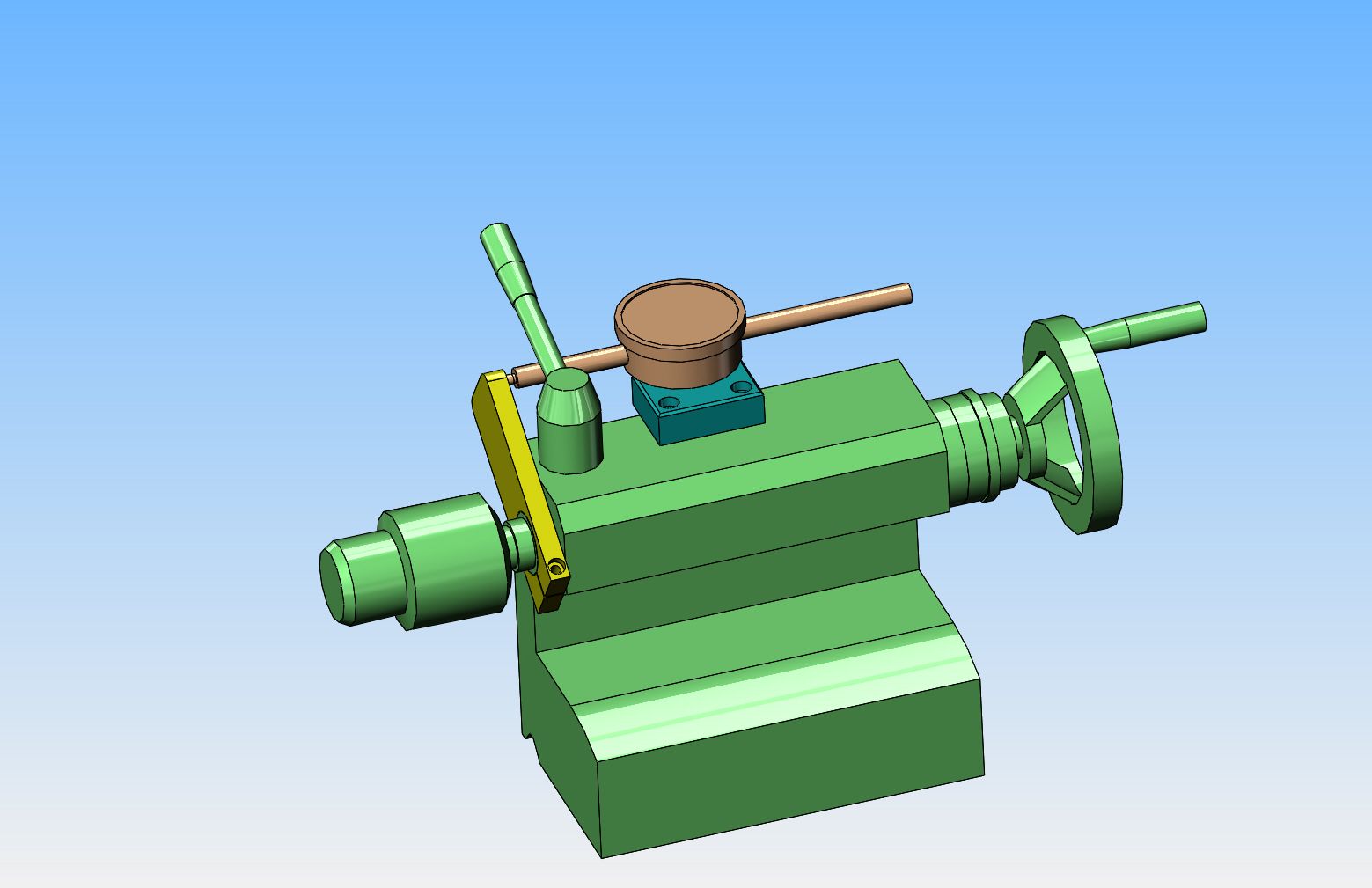

Dial Indicator On Tailstock . I adjust the tailstock and dial gauge such that when the chuck is rotated the gauge indicates any horizontal or vertical misalignment. Use a dial indicator mounted on a magnetic base to measure the misalignment between the tailstock spindle bore and the headstock spindle bore. I will mount a piece of bar stock with a hole drilled in it to fit around the tailstock ram and mount the dial on the tailstock casting with. Using a dial indicator is essential for measuring initial misalignments accurately, providing clear data on which areas require. Use a dial indicator to check the alignment between the spindle and tailstock quill. In the context of a lathe, a dial indicator is used to measure the alignment and accuracy of various components, such as the bed, spindle, and tailstock. The three photos show the gauge indicating on the front, top and rear respectively. The indicator should show no more than 0.001. Align a dial test indicator, digital test indicator dial drop indicator, or digital drop indicator that is held by a magnetic base. The dial indicator is moved along the length of the bar, and any misalignment between centers will be shown on the indicator.

