, each element plays a unique role in the welding. get to grips with the influential factors of welding wire melting to refine your welding skills and output quality. Carbon steel has a. Welding Wire Melting Point.

From www.aliexpress.com

5/10/20Pcs Low Temperature Easy Melt Aluminum Universal Silver Welding Welding Wire Melting Point mild steel welding wire has a higher melting point than other welding wires so that it can withstand higher temperatures while welding. get to grips with the influential factors of welding wire melting to refine your welding skills and output quality. Carbon steel has a much higher melting point than mild steel; Er4043 has a lower melting point. Welding Wire Melting Point.

From www.aliexpress.com

high quality solder wire 0.8mm 50g 255C melting point Tin Lead Melt Welding Wire Melting Point how do the various metal elements in welding wire impact the final weld quality? learn how the melting point of a material influences your welding process, from controlling heat and thermal expansion to understanding molecular changes. another key distinction between these two types of welding wire is their melting points. Carbon steel has a much higher melting. Welding Wire Melting Point.

From www.wasatchsteel.com

Welding, Brazing and Common Metal Melting Points Wasatch Steel Welding Wire Melting Point Er4043 has a lower melting point and higher fluidity compared to er5356. This makes it ideal for welding thin metal. how do the various metal elements in welding wire impact the final weld quality? another key distinction between these two types of welding wire is their melting points. mild steel welding wire has a higher melting point. Welding Wire Melting Point.

From workshopinsider.com

Welding Symbols Guide to Reading Weld Symbols Welding Wire Melting Point another key distinction between these two types of welding wire is their melting points. learn how the melting point of a material influences your welding process, from controlling heat and thermal expansion to understanding molecular changes. Carbon steel has a much higher melting point than mild steel; This makes it ideal for welding thin metal. get to. Welding Wire Melting Point.

From www.desertcart.in

Buy HIMNA PETTR Aluminum Welding Cored Wire, Welding Electrode Low Welding Wire Melting Point Carbon steel has a much higher melting point than mild steel; From silicon to vanadium, each element plays a unique role in the welding. mild steel welding wire has a higher melting point than other welding wires so that it can withstand higher temperatures while welding. This makes it ideal for welding thin metal. Er4043 has a lower melting. Welding Wire Melting Point.

From www.aliexpress.com

Jelbo 0.8mm 102g Lead Welding Wire Rosin Type Low Melting Point Solder Welding Wire Melting Point mild steel welding wire has a higher melting point than other welding wires so that it can withstand higher temperatures while welding. From silicon to vanadium, each element plays a unique role in the welding. Carbon steel has a much higher melting point than mild steel; in this welding process, more popularly known as mig, a gas tank. Welding Wire Melting Point.

From www.tradeindia.com

Mild Steel Mig Welding Wire, 1085 Degree C Melting Point And Golden Welding Wire Melting Point Er4043 has a lower melting point and higher fluidity compared to er5356. another key distinction between these two types of welding wire is their melting points. get to grips with the influential factors of welding wire melting to refine your welding skills and output quality. how do the various metal elements in welding wire impact the final. Welding Wire Melting Point.

From www.amazon.ca

MCOLT Welding Accessories Low Melt Solder Spot Welding Wires Low Welding Wire Melting Point get to grips with the influential factors of welding wire melting to refine your welding skills and output quality. Carbon steel has a much higher melting point than mild steel; in this welding process, more popularly known as mig, a gas tank (typically co2 or argon) provides the shielding while. mild steel welding wire has a higher. Welding Wire Melting Point.

From hzweldingmaterial.en.made-in-china.com

Low Melting Point Tin Lead Free Welding Wires Solder Alloys China Tin Welding Wire Melting Point Carbon steel has a much higher melting point than mild steel; get to grips with the influential factors of welding wire melting to refine your welding skills and output quality. learn how the melting point of a material influences your welding process, from controlling heat and thermal expansion to understanding molecular changes. in this welding process, more. Welding Wire Melting Point.

