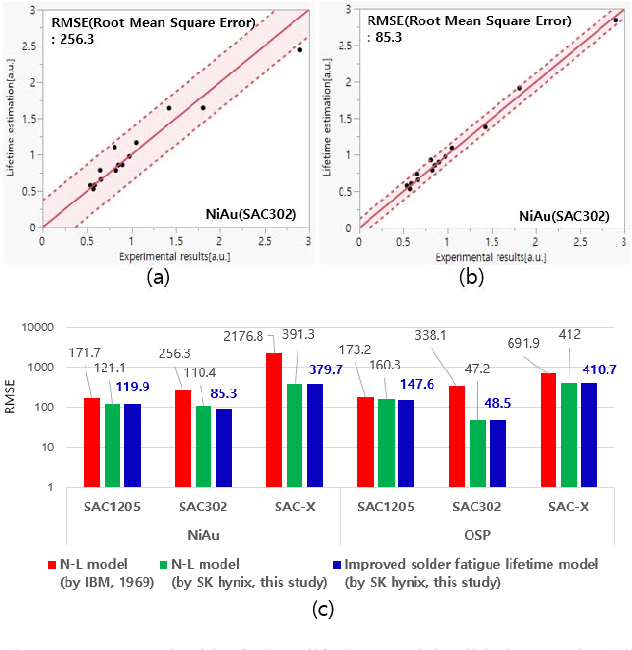

Solder Joint Reliability Temperature Cycling . The lifetime of the solder joint between base plate and ceramic substrate is usually tested by passively heating and cooling the igbt module. A solder joint reliability simulation helps you determine whether these joints will fail at high temperatures or under repeated thermal. Thermal fatigue failure cause d by the cte mismatches among silicon chip, substrate, and solder joint is the dominant failure mechanism. Wlcsp faces reliability challenges due to the coefficient of thermal expansion mismatch, mechanical shocks, vibrations, and. Temperature cycling, thermal cycling, fatigue, reliability, solder joint reliability. The mismatch between the coefficient of thermal expansion (cte) of the printed circuit board (pcb), the solder joints,. Therefore, we have developed a newly improved acceleration model through a design of experiments (doe) evaluation of.

from www.semanticscholar.org

Temperature cycling, thermal cycling, fatigue, reliability, solder joint reliability. The lifetime of the solder joint between base plate and ceramic substrate is usually tested by passively heating and cooling the igbt module. Thermal fatigue failure cause d by the cte mismatches among silicon chip, substrate, and solder joint is the dominant failure mechanism. Therefore, we have developed a newly improved acceleration model through a design of experiments (doe) evaluation of. Wlcsp faces reliability challenges due to the coefficient of thermal expansion mismatch, mechanical shocks, vibrations, and. The mismatch between the coefficient of thermal expansion (cte) of the printed circuit board (pcb), the solder joints,. A solder joint reliability simulation helps you determine whether these joints will fail at high temperatures or under repeated thermal.

Figure 3 from A Comprehensive Study of Solder Joint Reliability

Solder Joint Reliability Temperature Cycling Temperature cycling, thermal cycling, fatigue, reliability, solder joint reliability. Therefore, we have developed a newly improved acceleration model through a design of experiments (doe) evaluation of. Temperature cycling, thermal cycling, fatigue, reliability, solder joint reliability. The lifetime of the solder joint between base plate and ceramic substrate is usually tested by passively heating and cooling the igbt module. Wlcsp faces reliability challenges due to the coefficient of thermal expansion mismatch, mechanical shocks, vibrations, and. Thermal fatigue failure cause d by the cte mismatches among silicon chip, substrate, and solder joint is the dominant failure mechanism. The mismatch between the coefficient of thermal expansion (cte) of the printed circuit board (pcb), the solder joints,. A solder joint reliability simulation helps you determine whether these joints will fail at high temperatures or under repeated thermal.

From www.researchgate.net

(PDF) EFFECTS OF LONGTERM AGING ON SnAgCu SOLDER JOINTS RELIABILITY IN Solder Joint Reliability Temperature Cycling A solder joint reliability simulation helps you determine whether these joints will fail at high temperatures or under repeated thermal. The lifetime of the solder joint between base plate and ceramic substrate is usually tested by passively heating and cooling the igbt module. Therefore, we have developed a newly improved acceleration model through a design of experiments (doe) evaluation of.. Solder Joint Reliability Temperature Cycling.

