How To Make A Mold For Carbon Fiber Layup . This tutorial can be followed to make a mold. ***descriptions in pictures help explain the text below. However, it provides a lot of hands on experience and is cheaper and quicker than skipping to the final design. This article is intended to help novice through. — in this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. Prepping the mold for use. We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. — how to make a mould for a carbon fiber (fibre) part. The first picture is a simplified cad design that would not work as a final mold for a real bike.

from www.talkcomposites.com

— in this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. — how to make a mould for a carbon fiber (fibre) part. The first picture is a simplified cad design that would not work as a final mold for a real bike. This article is intended to help novice through. Prepping the mold for use. However, it provides a lot of hands on experience and is cheaper and quicker than skipping to the final design. ***descriptions in pictures help explain the text below. We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. This tutorial can be followed to make a mold.

Carbon Fiber Layup with Mould 3D Printer

How To Make A Mold For Carbon Fiber Layup This tutorial can be followed to make a mold. ***descriptions in pictures help explain the text below. However, it provides a lot of hands on experience and is cheaper and quicker than skipping to the final design. We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. This tutorial can be followed to make a mold. This article is intended to help novice through. The first picture is a simplified cad design that would not work as a final mold for a real bike. Prepping the mold for use. — in this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. — how to make a mould for a carbon fiber (fibre) part.

From www.youtube.com

Fibreglass/FRP SplitMould Making Guide (Carbon Fibre Airbox Pt.2 How To Make A Mold For Carbon Fiber Layup This tutorial can be followed to make a mold. — in this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. The first picture is a simplified cad design that would not work as a final mold for a real bike. ***descriptions in pictures help. How To Make A Mold For Carbon Fiber Layup.

From forum.onshape.com

Fiberglass mold design and fabrication. — Onshape How To Make A Mold For Carbon Fiber Layup Prepping the mold for use. We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. — in this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. The first picture is a simplified cad design. How To Make A Mold For Carbon Fiber Layup.

From bercella.it

Bercella first steps of carbon fiber layup process How To Make A Mold For Carbon Fiber Layup We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. This tutorial can be followed to make a mold. — in this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. ***descriptions in pictures help. How To Make A Mold For Carbon Fiber Layup.

From www.instructables.com

Easy Carbon Fiber Mold 7 Steps (with Pictures) Instructables How To Make A Mold For Carbon Fiber Layup Prepping the mold for use. — how to make a mould for a carbon fiber (fibre) part. This tutorial can be followed to make a mold. This article is intended to help novice through. We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. The first picture is a. How To Make A Mold For Carbon Fiber Layup.

From www.dynamism.com

Tutorial How to 3D Print Molds for Carbon Fiber Parts Dynamism How To Make A Mold For Carbon Fiber Layup We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. This article is intended to help novice through. ***descriptions in pictures help explain the text below. However, it provides a lot of hands on experience and is cheaper and quicker than skipping to the final design. This tutorial can be. How To Make A Mold For Carbon Fiber Layup.

From bercella.it

Bercella first steps of carbon fiber layup process How To Make A Mold For Carbon Fiber Layup This tutorial can be followed to make a mold. ***descriptions in pictures help explain the text below. Prepping the mold for use. However, it provides a lot of hands on experience and is cheaper and quicker than skipping to the final design. We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong,. How To Make A Mold For Carbon Fiber Layup.

From www.hotrod.com

Carbon Fiber StepbyStep How to Lay Up Carbon Fiber Hot Rod Hot How To Make A Mold For Carbon Fiber Layup — in this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. This article is intended to help novice through. Prepping the mold for use.. How To Make A Mold For Carbon Fiber Layup.

From www.hotrod.com

Carbon Fiber StepbyStep How to Lay Up Carbon Fiber Hot Rod Hot How To Make A Mold For Carbon Fiber Layup Prepping the mold for use. However, it provides a lot of hands on experience and is cheaper and quicker than skipping to the final design. ***descriptions in pictures help explain the text below. This tutorial can be followed to make a mold. The first picture is a simplified cad design that would not work as a final mold for a. How To Make A Mold For Carbon Fiber Layup.

From www.youtube.com

How to Make Carbon Fiber Parts (Including the Mold) YouTube How To Make A Mold For Carbon Fiber Layup We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. — in this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. Prepping the mold for use. However, it provides a lot of hands on. How To Make A Mold For Carbon Fiber Layup.

