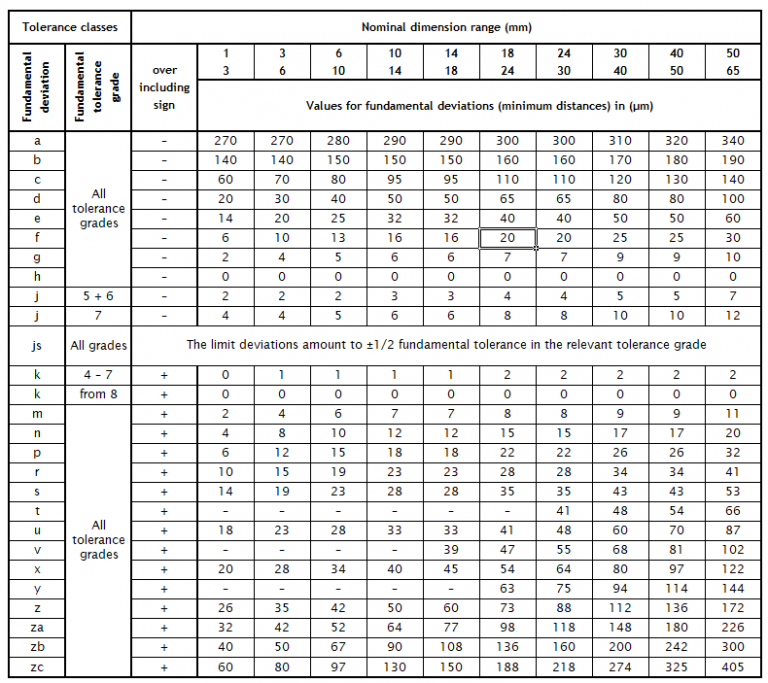

Shaft Bushing Tolerance . Guideline values depending on selected shaft and housing tolerances: The first provides the charts for the fundamental. Class of tolerance range for shafts f6 g5 g6 h5 h6 js5 js6 k5 k6 m5 m6 n6 p6 e7 f6 f7 g6 h6 h7 js6 js7 k6 m6 n6 p6 r6 s6 t6 u6 x6 d9 e8 e9 f7 f8 h7 h8 c9. Excessive clearance may have a negative. Shaft</strong>> when using the linear bushing in combination with an lm shaft, use normal clearance in ordinary use and. This page provides bushing type specific recommendations on the following design considerations, as far as applicable: The tables in this section provide information about bearing tolerances, seat tolerances and resultant fits (fig. These should enable you to determine easily the maximum and minimum values. The size ranges given are for typical size. The following links are to mechanical tolerance table charts for standard shaft hole fits per ansi 4.1.

from engineersfield.com

The following links are to mechanical tolerance table charts for standard shaft hole fits per ansi 4.1. Shaft</strong>> when using the linear bushing in combination with an lm shaft, use normal clearance in ordinary use and. The size ranges given are for typical size. Excessive clearance may have a negative. The first provides the charts for the fundamental. The tables in this section provide information about bearing tolerances, seat tolerances and resultant fits (fig. This page provides bushing type specific recommendations on the following design considerations, as far as applicable: These should enable you to determine easily the maximum and minimum values. Class of tolerance range for shafts f6 g5 g6 h5 h6 js5 js6 k5 k6 m5 m6 n6 p6 e7 f6 f7 g6 h6 h7 js6 js7 k6 m6 n6 p6 r6 s6 t6 u6 x6 d9 e8 e9 f7 f8 h7 h8 c9. Guideline values depending on selected shaft and housing tolerances:

Shaft Tolerances and fits ISO fundamental deviations for external

Shaft Bushing Tolerance The size ranges given are for typical size. This page provides bushing type specific recommendations on the following design considerations, as far as applicable: Class of tolerance range for shafts f6 g5 g6 h5 h6 js5 js6 k5 k6 m5 m6 n6 p6 e7 f6 f7 g6 h6 h7 js6 js7 k6 m6 n6 p6 r6 s6 t6 u6 x6 d9 e8 e9 f7 f8 h7 h8 c9. The size ranges given are for typical size. The first provides the charts for the fundamental. Shaft</strong>> when using the linear bushing in combination with an lm shaft, use normal clearance in ordinary use and. The following links are to mechanical tolerance table charts for standard shaft hole fits per ansi 4.1. Excessive clearance may have a negative. The tables in this section provide information about bearing tolerances, seat tolerances and resultant fits (fig. Guideline values depending on selected shaft and housing tolerances: These should enable you to determine easily the maximum and minimum values.

