Belt Splicing Process . Usually, this is done to. This creates a strong and. the process includes health & safety, tooling & equipment, materials, laying out of belt ends, stepping & preparing, splice assembly and. conveyor belt splicing is the process of joining together two pieces of conveyor belt. it involves cutting the belt ends into a pattern of fingers and bonding them with adhesive or vulcanization. conveyor belt splicing, as simply defined, involves the process of joining two trimmed ends of a conveyor. vulcanization is generally preferred for belt splicing due to its superior strength, longer service life, and cleaner operation. how to contact us. The process of preparing, building and curing of a vulcanized splice and why this is the critical foundation to delivering conveyor belt reliability, longevity and performance to the customer. the following points should always be considered when performing a hot vulcanised splice on any conveyor belt.

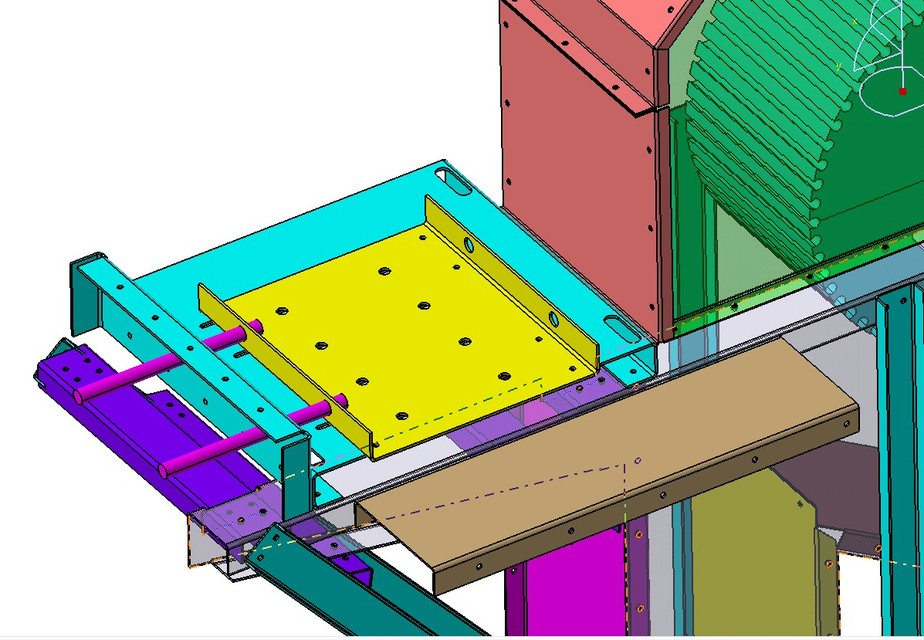

from grabcad.com

how to contact us. Usually, this is done to. the following points should always be considered when performing a hot vulcanised splice on any conveyor belt. conveyor belt splicing is the process of joining together two pieces of conveyor belt. conveyor belt splicing, as simply defined, involves the process of joining two trimmed ends of a conveyor. the process includes health & safety, tooling & equipment, materials, laying out of belt ends, stepping & preparing, splice assembly and. vulcanization is generally preferred for belt splicing due to its superior strength, longer service life, and cleaner operation. The process of preparing, building and curing of a vulcanized splice and why this is the critical foundation to delivering conveyor belt reliability, longevity and performance to the customer. This creates a strong and. it involves cutting the belt ends into a pattern of fingers and bonding them with adhesive or vulcanization.

What is conveyor belt splicing? Conveyor belt splicing is the process

Belt Splicing Process conveyor belt splicing, as simply defined, involves the process of joining two trimmed ends of a conveyor. Usually, this is done to. conveyor belt splicing is the process of joining together two pieces of conveyor belt. The process of preparing, building and curing of a vulcanized splice and why this is the critical foundation to delivering conveyor belt reliability, longevity and performance to the customer. the following points should always be considered when performing a hot vulcanised splice on any conveyor belt. vulcanization is generally preferred for belt splicing due to its superior strength, longer service life, and cleaner operation. the process includes health & safety, tooling & equipment, materials, laying out of belt ends, stepping & preparing, splice assembly and. how to contact us. it involves cutting the belt ends into a pattern of fingers and bonding them with adhesive or vulcanization. This creates a strong and. conveyor belt splicing, as simply defined, involves the process of joining two trimmed ends of a conveyor.

From exms.co.za

Belt Splicing Consumables Expert Mining Solutions Belt Splicing Process conveyor belt splicing, as simply defined, involves the process of joining two trimmed ends of a conveyor. it involves cutting the belt ends into a pattern of fingers and bonding them with adhesive or vulcanization. Usually, this is done to. the process includes health & safety, tooling & equipment, materials, laying out of belt ends, stepping &. Belt Splicing Process.

