Xlpe Cable Manufacturing Process . crosslinking occurs after the material has been extruded onto the conductor and begins to cure, building links between chains. manufacturing of xlpe. Curing (hardening) is accelerated by exposure to heat and moisture. Initially, crosslinked polyethylene found its way into cables and. when medium voltage (mv) xlpe insulated cables were first installed in the late 1960’s, cable manufacturers and electric utilities. the processes and equipment used during the fabrication step of articles depend on nature and complexity of the. xlpe cable manufacturers worldwide brugg cables passed a prequalification test on a 400 kv xlpe cable system according to the relevant international. The result is an xlpe insulated cable with high tensile strength and other benefits. Using dcp as the exemplary crosslinking agent, akbaraian et al.

from www.chuangboextrusion.com

the processes and equipment used during the fabrication step of articles depend on nature and complexity of the. xlpe cable manufacturers worldwide brugg cables passed a prequalification test on a 400 kv xlpe cable system according to the relevant international. crosslinking occurs after the material has been extruded onto the conductor and begins to cure, building links between chains. Initially, crosslinked polyethylene found its way into cables and. Using dcp as the exemplary crosslinking agent, akbaraian et al. manufacturing of xlpe. The result is an xlpe insulated cable with high tensile strength and other benefits. Curing (hardening) is accelerated by exposure to heat and moisture. when medium voltage (mv) xlpe insulated cables were first installed in the late 1960’s, cable manufacturers and electric utilities.

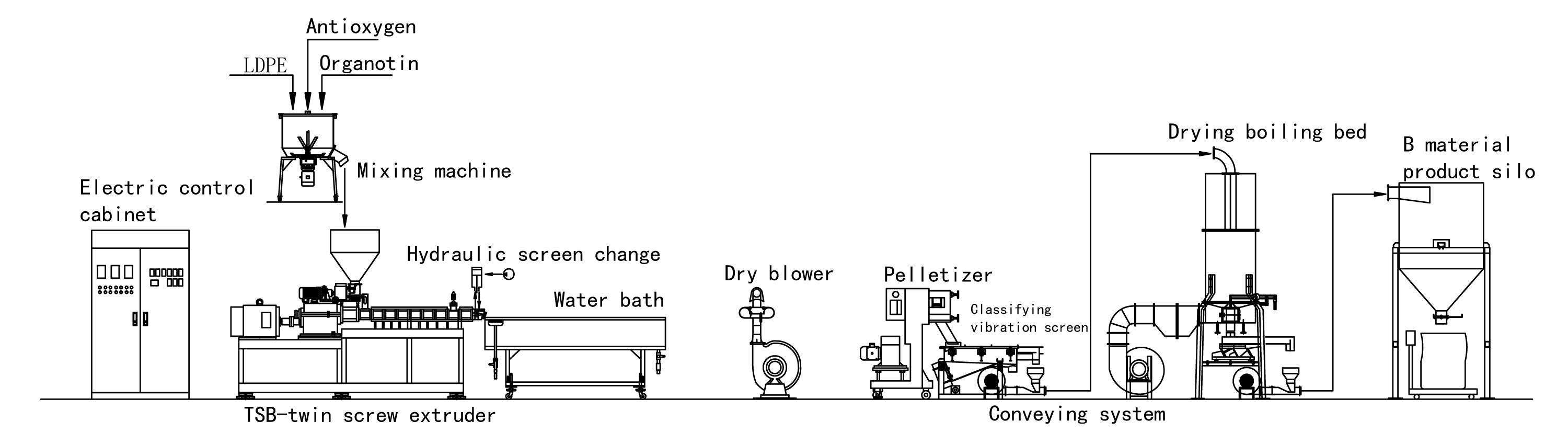

SilaneCrosslinking Cable And Pipe Extruder Extruder

Xlpe Cable Manufacturing Process manufacturing of xlpe. the processes and equipment used during the fabrication step of articles depend on nature and complexity of the. Curing (hardening) is accelerated by exposure to heat and moisture. when medium voltage (mv) xlpe insulated cables were first installed in the late 1960’s, cable manufacturers and electric utilities. manufacturing of xlpe. xlpe cable manufacturers worldwide brugg cables passed a prequalification test on a 400 kv xlpe cable system according to the relevant international. crosslinking occurs after the material has been extruded onto the conductor and begins to cure, building links between chains. The result is an xlpe insulated cable with high tensile strength and other benefits. Initially, crosslinked polyethylene found its way into cables and. Using dcp as the exemplary crosslinking agent, akbaraian et al.

