Plate Heat Exchanger Surface Area . Up to 700 plates can be contained within the frame of the largest paraflow exchanger, providing over 2400 m 2 of surface. This is due to the corrugations that are. Discover the remarkable scale and impact of plate heat exchangers in industrial applications. The six most important parameters include:. A plate heat exchanger is a compact type of heat exchanger that uses a series of thin plates to transfer heat between two fluids. It is important to understand that there is a difference in between the projected plate surface area, and the effective heat exchange surface area of a plate : For a given heat exchanger with constant area and heat transfer coefficient, the larger the lmtd, the more heat is transferred. The plates are specially selected from various patterns so as to achieve optimum heat transfer area and cost effective heat exchanger type for. Plate heat exchanger calculation method. To solve a thermal problem, we need to know several parameters. Further data can then be determined.

from netsolwater.com

To solve a thermal problem, we need to know several parameters. Further data can then be determined. A plate heat exchanger is a compact type of heat exchanger that uses a series of thin plates to transfer heat between two fluids. This is due to the corrugations that are. Plate heat exchanger calculation method. The plates are specially selected from various patterns so as to achieve optimum heat transfer area and cost effective heat exchanger type for. For a given heat exchanger with constant area and heat transfer coefficient, the larger the lmtd, the more heat is transferred. Discover the remarkable scale and impact of plate heat exchangers in industrial applications. The six most important parameters include:. Up to 700 plates can be contained within the frame of the largest paraflow exchanger, providing over 2400 m 2 of surface.