From www.beltpower.com

Conveyor Belt Splicing Endless Belt Splicing Belt Power Belt Splicing Process Usually, this is done to. vulcanization is generally preferred for belt splicing due to its superior strength, longer service life, and cleaner operation. The process of preparing, building and curing of a vulcanized splice and why this is the critical foundation to delivering conveyor belt reliability, longevity and performance to the customer. it involves cutting the belt ends. Belt Splicing Process.

From fennerdunlopamericas.com

Splicing & Installation Fenner Dunlop Conveyor Belting Belt Splicing Process conveyor belt splicing, as simply defined, involves the process of joining two trimmed ends of a conveyor. conveyor belt splicing is the process of joining together two pieces of conveyor belt. the process includes health & safety, tooling & equipment, materials, laying out of belt ends, stepping & preparing, splice assembly and. Usually, this is done to.. Belt Splicing Process.

From www.asgco.com

Conveyor Belt Splicing & Vulcanizing ASGCO Conveyor Services ASGCO Belt Splicing Process how to contact us. conveyor belt splicing, as simply defined, involves the process of joining two trimmed ends of a conveyor. it involves cutting the belt ends into a pattern of fingers and bonding them with adhesive or vulcanization. the following points should always be considered when performing a hot vulcanised splice on any conveyor belt.. Belt Splicing Process.

From fennerdunlopamericas.com

Splicing & Installation Fenner Dunlop Conveyor Belting Belt Splicing Process This creates a strong and. the process includes health & safety, tooling & equipment, materials, laying out of belt ends, stepping & preparing, splice assembly and. The process of preparing, building and curing of a vulcanized splice and why this is the critical foundation to delivering conveyor belt reliability, longevity and performance to the customer. how to contact. Belt Splicing Process.

From www.bsbeltfactory.com

3 Common Types of Conveyor Belt Splices Belt Splicing Process Usually, this is done to. the process includes health & safety, tooling & equipment, materials, laying out of belt ends, stepping & preparing, splice assembly and. conveyor belt splicing, as simply defined, involves the process of joining two trimmed ends of a conveyor. it involves cutting the belt ends into a pattern of fingers and bonding them. Belt Splicing Process.

From www.youtube.com

Splicing Steel Cord Timing Belt YouTube Belt Splicing Process The process of preparing, building and curing of a vulcanized splice and why this is the critical foundation to delivering conveyor belt reliability, longevity and performance to the customer. the following points should always be considered when performing a hot vulcanised splice on any conveyor belt. Usually, this is done to. conveyor belt splicing, as simply defined, involves. Belt Splicing Process.

From www.asgco.com

Conveyor Belt Splicing and Vulcanization ASGCO Manufacturing Inc Belt Splicing Process how to contact us. Usually, this is done to. the following points should always be considered when performing a hot vulcanised splice on any conveyor belt. conveyor belt splicing, as simply defined, involves the process of joining two trimmed ends of a conveyor. the process includes health & safety, tooling & equipment, materials, laying out of. Belt Splicing Process.

From www.youtube.com

Hot Splicing of conveyor belt with Multiface 5 and a Waterbag Belt Splicing Process conveyor belt splicing is the process of joining together two pieces of conveyor belt. This creates a strong and. it involves cutting the belt ends into a pattern of fingers and bonding them with adhesive or vulcanization. the following points should always be considered when performing a hot vulcanised splice on any conveyor belt. The process of. Belt Splicing Process.

From www.ingwesplicing.co.za

Hot And Cold Splicing Conveyor Belts Maintenance Ingwe Splicing Belt Splicing Process the following points should always be considered when performing a hot vulcanised splice on any conveyor belt. vulcanization is generally preferred for belt splicing due to its superior strength, longer service life, and cleaner operation. how to contact us. The process of preparing, building and curing of a vulcanized splice and why this is the critical foundation. Belt Splicing Process.

From www.ingwesplicing.co.za

Conveyor Belt Splicing Conveyor Belts Mechanical Splicing Belt Splicing Process how to contact us. the process includes health & safety, tooling & equipment, materials, laying out of belt ends, stepping & preparing, splice assembly and. vulcanization is generally preferred for belt splicing due to its superior strength, longer service life, and cleaner operation. conveyor belt splicing, as simply defined, involves the process of joining two trimmed. Belt Splicing Process.

From www.youtube.com

Belt Splicing 101 Video YouTube Belt Splicing Process the process includes health & safety, tooling & equipment, materials, laying out of belt ends, stepping & preparing, splice assembly and. it involves cutting the belt ends into a pattern of fingers and bonding them with adhesive or vulcanization. conveyor belt splicing, as simply defined, involves the process of joining two trimmed ends of a conveyor. Usually,. Belt Splicing Process.

