How To Shape Spring Steel . Spring steel very bendable when fully annealed. Producing spring steel involves a series of precise steps, from selecting the right materials to heat treatment processes. It has high corrosion resistance, making it suitable for use in harsh conditions. Most of them you heat them to shape, then quench in oil or saltwater if you. There are a few different types of spring steel. This guide on how to bend spring steel covers the essential steps, including preparation, heating, bending, and cooling. The technique that works for. The tensile strength and thickness of the material, type of tooling, and the type of bending all greatly influence springback. In addition to high yield strength, spring steels also possess excellent tensile strength and fatigue strength. You’ll need to heat treat it again to get it to perform like spring steel once it’s formed in the shape you want.

from www.vectorstock.com

It has high corrosion resistance, making it suitable for use in harsh conditions. Most of them you heat them to shape, then quench in oil or saltwater if you. The tensile strength and thickness of the material, type of tooling, and the type of bending all greatly influence springback. The technique that works for. In addition to high yield strength, spring steels also possess excellent tensile strength and fatigue strength. Producing spring steel involves a series of precise steps, from selecting the right materials to heat treatment processes. You’ll need to heat treat it again to get it to perform like spring steel once it’s formed in the shape you want. There are a few different types of spring steel. This guide on how to bend spring steel covers the essential steps, including preparation, heating, bending, and cooling. Spring steel very bendable when fully annealed.