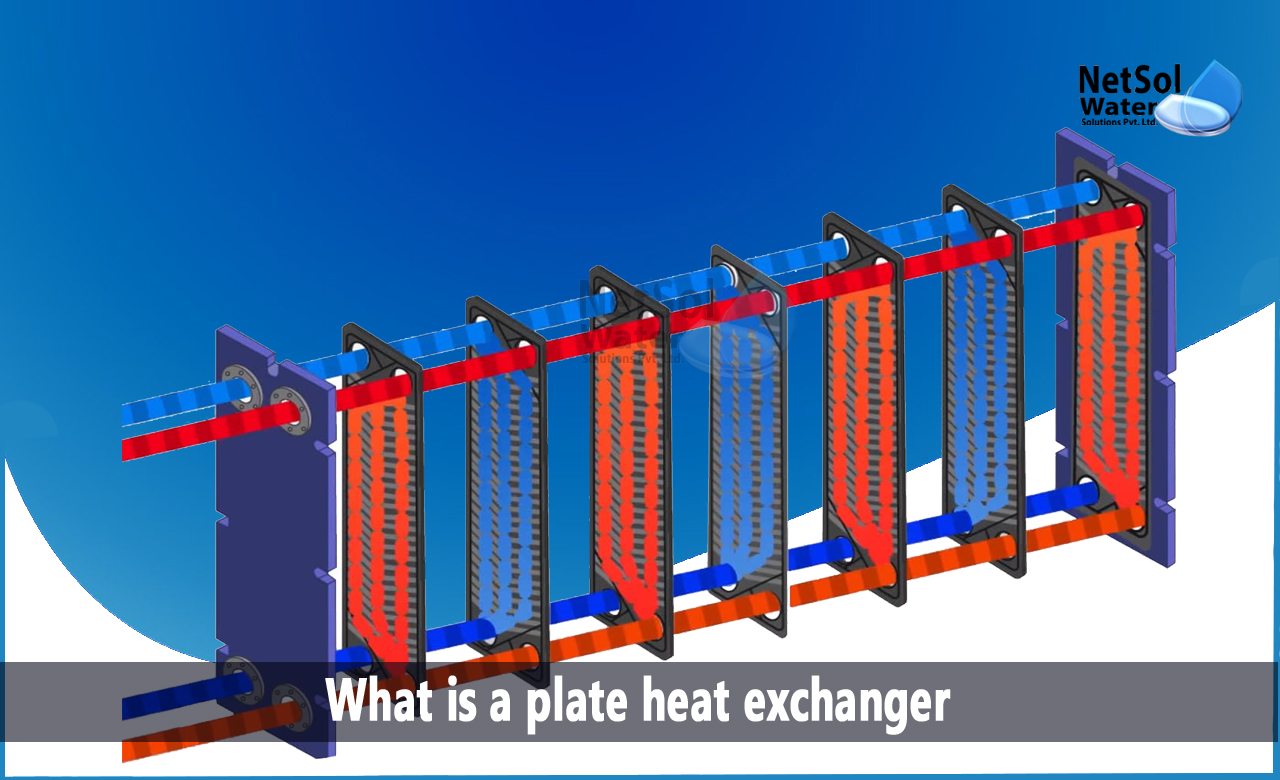

What is a plate heat exchanger? Advantages

Plate Heat Exchanger Surface Area To solve a thermal problem, we need to know several parameters. Up to 700 plates can be contained within the frame of the largest paraflow exchanger, providing over 2400 m 2 of surface. To solve a thermal problem, we need to know several parameters. The six most important parameters include:. A plate heat exchanger is a compact type of heat exchanger that uses a series of thin plates to transfer heat between two fluids. Plate heat exchanger calculation method. The plates are specially selected from various patterns so as to achieve optimum heat transfer area and cost effective heat exchanger type for. It is important to understand that there is a difference in between the projected plate surface area, and the effective heat exchange surface area of a plate : Further data can then be determined. For a given heat exchanger with constant area and heat transfer coefficient, the larger the lmtd, the more heat is transferred. This is due to the corrugations that are. Discover the remarkable scale and impact of plate heat exchangers in industrial applications.

From www.iqsdirectory.com

Plate Heat Exchangers Components, Types, Applications and Advantages Plate Heat Exchanger Surface Area This is due to the corrugations that are. Further data can then be determined. For a given heat exchanger with constant area and heat transfer coefficient, the larger the lmtd, the more heat is transferred. The six most important parameters include:. Discover the remarkable scale and impact of plate heat exchangers in industrial applications. Plate heat exchanger calculation method. To. Plate Heat Exchanger Surface Area.

From www.csidesigns.com

Understanding Types of Heat Exchangers Plate, Shell & Tube, and More Plate Heat Exchanger Surface Area Further data can then be determined. Discover the remarkable scale and impact of plate heat exchangers in industrial applications. The six most important parameters include:. It is important to understand that there is a difference in between the projected plate surface area, and the effective heat exchange surface area of a plate : A plate heat exchanger is a compact. Plate Heat Exchanger Surface Area.

From www.researchgate.net

Schematic diagram of a plate heat exchanger Download Scientific Diagram Plate Heat Exchanger Surface Area It is important to understand that there is a difference in between the projected plate surface area, and the effective heat exchange surface area of a plate : Discover the remarkable scale and impact of plate heat exchangers in industrial applications. The plates are specially selected from various patterns so as to achieve optimum heat transfer area and cost effective. Plate Heat Exchanger Surface Area.

From www.stollpche.com

A Guide on How to install heat exchanger plate correctly? Plate Heat Exchanger Surface Area The plates are specially selected from various patterns so as to achieve optimum heat transfer area and cost effective heat exchanger type for. This is due to the corrugations that are. A plate heat exchanger is a compact type of heat exchanger that uses a series of thin plates to transfer heat between two fluids. Up to 700 plates can. Plate Heat Exchanger Surface Area.

From www.slideserve.com

PPT HEAT EXCHANGERS PowerPoint Presentation, free download ID4204670 Plate Heat Exchanger Surface Area To solve a thermal problem, we need to know several parameters. Up to 700 plates can be contained within the frame of the largest paraflow exchanger, providing over 2400 m 2 of surface. This is due to the corrugations that are. Discover the remarkable scale and impact of plate heat exchangers in industrial applications. The plates are specially selected from. Plate Heat Exchanger Surface Area.

From lambdageeks.com

Plate and Frame Heat Exchanger What, How, Types, Working, Sizing Plate Heat Exchanger Surface Area This is due to the corrugations that are. A plate heat exchanger is a compact type of heat exchanger that uses a series of thin plates to transfer heat between two fluids. Further data can then be determined. Plate heat exchanger calculation method. It is important to understand that there is a difference in between the projected plate surface area,. Plate Heat Exchanger Surface Area.