From compositescanada.com

How To Layup Carbon Fiber On A Mold Composites Canada How To Make A Mold For Carbon Fiber Layup — in this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. This tutorial can be followed to make a mold. However, it provides a. How To Make A Mold For Carbon Fiber Layup.

From bigrep.com

How to Make Carbon Fiber Molds & Parts 2 Fast & Easy Ways How To Make A Mold For Carbon Fiber Layup This article is intended to help novice through. Prepping the mold for use. We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. — in this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods.. How To Make A Mold For Carbon Fiber Layup.

From www.instructables.com

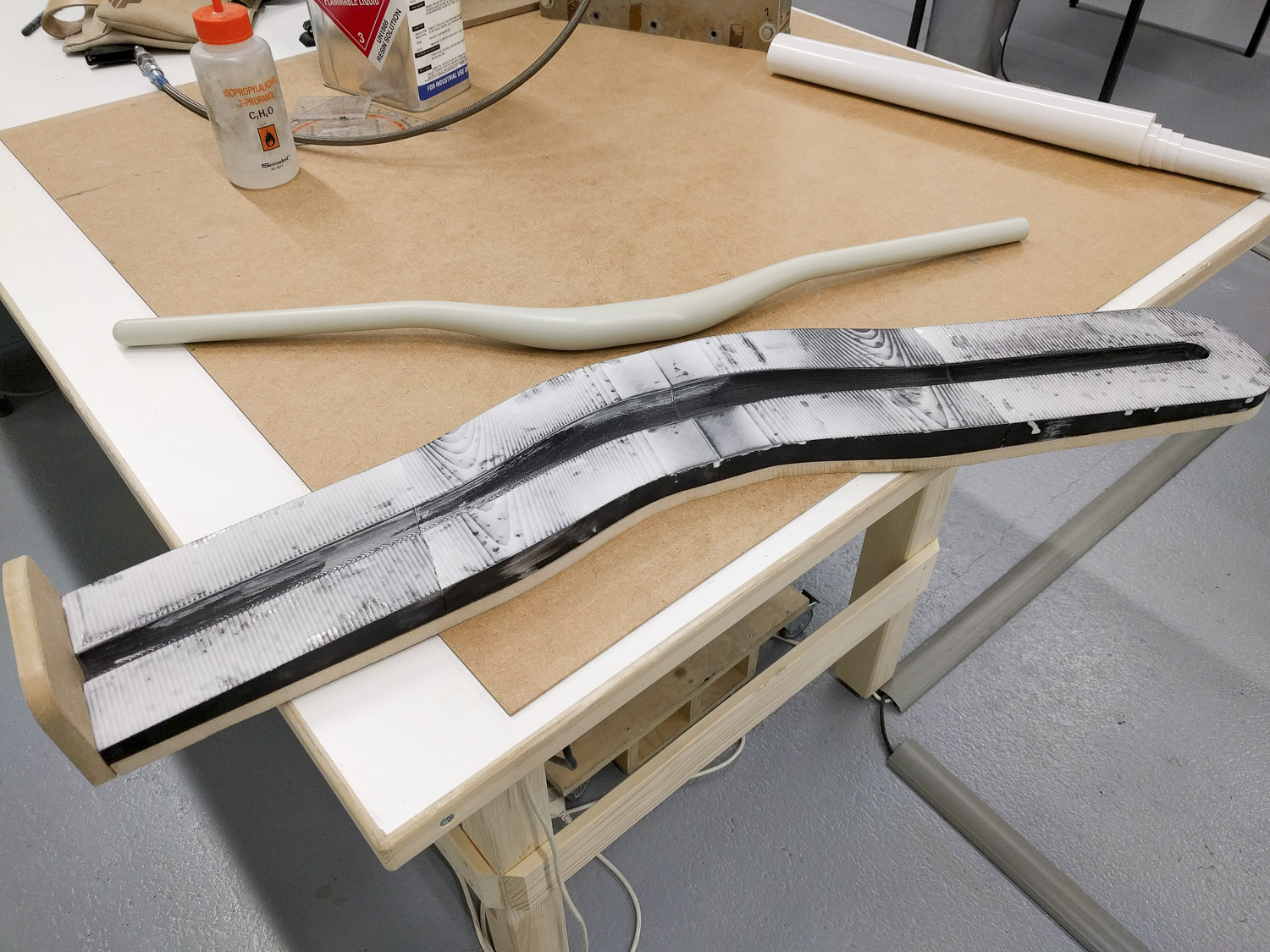

DIY Composite Layup and Vacuum Bagging Making a Carbon Fiber RipSurf How To Make A Mold For Carbon Fiber Layup The first picture is a simplified cad design that would not work as a final mold for a real bike. We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. — how to make a mould for a carbon fiber (fibre) part. Prepping the mold for use. —. How To Make A Mold For Carbon Fiber Layup.