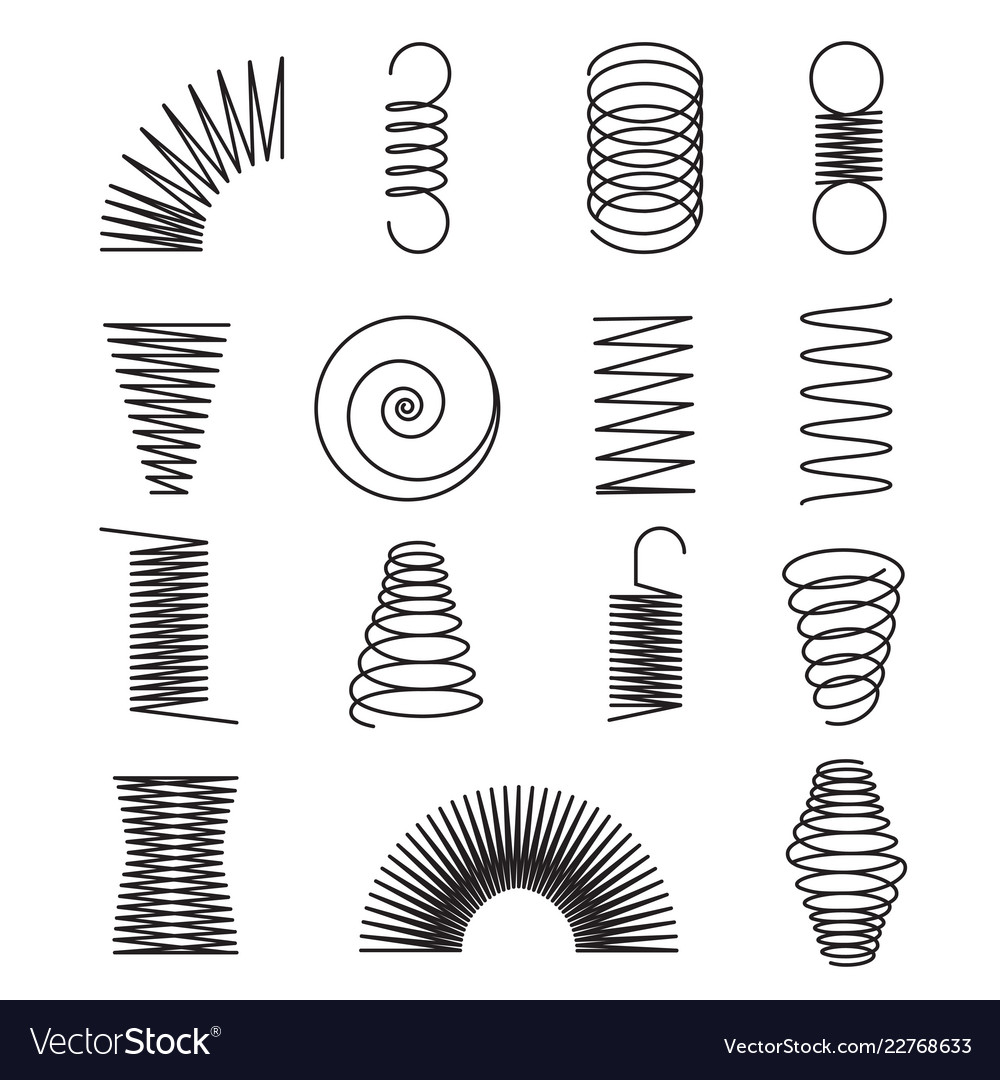

Metal springs spiral lines coil shapes isolated Vector Image

How To Shape Spring Steel Producing spring steel involves a series of precise steps, from selecting the right materials to heat treatment processes. There are a few different types of spring steel. In addition to high yield strength, spring steels also possess excellent tensile strength and fatigue strength. It has high corrosion resistance, making it suitable for use in harsh conditions. This guide on how to bend spring steel covers the essential steps, including preparation, heating, bending, and cooling. You’ll need to heat treat it again to get it to perform like spring steel once it’s formed in the shape you want. The technique that works for. Most of them you heat them to shape, then quench in oil or saltwater if you. The tensile strength and thickness of the material, type of tooling, and the type of bending all greatly influence springback. Producing spring steel involves a series of precise steps, from selecting the right materials to heat treatment processes. Spring steel very bendable when fully annealed.

From www.aps-ct.com

Plating & Finishing Capabilities Atlantic Precision Spring, Inc. How To Shape Spring Steel The tensile strength and thickness of the material, type of tooling, and the type of bending all greatly influence springback. It has high corrosion resistance, making it suitable for use in harsh conditions. Producing spring steel involves a series of precise steps, from selecting the right materials to heat treatment processes. You’ll need to heat treat it again to get. How To Shape Spring Steel.

From www.jamesspring.com

The Most Common Spring Wire Materials Springs Fabrication How To Shape Spring Steel You’ll need to heat treat it again to get it to perform like spring steel once it’s formed in the shape you want. There are a few different types of spring steel. In addition to high yield strength, spring steels also possess excellent tensile strength and fatigue strength. The tensile strength and thickness of the material, type of tooling, and. How To Shape Spring Steel.

From www.southwire.com

Spring Steel Southwire How To Shape Spring Steel You’ll need to heat treat it again to get it to perform like spring steel once it’s formed in the shape you want. This guide on how to bend spring steel covers the essential steps, including preparation, heating, bending, and cooling. The tensile strength and thickness of the material, type of tooling, and the type of bending all greatly influence. How To Shape Spring Steel.

From bestinau.com.au

What Are The Main Types of Spring Steel? [SOLVED] How To Shape Spring Steel In addition to high yield strength, spring steels also possess excellent tensile strength and fatigue strength. Producing spring steel involves a series of precise steps, from selecting the right materials to heat treatment processes. This guide on how to bend spring steel covers the essential steps, including preparation, heating, bending, and cooling. The technique that works for. There are a. How To Shape Spring Steel.

From www.okorder.com

Spring Steel Wire for Making Spring& Wire Forms Buy Metal Building How To Shape Spring Steel The technique that works for. Spring steel very bendable when fully annealed. Producing spring steel involves a series of precise steps, from selecting the right materials to heat treatment processes. It has high corrosion resistance, making it suitable for use in harsh conditions. There are a few different types of spring steel. In addition to high yield strength, spring steels. How To Shape Spring Steel.

From www.youtube.com

How to design a rectangular spring in SOLIDWORKS. YouTube How To Shape Spring Steel Most of them you heat them to shape, then quench in oil or saltwater if you. You’ll need to heat treat it again to get it to perform like spring steel once it’s formed in the shape you want. The technique that works for. There are a few different types of spring steel. Producing spring steel involves a series of. How To Shape Spring Steel.