From wcruk.com

Plate Heat Exchangers Functions & Principles Explained Plate Heat Exchanger Surface Area The plates are specially selected from various patterns so as to achieve optimum heat transfer area and cost effective heat exchanger type for. Further data can then be determined. For a given heat exchanger with constant area and heat transfer coefficient, the larger the lmtd, the more heat is transferred. This is due to the corrugations that are. Plate heat. Plate Heat Exchanger Surface Area.

From domain-to.blogspot.com

plate heat exchanger design code domainto Plate Heat Exchanger Surface Area A plate heat exchanger is a compact type of heat exchanger that uses a series of thin plates to transfer heat between two fluids. This is due to the corrugations that are. For a given heat exchanger with constant area and heat transfer coefficient, the larger the lmtd, the more heat is transferred. Further data can then be determined. Plate. Plate Heat Exchanger Surface Area.

From www.youtube.com

Sizing a Heat Exchanger CounterFlow YouTube Plate Heat Exchanger Surface Area The six most important parameters include:. Up to 700 plates can be contained within the frame of the largest paraflow exchanger, providing over 2400 m 2 of surface. It is important to understand that there is a difference in between the projected plate surface area, and the effective heat exchange surface area of a plate : Further data can then. Plate Heat Exchanger Surface Area.

From netsolwater.com

What is a plate heat exchanger? Advantages Plate Heat Exchanger Surface Area To solve a thermal problem, we need to know several parameters. Discover the remarkable scale and impact of plate heat exchangers in industrial applications. Further data can then be determined. A plate heat exchanger is a compact type of heat exchanger that uses a series of thin plates to transfer heat between two fluids. It is important to understand that. Plate Heat Exchanger Surface Area.

From www.arsopi-thermal.pt

Gasket Plate Heat Exchangers ArsopiThermal Plate Heat Exchanger Surface Area To solve a thermal problem, we need to know several parameters. It is important to understand that there is a difference in between the projected plate surface area, and the effective heat exchange surface area of a plate : Discover the remarkable scale and impact of plate heat exchangers in industrial applications. Plate heat exchanger calculation method. Further data can. Plate Heat Exchanger Surface Area.

From savree.com

Plate Heat Exchanger (PHE) Explained saVRee saVRee Plate Heat Exchanger Surface Area Further data can then be determined. The six most important parameters include:. A plate heat exchanger is a compact type of heat exchanger that uses a series of thin plates to transfer heat between two fluids. Plate heat exchanger calculation method. Discover the remarkable scale and impact of plate heat exchangers in industrial applications. Up to 700 plates can be. Plate Heat Exchanger Surface Area.

From academy.paulmueller.com

Which Heat Exchanger Is Best? The Three Main Types Explained... Plate Heat Exchanger Surface Area The plates are specially selected from various patterns so as to achieve optimum heat transfer area and cost effective heat exchanger type for. Discover the remarkable scale and impact of plate heat exchangers in industrial applications. This is due to the corrugations that are. A plate heat exchanger is a compact type of heat exchanger that uses a series of. Plate Heat Exchanger Surface Area.

From www.alfalaval.my

How plate heat exchanger work Alfa Laval Plate Heat Exchanger Surface Area For a given heat exchanger with constant area and heat transfer coefficient, the larger the lmtd, the more heat is transferred. To solve a thermal problem, we need to know several parameters. A plate heat exchanger is a compact type of heat exchanger that uses a series of thin plates to transfer heat between two fluids. This is due to. Plate Heat Exchanger Surface Area.

From savree.com

Plate Heat Exchanger (PHE) Explained saVRee saVRee Plate Heat Exchanger Surface Area It is important to understand that there is a difference in between the projected plate surface area, and the effective heat exchange surface area of a plate : The plates are specially selected from various patterns so as to achieve optimum heat transfer area and cost effective heat exchanger type for. The six most important parameters include:. A plate heat. Plate Heat Exchanger Surface Area.

From savree.com

Plate Heat Exchanger (PHE) Explained saVRee saVRee Plate Heat Exchanger Surface Area Further data can then be determined. Up to 700 plates can be contained within the frame of the largest paraflow exchanger, providing over 2400 m 2 of surface. The six most important parameters include:. Discover the remarkable scale and impact of plate heat exchangers in industrial applications. Plate heat exchanger calculation method. A plate heat exchanger is a compact type. Plate Heat Exchanger Surface Area.