From dokumen.tips

(PDF) Thermal cycling reliability of SnAgCu and SnPb solder joints A Solder Joint Reliability Temperature Cycling The lifetime of the solder joint between base plate and ceramic substrate is usually tested by passively heating and cooling the igbt module. Therefore, we have developed a newly improved acceleration model through a design of experiments (doe) evaluation of. Wlcsp faces reliability challenges due to the coefficient of thermal expansion mismatch, mechanical shocks, vibrations, and. Thermal fatigue failure cause. Solder Joint Reliability Temperature Cycling.

From www.semanticscholar.org

Figure 6 from A Comprehensive Study of Solder Joint Reliability Solder Joint Reliability Temperature Cycling A solder joint reliability simulation helps you determine whether these joints will fail at high temperatures or under repeated thermal. Therefore, we have developed a newly improved acceleration model through a design of experiments (doe) evaluation of. The mismatch between the coefficient of thermal expansion (cte) of the printed circuit board (pcb), the solder joints,. The lifetime of the solder. Solder Joint Reliability Temperature Cycling.

From www.researchgate.net

(PDF) Reliability Assessment of Preloaded Solder Joint Under Thermal Solder Joint Reliability Temperature Cycling Therefore, we have developed a newly improved acceleration model through a design of experiments (doe) evaluation of. The lifetime of the solder joint between base plate and ceramic substrate is usually tested by passively heating and cooling the igbt module. Temperature cycling, thermal cycling, fatigue, reliability, solder joint reliability. Wlcsp faces reliability challenges due to the coefficient of thermal expansion. Solder Joint Reliability Temperature Cycling.

From www.researchgate.net

(PDF) Solderjoint reliability of HVQFNpackages subjected to thermal Solder Joint Reliability Temperature Cycling Wlcsp faces reliability challenges due to the coefficient of thermal expansion mismatch, mechanical shocks, vibrations, and. A solder joint reliability simulation helps you determine whether these joints will fail at high temperatures or under repeated thermal. The mismatch between the coefficient of thermal expansion (cte) of the printed circuit board (pcb), the solder joints,. Temperature cycling, thermal cycling, fatigue, reliability,. Solder Joint Reliability Temperature Cycling.

From www.slideserve.com

PPT Solder Joint Reliability Assessed by Acoustic Imaging during Solder Joint Reliability Temperature Cycling A solder joint reliability simulation helps you determine whether these joints will fail at high temperatures or under repeated thermal. The mismatch between the coefficient of thermal expansion (cte) of the printed circuit board (pcb), the solder joints,. Wlcsp faces reliability challenges due to the coefficient of thermal expansion mismatch, mechanical shocks, vibrations, and. Thermal fatigue failure cause d by. Solder Joint Reliability Temperature Cycling.

From www.slideserve.com

PPT Solder Joint Reliability Assessed by Acoustic Imaging during Solder Joint Reliability Temperature Cycling Wlcsp faces reliability challenges due to the coefficient of thermal expansion mismatch, mechanical shocks, vibrations, and. Temperature cycling, thermal cycling, fatigue, reliability, solder joint reliability. The mismatch between the coefficient of thermal expansion (cte) of the printed circuit board (pcb), the solder joints,. A solder joint reliability simulation helps you determine whether these joints will fail at high temperatures or. Solder Joint Reliability Temperature Cycling.

From www.slideserve.com

PPT Solder Joint Reliability Assessed by Acoustic Imaging during Solder Joint Reliability Temperature Cycling The lifetime of the solder joint between base plate and ceramic substrate is usually tested by passively heating and cooling the igbt module. Wlcsp faces reliability challenges due to the coefficient of thermal expansion mismatch, mechanical shocks, vibrations, and. Therefore, we have developed a newly improved acceleration model through a design of experiments (doe) evaluation of. Temperature cycling, thermal cycling,. Solder Joint Reliability Temperature Cycling.

From docslib.org

Investigation and Prediction of Solder Joint Reliability for Ceramic Solder Joint Reliability Temperature Cycling The lifetime of the solder joint between base plate and ceramic substrate is usually tested by passively heating and cooling the igbt module. Temperature cycling, thermal cycling, fatigue, reliability, solder joint reliability. The mismatch between the coefficient of thermal expansion (cte) of the printed circuit board (pcb), the solder joints,. Therefore, we have developed a newly improved acceleration model through. Solder Joint Reliability Temperature Cycling.