from www.homemodelenginemachinist.com

In the context of a lathe, a dial indicator is used to measure the alignment and accuracy of various components, such as the bed, spindle, and tailstock. I adjust the tailstock and dial gauge such that when the chuck is rotated the gauge indicates any horizontal or vertical misalignment. Align a dial test indicator, digital test indicator dial drop indicator, or digital drop indicator that is held by a magnetic base. Using a dial indicator is essential for measuring initial misalignments accurately, providing clear data on which areas require. Use a dial indicator mounted on a magnetic base to measure the misalignment between the tailstock spindle bore and the headstock spindle bore. The dial indicator is moved along the length of the bar, and any misalignment between centers will be shown on the indicator. The three photos show the gauge indicating on the front, top and rear respectively. I will mount a piece of bar stock with a hole drilled in it to fit around the tailstock ram and mount the dial on the tailstock casting with. The indicator should show no more than 0.001. Use a dial indicator to check the alignment between the spindle and tailstock quill.

Adding dial indicator to lathe tailstock Home Model Engine Machinist

Dial Indicator On Tailstock Use a dial indicator mounted on a magnetic base to measure the misalignment between the tailstock spindle bore and the headstock spindle bore. I will mount a piece of bar stock with a hole drilled in it to fit around the tailstock ram and mount the dial on the tailstock casting with. The three photos show the gauge indicating on the front, top and rear respectively. Use a dial indicator to check the alignment between the spindle and tailstock quill. Use a dial indicator mounted on a magnetic base to measure the misalignment between the tailstock spindle bore and the headstock spindle bore. The indicator should show no more than 0.001. Using a dial indicator is essential for measuring initial misalignments accurately, providing clear data on which areas require. In the context of a lathe, a dial indicator is used to measure the alignment and accuracy of various components, such as the bed, spindle, and tailstock. The dial indicator is moved along the length of the bar, and any misalignment between centers will be shown on the indicator. Align a dial test indicator, digital test indicator dial drop indicator, or digital drop indicator that is held by a magnetic base. I adjust the tailstock and dial gauge such that when the chuck is rotated the gauge indicates any horizontal or vertical misalignment.

From www.randysworldwide.com

How To Use A Dial Indicator RANDYS Worldwide Dial Indicator On Tailstock The indicator should show no more than 0.001. Using a dial indicator is essential for measuring initial misalignments accurately, providing clear data on which areas require. I adjust the tailstock and dial gauge such that when the chuck is rotated the gauge indicates any horizontal or vertical misalignment. Use a dial indicator to check the alignment between the spindle and. Dial Indicator On Tailstock.

From matthewmalham.com

Lathe Tailstock alignent Matthew Malham Dial Indicator On Tailstock The dial indicator is moved along the length of the bar, and any misalignment between centers will be shown on the indicator. Align a dial test indicator, digital test indicator dial drop indicator, or digital drop indicator that is held by a magnetic base. Use a dial indicator mounted on a magnetic base to measure the misalignment between the tailstock. Dial Indicator On Tailstock.

From home-tools.wonderhowto.com

How to Make a dial indicator holder for your lathe tailstock « Tools Dial Indicator On Tailstock I adjust the tailstock and dial gauge such that when the chuck is rotated the gauge indicates any horizontal or vertical misalignment. In the context of a lathe, a dial indicator is used to measure the alignment and accuracy of various components, such as the bed, spindle, and tailstock. The dial indicator is moved along the length of the bar,. Dial Indicator On Tailstock.

From www.homemodelenginemachinist.com

Adding dial indicator to lathe tailstock Home Model Engine Machinist Dial Indicator On Tailstock The indicator should show no more than 0.001. Using a dial indicator is essential for measuring initial misalignments accurately, providing clear data on which areas require. Use a dial indicator to check the alignment between the spindle and tailstock quill. I adjust the tailstock and dial gauge such that when the chuck is rotated the gauge indicates any horizontal or. Dial Indicator On Tailstock.

From www.homemodelenginemachinist.com

Adding dial indicator to lathe tailstock Home Model Engine Machinist Dial Indicator On Tailstock In the context of a lathe, a dial indicator is used to measure the alignment and accuracy of various components, such as the bed, spindle, and tailstock. I will mount a piece of bar stock with a hole drilled in it to fit around the tailstock ram and mount the dial on the tailstock casting with. The indicator should show. Dial Indicator On Tailstock.