From bercella.it

Bercella first steps of carbon fiber layup process How To Make A Mold For Carbon Fiber Layup This article is intended to help novice through. However, it provides a lot of hands on experience and is cheaper and quicker than skipping to the final design. ***descriptions in pictures help explain the text below. — how to make a mould for a carbon fiber (fibre) part. We’ll detail the specific methods and materials used, ensuring clarity and. How To Make A Mold For Carbon Fiber Layup.

From www.hotrod.com

Carbon Fiber StepbyStep How to Lay Up Carbon Fiber Hot Rod Hot How To Make A Mold For Carbon Fiber Layup This tutorial can be followed to make a mold. The first picture is a simplified cad design that would not work as a final mold for a real bike. However, it provides a lot of hands on experience and is cheaper and quicker than skipping to the final design. This article is intended to help novice through. ***descriptions in pictures. How To Make A Mold For Carbon Fiber Layup.

From www.hotrod.com

Carbon Fiber StepbyStep How to Lay Up Carbon Fiber Hot Rod Hot How To Make A Mold For Carbon Fiber Layup Prepping the mold for use. This tutorial can be followed to make a mold. This article is intended to help novice through. — in this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. — how to make a mould for a carbon fiber. How To Make A Mold For Carbon Fiber Layup.

From bercella.it

Bercella first steps of carbon fiber layup process How To Make A Mold For Carbon Fiber Layup However, it provides a lot of hands on experience and is cheaper and quicker than skipping to the final design. Prepping the mold for use. ***descriptions in pictures help explain the text below. This article is intended to help novice through. — how to make a mould for a carbon fiber (fibre) part. The first picture is a simplified. How To Make A Mold For Carbon Fiber Layup.

From www.dynamism.com

How To Create Carbon Fiber Molds From 3D Printed Patterns Dynamism How To Make A Mold For Carbon Fiber Layup The first picture is a simplified cad design that would not work as a final mold for a real bike. This article is intended to help novice through. This tutorial can be followed to make a mold. Prepping the mold for use. — in this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing. How To Make A Mold For Carbon Fiber Layup.

From carbonfiberclassroom.com

Learn the secrets of making custom molds and carbon fiber parts How To Make A Mold For Carbon Fiber Layup This article is intended to help novice through. This tutorial can be followed to make a mold. Prepping the mold for use. — in this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. However, it provides a lot of hands on experience and is. How To Make A Mold For Carbon Fiber Layup.

From formlabs.com

How to Manufacture Carbon Fiber Parts How To Make A Mold For Carbon Fiber Layup We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. — in this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. Prepping the mold for use. This tutorial can be followed to make a. How To Make A Mold For Carbon Fiber Layup.

From www.easycomposites.eu

Complex Moulding Using Prepreg Carbon Fibre Video Tutorial Easy How To Make A Mold For Carbon Fiber Layup We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. This tutorial can be followed to make a mold. — in this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. This article is intended. How To Make A Mold For Carbon Fiber Layup.

From www.youtube.com

How To Hand Lay Carbon Fiber YouTube How To Make A Mold For Carbon Fiber Layup This article is intended to help novice through. ***descriptions in pictures help explain the text below. This tutorial can be followed to make a mold. The first picture is a simplified cad design that would not work as a final mold for a real bike. — in this section, we focus on the crucial steps for manufacturing carbon fiber. How To Make A Mold For Carbon Fiber Layup.

From www.moldplasticinjection.com

How To Make Carbon Fiber Molds & Parts Mold Making For Carbon Fiber How To Make A Mold For Carbon Fiber Layup We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. Prepping the mold for use. The first picture is a simplified cad design that would not work as a final mold for a real bike. However, it provides a lot of hands on experience and is cheaper and quicker than. How To Make A Mold For Carbon Fiber Layup.

From www.youtube.com

Introduction On Splitmoulds and Prepreg Carbon Fiber YouTube How To Make A Mold For Carbon Fiber Layup However, it provides a lot of hands on experience and is cheaper and quicker than skipping to the final design. — in this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. — how to make a mould for a carbon fiber (fibre) part.. How To Make A Mold For Carbon Fiber Layup.