From www.airedalesprings.co.uk

Spring Materials Information Airedale Springs How To Shape Spring Steel You’ll need to heat treat it again to get it to perform like spring steel once it’s formed in the shape you want. This guide on how to bend spring steel covers the essential steps, including preparation, heating, bending, and cooling. Producing spring steel involves a series of precise steps, from selecting the right materials to heat treatment processes. The. How To Shape Spring Steel.

From www.metalsupermarkets.com

What Is Spring Steel? Metal Supermarkets How To Shape Spring Steel It has high corrosion resistance, making it suitable for use in harsh conditions. The technique that works for. In addition to high yield strength, spring steels also possess excellent tensile strength and fatigue strength. This guide on how to bend spring steel covers the essential steps, including preparation, heating, bending, and cooling. Spring steel very bendable when fully annealed. Most. How To Shape Spring Steel.

From senometal.com

SPRING STEEL SENO METAL INC. How To Shape Spring Steel The technique that works for. The tensile strength and thickness of the material, type of tooling, and the type of bending all greatly influence springback. Most of them you heat them to shape, then quench in oil or saltwater if you. Producing spring steel involves a series of precise steps, from selecting the right materials to heat treatment processes. This. How To Shape Spring Steel.

From www.youtube.com

Shaping spring steel YouTube How To Shape Spring Steel Spring steel very bendable when fully annealed. This guide on how to bend spring steel covers the essential steps, including preparation, heating, bending, and cooling. You’ll need to heat treat it again to get it to perform like spring steel once it’s formed in the shape you want. There are a few different types of spring steel. Producing spring steel. How To Shape Spring Steel.

From www.linquip.com

How Springs Are Made 5 Fundamental Steps How To Shape Spring Steel There are a few different types of spring steel. It has high corrosion resistance, making it suitable for use in harsh conditions. The technique that works for. In addition to high yield strength, spring steels also possess excellent tensile strength and fatigue strength. The tensile strength and thickness of the material, type of tooling, and the type of bending all. How To Shape Spring Steel.

From samuraiswords.store

9260 Spring Steel Beginners Guide to 9260 Steel Katana How To Shape Spring Steel There are a few different types of spring steel. This guide on how to bend spring steel covers the essential steps, including preparation, heating, bending, and cooling. The technique that works for. Most of them you heat them to shape, then quench in oil or saltwater if you. In addition to high yield strength, spring steels also possess excellent tensile. How To Shape Spring Steel.

From www.vectorstock.com

Coil spring steel spring metal spring on white ba Vector Image How To Shape Spring Steel You’ll need to heat treat it again to get it to perform like spring steel once it’s formed in the shape you want. Most of them you heat them to shape, then quench in oil or saltwater if you. There are a few different types of spring steel. It has high corrosion resistance, making it suitable for use in harsh. How To Shape Spring Steel.

From www.aerospacealloy.com

Benefits & Uses of Spring Steel EN42J Sheet How To Shape Spring Steel The tensile strength and thickness of the material, type of tooling, and the type of bending all greatly influence springback. Most of them you heat them to shape, then quench in oil or saltwater if you. The technique that works for. In addition to high yield strength, spring steels also possess excellent tensile strength and fatigue strength. Spring steel very. How To Shape Spring Steel.

From www.iqsdirectory.com

Compression Springs Materials, Types, Applications, and Advantages How To Shape Spring Steel It has high corrosion resistance, making it suitable for use in harsh conditions. The tensile strength and thickness of the material, type of tooling, and the type of bending all greatly influence springback. There are a few different types of spring steel. Spring steel very bendable when fully annealed. Producing spring steel involves a series of precise steps, from selecting. How To Shape Spring Steel.

From www.pinterest.co.kr

Pin on Metal How To Shape Spring Steel Spring steel very bendable when fully annealed. The technique that works for. There are a few different types of spring steel. Most of them you heat them to shape, then quench in oil or saltwater if you. In addition to high yield strength, spring steels also possess excellent tensile strength and fatigue strength. It has high corrosion resistance, making it. How To Shape Spring Steel.