From www.homemodelenginemachinist.com

Adding dial indicator to lathe tailstock Home Model Engine Machinist Dial Indicator On Tailstock The three photos show the gauge indicating on the front, top and rear respectively. In the context of a lathe, a dial indicator is used to measure the alignment and accuracy of various components, such as the bed, spindle, and tailstock. I adjust the tailstock and dial gauge such that when the chuck is rotated the gauge indicates any horizontal. Dial Indicator On Tailstock.

From www.penntoolco.com

Precise Metric Dial Indicator with Range 020mm DCI008 Penn Tool Dial Indicator On Tailstock Use a dial indicator mounted on a magnetic base to measure the misalignment between the tailstock spindle bore and the headstock spindle bore. The indicator should show no more than 0.001. Use a dial indicator to check the alignment between the spindle and tailstock quill. Using a dial indicator is essential for measuring initial misalignments accurately, providing clear data on. Dial Indicator On Tailstock.

From www.pinterest.es

Tailstock Dial Indicator Stop with Indicator Metal working Dial Indicator On Tailstock The indicator should show no more than 0.001. Use a dial indicator to check the alignment between the spindle and tailstock quill. I adjust the tailstock and dial gauge such that when the chuck is rotated the gauge indicates any horizontal or vertical misalignment. Align a dial test indicator, digital test indicator dial drop indicator, or digital drop indicator that. Dial Indicator On Tailstock.

From www.mmsonline.com

How to Choose the Right Dial Indicator Modern Machine Shop Dial Indicator On Tailstock Use a dial indicator mounted on a magnetic base to measure the misalignment between the tailstock spindle bore and the headstock spindle bore. The dial indicator is moved along the length of the bar, and any misalignment between centers will be shown on the indicator. Align a dial test indicator, digital test indicator dial drop indicator, or digital drop indicator. Dial Indicator On Tailstock.

From www.practicalmachinist.com

Ideas on mounting a dial indicator on tailstock Dial Indicator On Tailstock I adjust the tailstock and dial gauge such that when the chuck is rotated the gauge indicates any horizontal or vertical misalignment. The three photos show the gauge indicating on the front, top and rear respectively. Using a dial indicator is essential for measuring initial misalignments accurately, providing clear data on which areas require. In the context of a lathe,. Dial Indicator On Tailstock.

From www.machine-dro.co.uk

Mitutoyo 0.001" Graduation Dial Indicator 0.5" Range MIT2414S Dial Indicator On Tailstock In the context of a lathe, a dial indicator is used to measure the alignment and accuracy of various components, such as the bed, spindle, and tailstock. The indicator should show no more than 0.001. Use a dial indicator mounted on a magnetic base to measure the misalignment between the tailstock spindle bore and the headstock spindle bore. The dial. Dial Indicator On Tailstock.

From www.youtube.com

Dial indicator on lathe tailstock quill YouTube Dial Indicator On Tailstock Align a dial test indicator, digital test indicator dial drop indicator, or digital drop indicator that is held by a magnetic base. Use a dial indicator mounted on a magnetic base to measure the misalignment between the tailstock spindle bore and the headstock spindle bore. Using a dial indicator is essential for measuring initial misalignments accurately, providing clear data on. Dial Indicator On Tailstock.

From www.lfc.co.id

Jual Dial Gauge Indicator Jenis dan Contoh Dial Gauge Terbaik LFC Dial Indicator On Tailstock The dial indicator is moved along the length of the bar, and any misalignment between centers will be shown on the indicator. I will mount a piece of bar stock with a hole drilled in it to fit around the tailstock ram and mount the dial on the tailstock casting with. Using a dial indicator is essential for measuring initial. Dial Indicator On Tailstock.

From joicdmxnb.blob.core.windows.net

Dial Indicator Tolerance at Mary Dotson blog Dial Indicator On Tailstock The dial indicator is moved along the length of the bar, and any misalignment between centers will be shown on the indicator. Align a dial test indicator, digital test indicator dial drop indicator, or digital drop indicator that is held by a magnetic base. The three photos show the gauge indicating on the front, top and rear respectively. The indicator. Dial Indicator On Tailstock.

From www.homemodelenginemachinist.com

Adding dial indicator to lathe tailstock Home Model Engine Machinist Dial Indicator On Tailstock I adjust the tailstock and dial gauge such that when the chuck is rotated the gauge indicates any horizontal or vertical misalignment. Using a dial indicator is essential for measuring initial misalignments accurately, providing clear data on which areas require. I will mount a piece of bar stock with a hole drilled in it to fit around the tailstock ram. Dial Indicator On Tailstock.