From www.youtube.com

Service Tips Belt Splicing YouTube Belt Splicing Process the process includes health & safety, tooling & equipment, materials, laying out of belt ends, stepping & preparing, splice assembly and. it involves cutting the belt ends into a pattern of fingers and bonding them with adhesive or vulcanization. Usually, this is done to. how to contact us. vulcanization is generally preferred for belt splicing due. Belt Splicing Process.

From www.sparksbelting.com

Conveyor Belt Splicing Endless Construction Sparks Belting Belt Splicing Process it involves cutting the belt ends into a pattern of fingers and bonding them with adhesive or vulcanization. The process of preparing, building and curing of a vulcanized splice and why this is the critical foundation to delivering conveyor belt reliability, longevity and performance to the customer. vulcanization is generally preferred for belt splicing due to its superior. Belt Splicing Process.

From www.youtube.com

Conveyor Belt Cold Splicing Process Detail Video YouTube Belt Splicing Process how to contact us. The process of preparing, building and curing of a vulcanized splice and why this is the critical foundation to delivering conveyor belt reliability, longevity and performance to the customer. it involves cutting the belt ends into a pattern of fingers and bonding them with adhesive or vulcanization. conveyor belt splicing is the process. Belt Splicing Process.

From www.ibeltrepair.com

How does conveyor belt splicing work? Belt Splicing Process This creates a strong and. conveyor belt splicing is the process of joining together two pieces of conveyor belt. the following points should always be considered when performing a hot vulcanised splice on any conveyor belt. conveyor belt splicing, as simply defined, involves the process of joining two trimmed ends of a conveyor. it involves cutting. Belt Splicing Process.

From foundations.martin-eng.com

Vulcanizing conveyor belt splices entails 3 steps Martin Engineering Belt Splicing Process conveyor belt splicing is the process of joining together two pieces of conveyor belt. it involves cutting the belt ends into a pattern of fingers and bonding them with adhesive or vulcanization. conveyor belt splicing, as simply defined, involves the process of joining two trimmed ends of a conveyor. Usually, this is done to. The process of. Belt Splicing Process.

From www.asgco.com

Conveyor Belt Splicing & Vulcanizing ASGCO Conveyor Services ASGCO Belt Splicing Process the following points should always be considered when performing a hot vulcanised splice on any conveyor belt. conveyor belt splicing, as simply defined, involves the process of joining two trimmed ends of a conveyor. conveyor belt splicing is the process of joining together two pieces of conveyor belt. how to contact us. Usually, this is done. Belt Splicing Process.

From www.youtube.com

Cold belt splicing YouTube Belt Splicing Process the following points should always be considered when performing a hot vulcanised splice on any conveyor belt. The process of preparing, building and curing of a vulcanized splice and why this is the critical foundation to delivering conveyor belt reliability, longevity and performance to the customer. conveyor belt splicing is the process of joining together two pieces of. Belt Splicing Process.

From toprs.ro

Conveyor belt splicing Belt Splicing Process the process includes health & safety, tooling & equipment, materials, laying out of belt ends, stepping & preparing, splice assembly and. conveyor belt splicing is the process of joining together two pieces of conveyor belt. Usually, this is done to. the following points should always be considered when performing a hot vulcanised splice on any conveyor belt.. Belt Splicing Process.

From www.conbelt.com

Definition of Conveyor Belt Splicing • Con Belt Belt Splicing Process how to contact us. This creates a strong and. The process of preparing, building and curing of a vulcanized splice and why this is the critical foundation to delivering conveyor belt reliability, longevity and performance to the customer. the following points should always be considered when performing a hot vulcanised splice on any conveyor belt. the process. Belt Splicing Process.

From www.asgco.com

Conveyor Belt Splicing & Vulcanizing ASGCO Conveyor Services ASGCO Belt Splicing Process vulcanization is generally preferred for belt splicing due to its superior strength, longer service life, and cleaner operation. The process of preparing, building and curing of a vulcanized splice and why this is the critical foundation to delivering conveyor belt reliability, longevity and performance to the customer. it involves cutting the belt ends into a pattern of fingers. Belt Splicing Process.

From www.conveyorbeltjoint.com

Belt Jointer Process Sai Conveyor Belt Belt Splicing Process how to contact us. conveyor belt splicing, as simply defined, involves the process of joining two trimmed ends of a conveyor. The process of preparing, building and curing of a vulcanized splice and why this is the critical foundation to delivering conveyor belt reliability, longevity and performance to the customer. it involves cutting the belt ends into. Belt Splicing Process.

From www.youtube.com

Conveyor Belt splicing YouTube Belt Splicing Process vulcanization is generally preferred for belt splicing due to its superior strength, longer service life, and cleaner operation. The process of preparing, building and curing of a vulcanized splice and why this is the critical foundation to delivering conveyor belt reliability, longevity and performance to the customer. how to contact us. This creates a strong and. the. Belt Splicing Process.