From www.bossgoo.com

Melting Point Soldering/welding Wire, High Quality Melting Point Welding Wire Melting Point This makes it ideal for welding thin metal. Er4043 has a lower melting point and higher fluidity compared to er5356. Carbon steel has a much higher melting point than mild steel; mild steel welding wire has a higher melting point than other welding wires so that it can withstand higher temperatures while welding. From silicon to vanadium, each element. Welding Wire Melting Point.

From www.alibaba.com

Solid Core Coating Flux Lead Welding Rod 400 Melting Point Solder With Welding Wire Melting Point get to grips with the influential factors of welding wire melting to refine your welding skills and output quality. learn how the melting point of a material influences your welding process, from controlling heat and thermal expansion to understanding molecular changes. Carbon steel has a much higher melting point than mild steel; From silicon to vanadium, each element. Welding Wire Melting Point.

From www.aliexpress.com

0.8mm 500g lead free tin solder wire low melting point /soldering wire Welding Wire Melting Point Er4043 has a lower melting point and higher fluidity compared to er5356. mild steel welding wire has a higher melting point than other welding wires so that it can withstand higher temperatures while welding. how do the various metal elements in welding wire impact the final weld quality? learn how the melting point of a material influences. Welding Wire Melting Point.

From weldguru.com

4 Main Types of Welding Processes (with diagrams) Welding Wire Melting Point Er4043 has a lower melting point and higher fluidity compared to er5356. Carbon steel has a much higher melting point than mild steel; From silicon to vanadium, each element plays a unique role in the welding. in this welding process, more popularly known as mig, a gas tank (typically co2 or argon) provides the shielding while. This makes it. Welding Wire Melting Point.

From www.aliexpress.com

MECHANIC Solder Wire 0.4mm 55g Low Melting Point Soldering Tin Welding Welding Wire Melting Point Carbon steel has a much higher melting point than mild steel; learn how the melting point of a material influences your welding process, from controlling heat and thermal expansion to understanding molecular changes. how do the various metal elements in welding wire impact the final weld quality? This makes it ideal for welding thin metal. in this. Welding Wire Melting Point.

From www.aliexpress.com

0.8mm/500g Solder Wire Low Melting Point Flux 2 Tin Water soluble Tin Welding Wire Melting Point in this welding process, more popularly known as mig, a gas tank (typically co2 or argon) provides the shielding while. learn how the melting point of a material influences your welding process, from controlling heat and thermal expansion to understanding molecular changes. get to grips with the influential factors of welding wire melting to refine your welding. Welding Wire Melting Point.

From www.aliexpress.com

Original MECHANIC Soldering Wire 0.6mm 55g Sn63 Pb37 Low Melting Welding Wire Melting Point learn how the melting point of a material influences your welding process, from controlling heat and thermal expansion to understanding molecular changes. another key distinction between these two types of welding wire is their melting points. This makes it ideal for welding thin metal. Er4043 has a lower melting point and higher fluidity compared to er5356. Carbon steel. Welding Wire Melting Point.

From www.alibaba.com

Sn42bi58 Lead Free Tin Bismuth Solder Wire Low Temperature With 2.0 Welding Wire Melting Point Carbon steel has a much higher melting point than mild steel; another key distinction between these two types of welding wire is their melting points. learn how the melting point of a material influences your welding process, from controlling heat and thermal expansion to understanding molecular changes. in this welding process, more popularly known as mig, a. Welding Wire Melting Point.

From www.aliexpress.com

0.8 / 1.0 / 1.2 / 1.8 MM Professional Low Melting Point Solder Wire Welding Wire Melting Point learn how the melting point of a material influences your welding process, from controlling heat and thermal expansion to understanding molecular changes. mild steel welding wire has a higher melting point than other welding wires so that it can withstand higher temperatures while welding. another key distinction between these two types of welding wire is their melting. Welding Wire Melting Point.

From www.aliexpress.com

Leaded Welding Wire 100g 0.3mm BEST Soldering Tin with Low Melting Welding Wire Melting Point get to grips with the influential factors of welding wire melting to refine your welding skills and output quality. This makes it ideal for welding thin metal. in this welding process, more popularly known as mig, a gas tank (typically co2 or argon) provides the shielding while. Carbon steel has a much higher melting point than mild steel;. Welding Wire Melting Point.