From www.practicalmachinist.com

Ideas on mounting a dial indicator on tailstock Dial Indicator On Tailstock Use a dial indicator mounted on a magnetic base to measure the misalignment between the tailstock spindle bore and the headstock spindle bore. I adjust the tailstock and dial gauge such that when the chuck is rotated the gauge indicates any horizontal or vertical misalignment. The three photos show the gauge indicating on the front, top and rear respectively. The. Dial Indicator On Tailstock.

From www.youtube.com

Use a coaxial indicator to get your tailstock back in adjustment (Tips Dial Indicator On Tailstock Align a dial test indicator, digital test indicator dial drop indicator, or digital drop indicator that is held by a magnetic base. The three photos show the gauge indicating on the front, top and rear respectively. I will mount a piece of bar stock with a hole drilled in it to fit around the tailstock ram and mount the dial. Dial Indicator On Tailstock.

From www.magzter.com

Beginner's guide to tailstock alignment Dial Indicator On Tailstock Use a dial indicator to check the alignment between the spindle and tailstock quill. Use a dial indicator mounted on a magnetic base to measure the misalignment between the tailstock spindle bore and the headstock spindle bore. Align a dial test indicator, digital test indicator dial drop indicator, or digital drop indicator that is held by a magnetic base. I. Dial Indicator On Tailstock.

From www.pinterest.jp

Pin on Lathe Tailstock Dial Indicator On Tailstock Use a dial indicator mounted on a magnetic base to measure the misalignment between the tailstock spindle bore and the headstock spindle bore. Align a dial test indicator, digital test indicator dial drop indicator, or digital drop indicator that is held by a magnetic base. I adjust the tailstock and dial gauge such that when the chuck is rotated the. Dial Indicator On Tailstock.

From www.homemodelenginemachinist.com

Adding dial indicator to lathe tailstock Home Model Engine Machinist Dial Indicator On Tailstock Align a dial test indicator, digital test indicator dial drop indicator, or digital drop indicator that is held by a magnetic base. Use a dial indicator to check the alignment between the spindle and tailstock quill. The indicator should show no more than 0.001. Using a dial indicator is essential for measuring initial misalignments accurately, providing clear data on which. Dial Indicator On Tailstock.

From www.youtube.com

Dial Indicator Holder for Lathe Tailstock YouTube Dial Indicator On Tailstock I adjust the tailstock and dial gauge such that when the chuck is rotated the gauge indicates any horizontal or vertical misalignment. I will mount a piece of bar stock with a hole drilled in it to fit around the tailstock ram and mount the dial on the tailstock casting with. Use a dial indicator mounted on a magnetic base. Dial Indicator On Tailstock.

From www.practicalmachinist.com

Ideas on mounting a dial indicator on tailstock Dial Indicator On Tailstock Use a dial indicator mounted on a magnetic base to measure the misalignment between the tailstock spindle bore and the headstock spindle bore. Align a dial test indicator, digital test indicator dial drop indicator, or digital drop indicator that is held by a magnetic base. I will mount a piece of bar stock with a hole drilled in it to. Dial Indicator On Tailstock.

From www.youtube.com

Tail Stock Dial Indicator Attachment YouTube Dial Indicator On Tailstock I will mount a piece of bar stock with a hole drilled in it to fit around the tailstock ram and mount the dial on the tailstock casting with. Using a dial indicator is essential for measuring initial misalignments accurately, providing clear data on which areas require. The three photos show the gauge indicating on the front, top and rear. Dial Indicator On Tailstock.

From www.toolsid.com

Starrett® 81111630J 81 Series™ 0 to 0.25" SAE Dial Indicator Dial Indicator On Tailstock Using a dial indicator is essential for measuring initial misalignments accurately, providing clear data on which areas require. Align a dial test indicator, digital test indicator dial drop indicator, or digital drop indicator that is held by a magnetic base. I adjust the tailstock and dial gauge such that when the chuck is rotated the gauge indicates any horizontal or. Dial Indicator On Tailstock.

From ru.zipy.co.il

Купить Ибей South Bend 9" Metal Lathe Tailstock Tail stock Dial Dial Indicator On Tailstock The indicator should show no more than 0.001. Using a dial indicator is essential for measuring initial misalignments accurately, providing clear data on which areas require. The dial indicator is moved along the length of the bar, and any misalignment between centers will be shown on the indicator. I adjust the tailstock and dial gauge such that when the chuck. Dial Indicator On Tailstock.