From blog.thepipingmart.com

9260 Spring Steel Composition, Properties and Uses How To Shape Spring Steel Producing spring steel involves a series of precise steps, from selecting the right materials to heat treatment processes. There are a few different types of spring steel. Most of them you heat them to shape, then quench in oil or saltwater if you. Spring steel very bendable when fully annealed. The tensile strength and thickness of the material, type of. How To Shape Spring Steel.

From www.eigenplus.com

What are different steel sections used for construction? eigenplus How To Shape Spring Steel Most of them you heat them to shape, then quench in oil or saltwater if you. The tensile strength and thickness of the material, type of tooling, and the type of bending all greatly influence springback. There are a few different types of spring steel. This guide on how to bend spring steel covers the essential steps, including preparation, heating,. How To Shape Spring Steel.

From engineeringlearn.com

Types of Spring and Their Uses [with Pictures] Engineering Learn How To Shape Spring Steel Most of them you heat them to shape, then quench in oil or saltwater if you. There are a few different types of spring steel. This guide on how to bend spring steel covers the essential steps, including preparation, heating, bending, and cooling. In addition to high yield strength, spring steels also possess excellent tensile strength and fatigue strength. Producing. How To Shape Spring Steel.

From www.springworksutah.com

Custom Flat Springs Spring Works Utah Inc. How To Shape Spring Steel In addition to high yield strength, spring steels also possess excellent tensile strength and fatigue strength. Producing spring steel involves a series of precise steps, from selecting the right materials to heat treatment processes. It has high corrosion resistance, making it suitable for use in harsh conditions. You’ll need to heat treat it again to get it to perform like. How To Shape Spring Steel.

From www.metalwireforms.com

Custom High Quality Square Rectangular Compression Spring Metal Wire How To Shape Spring Steel There are a few different types of spring steel. You’ll need to heat treat it again to get it to perform like spring steel once it’s formed in the shape you want. The tensile strength and thickness of the material, type of tooling, and the type of bending all greatly influence springback. This guide on how to bend spring steel. How To Shape Spring Steel.

From www.mech4study.com

What is Spring? What are Types of Springs? Mech4study How To Shape Spring Steel Most of them you heat them to shape, then quench in oil or saltwater if you. Producing spring steel involves a series of precise steps, from selecting the right materials to heat treatment processes. Spring steel very bendable when fully annealed. This guide on how to bend spring steel covers the essential steps, including preparation, heating, bending, and cooling. The. How To Shape Spring Steel.

From www.jamesspring.com

Types of Steel Springs and Their Unique Characteristics & Applications How To Shape Spring Steel You’ll need to heat treat it again to get it to perform like spring steel once it’s formed in the shape you want. There are a few different types of spring steel. Producing spring steel involves a series of precise steps, from selecting the right materials to heat treatment processes. This guide on how to bend spring steel covers the. How To Shape Spring Steel.

From www.youtube.com

How to make Spring steel in 3ds max ? ( basic tutorial Tyflow ) YouTube How To Shape Spring Steel Producing spring steel involves a series of precise steps, from selecting the right materials to heat treatment processes. In addition to high yield strength, spring steels also possess excellent tensile strength and fatigue strength. Spring steel very bendable when fully annealed. You’ll need to heat treat it again to get it to perform like spring steel once it’s formed in. How To Shape Spring Steel.

From www.vectorstock.com

Metal springs spiral lines coil shapes isolated Vector Image How To Shape Spring Steel You’ll need to heat treat it again to get it to perform like spring steel once it’s formed in the shape you want. There are a few different types of spring steel. It has high corrosion resistance, making it suitable for use in harsh conditions. This guide on how to bend spring steel covers the essential steps, including preparation, heating,. How To Shape Spring Steel.

From www.metalwireforms.com

Stainless steel Sshaped spring production and processing Metal Wire How To Shape Spring Steel You’ll need to heat treat it again to get it to perform like spring steel once it’s formed in the shape you want. This guide on how to bend spring steel covers the essential steps, including preparation, heating, bending, and cooling. The technique that works for. It has high corrosion resistance, making it suitable for use in harsh conditions. Spring. How To Shape Spring Steel.