From www.scribd.com

ISO Tolerances for Shafts (ISO 2862) Engineering Tolerance Chess Shaft Bushing Tolerance The following links are to mechanical tolerance table charts for standard shaft hole fits per ansi 4.1. Guideline values depending on selected shaft and housing tolerances: Excessive clearance may have a negative. The tables in this section provide information about bearing tolerances, seat tolerances and resultant fits (fig. The size ranges given are for typical size. The first provides the. Shaft Bushing Tolerance.

From gatesbeltsandapplications.blogspot.co.uk

Gates Belts, Hoses, and Applications Standard & NonStandard Shaft Key Shaft Bushing Tolerance The first provides the charts for the fundamental. Excessive clearance may have a negative. These should enable you to determine easily the maximum and minimum values. The following links are to mechanical tolerance table charts for standard shaft hole fits per ansi 4.1. The tables in this section provide information about bearing tolerances, seat tolerances and resultant fits (fig. This. Shaft Bushing Tolerance.

From baartgroup.com

How to Install and Remove a Bushing Baart Industrial Group Shaft Bushing Tolerance The size ranges given are for typical size. Class of tolerance range for shafts f6 g5 g6 h5 h6 js5 js6 k5 k6 m5 m6 n6 p6 e7 f6 f7 g6 h6 h7 js6 js7 k6 m6 n6 p6 r6 s6 t6 u6 x6 d9 e8 e9 f7 f8 h7 h8 c9. Guideline values depending on selected shaft and housing. Shaft Bushing Tolerance.

From www.scribd.com

Shaft Tolerance Chart Heat Treating Alloy Shaft Bushing Tolerance The size ranges given are for typical size. The following links are to mechanical tolerance table charts for standard shaft hole fits per ansi 4.1. The first provides the charts for the fundamental. This page provides bushing type specific recommendations on the following design considerations, as far as applicable: Shaft</strong>> when using the linear bushing in combination with an lm. Shaft Bushing Tolerance.

From engineersfield.com

Shaft Tolerances and fits ISO fundamental deviations for external Shaft Bushing Tolerance Excessive clearance may have a negative. Guideline values depending on selected shaft and housing tolerances: The first provides the charts for the fundamental. Class of tolerance range for shafts f6 g5 g6 h5 h6 js5 js6 k5 k6 m5 m6 n6 p6 e7 f6 f7 g6 h6 h7 js6 js7 k6 m6 n6 p6 r6 s6 t6 u6 x6 d9. Shaft Bushing Tolerance.

From www.carrlane.com

Understanding Standard Drill Bushings Comprehensive Guide Shaft Bushing Tolerance The tables in this section provide information about bearing tolerances, seat tolerances and resultant fits (fig. Guideline values depending on selected shaft and housing tolerances: Excessive clearance may have a negative. Shaft</strong>> when using the linear bushing in combination with an lm shaft, use normal clearance in ordinary use and. This page provides bushing type specific recommendations on the following. Shaft Bushing Tolerance.

From mavink.com

H9 Shaft Tolerance Chart Shaft Bushing Tolerance The first provides the charts for the fundamental. The following links are to mechanical tolerance table charts for standard shaft hole fits per ansi 4.1. Excessive clearance may have a negative. The size ranges given are for typical size. These should enable you to determine easily the maximum and minimum values. Shaft</strong>> when using the linear bushing in combination with. Shaft Bushing Tolerance.

From www.scribd.com

ISO Tolerances for Shafts (ISO 2862) Shaft Bushing Tolerance The size ranges given are for typical size. Class of tolerance range for shafts f6 g5 g6 h5 h6 js5 js6 k5 k6 m5 m6 n6 p6 e7 f6 f7 g6 h6 h7 js6 js7 k6 m6 n6 p6 r6 s6 t6 u6 x6 d9 e8 e9 f7 f8 h7 h8 c9. The first provides the charts for the fundamental.. Shaft Bushing Tolerance.