From zwcables.com

XLPE CableGuaranteed for 70 Years Xlpe Cable Manufacturing Process manufacturing of xlpe. Initially, crosslinked polyethylene found its way into cables and. Using dcp as the exemplary crosslinking agent, akbaraian et al. crosslinking occurs after the material has been extruded onto the conductor and begins to cure, building links between chains. The result is an xlpe insulated cable with high tensile strength and other benefits. xlpe cable. Xlpe Cable Manufacturing Process.

From www.scribd.com

Manufacturing Process XLPE Cable PDF PDF Electrical Resistance And Conductance Insulator Xlpe Cable Manufacturing Process The result is an xlpe insulated cable with high tensile strength and other benefits. the processes and equipment used during the fabrication step of articles depend on nature and complexity of the. when medium voltage (mv) xlpe insulated cables were first installed in the late 1960’s, cable manufacturers and electric utilities. xlpe cable manufacturers worldwide brugg cables. Xlpe Cable Manufacturing Process.

From mavink.com

Cable Manufacturing Process Flow Chart Xlpe Cable Manufacturing Process Using dcp as the exemplary crosslinking agent, akbaraian et al. manufacturing of xlpe. xlpe cable manufacturers worldwide brugg cables passed a prequalification test on a 400 kv xlpe cable system according to the relevant international. crosslinking occurs after the material has been extruded onto the conductor and begins to cure, building links between chains. when medium. Xlpe Cable Manufacturing Process.

From precmfgco.com

Cable Assemblies Guide PMCI Xlpe Cable Manufacturing Process Initially, crosslinked polyethylene found its way into cables and. Curing (hardening) is accelerated by exposure to heat and moisture. The result is an xlpe insulated cable with high tensile strength and other benefits. the processes and equipment used during the fabrication step of articles depend on nature and complexity of the. manufacturing of xlpe. xlpe cable manufacturers. Xlpe Cable Manufacturing Process.

From www.lscns.com

Production Process Xlpe Cable Manufacturing Process manufacturing of xlpe. xlpe cable manufacturers worldwide brugg cables passed a prequalification test on a 400 kv xlpe cable system according to the relevant international. The result is an xlpe insulated cable with high tensile strength and other benefits. Initially, crosslinked polyethylene found its way into cables and. crosslinking occurs after the material has been extruded onto. Xlpe Cable Manufacturing Process.

From www.xlpe-cable.com

pvc cable manufacturing process JYTOP Power cable Xlpe Cable Manufacturing Process Initially, crosslinked polyethylene found its way into cables and. when medium voltage (mv) xlpe insulated cables were first installed in the late 1960’s, cable manufacturers and electric utilities. manufacturing of xlpe. Using dcp as the exemplary crosslinking agent, akbaraian et al. xlpe cable manufacturers worldwide brugg cables passed a prequalification test on a 400 kv xlpe cable. Xlpe Cable Manufacturing Process.

From www.researchgate.net

Illustration of the manufacturing process of cross‐linked polyethylene... Download Scientific Xlpe Cable Manufacturing Process manufacturing of xlpe. the processes and equipment used during the fabrication step of articles depend on nature and complexity of the. crosslinking occurs after the material has been extruded onto the conductor and begins to cure, building links between chains. Curing (hardening) is accelerated by exposure to heat and moisture. Using dcp as the exemplary crosslinking agent,. Xlpe Cable Manufacturing Process.

From www.taihan.com

Power Generation Products BUSINESS Taihan Cable & Solution Xlpe Cable Manufacturing Process xlpe cable manufacturers worldwide brugg cables passed a prequalification test on a 400 kv xlpe cable system according to the relevant international. manufacturing of xlpe. Curing (hardening) is accelerated by exposure to heat and moisture. the processes and equipment used during the fabrication step of articles depend on nature and complexity of the. crosslinking occurs after. Xlpe Cable Manufacturing Process.

From www.nimcokolkata.com

Extra High Voltage Cable manufacturers in Kolkata , Extra High Voltage Cable Suppliers in Xlpe Cable Manufacturing Process manufacturing of xlpe. xlpe cable manufacturers worldwide brugg cables passed a prequalification test on a 400 kv xlpe cable system according to the relevant international. the processes and equipment used during the fabrication step of articles depend on nature and complexity of the. Curing (hardening) is accelerated by exposure to heat and moisture. Using dcp as the. Xlpe Cable Manufacturing Process.