From bandung-training.com

Pelatihan Plate Heat Exchanger Operation and Maintenance Informasi Plate Heat Exchanger Surface Area For a given heat exchanger with constant area and heat transfer coefficient, the larger the lmtd, the more heat is transferred. To solve a thermal problem, we need to know several parameters. The plates are specially selected from various patterns so as to achieve optimum heat transfer area and cost effective heat exchanger type for. The six most important parameters. Plate Heat Exchanger Surface Area.

From mepacademy.com

How Plate Heat Exchangers Work MEP Academy Plate Heat Exchanger Surface Area This is due to the corrugations that are. Plate heat exchanger calculation method. It is important to understand that there is a difference in between the projected plate surface area, and the effective heat exchange surface area of a plate : The six most important parameters include:. Up to 700 plates can be contained within the frame of the largest. Plate Heat Exchanger Surface Area.

From www.csidesigns.com

How Do Heat Exchangers Work A 101 Guide Plate Heat Exchanger Surface Area For a given heat exchanger with constant area and heat transfer coefficient, the larger the lmtd, the more heat is transferred. A plate heat exchanger is a compact type of heat exchanger that uses a series of thin plates to transfer heat between two fluids. To solve a thermal problem, we need to know several parameters. Further data can then. Plate Heat Exchanger Surface Area.

From heatrecoveryinnovations.com

Plate Fin Heat Exchanger Heat Recovery Innovations Plate Heat Exchanger Surface Area The six most important parameters include:. It is important to understand that there is a difference in between the projected plate surface area, and the effective heat exchange surface area of a plate : To solve a thermal problem, we need to know several parameters. Discover the remarkable scale and impact of plate heat exchangers in industrial applications. A plate. Plate Heat Exchanger Surface Area.

From www.ino.com.vn

Plate Heat Exchanger Applications and working principle hvac heat Plate Heat Exchanger Surface Area It is important to understand that there is a difference in between the projected plate surface area, and the effective heat exchange surface area of a plate : Plate heat exchanger calculation method. Further data can then be determined. This is due to the corrugations that are. To solve a thermal problem, we need to know several parameters. The plates. Plate Heat Exchanger Surface Area.

From www.researchgate.net

43 Heat transfer surface area density β, m 2 /m 3 Download Scientific Plate Heat Exchanger Surface Area To solve a thermal problem, we need to know several parameters. A plate heat exchanger is a compact type of heat exchanger that uses a series of thin plates to transfer heat between two fluids. It is important to understand that there is a difference in between the projected plate surface area, and the effective heat exchange surface area of. Plate Heat Exchanger Surface Area.

From www.researchgate.net

(a) Simplified flow schematic of platefin heat exchanger and example Plate Heat Exchanger Surface Area A plate heat exchanger is a compact type of heat exchanger that uses a series of thin plates to transfer heat between two fluids. Plate heat exchanger calculation method. This is due to the corrugations that are. Further data can then be determined. It is important to understand that there is a difference in between the projected plate surface area,. Plate Heat Exchanger Surface Area.

From www.sugarprocesstech.com

Plate Heat Exchanger Theory PHE Structure and Functional Description Plate Heat Exchanger Surface Area To solve a thermal problem, we need to know several parameters. A plate heat exchanger is a compact type of heat exchanger that uses a series of thin plates to transfer heat between two fluids. Discover the remarkable scale and impact of plate heat exchangers in industrial applications. Up to 700 plates can be contained within the frame of the. Plate Heat Exchanger Surface Area.

From ar.inspiredpencil.com

How A Plate And Frame Heat Exchanger Works Plate Heat Exchanger Surface Area It is important to understand that there is a difference in between the projected plate surface area, and the effective heat exchange surface area of a plate : To solve a thermal problem, we need to know several parameters. Further data can then be determined. For a given heat exchanger with constant area and heat transfer coefficient, the larger the. Plate Heat Exchanger Surface Area.

From www.youtube.com

How Plate Heat Exchangers Work YouTube Plate Heat Exchanger Surface Area To solve a thermal problem, we need to know several parameters. For a given heat exchanger with constant area and heat transfer coefficient, the larger the lmtd, the more heat is transferred. Further data can then be determined. Plate heat exchanger calculation method. A plate heat exchanger is a compact type of heat exchanger that uses a series of thin. Plate Heat Exchanger Surface Area.