From extrudesign.com

How to Calculate tolerance values for shaft or a hole? ExtruDesign Shaft Bushing Tolerance The tables in this section provide information about bearing tolerances, seat tolerances and resultant fits (fig. The size ranges given are for typical size. Excessive clearance may have a negative. These should enable you to determine easily the maximum and minimum values. Guideline values depending on selected shaft and housing tolerances: Shaft</strong>> when using the linear bushing in combination with. Shaft Bushing Tolerance.

From engr1304.blogspot.com

ENGR1304 Chapter 7 Tolerances Shaft Bushing Tolerance The following links are to mechanical tolerance table charts for standard shaft hole fits per ansi 4.1. The tables in this section provide information about bearing tolerances, seat tolerances and resultant fits (fig. Shaft</strong>> when using the linear bushing in combination with an lm shaft, use normal clearance in ordinary use and. Class of tolerance range for shafts f6 g5. Shaft Bushing Tolerance.

From www.scribd.com

ISO Tolerances for Holes & Shafts Engineering Tolerance Business Shaft Bushing Tolerance Shaft</strong>> when using the linear bushing in combination with an lm shaft, use normal clearance in ordinary use and. These should enable you to determine easily the maximum and minimum values. Class of tolerance range for shafts f6 g5 g6 h5 h6 js5 js6 k5 k6 m5 m6 n6 p6 e7 f6 f7 g6 h6 h7 js6 js7 k6 m6. Shaft Bushing Tolerance.

From www.youtube.com

Dimensional tolerancing of a shaft YouTube Shaft Bushing Tolerance Class of tolerance range for shafts f6 g5 g6 h5 h6 js5 js6 k5 k6 m5 m6 n6 p6 e7 f6 f7 g6 h6 h7 js6 js7 k6 m6 n6 p6 r6 s6 t6 u6 x6 d9 e8 e9 f7 f8 h7 h8 c9. Excessive clearance may have a negative. Guideline values depending on selected shaft and housing tolerances: Shaft</strong>>. Shaft Bushing Tolerance.

From engineersfield.com

Shaft Tolerances and fits ISO fundamental deviations for external Shaft Bushing Tolerance The following links are to mechanical tolerance table charts for standard shaft hole fits per ansi 4.1. Class of tolerance range for shafts f6 g5 g6 h5 h6 js5 js6 k5 k6 m5 m6 n6 p6 e7 f6 f7 g6 h6 h7 js6 js7 k6 m6 n6 p6 r6 s6 t6 u6 x6 d9 e8 e9 f7 f8 h7 h8. Shaft Bushing Tolerance.

From id.scribd.com

ISO Tolerances For Shafts PDF Shaft Bushing Tolerance The following links are to mechanical tolerance table charts for standard shaft hole fits per ansi 4.1. This page provides bushing type specific recommendations on the following design considerations, as far as applicable: The tables in this section provide information about bearing tolerances, seat tolerances and resultant fits (fig. Excessive clearance may have a negative. The first provides the charts. Shaft Bushing Tolerance.

From www.scribd.com

iso tolerances for shafts (iso 2862) Engineering Tolerance Game Theory Shaft Bushing Tolerance Class of tolerance range for shafts f6 g5 g6 h5 h6 js5 js6 k5 k6 m5 m6 n6 p6 e7 f6 f7 g6 h6 h7 js6 js7 k6 m6 n6 p6 r6 s6 t6 u6 x6 d9 e8 e9 f7 f8 h7 h8 c9. This page provides bushing type specific recommendations on the following design considerations, as far as applicable:. Shaft Bushing Tolerance.

From info.rw-america.com

DIN Shaft Fit Tolerances Shaft Bushing Tolerance These should enable you to determine easily the maximum and minimum values. The first provides the charts for the fundamental. This page provides bushing type specific recommendations on the following design considerations, as far as applicable: The tables in this section provide information about bearing tolerances, seat tolerances and resultant fits (fig. Class of tolerance range for shafts f6 g5. Shaft Bushing Tolerance.

From chartdata.web.app

Tolerance Chart For Holes And Shafts Shaft Bushing Tolerance The first provides the charts for the fundamental. Guideline values depending on selected shaft and housing tolerances: The size ranges given are for typical size. These should enable you to determine easily the maximum and minimum values. The following links are to mechanical tolerance table charts for standard shaft hole fits per ansi 4.1. Excessive clearance may have a negative.. Shaft Bushing Tolerance.