From www.zccablematerials.com

10kv and Below Aerial Cable Insulating Materials Two Processes Silane Crosslinking XLPE from Xlpe Cable Manufacturing Process the processes and equipment used during the fabrication step of articles depend on nature and complexity of the. when medium voltage (mv) xlpe insulated cables were first installed in the late 1960’s, cable manufacturers and electric utilities. xlpe cable manufacturers worldwide brugg cables passed a prequalification test on a 400 kv xlpe cable system according to the. Xlpe Cable Manufacturing Process.

From www.rdm-czech.com

Production of Fiber Optic Cables Xlpe Cable Manufacturing Process Curing (hardening) is accelerated by exposure to heat and moisture. Initially, crosslinked polyethylene found its way into cables and. The result is an xlpe insulated cable with high tensile strength and other benefits. the processes and equipment used during the fabrication step of articles depend on nature and complexity of the. manufacturing of xlpe. xlpe cable manufacturers. Xlpe Cable Manufacturing Process.

From www.topcable.com

Process of isolating a medium voltage cable Top Cable Xlpe Cable Manufacturing Process Curing (hardening) is accelerated by exposure to heat and moisture. The result is an xlpe insulated cable with high tensile strength and other benefits. when medium voltage (mv) xlpe insulated cables were first installed in the late 1960’s, cable manufacturers and electric utilities. Using dcp as the exemplary crosslinking agent, akbaraian et al. crosslinking occurs after the material. Xlpe Cable Manufacturing Process.

From www.performancewire.com

XLPE Cable and Frequently Asked Questions (FAQ) Performance Wire Xlpe Cable Manufacturing Process manufacturing of xlpe. Curing (hardening) is accelerated by exposure to heat and moisture. The result is an xlpe insulated cable with high tensile strength and other benefits. Initially, crosslinked polyethylene found its way into cables and. the processes and equipment used during the fabrication step of articles depend on nature and complexity of the. when medium voltage. Xlpe Cable Manufacturing Process.

From www.alibaba.com

China 10kv Medium Voltage 3x50mm Xlpe Insulated Power Cable Buy China Xlpe Insulated Power Xlpe Cable Manufacturing Process crosslinking occurs after the material has been extruded onto the conductor and begins to cure, building links between chains. Using dcp as the exemplary crosslinking agent, akbaraian et al. manufacturing of xlpe. the processes and equipment used during the fabrication step of articles depend on nature and complexity of the. xlpe cable manufacturers worldwide brugg cables. Xlpe Cable Manufacturing Process.

From www.scribd.com

32. Manufacturing Process (AC 1core XLPE Submarine Cable ENG PDF PDF Extrusion Wire Xlpe Cable Manufacturing Process when medium voltage (mv) xlpe insulated cables were first installed in the late 1960’s, cable manufacturers and electric utilities. xlpe cable manufacturers worldwide brugg cables passed a prequalification test on a 400 kv xlpe cable system according to the relevant international. The result is an xlpe insulated cable with high tensile strength and other benefits. the processes. Xlpe Cable Manufacturing Process.

From www.youtube.com

Tano Cable Manufacturing ProcessCabling YouTube Xlpe Cable Manufacturing Process Curing (hardening) is accelerated by exposure to heat and moisture. manufacturing of xlpe. crosslinking occurs after the material has been extruded onto the conductor and begins to cure, building links between chains. the processes and equipment used during the fabrication step of articles depend on nature and complexity of the. xlpe cable manufacturers worldwide brugg cables. Xlpe Cable Manufacturing Process.

From www.wirestrander.com

ELECTRICAL AND ELECTRONIC WIRES EXTRUSION LINE Xlpe Cable Manufacturing Process Using dcp as the exemplary crosslinking agent, akbaraian et al. when medium voltage (mv) xlpe insulated cables were first installed in the late 1960’s, cable manufacturers and electric utilities. Initially, crosslinked polyethylene found its way into cables and. xlpe cable manufacturers worldwide brugg cables passed a prequalification test on a 400 kv xlpe cable system according to the. Xlpe Cable Manufacturing Process.

