What Do You Mean By Visual Inspection . Visual inspection is a process of finding defects in an object or system that are visible to the naked eye. A visual inspection is an inspection implemented to detect scratches, dirt, foreign matter, and other physical defects on an object. Visual inspection is a technique for detecting defects using observation analytical skills and inspection tools to ensure equipment. Visual inspection is a crucial component of quality control (qc) and assurance processes across various industries. At its core, it involves using the human eye, either unaided or with the help of tools like magnifying glasses and microscopes, to search for visible defects. It helps ensure equipment is functioning properly and meet specific requirements. Various industries, like manufacturing, energy, and medicine, use visual inspection techniques to maintain tools and gears. Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment is working properly or that manufactured products are being made to.

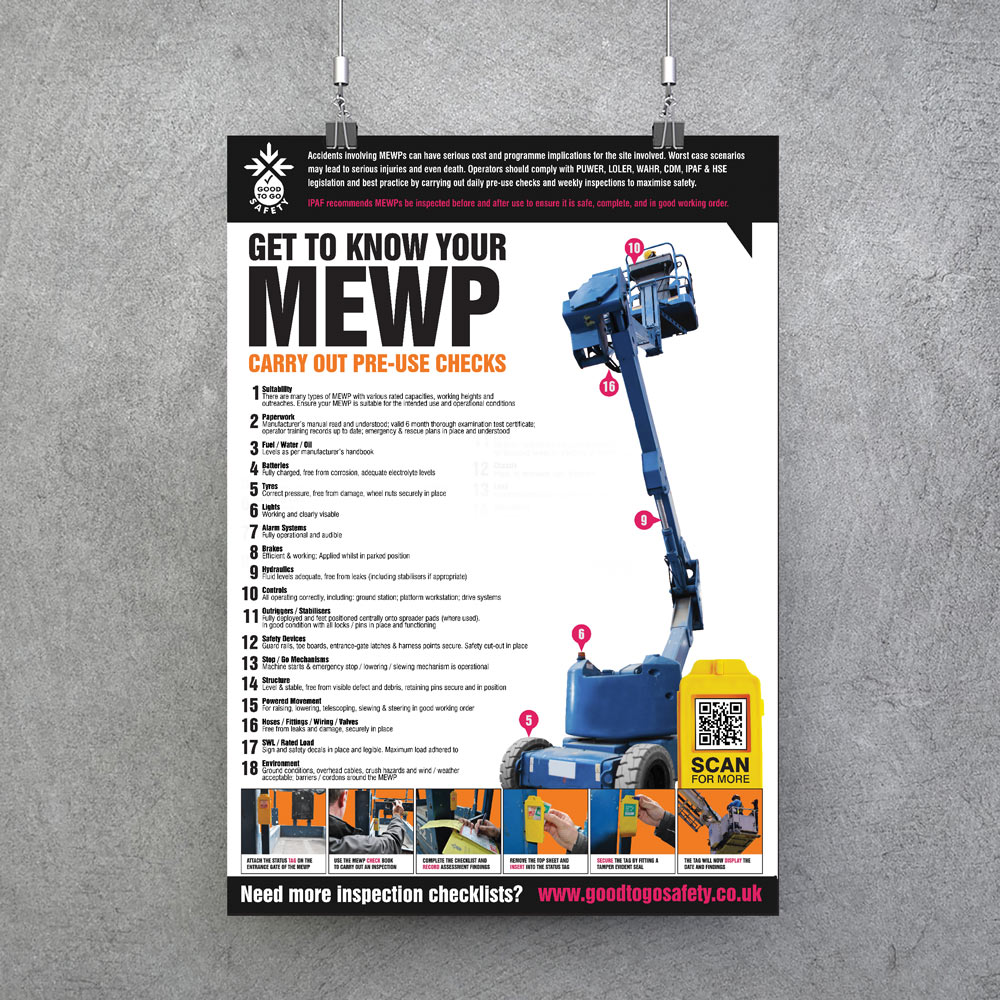

from www.goodtogosafety.co.uk

Visual inspection is a process of finding defects in an object or system that are visible to the naked eye. A visual inspection is an inspection implemented to detect scratches, dirt, foreign matter, and other physical defects on an object. It helps ensure equipment is functioning properly and meet specific requirements. Visual inspection is a crucial component of quality control (qc) and assurance processes across various industries. Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment is working properly or that manufactured products are being made to. Visual inspection is a technique for detecting defects using observation analytical skills and inspection tools to ensure equipment. Various industries, like manufacturing, energy, and medicine, use visual inspection techniques to maintain tools and gears. At its core, it involves using the human eye, either unaided or with the help of tools like magnifying glasses and microscopes, to search for visible defects.

MEWP Poster Visual Inspection Checklist

What Do You Mean By Visual Inspection A visual inspection is an inspection implemented to detect scratches, dirt, foreign matter, and other physical defects on an object. Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment is working properly or that manufactured products are being made to. It helps ensure equipment is functioning properly and meet specific requirements. Visual inspection is a process of finding defects in an object or system that are visible to the naked eye. At its core, it involves using the human eye, either unaided or with the help of tools like magnifying glasses and microscopes, to search for visible defects. Various industries, like manufacturing, energy, and medicine, use visual inspection techniques to maintain tools and gears. A visual inspection is an inspection implemented to detect scratches, dirt, foreign matter, and other physical defects on an object. Visual inspection is a crucial component of quality control (qc) and assurance processes across various industries. Visual inspection is a technique for detecting defects using observation analytical skills and inspection tools to ensure equipment.

