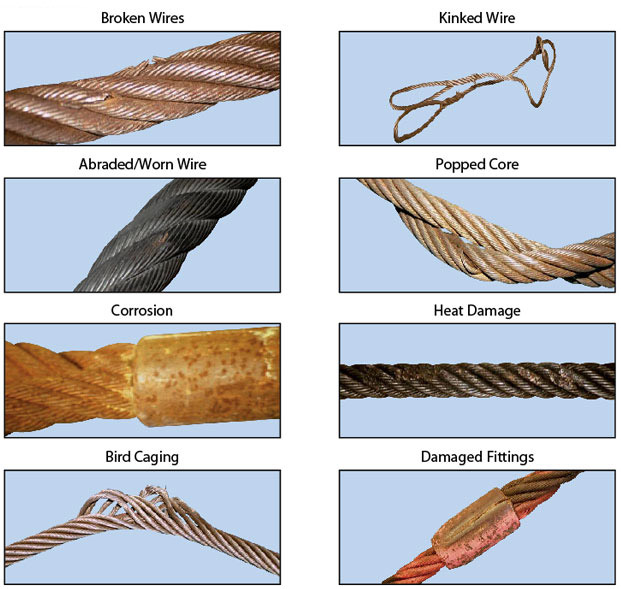

Wire Rope Inspection Broken Wires . A wire rope must be discarded if the permissible number of wire breaks, according to din 15 020, has been reached or exceeded. Most of these warning signs indicate that the rope should be replaced. Recommended retirement criteria for all rotation resistant ropes are 2 broken wires in 6 rope diameters or 4 broken wires in 30 rope diameters (i.e. Therefore, wire ropes should be inspected and maintained by appropriate personnel to ensure that they are in a safe condition for use. 6 rope diameters for a 1″ diameter rope = 6″). Proper inspection can ensure high performance, long service life, safety of personnel and equipment and reduce operating costs. Distortion of rotation resistant ropes, as shown below, can be caused by shock load / sudden load release and/or induced torque, and is. Broken wires occasional wire breaks. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent. Understanding how wire rope is structured, what causes degradation, what to look for when inspecting ropes, and how often to inspect them. During your inspection, pay close attention to the areas of the rope in contact with sheaves and drums when loads are picked up.

from www.lift-it.com

Proper inspection can ensure high performance, long service life, safety of personnel and equipment and reduce operating costs. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent. Therefore, wire ropes should be inspected and maintained by appropriate personnel to ensure that they are in a safe condition for use. A wire rope must be discarded if the permissible number of wire breaks, according to din 15 020, has been reached or exceeded. Broken wires occasional wire breaks. Understanding how wire rope is structured, what causes degradation, what to look for when inspecting ropes, and how often to inspect them. Most of these warning signs indicate that the rope should be replaced. Distortion of rotation resistant ropes, as shown below, can be caused by shock load / sudden load release and/or induced torque, and is. During your inspection, pay close attention to the areas of the rope in contact with sheaves and drums when loads are picked up. Recommended retirement criteria for all rotation resistant ropes are 2 broken wires in 6 rope diameters or 4 broken wires in 30 rope diameters (i.e.

Wire Rope Sling Inspection Criteria LiftIt® Manufacturing

Wire Rope Inspection Broken Wires Understanding how wire rope is structured, what causes degradation, what to look for when inspecting ropes, and how often to inspect them. Most of these warning signs indicate that the rope should be replaced. Therefore, wire ropes should be inspected and maintained by appropriate personnel to ensure that they are in a safe condition for use. During your inspection, pay close attention to the areas of the rope in contact with sheaves and drums when loads are picked up. Understanding how wire rope is structured, what causes degradation, what to look for when inspecting ropes, and how often to inspect them. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent. Broken wires occasional wire breaks. Recommended retirement criteria for all rotation resistant ropes are 2 broken wires in 6 rope diameters or 4 broken wires in 30 rope diameters (i.e. A wire rope must be discarded if the permissible number of wire breaks, according to din 15 020, has been reached or exceeded. Proper inspection can ensure high performance, long service life, safety of personnel and equipment and reduce operating costs. Distortion of rotation resistant ropes, as shown below, can be caused by shock load / sudden load release and/or induced torque, and is. 6 rope diameters for a 1″ diameter rope = 6″).