From www.mdpi.com

Energies Free FullText Development of Heat Transfer Surface Area Plate Heat Exchanger Surface Area The plates are specially selected from various patterns so as to achieve optimum heat transfer area and cost effective heat exchanger type for. The six most important parameters include:. To solve a thermal problem, we need to know several parameters. Plate heat exchanger calculation method. Discover the remarkable scale and impact of plate heat exchangers in industrial applications. For a. Plate Heat Exchanger Surface Area.

From www.deeprocess.com

All Welded Plate Heat Exchanger for Corn Starch Ethanol Cooling Plate Heat Exchanger Surface Area The plates are specially selected from various patterns so as to achieve optimum heat transfer area and cost effective heat exchanger type for. Up to 700 plates can be contained within the frame of the largest paraflow exchanger, providing over 2400 m 2 of surface. To solve a thermal problem, we need to know several parameters. For a given heat. Plate Heat Exchanger Surface Area.

From www.intechopen.com

Modeling and Design of Plate Heat Exchanger IntechOpen Plate Heat Exchanger Surface Area Further data can then be determined. This is due to the corrugations that are. Plate heat exchanger calculation method. The six most important parameters include:. Up to 700 plates can be contained within the frame of the largest paraflow exchanger, providing over 2400 m 2 of surface. It is important to understand that there is a difference in between the. Plate Heat Exchanger Surface Area.

From ar.inspiredpencil.com

How A Plate And Frame Heat Exchanger Works Plate Heat Exchanger Surface Area Further data can then be determined. For a given heat exchanger with constant area and heat transfer coefficient, the larger the lmtd, the more heat is transferred. Up to 700 plates can be contained within the frame of the largest paraflow exchanger, providing over 2400 m 2 of surface. This is due to the corrugations that are. A plate heat. Plate Heat Exchanger Surface Area.

From www.iqsdirectory.com

Plate Heat Exchangers Components, Types, Applications and Advantages Plate Heat Exchanger Surface Area The six most important parameters include:. For a given heat exchanger with constant area and heat transfer coefficient, the larger the lmtd, the more heat is transferred. Discover the remarkable scale and impact of plate heat exchangers in industrial applications. Further data can then be determined. Plate heat exchanger calculation method. To solve a thermal problem, we need to know. Plate Heat Exchanger Surface Area.

From mepacademy.com

How Plate Heat Exchangers Work MEP Academy Plate Heat Exchanger Surface Area This is due to the corrugations that are. For a given heat exchanger with constant area and heat transfer coefficient, the larger the lmtd, the more heat is transferred. The six most important parameters include:. Discover the remarkable scale and impact of plate heat exchangers in industrial applications. Up to 700 plates can be contained within the frame of the. Plate Heat Exchanger Surface Area.

From www.semanticscholar.org

Figure 1 from Heat Transfer Analysis of Corrugated Plate Heat Exchanger Plate Heat Exchanger Surface Area The plates are specially selected from various patterns so as to achieve optimum heat transfer area and cost effective heat exchanger type for. To solve a thermal problem, we need to know several parameters. For a given heat exchanger with constant area and heat transfer coefficient, the larger the lmtd, the more heat is transferred. Up to 700 plates can. Plate Heat Exchanger Surface Area.

From msecinc.com

Heat Exchanger Basics MSEC Plate Heat Exchanger Surface Area For a given heat exchanger with constant area and heat transfer coefficient, the larger the lmtd, the more heat is transferred. The plates are specially selected from various patterns so as to achieve optimum heat transfer area and cost effective heat exchanger type for. A plate heat exchanger is a compact type of heat exchanger that uses a series of. Plate Heat Exchanger Surface Area.

From savree.com

Plate Heat Exchanger (PHE) Explained saVRee saVRee Plate Heat Exchanger Surface Area Plate heat exchanger calculation method. For a given heat exchanger with constant area and heat transfer coefficient, the larger the lmtd, the more heat is transferred. To solve a thermal problem, we need to know several parameters. Up to 700 plates can be contained within the frame of the largest paraflow exchanger, providing over 2400 m 2 of surface. Further. Plate Heat Exchanger Surface Area.