From studylib.net

Visual Inspection What Do You Mean By Visual Inspection Visual inspection is a crucial component of quality control (qc) and assurance processes across various industries. Visual inspection is a technique for detecting defects using observation analytical skills and inspection tools to ensure equipment. Various industries, like manufacturing, energy, and medicine, use visual inspection techniques to maintain tools and gears. Visual inspection is a technique for detecting defects by using. What Do You Mean By Visual Inspection.

From www.bustmold.com

Professional Visual Inspection Services Scope of Work Assessment What Do You Mean By Visual Inspection Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment is working properly or that manufactured products are being made to. Various industries, like manufacturing, energy, and medicine, use visual inspection techniques to maintain tools and gears. At its core, it involves using the human eye, either unaided or with the help of. What Do You Mean By Visual Inspection.

From eam360.com

Demystifying Maximo Visual Inspection EAM360 What Do You Mean By Visual Inspection It helps ensure equipment is functioning properly and meet specific requirements. At its core, it involves using the human eye, either unaided or with the help of tools like magnifying glasses and microscopes, to search for visible defects. Visual inspection is a technique for detecting defects using observation analytical skills and inspection tools to ensure equipment. A visual inspection is. What Do You Mean By Visual Inspection.

From www.slideserve.com

PPT Visual inspection with acetic acid (VIA) Evidence to date What Do You Mean By Visual Inspection Visual inspection is a crucial component of quality control (qc) and assurance processes across various industries. Visual inspection is a process of finding defects in an object or system that are visible to the naked eye. At its core, it involves using the human eye, either unaided or with the help of tools like magnifying glasses and microscopes, to search. What Do You Mean By Visual Inspection.

From www.slideserve.com

PPT Research directions on Visual Inspection Planning PowerPoint What Do You Mean By Visual Inspection A visual inspection is an inspection implemented to detect scratches, dirt, foreign matter, and other physical defects on an object. At its core, it involves using the human eye, either unaided or with the help of tools like magnifying glasses and microscopes, to search for visible defects. Various industries, like manufacturing, energy, and medicine, use visual inspection techniques to maintain. What Do You Mean By Visual Inspection.

From www.patlabelsonline.co.uk

Visual Inspection Labels for Portable Appliances Pat Labels What Do You Mean By Visual Inspection Visual inspection is a process of finding defects in an object or system that are visible to the naked eye. It helps ensure equipment is functioning properly and meet specific requirements. Visual inspection is a technique for detecting defects using observation analytical skills and inspection tools to ensure equipment. Visual inspection is a crucial component of quality control (qc) and. What Do You Mean By Visual Inspection.