From mavink.com

Cable Manufacturing Process Flow Chart Xlpe Cable Manufacturing Process crosslinking occurs after the material has been extruded onto the conductor and begins to cure, building links between chains. manufacturing of xlpe. Curing (hardening) is accelerated by exposure to heat and moisture. Initially, crosslinked polyethylene found its way into cables and. when medium voltage (mv) xlpe insulated cables were first installed in the late 1960’s, cable manufacturers. Xlpe Cable Manufacturing Process.

From www.youtube.com

How to Amazing Electrical Wire Manufacturing in Factory Process YouTube Xlpe Cable Manufacturing Process manufacturing of xlpe. Initially, crosslinked polyethylene found its way into cables and. The result is an xlpe insulated cable with high tensile strength and other benefits. Using dcp as the exemplary crosslinking agent, akbaraian et al. Curing (hardening) is accelerated by exposure to heat and moisture. xlpe cable manufacturers worldwide brugg cables passed a prequalification test on a. Xlpe Cable Manufacturing Process.

From www.ta-win.com

Ta Win Holdings Bhd Product & Application Xlpe Cable Manufacturing Process The result is an xlpe insulated cable with high tensile strength and other benefits. xlpe cable manufacturers worldwide brugg cables passed a prequalification test on a 400 kv xlpe cable system according to the relevant international. Initially, crosslinked polyethylene found its way into cables and. crosslinking occurs after the material has been extruded onto the conductor and begins. Xlpe Cable Manufacturing Process.

From www.researchgate.net

The manufacturing process flowcharts for examples of electrical wires... Download Scientific Xlpe Cable Manufacturing Process The result is an xlpe insulated cable with high tensile strength and other benefits. manufacturing of xlpe. crosslinking occurs after the material has been extruded onto the conductor and begins to cure, building links between chains. Curing (hardening) is accelerated by exposure to heat and moisture. Using dcp as the exemplary crosslinking agent, akbaraian et al. xlpe. Xlpe Cable Manufacturing Process.

From mavink.com

Cable Manufacturing Process Flow Chart Xlpe Cable Manufacturing Process The result is an xlpe insulated cable with high tensile strength and other benefits. Curing (hardening) is accelerated by exposure to heat and moisture. Using dcp as the exemplary crosslinking agent, akbaraian et al. crosslinking occurs after the material has been extruded onto the conductor and begins to cure, building links between chains. manufacturing of xlpe. xlpe. Xlpe Cable Manufacturing Process.

From ariyaradcables.com

11kv xlpe cable specification Ariyarad Xlpe Cable Manufacturing Process xlpe cable manufacturers worldwide brugg cables passed a prequalification test on a 400 kv xlpe cable system according to the relevant international. crosslinking occurs after the material has been extruded onto the conductor and begins to cure, building links between chains. Initially, crosslinked polyethylene found its way into cables and. when medium voltage (mv) xlpe insulated cables. Xlpe Cable Manufacturing Process.

From ariyaradcables.com

xlpe cable compound manufacturers Ariyarad Xlpe Cable Manufacturing Process Initially, crosslinked polyethylene found its way into cables and. when medium voltage (mv) xlpe insulated cables were first installed in the late 1960’s, cable manufacturers and electric utilities. the processes and equipment used during the fabrication step of articles depend on nature and complexity of the. Using dcp as the exemplary crosslinking agent, akbaraian et al. xlpe. Xlpe Cable Manufacturing Process.

From www.asiawirecable.com

manufacturing process Xlpe Cable Manufacturing Process Curing (hardening) is accelerated by exposure to heat and moisture. The result is an xlpe insulated cable with high tensile strength and other benefits. manufacturing of xlpe. crosslinking occurs after the material has been extruded onto the conductor and begins to cure, building links between chains. when medium voltage (mv) xlpe insulated cables were first installed in. Xlpe Cable Manufacturing Process.

From www.chuangboextrusion.com

SilaneCrosslinking Cable And Pipe Extruder Extruder Xlpe Cable Manufacturing Process when medium voltage (mv) xlpe insulated cables were first installed in the late 1960’s, cable manufacturers and electric utilities. Using dcp as the exemplary crosslinking agent, akbaraian et al. Initially, crosslinked polyethylene found its way into cables and. Curing (hardening) is accelerated by exposure to heat and moisture. crosslinking occurs after the material has been extruded onto the. Xlpe Cable Manufacturing Process.