From www.equipmentandcontracting.com

How to Prevent Hoist Wire Rope Failures Equipment & Contracting Wire Rope Inspection Broken Wires Proper inspection can ensure high performance, long service life, safety of personnel and equipment and reduce operating costs. Distortion of rotation resistant ropes, as shown below, can be caused by shock load / sudden load release and/or induced torque, and is. Broken wires occasional wire breaks. During your inspection, pay close attention to the areas of the rope in contact. Wire Rope Inspection Broken Wires.

From www.youtube.com

LiftAll Wire Rope Sling Inspection YouTube Wire Rope Inspection Broken Wires Proper inspection can ensure high performance, long service life, safety of personnel and equipment and reduce operating costs. During your inspection, pay close attention to the areas of the rope in contact with sheaves and drums when loads are picked up. Recommended retirement criteria for all rotation resistant ropes are 2 broken wires in 6 rope diameters or 4 broken. Wire Rope Inspection Broken Wires.

From www.katradis.com

Wire Rope Inspection & Maintenance A full guide Katradis Wire Rope Inspection Broken Wires During your inspection, pay close attention to the areas of the rope in contact with sheaves and drums when loads are picked up. Distortion of rotation resistant ropes, as shown below, can be caused by shock load / sudden load release and/or induced torque, and is. Most of these warning signs indicate that the rope should be replaced. Recommended retirement. Wire Rope Inspection Broken Wires.

From acculift.com

Wire Rope the wear and tear you need to watch for Acculift Wire Rope Inspection Broken Wires Proper inspection can ensure high performance, long service life, safety of personnel and equipment and reduce operating costs. During your inspection, pay close attention to the areas of the rope in contact with sheaves and drums when loads are picked up. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use. Wire Rope Inspection Broken Wires.

From blog.demagcranes.com

Understanding Wire Rope Lay for Your Next Wire Rope Hoist Repair or Wire Rope Inspection Broken Wires Most of these warning signs indicate that the rope should be replaced. A wire rope must be discarded if the permissible number of wire breaks, according to din 15 020, has been reached or exceeded. Understanding how wire rope is structured, what causes degradation, what to look for when inspecting ropes, and how often to inspect them. During your inspection,. Wire Rope Inspection Broken Wires.

From liftingandrigging.com.my

lifting and rigging Crane wire rope findings and failures Wire Rope Inspection Broken Wires Distortion of rotation resistant ropes, as shown below, can be caused by shock load / sudden load release and/or induced torque, and is. During your inspection, pay close attention to the areas of the rope in contact with sheaves and drums when loads are picked up. Recommended retirement criteria for all rotation resistant ropes are 2 broken wires in 6. Wire Rope Inspection Broken Wires.

From www.slideserve.com

PPT Overhead Crane Safety and Inspection Requirements PowerPoint Wire Rope Inspection Broken Wires A wire rope must be discarded if the permissible number of wire breaks, according to din 15 020, has been reached or exceeded. Broken wires occasional wire breaks. Distortion of rotation resistant ropes, as shown below, can be caused by shock load / sudden load release and/or induced torque, and is. Therefore, wire ropes should be inspected and maintained by. Wire Rope Inspection Broken Wires.

From pdfslide.net

(PDF) WIRE ROPE INSPECTION FORM Home Sanford … Rope... · Wire Rope Wire Rope Inspection Broken Wires The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent. During your inspection, pay close attention to the areas of the rope in contact with sheaves and drums when loads are picked up. 6 rope diameters for a 1″ diameter rope = 6″). Therefore, wire ropes. Wire Rope Inspection Broken Wires.

From www.youtube.com

Safety inar Wire Rope Inspection and Maintenance for Your Underhung Wire Rope Inspection Broken Wires During your inspection, pay close attention to the areas of the rope in contact with sheaves and drums when loads are picked up. A wire rope must be discarded if the permissible number of wire breaks, according to din 15 020, has been reached or exceeded. Therefore, wire ropes should be inspected and maintained by appropriate personnel to ensure that. Wire Rope Inspection Broken Wires.