From www.goodtogosafety.co.uk

MEWP Poster Visual Inspection Checklist What Do You Mean By Visual Inspection It helps ensure equipment is functioning properly and meet specific requirements. At its core, it involves using the human eye, either unaided or with the help of tools like magnifying glasses and microscopes, to search for visible defects. Visual inspection is a technique for detecting defects using observation analytical skills and inspection tools to ensure equipment. Visual inspection is a. What Do You Mean By Visual Inspection.

From www.fogwing.io

New Visual Inspection Techniques Fogwing.io What Do You Mean By Visual Inspection Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment is working properly or that manufactured products are being made to. Various industries, like manufacturing, energy, and medicine, use visual inspection techniques to maintain tools and gears. Visual inspection is a technique for detecting defects using observation analytical skills and inspection tools to. What Do You Mean By Visual Inspection.

From dokumen.tips

(PDF) Visual Inspection of Injectable Products DOKUMEN.TIPS What Do You Mean By Visual Inspection Visual inspection is a crucial component of quality control (qc) and assurance processes across various industries. It helps ensure equipment is functioning properly and meet specific requirements. Various industries, like manufacturing, energy, and medicine, use visual inspection techniques to maintain tools and gears. At its core, it involves using the human eye, either unaided or with the help of tools. What Do You Mean By Visual Inspection.

From www.standwinspections.co.uk

Visual Inspection S.T & W Inspections What Do You Mean By Visual Inspection Visual inspection is a crucial component of quality control (qc) and assurance processes across various industries. A visual inspection is an inspection implemented to detect scratches, dirt, foreign matter, and other physical defects on an object. It helps ensure equipment is functioning properly and meet specific requirements. Visual inspection is a technique for detecting defects by using the naked eye. What Do You Mean By Visual Inspection.

From marutitech.com

What is AI Visual Inspection for Defect Detection? A Deep Dive What Do You Mean By Visual Inspection A visual inspection is an inspection implemented to detect scratches, dirt, foreign matter, and other physical defects on an object. Visual inspection is a crucial component of quality control (qc) and assurance processes across various industries. Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment is working properly or that manufactured products. What Do You Mean By Visual Inspection.

From www.pinterest.com.au

Visual Inspection is a method of checking the overall visual appearance What Do You Mean By Visual Inspection Visual inspection is a crucial component of quality control (qc) and assurance processes across various industries. At its core, it involves using the human eye, either unaided or with the help of tools like magnifying glasses and microscopes, to search for visible defects. Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment. What Do You Mean By Visual Inspection.

From www.apizee.com

A Simple Guide to Remote Visual Inspection Apizee What Do You Mean By Visual Inspection Visual inspection is a crucial component of quality control (qc) and assurance processes across various industries. A visual inspection is an inspection implemented to detect scratches, dirt, foreign matter, and other physical defects on an object. Visual inspection is a process of finding defects in an object or system that are visible to the naked eye. It helps ensure equipment. What Do You Mean By Visual Inspection.

From limblecmms.com

What, Why, and How of Visual Inspection Processes and Benefits What Do You Mean By Visual Inspection A visual inspection is an inspection implemented to detect scratches, dirt, foreign matter, and other physical defects on an object. It helps ensure equipment is functioning properly and meet specific requirements. Visual inspection is a process of finding defects in an object or system that are visible to the naked eye. Visual inspection is a technique for detecting defects using. What Do You Mean By Visual Inspection.

From weldinginspectornote.blogspot.com

Welding Inspector Note Visual inspection vs Non destructive testing (NDT) What Do You Mean By Visual Inspection It helps ensure equipment is functioning properly and meet specific requirements. Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment is working properly or that manufactured products are being made to. At its core, it involves using the human eye, either unaided or with the help of tools like magnifying glasses and. What Do You Mean By Visual Inspection.

From www.ibm.com

What is visual inspection? IBM What Do You Mean By Visual Inspection Visual inspection is a crucial component of quality control (qc) and assurance processes across various industries. At its core, it involves using the human eye, either unaided or with the help of tools like magnifying glasses and microscopes, to search for visible defects. Visual inspection is a technique for detecting defects using observation analytical skills and inspection tools to ensure. What Do You Mean By Visual Inspection.