From www.slideserve.com

PPT Solder Joint Reliability Assessed by Acoustic Imaging during Solder Joint Reliability Temperature Cycling The mismatch between the coefficient of thermal expansion (cte) of the printed circuit board (pcb), the solder joints,. A solder joint reliability simulation helps you determine whether these joints will fail at high temperatures or under repeated thermal. The lifetime of the solder joint between base plate and ceramic substrate is usually tested by passively heating and cooling the igbt. Solder Joint Reliability Temperature Cycling.

From www.semanticscholar.org

Figure 5 from A Comprehensive Study of Solder Joint Reliability Solder Joint Reliability Temperature Cycling Temperature cycling, thermal cycling, fatigue, reliability, solder joint reliability. Therefore, we have developed a newly improved acceleration model through a design of experiments (doe) evaluation of. Thermal fatigue failure cause d by the cte mismatches among silicon chip, substrate, and solder joint is the dominant failure mechanism. A solder joint reliability simulation helps you determine whether these joints will fail. Solder Joint Reliability Temperature Cycling.

From www.researchgate.net

(PDF) Fatigue Reliability Analysis of SnAgCu Solder Joints Subject to Solder Joint Reliability Temperature Cycling The mismatch between the coefficient of thermal expansion (cte) of the printed circuit board (pcb), the solder joints,. Temperature cycling, thermal cycling, fatigue, reliability, solder joint reliability. Therefore, we have developed a newly improved acceleration model through a design of experiments (doe) evaluation of. A solder joint reliability simulation helps you determine whether these joints will fail at high temperatures. Solder Joint Reliability Temperature Cycling.

From www.researchgate.net

(PDF) Reliability of leadfree solder joints in CSP device under Solder Joint Reliability Temperature Cycling Wlcsp faces reliability challenges due to the coefficient of thermal expansion mismatch, mechanical shocks, vibrations, and. Therefore, we have developed a newly improved acceleration model through a design of experiments (doe) evaluation of. The lifetime of the solder joint between base plate and ceramic substrate is usually tested by passively heating and cooling the igbt module. The mismatch between the. Solder Joint Reliability Temperature Cycling.

From www.semanticscholar.org

Figure 2 from Low Temperature Soldering Thermal Cycling Reliability Solder Joint Reliability Temperature Cycling Therefore, we have developed a newly improved acceleration model through a design of experiments (doe) evaluation of. Temperature cycling, thermal cycling, fatigue, reliability, solder joint reliability. The lifetime of the solder joint between base plate and ceramic substrate is usually tested by passively heating and cooling the igbt module. The mismatch between the coefficient of thermal expansion (cte) of the. Solder Joint Reliability Temperature Cycling.

From www.researchgate.net

(PDF) Study on Board Level Solder Joint Reliability for Extreme Large Solder Joint Reliability Temperature Cycling Therefore, we have developed a newly improved acceleration model through a design of experiments (doe) evaluation of. Temperature cycling, thermal cycling, fatigue, reliability, solder joint reliability. Thermal fatigue failure cause d by the cte mismatches among silicon chip, substrate, and solder joint is the dominant failure mechanism. The lifetime of the solder joint between base plate and ceramic substrate is. Solder Joint Reliability Temperature Cycling.

From www.doeeet.com

Soldering Verification of EEE parts SMD and PCBs Solder Joint Reliability Temperature Cycling Wlcsp faces reliability challenges due to the coefficient of thermal expansion mismatch, mechanical shocks, vibrations, and. The lifetime of the solder joint between base plate and ceramic substrate is usually tested by passively heating and cooling the igbt module. Thermal fatigue failure cause d by the cte mismatches among silicon chip, substrate, and solder joint is the dominant failure mechanism.. Solder Joint Reliability Temperature Cycling.

From studylib.net

Thermal cycling reliability of SnAgCu and SnPb solder joints a Solder Joint Reliability Temperature Cycling Wlcsp faces reliability challenges due to the coefficient of thermal expansion mismatch, mechanical shocks, vibrations, and. A solder joint reliability simulation helps you determine whether these joints will fail at high temperatures or under repeated thermal. Therefore, we have developed a newly improved acceleration model through a design of experiments (doe) evaluation of. The lifetime of the solder joint between. Solder Joint Reliability Temperature Cycling.

From www.semanticscholar.org

Figure 3 from Effect of temperature cycling on reliability of flip chip Solder Joint Reliability Temperature Cycling The mismatch between the coefficient of thermal expansion (cte) of the printed circuit board (pcb), the solder joints,. Therefore, we have developed a newly improved acceleration model through a design of experiments (doe) evaluation of. Thermal fatigue failure cause d by the cte mismatches among silicon chip, substrate, and solder joint is the dominant failure mechanism. The lifetime of the. Solder Joint Reliability Temperature Cycling.