From www.alllifting.com.au

Fraying Wire Rope All Lifting Wire Rope Inspection Broken Wires The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent. Most of these warning signs indicate that the rope should be replaced. Proper inspection can ensure high performance, long service life, safety of personnel and equipment and reduce operating costs. Distortion of rotation resistant ropes, as. Wire Rope Inspection Broken Wires.

From enginemechanics.tpub.com

Wire Rope Inspection Wire Rope Inspection Broken Wires 6 rope diameters for a 1″ diameter rope = 6″). Distortion of rotation resistant ropes, as shown below, can be caused by shock load / sudden load release and/or induced torque, and is. Broken wires occasional wire breaks. During your inspection, pay close attention to the areas of the rope in contact with sheaves and drums when loads are picked. Wire Rope Inspection Broken Wires.

From www.yumpu.com

14 Wire Rope Inspection WorkSafeNB Wire Rope Inspection Broken Wires Understanding how wire rope is structured, what causes degradation, what to look for when inspecting ropes, and how often to inspect them. Recommended retirement criteria for all rotation resistant ropes are 2 broken wires in 6 rope diameters or 4 broken wires in 30 rope diameters (i.e. A wire rope must be discarded if the permissible number of wire breaks,. Wire Rope Inspection Broken Wires.

From lrm-nde.com

Crane Wire Ropes Inspection Services LRMNDE Laboratory Wire Rope Inspection Broken Wires A wire rope must be discarded if the permissible number of wire breaks, according to din 15 020, has been reached or exceeded. Distortion of rotation resistant ropes, as shown below, can be caused by shock load / sudden load release and/or induced torque, and is. Most of these warning signs indicate that the rope should be replaced. 6 rope. Wire Rope Inspection Broken Wires.

From liftingandrigging.com.my

lifting and rigging Crane wire rope findings and failures Wire Rope Inspection Broken Wires A wire rope must be discarded if the permissible number of wire breaks, according to din 15 020, has been reached or exceeded. 6 rope diameters for a 1″ diameter rope = 6″). Therefore, wire ropes should be inspected and maintained by appropriate personnel to ensure that they are in a safe condition for use. Most of these warning signs. Wire Rope Inspection Broken Wires.

From www.linkedin.com

Wire Rope Inspection Wire Rope Inspection Broken Wires Distortion of rotation resistant ropes, as shown below, can be caused by shock load / sudden load release and/or induced torque, and is. During your inspection, pay close attention to the areas of the rope in contact with sheaves and drums when loads are picked up. A wire rope must be discarded if the permissible number of wire breaks, according. Wire Rope Inspection Broken Wires.

From www.craneropesaustralia.com.au

Broken Wires in Wire Ropes Crane Ropes Australia Wire Rope Inspection Broken Wires Broken wires occasional wire breaks. Distortion of rotation resistant ropes, as shown below, can be caused by shock load / sudden load release and/or induced torque, and is. During your inspection, pay close attention to the areas of the rope in contact with sheaves and drums when loads are picked up. 6 rope diameters for a 1″ diameter rope =. Wire Rope Inspection Broken Wires.

From liftingandrigging.com.my

lifting and rigging Crane wire rope findings and failures Wire Rope Inspection Broken Wires During your inspection, pay close attention to the areas of the rope in contact with sheaves and drums when loads are picked up. Distortion of rotation resistant ropes, as shown below, can be caused by shock load / sudden load release and/or induced torque, and is. Understanding how wire rope is structured, what causes degradation, what to look for when. Wire Rope Inspection Broken Wires.

From mavink.com

Wire Rope Damage Chart Wire Rope Inspection Broken Wires Proper inspection can ensure high performance, long service life, safety of personnel and equipment and reduce operating costs. Recommended retirement criteria for all rotation resistant ropes are 2 broken wires in 6 rope diameters or 4 broken wires in 30 rope diameters (i.e. 6 rope diameters for a 1″ diameter rope = 6″). During your inspection, pay close attention to. Wire Rope Inspection Broken Wires.