From www.hqts.com

The Guide to Visual Inspection Techniques in Quality Inspections HQTS What Do You Mean By Visual Inspection A visual inspection is an inspection implemented to detect scratches, dirt, foreign matter, and other physical defects on an object. Visual inspection is a process of finding defects in an object or system that are visible to the naked eye. Visual inspection is a crucial component of quality control (qc) and assurance processes across various industries. At its core, it. What Do You Mean By Visual Inspection.

From sharpml.com

AI Will Transform Your Visual Inspection Workflows SharpML What Do You Mean By Visual Inspection Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment is working properly or that manufactured products are being made to. Visual inspection is a crucial component of quality control (qc) and assurance processes across various industries. Visual inspection is a technique for detecting defects using observation analytical skills and inspection tools to. What Do You Mean By Visual Inspection.

From www.studocu.com

Visual Inspection useful study materials Visual Inspection Most What Do You Mean By Visual Inspection At its core, it involves using the human eye, either unaided or with the help of tools like magnifying glasses and microscopes, to search for visible defects. Visual inspection is a process of finding defects in an object or system that are visible to the naked eye. Various industries, like manufacturing, energy, and medicine, use visual inspection techniques to maintain. What Do You Mean By Visual Inspection.

From saxon.ai

AIbased visual inspection for defect detection What Do You Mean By Visual Inspection Visual inspection is a technique for detecting defects using observation analytical skills and inspection tools to ensure equipment. It helps ensure equipment is functioning properly and meet specific requirements. At its core, it involves using the human eye, either unaided or with the help of tools like magnifying glasses and microscopes, to search for visible defects. Visual inspection is a. What Do You Mean By Visual Inspection.

From www.petrosync.com

Mastering Visual Inspection for Quality Assurance What Do You Mean By Visual Inspection It helps ensure equipment is functioning properly and meet specific requirements. Visual inspection is a technique for detecting defects using observation analytical skills and inspection tools to ensure equipment. Visual inspection is a process of finding defects in an object or system that are visible to the naked eye. Visual inspection is a crucial component of quality control (qc) and. What Do You Mean By Visual Inspection.

From datamyte.com

Visual Inspection for Quality Control Checklist Full Guide DataMyte What Do You Mean By Visual Inspection Various industries, like manufacturing, energy, and medicine, use visual inspection techniques to maintain tools and gears. Visual inspection is a process of finding defects in an object or system that are visible to the naked eye. Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment is working properly or that manufactured products. What Do You Mean By Visual Inspection.

From marutitech.com

What is AI Visual Inspection for Defect Detection? A Deep Dive What Do You Mean By Visual Inspection Visual inspection is a technique for detecting defects using observation analytical skills and inspection tools to ensure equipment. A visual inspection is an inspection implemented to detect scratches, dirt, foreign matter, and other physical defects on an object. Various industries, like manufacturing, energy, and medicine, use visual inspection techniques to maintain tools and gears. At its core, it involves using. What Do You Mean By Visual Inspection.

From www.youtube.com

What's Included in a Visual Inspection? YouTube What Do You Mean By Visual Inspection Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment is working properly or that manufactured products are being made to. Visual inspection is a technique for detecting defects using observation analytical skills and inspection tools to ensure equipment. Visual inspection is a process of finding defects in an object or system that. What Do You Mean By Visual Inspection.

From www.labelbar.co.uk

4th Edition Visual Inspection Labels for Portable Appliances What Do You Mean By Visual Inspection Various industries, like manufacturing, energy, and medicine, use visual inspection techniques to maintain tools and gears. Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment is working properly or that manufactured products are being made to. Visual inspection is a technique for detecting defects using observation analytical skills and inspection tools to. What Do You Mean By Visual Inspection.

From biobuzz.io

The Ins and Outs of Manual Visual Inspection BioBuzz What Do You Mean By Visual Inspection Visual inspection is a technique for detecting defects using observation analytical skills and inspection tools to ensure equipment. Visual inspection is a crucial component of quality control (qc) and assurance processes across various industries. Visual inspection is a process of finding defects in an object or system that are visible to the naked eye. A visual inspection is an inspection. What Do You Mean By Visual Inspection.