From www.instructables.com

Easy Carbon Fiber Mold 7 Steps (with Pictures) Instructables How To Make A Mold For Carbon Fiber Layup Prepping the mold for use. — how to make a mould for a carbon fiber (fibre) part. We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. This tutorial can be followed to make a mold. — in this section, we focus on the crucial steps for manufacturing. How To Make A Mold For Carbon Fiber Layup.

From www.easycomposites.eu

Complex Moulding Using Prepreg Carbon Fibre Video Tutorial Easy How To Make A Mold For Carbon Fiber Layup This article is intended to help novice through. However, it provides a lot of hands on experience and is cheaper and quicker than skipping to the final design. This tutorial can be followed to make a mold. Prepping the mold for use. ***descriptions in pictures help explain the text below. We’ll detail the specific methods and materials used, ensuring clarity. How To Make A Mold For Carbon Fiber Layup.

From www.youtube.com

Making A New Fiberglass Hatch From A Mold YouTube How To Make A Mold For Carbon Fiber Layup — in this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. ***descriptions in pictures help explain the text below. — how to make a mould for a carbon fiber (fibre) part. However, it provides a lot of hands on experience and is cheaper. How To Make A Mold For Carbon Fiber Layup.

From www.talkcomposites.com

Carbon Fiber Layup with Mould 3D Printer How To Make A Mold For Carbon Fiber Layup — how to make a mould for a carbon fiber (fibre) part. ***descriptions in pictures help explain the text below. This tutorial can be followed to make a mold. However, it provides a lot of hands on experience and is cheaper and quicker than skipping to the final design. The first picture is a simplified cad design that would. How To Make A Mold For Carbon Fiber Layup.

From car-mods.wonderhowto.com

How to Make a mold for a carbon fiber part « Car Mods WonderHowTo How To Make A Mold For Carbon Fiber Layup However, it provides a lot of hands on experience and is cheaper and quicker than skipping to the final design. Prepping the mold for use. — in this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. ***descriptions in pictures help explain the text below.. How To Make A Mold For Carbon Fiber Layup.

From www.instructables.com

DIY Composite Layup and Vacuum Bagging Making a Carbon Fiber RipSurf How To Make A Mold For Carbon Fiber Layup — in this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. The first picture is a simplified cad design that would not work as. How To Make A Mold For Carbon Fiber Layup.

From www.youtube.com

How to Make a Prepreg Carbon Fibre Mould (Using XPREG® Tooling Prepreg How To Make A Mold For Carbon Fiber Layup We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. The first picture is a simplified cad design that would not work as a final mold for a real bike. Prepping the mold for use. This tutorial can be followed to make a mold. — in this section, we. How To Make A Mold For Carbon Fiber Layup.

From www.pinterest.com

The ultimate guide on how to make a fibreglass/FRP/GRP splitmould How To Make A Mold For Carbon Fiber Layup We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. The first picture is a simplified cad design that would not work as a final mold for a real bike. This article is intended to help novice through. — how to make a mould for a carbon fiber (fibre). How To Make A Mold For Carbon Fiber Layup.

From www.dynamism.com

How To Create Carbon Fiber Molds From 3D Printed Patterns Dynamism How To Make A Mold For Carbon Fiber Layup We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. The first picture is a simplified cad design that would not work as a final mold for a real bike. — how to make a mould for a carbon fiber (fibre) part. This tutorial can be followed to make. How To Make A Mold For Carbon Fiber Layup.

From www.talkcomposites.com

Carbon Fiber Layup with Mould 3D Printer How To Make A Mold For Carbon Fiber Layup ***descriptions in pictures help explain the text below. Prepping the mold for use. However, it provides a lot of hands on experience and is cheaper and quicker than skipping to the final design. — in this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods.. How To Make A Mold For Carbon Fiber Layup.

From www.youtube.com

Wet Layup Vacuum Bagging Cored Carbon Fiber Panel YouTube How To Make A Mold For Carbon Fiber Layup However, it provides a lot of hands on experience and is cheaper and quicker than skipping to the final design. — how to make a mould for a carbon fiber (fibre) part. The first picture is a simplified cad design that would not work as a final mold for a real bike. We’ll detail the specific methods and materials. How To Make A Mold For Carbon Fiber Layup.

From www.youtube.com

Making Complex Carbon Fibre Tubes Using a SplitMould YouTube How To Make A Mold For Carbon Fiber Layup However, it provides a lot of hands on experience and is cheaper and quicker than skipping to the final design. This tutorial can be followed to make a mold. Prepping the mold for use. This article is intended to help novice through. We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong,. How To Make A Mold For Carbon Fiber Layup.