From www.youtube.com

Wire Rope Sling Inspection By Tariq Momin YouTube Wire Rope Inspection Broken Wires Distortion of rotation resistant ropes, as shown below, can be caused by shock load / sudden load release and/or induced torque, and is. Understanding how wire rope is structured, what causes degradation, what to look for when inspecting ropes, and how often to inspect them. Most of these warning signs indicate that the rope should be replaced. Therefore, wire ropes. Wire Rope Inspection Broken Wires.

From www.techknowserv.com

Wire Rope Testing A Review of Different Nondestructive Testing Methods Wire Rope Inspection Broken Wires The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent. During your inspection, pay close attention to the areas of the rope in contact with sheaves and drums when loads are picked up. Distortion of rotation resistant ropes, as shown below, can be caused by shock. Wire Rope Inspection Broken Wires.

From journals.sagepub.com

Detection of broken wires in elevator wire ropes with ultrasonic guided Wire Rope Inspection Broken Wires Recommended retirement criteria for all rotation resistant ropes are 2 broken wires in 6 rope diameters or 4 broken wires in 30 rope diameters (i.e. During your inspection, pay close attention to the areas of the rope in contact with sheaves and drums when loads are picked up. The inspection must consist of observation of wire ropes (running and standing). Wire Rope Inspection Broken Wires.

From www.mazzellacompanies.com

How to Inspect Wire Rope Slings According to ASME B30.9 Standards Wire Rope Inspection Broken Wires Broken wires occasional wire breaks. Therefore, wire ropes should be inspected and maintained by appropriate personnel to ensure that they are in a safe condition for use. Recommended retirement criteria for all rotation resistant ropes are 2 broken wires in 6 rope diameters or 4 broken wires in 30 rope diameters (i.e. Understanding how wire rope is structured, what causes. Wire Rope Inspection Broken Wires.

From inspectiongc.com

Wire Rope Inspection Inspection GC Wire Rope Inspection Broken Wires The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent. A wire rope must be discarded if the permissible number of wire breaks, according to din 15 020, has been reached or exceeded. Broken wires occasional wire breaks. 6 rope diameters for a 1″ diameter rope. Wire Rope Inspection Broken Wires.

From liftingandrigging.com.my

lifting and rigging Crane wire rope findings and failures Wire Rope Inspection Broken Wires Proper inspection can ensure high performance, long service life, safety of personnel and equipment and reduce operating costs. Understanding how wire rope is structured, what causes degradation, what to look for when inspecting ropes, and how often to inspect them. During your inspection, pay close attention to the areas of the rope in contact with sheaves and drums when loads. Wire Rope Inspection Broken Wires.

From www.slideserve.com

PPT Wire Rope Inspection PowerPoint Presentation, free download ID Wire Rope Inspection Broken Wires Therefore, wire ropes should be inspected and maintained by appropriate personnel to ensure that they are in a safe condition for use. Most of these warning signs indicate that the rope should be replaced. Proper inspection can ensure high performance, long service life, safety of personnel and equipment and reduce operating costs. 6 rope diameters for a 1″ diameter rope. Wire Rope Inspection Broken Wires.

From liftingandrigging.com.my

lifting and rigging Crane wire rope findings and failures Wire Rope Inspection Broken Wires Therefore, wire ropes should be inspected and maintained by appropriate personnel to ensure that they are in a safe condition for use. During your inspection, pay close attention to the areas of the rope in contact with sheaves and drums when loads are picked up. Most of these warning signs indicate that the rope should be replaced. Understanding how wire. Wire Rope Inspection Broken Wires.

From www.drillsafe.co.za

WIRE ROPE DEFECTS — DrillSafe Wire Rope Inspection Broken Wires Understanding how wire rope is structured, what causes degradation, what to look for when inspecting ropes, and how often to inspect them. Distortion of rotation resistant ropes, as shown below, can be caused by shock load / sudden load release and/or induced torque, and is. Therefore, wire ropes should be inspected and maintained by appropriate personnel to ensure that they. Wire Rope Inspection Broken Wires.