From rawgoodtext.web.fc2.com

Iso 2768 Hole Tolerance Table Shaft Bushing Tolerance Excessive clearance may have a negative. The tables in this section provide information about bearing tolerances, seat tolerances and resultant fits (fig. The following links are to mechanical tolerance table charts for standard shaft hole fits per ansi 4.1. The size ranges given are for typical size. This page provides bushing type specific recommendations on the following design considerations, as. Shaft Bushing Tolerance.

From mavink.com

Engineering Drawing Symbols Tolerances Shaft Bushing Tolerance Shaft</strong>> when using the linear bushing in combination with an lm shaft, use normal clearance in ordinary use and. The following links are to mechanical tolerance table charts for standard shaft hole fits per ansi 4.1. The first provides the charts for the fundamental. Excessive clearance may have a negative. These should enable you to determine easily the maximum and. Shaft Bushing Tolerance.

From www.youtube.com

Tolerance Analysis Relationships between dimensional tolerances Shaft Bushing Tolerance This page provides bushing type specific recommendations on the following design considerations, as far as applicable: The tables in this section provide information about bearing tolerances, seat tolerances and resultant fits (fig. The size ranges given are for typical size. The first provides the charts for the fundamental. Excessive clearance may have a negative. These should enable you to determine. Shaft Bushing Tolerance.

From loekcqvji.blob.core.windows.net

Bushing Tolerances at Francisco Tillotson blog Shaft Bushing Tolerance The tables in this section provide information about bearing tolerances, seat tolerances and resultant fits (fig. Shaft</strong>> when using the linear bushing in combination with an lm shaft, use normal clearance in ordinary use and. The following links are to mechanical tolerance table charts for standard shaft hole fits per ansi 4.1. The size ranges given are for typical size.. Shaft Bushing Tolerance.

From morganwells.z19.web.core.windows.net

Hole And Shaft Tolerance Chart Shaft Bushing Tolerance Guideline values depending on selected shaft and housing tolerances: These should enable you to determine easily the maximum and minimum values. The following links are to mechanical tolerance table charts for standard shaft hole fits per ansi 4.1. The size ranges given are for typical size. The tables in this section provide information about bearing tolerances, seat tolerances and resultant. Shaft Bushing Tolerance.

From cebcpiuq.blob.core.windows.net

Shaft Hub Tolerance Calculator at Lee Leeds blog Shaft Bushing Tolerance These should enable you to determine easily the maximum and minimum values. This page provides bushing type specific recommendations on the following design considerations, as far as applicable: Guideline values depending on selected shaft and housing tolerances: Shaft</strong>> when using the linear bushing in combination with an lm shaft, use normal clearance in ordinary use and. Class of tolerance range. Shaft Bushing Tolerance.

From my.misumi-ec.com

MISUMI Malaysia Industrial Configurable Components Supply Shaft Bushing Tolerance The size ranges given are for typical size. Class of tolerance range for shafts f6 g5 g6 h5 h6 js5 js6 k5 k6 m5 m6 n6 p6 e7 f6 f7 g6 h6 h7 js6 js7 k6 m6 n6 p6 r6 s6 t6 u6 x6 d9 e8 e9 f7 f8 h7 h8 c9. These should enable you to determine easily the. Shaft Bushing Tolerance.

From www.wasyresearch.com

Examples on how to interpret GD&T Form, orientation, location and run Shaft Bushing Tolerance The following links are to mechanical tolerance table charts for standard shaft hole fits per ansi 4.1. Class of tolerance range for shafts f6 g5 g6 h5 h6 js5 js6 k5 k6 m5 m6 n6 p6 e7 f6 f7 g6 h6 h7 js6 js7 k6 m6 n6 p6 r6 s6 t6 u6 x6 d9 e8 e9 f7 f8 h7 h8. Shaft Bushing Tolerance.

From atelier-yuwa.ciao.jp

Bearing Shaft Tolerance Chart atelieryuwa.ciao.jp Shaft Bushing Tolerance Guideline values depending on selected shaft and housing tolerances: Shaft</strong>> when using the linear bushing in combination with an lm shaft, use normal clearance in ordinary use and. These should enable you to determine easily the maximum and minimum values. The tables in this section provide information about bearing tolerances, seat tolerances and resultant fits (fig. This page provides bushing. Shaft Bushing Tolerance.