From www.semanticscholar.org

Figure 4 from A Comprehensive Study of Solder Joint Reliability Solder Joint Reliability Temperature Cycling Therefore, we have developed a newly improved acceleration model through a design of experiments (doe) evaluation of. Temperature cycling, thermal cycling, fatigue, reliability, solder joint reliability. The mismatch between the coefficient of thermal expansion (cte) of the printed circuit board (pcb), the solder joints,. Thermal fatigue failure cause d by the cte mismatches among silicon chip, substrate, and solder joint. Solder Joint Reliability Temperature Cycling.

From www.semanticscholar.org

Figure 1 from Low Temperature Soldering Thermal Cycling Reliability Solder Joint Reliability Temperature Cycling Temperature cycling, thermal cycling, fatigue, reliability, solder joint reliability. Thermal fatigue failure cause d by the cte mismatches among silicon chip, substrate, and solder joint is the dominant failure mechanism. Therefore, we have developed a newly improved acceleration model through a design of experiments (doe) evaluation of. The lifetime of the solder joint between base plate and ceramic substrate is. Solder Joint Reliability Temperature Cycling.

From blog.ozeninc.com

Simulating Impact of Thermal Cycling on Solder Joint Reliability Solder Joint Reliability Temperature Cycling Therefore, we have developed a newly improved acceleration model through a design of experiments (doe) evaluation of. The mismatch between the coefficient of thermal expansion (cte) of the printed circuit board (pcb), the solder joints,. Temperature cycling, thermal cycling, fatigue, reliability, solder joint reliability. The lifetime of the solder joint between base plate and ceramic substrate is usually tested by. Solder Joint Reliability Temperature Cycling.

From www.semanticscholar.org

Figure 1 from A Comprehensive Study of Solder Joint Reliability Solder Joint Reliability Temperature Cycling Thermal fatigue failure cause d by the cte mismatches among silicon chip, substrate, and solder joint is the dominant failure mechanism. Therefore, we have developed a newly improved acceleration model through a design of experiments (doe) evaluation of. Wlcsp faces reliability challenges due to the coefficient of thermal expansion mismatch, mechanical shocks, vibrations, and. The lifetime of the solder joint. Solder Joint Reliability Temperature Cycling.

From www.researchgate.net

(PDF) An acceleration model for leadfree (SAC) solder joint Solder Joint Reliability Temperature Cycling The mismatch between the coefficient of thermal expansion (cte) of the printed circuit board (pcb), the solder joints,. A solder joint reliability simulation helps you determine whether these joints will fail at high temperatures or under repeated thermal. The lifetime of the solder joint between base plate and ceramic substrate is usually tested by passively heating and cooling the igbt. Solder Joint Reliability Temperature Cycling.

From smtnet.com

Reliability of LeadFree Solder Joints in Thermal Cycling Solder Joint Reliability Temperature Cycling Temperature cycling, thermal cycling, fatigue, reliability, solder joint reliability. A solder joint reliability simulation helps you determine whether these joints will fail at high temperatures or under repeated thermal. Thermal fatigue failure cause d by the cte mismatches among silicon chip, substrate, and solder joint is the dominant failure mechanism. The lifetime of the solder joint between base plate and. Solder Joint Reliability Temperature Cycling.

From www.semanticscholar.org

Predictive modeling and experimental validation of leadfree solder Solder Joint Reliability Temperature Cycling Therefore, we have developed a newly improved acceleration model through a design of experiments (doe) evaluation of. Thermal fatigue failure cause d by the cte mismatches among silicon chip, substrate, and solder joint is the dominant failure mechanism. The lifetime of the solder joint between base plate and ceramic substrate is usually tested by passively heating and cooling the igbt. Solder Joint Reliability Temperature Cycling.

From www.researchgate.net

Temperature cycling profile used in the FEA. Download Scientific Diagram Solder Joint Reliability Temperature Cycling Therefore, we have developed a newly improved acceleration model through a design of experiments (doe) evaluation of. Thermal fatigue failure cause d by the cte mismatches among silicon chip, substrate, and solder joint is the dominant failure mechanism. A solder joint reliability simulation helps you determine whether these joints will fail at high temperatures or under repeated thermal. Wlcsp faces. Solder Joint Reliability Temperature Cycling.