From furnilly.com

What Is Spring Steel? A Closer Look At This Unique Material How To Shape Spring Steel Spring steel very bendable when fully annealed. Most of them you heat them to shape, then quench in oil or saltwater if you. It has high corrosion resistance, making it suitable for use in harsh conditions. The tensile strength and thickness of the material, type of tooling, and the type of bending all greatly influence springback. Producing spring steel involves. How To Shape Spring Steel.

From samuraiswords.store

9260 Spring Steel Beginners Guide to 9260 Steel Katana How To Shape Spring Steel Producing spring steel involves a series of precise steps, from selecting the right materials to heat treatment processes. The tensile strength and thickness of the material, type of tooling, and the type of bending all greatly influence springback. Spring steel very bendable when fully annealed. In addition to high yield strength, spring steels also possess excellent tensile strength and fatigue. How To Shape Spring Steel.

From sheetstainlesssteel.com

Spring Steel vs Stainless Steel A Comprehensive Comparison How To Shape Spring Steel This guide on how to bend spring steel covers the essential steps, including preparation, heating, bending, and cooling. There are a few different types of spring steel. In addition to high yield strength, spring steels also possess excellent tensile strength and fatigue strength. The technique that works for. Spring steel very bendable when fully annealed. It has high corrosion resistance,. How To Shape Spring Steel.

From www.meadmetals.com

Mead Metals Blog Annealed Spring Steel How To Shape Spring Steel Most of them you heat them to shape, then quench in oil or saltwater if you. In addition to high yield strength, spring steels also possess excellent tensile strength and fatigue strength. This guide on how to bend spring steel covers the essential steps, including preparation, heating, bending, and cooling. Producing spring steel involves a series of precise steps, from. How To Shape Spring Steel.

From blog.thepipingmart.com

How To Make Spring Steel From Mild Steel A Complete Guide How To Shape Spring Steel Producing spring steel involves a series of precise steps, from selecting the right materials to heat treatment processes. It has high corrosion resistance, making it suitable for use in harsh conditions. The tensile strength and thickness of the material, type of tooling, and the type of bending all greatly influence springback. The technique that works for. You’ll need to heat. How To Shape Spring Steel.

From www.metalwireforms.com

Custom Stainless Steel Metal Sshaped Flat Spring Metal Wire Forms Custom How To Shape Spring Steel Spring steel very bendable when fully annealed. This guide on how to bend spring steel covers the essential steps, including preparation, heating, bending, and cooling. Most of them you heat them to shape, then quench in oil or saltwater if you. In addition to high yield strength, spring steels also possess excellent tensile strength and fatigue strength. You’ll need to. How To Shape Spring Steel.

From www.masterspring.com

Compression Springs Resources Helical Compression Spring Design How To Shape Spring Steel There are a few different types of spring steel. Most of them you heat them to shape, then quench in oil or saltwater if you. In addition to high yield strength, spring steels also possess excellent tensile strength and fatigue strength. Producing spring steel involves a series of precise steps, from selecting the right materials to heat treatment processes. Spring. How To Shape Spring Steel.

From www.javelin-tech.com

How to create a Curved Spring in SOLIDWORKS How To Shape Spring Steel Spring steel very bendable when fully annealed. There are a few different types of spring steel. The technique that works for. In addition to high yield strength, spring steels also possess excellent tensile strength and fatigue strength. The tensile strength and thickness of the material, type of tooling, and the type of bending all greatly influence springback. Most of them. How To Shape Spring Steel.

From slidemodel.com

Flat Springs PowerPoint Shapes SlideModel How To Shape Spring Steel It has high corrosion resistance, making it suitable for use in harsh conditions. Producing spring steel involves a series of precise steps, from selecting the right materials to heat treatment processes. This guide on how to bend spring steel covers the essential steps, including preparation, heating, bending, and cooling. There are a few different types of spring steel. Most of. How To Shape Spring Steel.