From www.villageinframe.com

Iso Tolerances For Shafts And Holes A Pictures Of Hole 2018 Shaft Bushing Tolerance Guideline values depending on selected shaft and housing tolerances: This page provides bushing type specific recommendations on the following design considerations, as far as applicable: Excessive clearance may have a negative. The following links are to mechanical tolerance table charts for standard shaft hole fits per ansi 4.1. The first provides the charts for the fundamental. Shaft</strong>> when using the. Shaft Bushing Tolerance.

From www.villageinframe.com

Iso Tolerances For Shafts And Holes A Pictures Of Hole 2018 Shaft Bushing Tolerance This page provides bushing type specific recommendations on the following design considerations, as far as applicable: The following links are to mechanical tolerance table charts for standard shaft hole fits per ansi 4.1. These should enable you to determine easily the maximum and minimum values. Shaft</strong>> when using the linear bushing in combination with an lm shaft, use normal clearance. Shaft Bushing Tolerance.

From mavink.com

Bearing Tolerance Chart Shaft Bushing Tolerance These should enable you to determine easily the maximum and minimum values. The size ranges given are for typical size. The first provides the charts for the fundamental. Guideline values depending on selected shaft and housing tolerances: Excessive clearance may have a negative. The tables in this section provide information about bearing tolerances, seat tolerances and resultant fits (fig. This. Shaft Bushing Tolerance.

From cebcpiuq.blob.core.windows.net

Shaft Hub Tolerance Calculator at Lee Leeds blog Shaft Bushing Tolerance Class of tolerance range for shafts f6 g5 g6 h5 h6 js5 js6 k5 k6 m5 m6 n6 p6 e7 f6 f7 g6 h6 h7 js6 js7 k6 m6 n6 p6 r6 s6 t6 u6 x6 d9 e8 e9 f7 f8 h7 h8 c9. These should enable you to determine easily the maximum and minimum values. The following links are. Shaft Bushing Tolerance.

From www.scribd.com

ISO Tolerances for Shafts Engineering Tolerance Chess Shaft Bushing Tolerance The tables in this section provide information about bearing tolerances, seat tolerances and resultant fits (fig. These should enable you to determine easily the maximum and minimum values. Class of tolerance range for shafts f6 g5 g6 h5 h6 js5 js6 k5 k6 m5 m6 n6 p6 e7 f6 f7 g6 h6 h7 js6 js7 k6 m6 n6 p6 r6. Shaft Bushing Tolerance.

From www.encoder.com

Guidelines for Shaft and Bore Tolerances Encoder Product Company Shaft Bushing Tolerance Shaft</strong>> when using the linear bushing in combination with an lm shaft, use normal clearance in ordinary use and. The tables in this section provide information about bearing tolerances, seat tolerances and resultant fits (fig. These should enable you to determine easily the maximum and minimum values. Excessive clearance may have a negative. Guideline values depending on selected shaft and. Shaft Bushing Tolerance.

From gatesbeltsandapplications.blogspot.com

Gates Belts, Hoses, and Applications Standard & NonStandard Shaft Key Shaft Bushing Tolerance The tables in this section provide information about bearing tolerances, seat tolerances and resultant fits (fig. The size ranges given are for typical size. Excessive clearance may have a negative. This page provides bushing type specific recommendations on the following design considerations, as far as applicable: These should enable you to determine easily the maximum and minimum values. Shaft</strong>> when. Shaft Bushing Tolerance.

From www.scribd.com

ISO Tolerances For Holes and Shafts PDF Engineering Tolerance Shaft Bushing Tolerance Guideline values depending on selected shaft and housing tolerances: The first provides the charts for the fundamental. The size ranges given are for typical size. The tables in this section provide information about bearing tolerances, seat tolerances and resultant fits (fig. These should enable you to determine easily the maximum and minimum values. Class of tolerance range for shafts f6. Shaft Bushing Tolerance.

From mungfali.com

ISO Shaft Tolerance Chart Shaft Bushing Tolerance The size ranges given are for typical size. The following links are to mechanical tolerance table charts for standard shaft hole fits per ansi 4.1. Shaft</strong>> when using the linear bushing in combination with an lm shaft, use normal clearance in ordinary use and. Class of tolerance range for shafts f6 g5 g6 h5 h6 js5 js6 k5 k6 m5. Shaft Bushing Tolerance.