From www.mazzellacompanies.com

How to Inspect Wire Rope Slings According to ASME B30.9 Standards Wire Rope Inspection Broken Wires Therefore, wire ropes should be inspected and maintained by appropriate personnel to ensure that they are in a safe condition for use. Proper inspection can ensure high performance, long service life, safety of personnel and equipment and reduce operating costs. Recommended retirement criteria for all rotation resistant ropes are 2 broken wires in 6 rope diameters or 4 broken wires. Wire Rope Inspection Broken Wires.

From www.mazzellacompanies.com

Wire Rope Inspection and Removal from Service Criteria Wire Rope Inspection Broken Wires A wire rope must be discarded if the permissible number of wire breaks, according to din 15 020, has been reached or exceeded. Broken wires occasional wire breaks. Therefore, wire ropes should be inspected and maintained by appropriate personnel to ensure that they are in a safe condition for use. 6 rope diameters for a 1″ diameter rope = 6″).. Wire Rope Inspection Broken Wires.

From www.maintworld.com

Steel Wire Rope Failures Who Is Accountable? HSE Maintworld Wire Rope Inspection Broken Wires Broken wires occasional wire breaks. During your inspection, pay close attention to the areas of the rope in contact with sheaves and drums when loads are picked up. Proper inspection can ensure high performance, long service life, safety of personnel and equipment and reduce operating costs. Therefore, wire ropes should be inspected and maintained by appropriate personnel to ensure that. Wire Rope Inspection Broken Wires.

From www.youtube.com

Inspection of Wire rope Discard Criteria of Wire Ropes Crushing Bird Wire Rope Inspection Broken Wires Understanding how wire rope is structured, what causes degradation, what to look for when inspecting ropes, and how often to inspect them. Therefore, wire ropes should be inspected and maintained by appropriate personnel to ensure that they are in a safe condition for use. During your inspection, pay close attention to the areas of the rope in contact with sheaves. Wire Rope Inspection Broken Wires.

From maritime-executive.com

Wire Rope Parted After Years of Neglect and Daily Inspections Wire Rope Inspection Broken Wires Proper inspection can ensure high performance, long service life, safety of personnel and equipment and reduce operating costs. Recommended retirement criteria for all rotation resistant ropes are 2 broken wires in 6 rope diameters or 4 broken wires in 30 rope diameters (i.e. Broken wires occasional wire breaks. A wire rope must be discarded if the permissible number of wire. Wire Rope Inspection Broken Wires.

From www.researchgate.net

Specimens with typical wire rope defects Download Scientific Diagram Wire Rope Inspection Broken Wires 6 rope diameters for a 1″ diameter rope = 6″). During your inspection, pay close attention to the areas of the rope in contact with sheaves and drums when loads are picked up. A wire rope must be discarded if the permissible number of wire breaks, according to din 15 020, has been reached or exceeded. Broken wires occasional wire. Wire Rope Inspection Broken Wires.

From www.lift-it.com

Wire Rope Sling Inspection Criteria LiftIt® Manufacturing Wire Rope Inspection Broken Wires Distortion of rotation resistant ropes, as shown below, can be caused by shock load / sudden load release and/or induced torque, and is. Therefore, wire ropes should be inspected and maintained by appropriate personnel to ensure that they are in a safe condition for use. A wire rope must be discarded if the permissible number of wire breaks, according to. Wire Rope Inspection Broken Wires.

From macmorwebsitewebapp.azurewebsites.net

Wire Rope vs Chain Slings MacMor Industries Wire Rope Inspection Broken Wires Most of these warning signs indicate that the rope should be replaced. 6 rope diameters for a 1″ diameter rope = 6″). Broken wires occasional wire breaks. Therefore, wire ropes should be inspected and maintained by appropriate personnel to ensure that they are in a safe condition for use. Recommended retirement criteria for all rotation resistant ropes are 2 broken. Wire Rope Inspection Broken Wires.