From www.asgco.com

Conveyor Belt Splicing and Vulcanization ASGCO Manufacturing Inc Belt Splicing Process the process includes health & safety, tooling & equipment, materials, laying out of belt ends, stepping & preparing, splice assembly and. it involves cutting the belt ends into a pattern of fingers and bonding them with adhesive or vulcanization. The process of preparing, building and curing of a vulcanized splice and why this is the critical foundation to. Belt Splicing Process.

From www.youtube.com

How to Joint / Splice Homogeneous PU Belt / Thermodrive Belt By Belt Belt Splicing Process vulcanization is generally preferred for belt splicing due to its superior strength, longer service life, and cleaner operation. the process includes health & safety, tooling & equipment, materials, laying out of belt ends, stepping & preparing, splice assembly and. how to contact us. This creates a strong and. the following points should always be considered when. Belt Splicing Process.

From accurateindustrial.com

Conveyor Belt Splicing Accurate Industrial Belt Splicing Process The process of preparing, building and curing of a vulcanized splice and why this is the critical foundation to delivering conveyor belt reliability, longevity and performance to the customer. it involves cutting the belt ends into a pattern of fingers and bonding them with adhesive or vulcanization. the following points should always be considered when performing a hot. Belt Splicing Process.

From www.asgco.com

Conveyor Belt Splicing and Vulcanization ASGCO Manufacturing Inc Belt Splicing Process it involves cutting the belt ends into a pattern of fingers and bonding them with adhesive or vulcanization. This creates a strong and. The process of preparing, building and curing of a vulcanized splice and why this is the critical foundation to delivering conveyor belt reliability, longevity and performance to the customer. how to contact us. conveyor. Belt Splicing Process.

From www.scribd.com

Working Instructions For Splicing Fabric Belts Using A Cold Process Belt Splicing Process the following points should always be considered when performing a hot vulcanised splice on any conveyor belt. conveyor belt splicing is the process of joining together two pieces of conveyor belt. it involves cutting the belt ends into a pattern of fingers and bonding them with adhesive or vulcanization. the process includes health & safety, tooling. Belt Splicing Process.

From www.conveyorbeltjoint.com

Belt Jointer Process Sai Conveyor Belt Belt Splicing Process conveyor belt splicing, as simply defined, involves the process of joining two trimmed ends of a conveyor. Usually, this is done to. the following points should always be considered when performing a hot vulcanised splice on any conveyor belt. This creates a strong and. vulcanization is generally preferred for belt splicing due to its superior strength, longer. Belt Splicing Process.

From www.asgco.com

Conveyor Belt Splicing And Vulcanization ASGCO ASGCO Belt Splicing Process conveyor belt splicing is the process of joining together two pieces of conveyor belt. conveyor belt splicing, as simply defined, involves the process of joining two trimmed ends of a conveyor. The process of preparing, building and curing of a vulcanized splice and why this is the critical foundation to delivering conveyor belt reliability, longevity and performance to. Belt Splicing Process.

From www.ingwesplicing.co.za

Conveyor Belt Splicing Conveyor Belts Mechanical Splicing Belt Splicing Process it involves cutting the belt ends into a pattern of fingers and bonding them with adhesive or vulcanization. Usually, this is done to. conveyor belt splicing, as simply defined, involves the process of joining two trimmed ends of a conveyor. vulcanization is generally preferred for belt splicing due to its superior strength, longer service life, and cleaner. Belt Splicing Process.

From www.asgco.com

Conveyor Belt Splicing & Vulcanizing ASGCO Conveyor Services ASGCO Belt Splicing Process Usually, this is done to. conveyor belt splicing is the process of joining together two pieces of conveyor belt. how to contact us. The process of preparing, building and curing of a vulcanized splice and why this is the critical foundation to delivering conveyor belt reliability, longevity and performance to the customer. vulcanization is generally preferred for. Belt Splicing Process.

From grabcad.com

What is conveyor belt splicing? Conveyor belt splicing is the process Belt Splicing Process The process of preparing, building and curing of a vulcanized splice and why this is the critical foundation to delivering conveyor belt reliability, longevity and performance to the customer. Usually, this is done to. This creates a strong and. how to contact us. the process includes health & safety, tooling & equipment, materials, laying out of belt ends,. Belt Splicing Process.

From www.youtube.com

PVC PU conveyor belt splicing joint machine belts splice press machine Belt Splicing Process The process of preparing, building and curing of a vulcanized splice and why this is the critical foundation to delivering conveyor belt reliability, longevity and performance to the customer. how to contact us. vulcanization is generally preferred for belt splicing due to its superior strength, longer service life, and cleaner operation. This creates a strong and. conveyor. Belt Splicing Process.