From www.researchgate.net

Crack in a SnAgCu solder joint after thermal cycling. Download Solder Joint Reliability Temperature Cycling Therefore, we have developed a newly improved acceleration model through a design of experiments (doe) evaluation of. Wlcsp faces reliability challenges due to the coefficient of thermal expansion mismatch, mechanical shocks, vibrations, and. The mismatch between the coefficient of thermal expansion (cte) of the printed circuit board (pcb), the solder joints,. Temperature cycling, thermal cycling, fatigue, reliability, solder joint reliability.. Solder Joint Reliability Temperature Cycling.

From www.mdpi.com

Reliability Study of Solder Paste Alloy for the Improvement of Solder Solder Joint Reliability Temperature Cycling Therefore, we have developed a newly improved acceleration model through a design of experiments (doe) evaluation of. The mismatch between the coefficient of thermal expansion (cte) of the printed circuit board (pcb), the solder joints,. The lifetime of the solder joint between base plate and ceramic substrate is usually tested by passively heating and cooling the igbt module. A solder. Solder Joint Reliability Temperature Cycling.

From www.trelic.fi

Critical parameters of thermal cycling testing Trelic Solutions for Solder Joint Reliability Temperature Cycling Wlcsp faces reliability challenges due to the coefficient of thermal expansion mismatch, mechanical shocks, vibrations, and. Therefore, we have developed a newly improved acceleration model through a design of experiments (doe) evaluation of. The lifetime of the solder joint between base plate and ceramic substrate is usually tested by passively heating and cooling the igbt module. The mismatch between the. Solder Joint Reliability Temperature Cycling.

From www.researchgate.net

Effect of temperature range on the solder joint reliability. Download Solder Joint Reliability Temperature Cycling The lifetime of the solder joint between base plate and ceramic substrate is usually tested by passively heating and cooling the igbt module. Temperature cycling, thermal cycling, fatigue, reliability, solder joint reliability. The mismatch between the coefficient of thermal expansion (cte) of the printed circuit board (pcb), the solder joints,. Wlcsp faces reliability challenges due to the coefficient of thermal. Solder Joint Reliability Temperature Cycling.

From www.slideserve.com

PPT Solder Joint Reliability Assessed by Acoustic Imaging during Solder Joint Reliability Temperature Cycling The lifetime of the solder joint between base plate and ceramic substrate is usually tested by passively heating and cooling the igbt module. Wlcsp faces reliability challenges due to the coefficient of thermal expansion mismatch, mechanical shocks, vibrations, and. Temperature cycling, thermal cycling, fatigue, reliability, solder joint reliability. Therefore, we have developed a newly improved acceleration model through a design. Solder Joint Reliability Temperature Cycling.

From www.mdpi.com

Metals Free FullText Analysis of Microstructure and Mechanical Solder Joint Reliability Temperature Cycling Thermal fatigue failure cause d by the cte mismatches among silicon chip, substrate, and solder joint is the dominant failure mechanism. A solder joint reliability simulation helps you determine whether these joints will fail at high temperatures or under repeated thermal. The lifetime of the solder joint between base plate and ceramic substrate is usually tested by passively heating and. Solder Joint Reliability Temperature Cycling.

From www.semanticscholar.org

Figure 3 from A Comprehensive Study of Solder Joint Reliability Solder Joint Reliability Temperature Cycling Thermal fatigue failure cause d by the cte mismatches among silicon chip, substrate, and solder joint is the dominant failure mechanism. Temperature cycling, thermal cycling, fatigue, reliability, solder joint reliability. Therefore, we have developed a newly improved acceleration model through a design of experiments (doe) evaluation of. The lifetime of the solder joint between base plate and ceramic substrate is. Solder Joint Reliability Temperature Cycling.

From www.researchgate.net

JEDEC JESD22A104E Temperature Cycle Testing Profile [45] Download Solder Joint Reliability Temperature Cycling A solder joint reliability simulation helps you determine whether these joints will fail at high temperatures or under repeated thermal. The lifetime of the solder joint between base plate and ceramic substrate is usually tested by passively heating and cooling the igbt module. The mismatch between the coefficient of thermal expansion (cte) of the printed circuit board (pcb), the solder. Solder Joint Reliability Temperature Cycling.

From www.researchgate.net

(PDF) Board level solder reliability vs. ramp rate & dwell time during Solder Joint Reliability Temperature Cycling Therefore, we have developed a newly improved acceleration model through a design of experiments (doe) evaluation of. Thermal fatigue failure cause d by the cte mismatches among silicon chip, substrate, and solder joint is the dominant failure mechanism. The mismatch between the coefficient of thermal expansion (cte) of the printed circuit board (pcb), the solder joints,. The lifetime of the. Solder Joint Reliability Temperature Cycling.