From ndttrainingonline.com

Visual Inspection Course What Do You Mean By Visual Inspection A visual inspection is an inspection implemented to detect scratches, dirt, foreign matter, and other physical defects on an object. Visual inspection is a technique for detecting defects using observation analytical skills and inspection tools to ensure equipment. At its core, it involves using the human eye, either unaided or with the help of tools like magnifying glasses and microscopes,. What Do You Mean By Visual Inspection.

From issuu.com

Visual inspection by Alireza Samimi Mottaghi Issuu What Do You Mean By Visual Inspection Visual inspection is a crucial component of quality control (qc) and assurance processes across various industries. At its core, it involves using the human eye, either unaided or with the help of tools like magnifying glasses and microscopes, to search for visible defects. Visual inspection is a process of finding defects in an object or system that are visible to. What Do You Mean By Visual Inspection.

From www.zzfmdn.com

Everything you need to know about Visual Inspection with AI What Do You Mean By Visual Inspection A visual inspection is an inspection implemented to detect scratches, dirt, foreign matter, and other physical defects on an object. Visual inspection is a process of finding defects in an object or system that are visible to the naked eye. Visual inspection is a crucial component of quality control (qc) and assurance processes across various industries. Various industries, like manufacturing,. What Do You Mean By Visual Inspection.

From www.asseteng.com.au

Visual Inspection (NDT) Explained » Your Complete Guide AME What Do You Mean By Visual Inspection Various industries, like manufacturing, energy, and medicine, use visual inspection techniques to maintain tools and gears. A visual inspection is an inspection implemented to detect scratches, dirt, foreign matter, and other physical defects on an object. At its core, it involves using the human eye, either unaided or with the help of tools like magnifying glasses and microscopes, to search. What Do You Mean By Visual Inspection.

From monitoringclub.org

What Is Inspection? Know The 5 Functions And Types » 2024 What Do You Mean By Visual Inspection At its core, it involves using the human eye, either unaided or with the help of tools like magnifying glasses and microscopes, to search for visible defects. Visual inspection is a crucial component of quality control (qc) and assurance processes across various industries. Visual inspection is a process of finding defects in an object or system that are visible to. What Do You Mean By Visual Inspection.

From trdsf.com

Visual Inspection Evolution, Methods, and Applications TRADESAFE What Do You Mean By Visual Inspection Various industries, like manufacturing, energy, and medicine, use visual inspection techniques to maintain tools and gears. It helps ensure equipment is functioning properly and meet specific requirements. At its core, it involves using the human eye, either unaided or with the help of tools like magnifying glasses and microscopes, to search for visible defects. Visual inspection is a technique for. What Do You Mean By Visual Inspection.

From facilio.com

Visual Inspection What Is It, Benefits, and more! What Do You Mean By Visual Inspection At its core, it involves using the human eye, either unaided or with the help of tools like magnifying glasses and microscopes, to search for visible defects. Visual inspection is a crucial component of quality control (qc) and assurance processes across various industries. Various industries, like manufacturing, energy, and medicine, use visual inspection techniques to maintain tools and gears. Visual. What Do You Mean By Visual Inspection.

From marutitech.com

What is AI Visual Inspection for Defect Detection? A Deep Dive What Do You Mean By Visual Inspection Visual inspection is a process of finding defects in an object or system that are visible to the naked eye. Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment is working properly or that manufactured products are being made to. Visual inspection is a technique for detecting defects using observation analytical skills. What Do You Mean By Visual Inspection.

From www.resco.net

Visual inspection Resco What Do You Mean By Visual Inspection A visual inspection is an inspection implemented to detect scratches, dirt, foreign matter, and other physical defects on an object. Visual inspection is a process of finding defects in an object or system that are visible to the naked eye. Visual inspection is a technique for detecting defects by using the naked eye to ensure that equipment is working properly. What Do You Mean By Visual Inspection.