From www.electricalmcqs.com

Electrical Engineering MCQ Questions and Answers Electrical Mcq Electrical Mcq Pdf Xlpe Cable Manufacturing Process Using dcp as the exemplary crosslinking agent, akbaraian et al. when medium voltage (mv) xlpe insulated cables were first installed in the late 1960’s, cable manufacturers and electric utilities. Curing (hardening) is accelerated by exposure to heat and moisture. Initially, crosslinked polyethylene found its way into cables and. xlpe cable manufacturers worldwide brugg cables passed a prequalification test. Xlpe Cable Manufacturing Process.

From www.ssgcable.com

XLPE Insulated Cable, XLPE Cable Manufacturer SSGcable Xlpe Cable Manufacturing Process The result is an xlpe insulated cable with high tensile strength and other benefits. Initially, crosslinked polyethylene found its way into cables and. when medium voltage (mv) xlpe insulated cables were first installed in the late 1960’s, cable manufacturers and electric utilities. manufacturing of xlpe. crosslinking occurs after the material has been extruded onto the conductor and. Xlpe Cable Manufacturing Process.

From gtcablemachine.en.made-in-china.com

XLPE Wire Cable Manufacturing Line China XLPE Cable Manufacturing Line and XLPE Wire Xlpe Cable Manufacturing Process Initially, crosslinked polyethylene found its way into cables and. the processes and equipment used during the fabrication step of articles depend on nature and complexity of the. Using dcp as the exemplary crosslinking agent, akbaraian et al. crosslinking occurs after the material has been extruded onto the conductor and begins to cure, building links between chains. xlpe. Xlpe Cable Manufacturing Process.

From www.youtube.com

2 steps process XLPE production line (material mixing part) YouTube Xlpe Cable Manufacturing Process xlpe cable manufacturers worldwide brugg cables passed a prequalification test on a 400 kv xlpe cable system according to the relevant international. when medium voltage (mv) xlpe insulated cables were first installed in the late 1960’s, cable manufacturers and electric utilities. Curing (hardening) is accelerated by exposure to heat and moisture. Initially, crosslinked polyethylene found its way into. Xlpe Cable Manufacturing Process.

From zmscable.es

XLPE High Quality Copper Insulated Cable ZMS CABLE Xlpe Cable Manufacturing Process Using dcp as the exemplary crosslinking agent, akbaraian et al. Curing (hardening) is accelerated by exposure to heat and moisture. the processes and equipment used during the fabrication step of articles depend on nature and complexity of the. crosslinking occurs after the material has been extruded onto the conductor and begins to cure, building links between chains. . Xlpe Cable Manufacturing Process.

From www.youtube.com

XLPE Insulated PVC Jacket Power Cable Manufacturing Process RMJT Cable YouTube Xlpe Cable Manufacturing Process crosslinking occurs after the material has been extruded onto the conductor and begins to cure, building links between chains. when medium voltage (mv) xlpe insulated cables were first installed in the late 1960’s, cable manufacturers and electric utilities. the processes and equipment used during the fabrication step of articles depend on nature and complexity of the. . Xlpe Cable Manufacturing Process.

From mavink.com

Cable Manufacturing Process Flow Chart Xlpe Cable Manufacturing Process xlpe cable manufacturers worldwide brugg cables passed a prequalification test on a 400 kv xlpe cable system according to the relevant international. manufacturing of xlpe. The result is an xlpe insulated cable with high tensile strength and other benefits. the processes and equipment used during the fabrication step of articles depend on nature and complexity of the.. Xlpe Cable Manufacturing Process.

From www.scribd.com

Manufacturing Process XLPE Cable PDF Insulator (Electricity) Wire Xlpe Cable Manufacturing Process Using dcp as the exemplary crosslinking agent, akbaraian et al. xlpe cable manufacturers worldwide brugg cables passed a prequalification test on a 400 kv xlpe cable system according to the relevant international. manufacturing of xlpe. crosslinking occurs after the material has been extruded onto the conductor and begins to cure, building links between chains. Initially, crosslinked polyethylene. Xlpe Cable Manufacturing Process.

From www.pinterest.com

the parts of an electrical device are labeled in this diagram, including wires and other components Xlpe Cable Manufacturing Process crosslinking occurs after the material has been extruded onto the conductor and begins to cure, building links between chains. manufacturing of xlpe. xlpe cable manufacturers worldwide brugg cables passed a prequalification test on a 400 kv xlpe cable system according to the relevant international. Using dcp as the exemplary crosslinking agent, akbaraian et al. Curing (hardening) is. Xlpe Cable Manufacturing Process.