From www.ebay.com

South Bend 9" Metal Lathe Tailstock Tail stock Dial Indicator Mount Dial Indicator On Tailstock The dial indicator is moved along the length of the bar, and any misalignment between centers will be shown on the indicator. In the context of a lathe, a dial indicator is used to measure the alignment and accuracy of various components, such as the bed, spindle, and tailstock. Align a dial test indicator, digital test indicator dial drop indicator,. Dial Indicator On Tailstock.

From www.reddit.com

100 mm Tailstock dial indicator r/Machinists Dial Indicator On Tailstock Use a dial indicator mounted on a magnetic base to measure the misalignment between the tailstock spindle bore and the headstock spindle bore. Use a dial indicator to check the alignment between the spindle and tailstock quill. The dial indicator is moved along the length of the bar, and any misalignment between centers will be shown on the indicator. The. Dial Indicator On Tailstock.

From www.reddit.com

100 mm Tailstock dial indicator r/Machinists Dial Indicator On Tailstock Align a dial test indicator, digital test indicator dial drop indicator, or digital drop indicator that is held by a magnetic base. I adjust the tailstock and dial gauge such that when the chuck is rotated the gauge indicates any horizontal or vertical misalignment. Using a dial indicator is essential for measuring initial misalignments accurately, providing clear data on which. Dial Indicator On Tailstock.

From www.ebay.com

South Bend 9" Metal Lathe Tailstock Tail stock Dial Indicator Mount Dial Indicator On Tailstock I will mount a piece of bar stock with a hole drilled in it to fit around the tailstock ram and mount the dial on the tailstock casting with. Use a dial indicator mounted on a magnetic base to measure the misalignment between the tailstock spindle bore and the headstock spindle bore. I adjust the tailstock and dial gauge such. Dial Indicator On Tailstock.

From www.pinterest.com

EE Tailstock Photo by brufsupbane Photobucket Machine shop projects Dial Indicator On Tailstock I will mount a piece of bar stock with a hole drilled in it to fit around the tailstock ram and mount the dial on the tailstock casting with. Align a dial test indicator, digital test indicator dial drop indicator, or digital drop indicator that is held by a magnetic base. Using a dial indicator is essential for measuring initial. Dial Indicator On Tailstock.

From www.stubmandrel.co.uk

Dr Schlesinger's Limits Dial Indicator On Tailstock The indicator should show no more than 0.001. The three photos show the gauge indicating on the front, top and rear respectively. In the context of a lathe, a dial indicator is used to measure the alignment and accuracy of various components, such as the bed, spindle, and tailstock. I adjust the tailstock and dial gauge such that when the. Dial Indicator On Tailstock.

From www.toolsid.com

Starrett® 25 Series™ Metric Dial Indicator Dial Indicator On Tailstock Use a dial indicator mounted on a magnetic base to measure the misalignment between the tailstock spindle bore and the headstock spindle bore. I will mount a piece of bar stock with a hole drilled in it to fit around the tailstock ram and mount the dial on the tailstock casting with. Use a dial indicator to check the alignment. Dial Indicator On Tailstock.

From www.ebay.com

South Bend 9" Metal Lathe Tailstock Tail stock Dial Indicator Mount Dial Indicator On Tailstock Align a dial test indicator, digital test indicator dial drop indicator, or digital drop indicator that is held by a magnetic base. I adjust the tailstock and dial gauge such that when the chuck is rotated the gauge indicates any horizontal or vertical misalignment. The three photos show the gauge indicating on the front, top and rear respectively. In the. Dial Indicator On Tailstock.

From www.youtube.com

Making a Tailstock Dial Indicator Stop for a Grizzly G0602 Lathe YouTube Dial Indicator On Tailstock Using a dial indicator is essential for measuring initial misalignments accurately, providing clear data on which areas require. Align a dial test indicator, digital test indicator dial drop indicator, or digital drop indicator that is held by a magnetic base. The three photos show the gauge indicating on the front, top and rear respectively. Use a dial indicator mounted on. Dial Indicator On Tailstock.

From www.ebay.com

South Bend 9" Metal Lathe Tailstock Tail stock Dial Indicator Mount Dial Indicator On Tailstock I adjust the tailstock and dial gauge such that when the chuck is rotated the gauge indicates any horizontal or vertical misalignment. Using a dial indicator is essential for measuring initial misalignments accurately, providing clear data on which areas require. Use a dial indicator to check the alignment between the spindle and tailstock quill. The indicator should show no more. Dial Indicator On Tailstock.