Wire Edm Graphite . Suitable for wire edm electrodes, deep holes, and fine ribs. The shape and thickness of the workpiece directly influence the wire’s diameter, typically ranging from 0.05 to 0.25mm. Best performance on steel, refractory steel, titanium, molybdenum, copper, and. Our sales team can help you select an edm wire to reduce costs and improve throughput. We offer an extensive range of edm graphite materials, including our renowned “ec” and “hk” grade graphite, specifically engineered for sinker edm applications. Plasma cutting uses a constricted arc of ionized gas while wire edm utilizes liquid dielectric and electricity. Belmont carries a comprehensive line of edm wire to meet a wide range of applications. Wire cutting electrical discharge machining (edm) is a highly precise manufacturing process used to cut intricate.

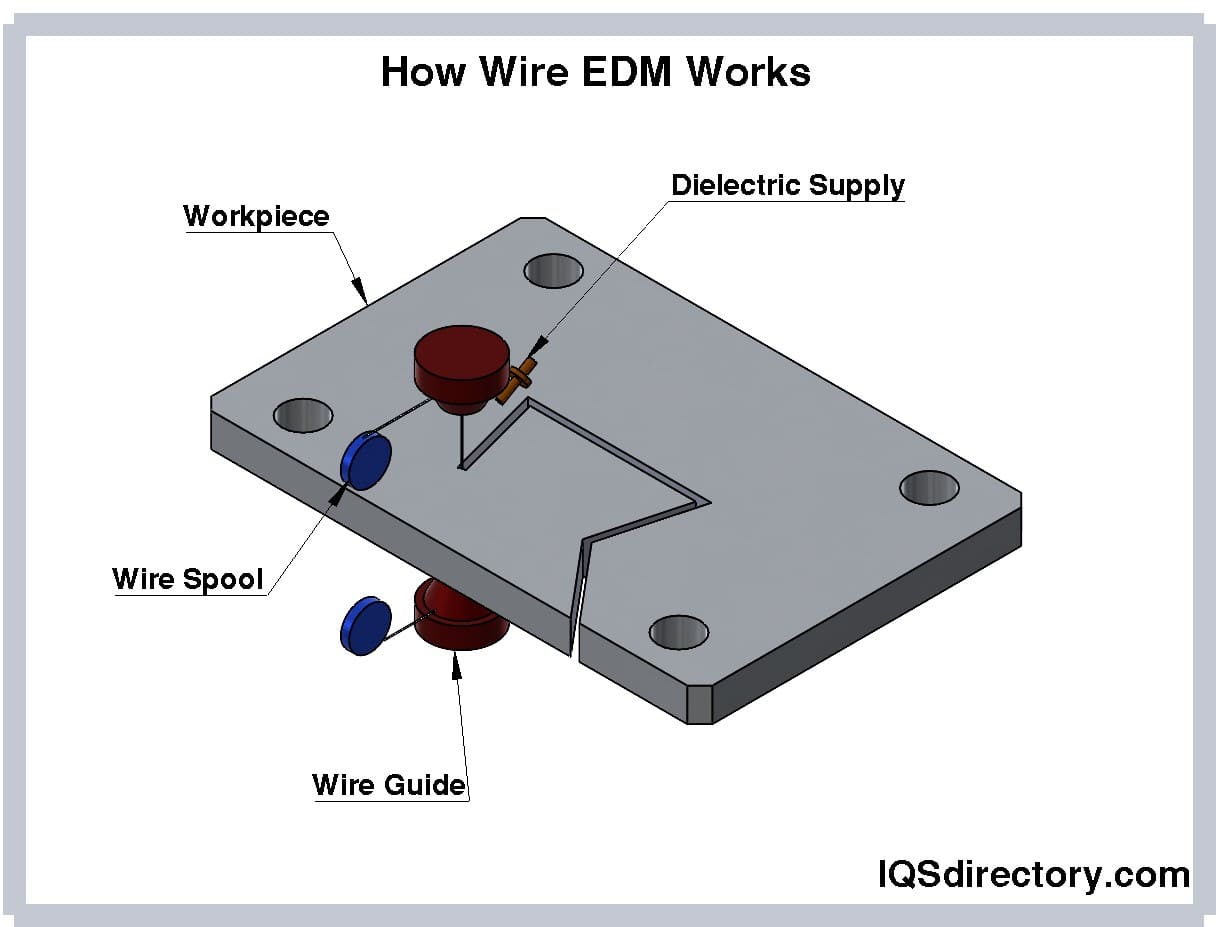

from www.iqsdirectory.com

Best performance on steel, refractory steel, titanium, molybdenum, copper, and. Our sales team can help you select an edm wire to reduce costs and improve throughput. Plasma cutting uses a constricted arc of ionized gas while wire edm utilizes liquid dielectric and electricity. The shape and thickness of the workpiece directly influence the wire’s diameter, typically ranging from 0.05 to 0.25mm. We offer an extensive range of edm graphite materials, including our renowned “ec” and “hk” grade graphite, specifically engineered for sinker edm applications. Wire cutting electrical discharge machining (edm) is a highly precise manufacturing process used to cut intricate. Suitable for wire edm electrodes, deep holes, and fine ribs. Belmont carries a comprehensive line of edm wire to meet a wide range of applications.

Wire EDM Components, Types, Applications, and Advantages

Wire Edm Graphite Suitable for wire edm electrodes, deep holes, and fine ribs. Best performance on steel, refractory steel, titanium, molybdenum, copper, and. Belmont carries a comprehensive line of edm wire to meet a wide range of applications. Suitable for wire edm electrodes, deep holes, and fine ribs. Plasma cutting uses a constricted arc of ionized gas while wire edm utilizes liquid dielectric and electricity. Our sales team can help you select an edm wire to reduce costs and improve throughput. Wire cutting electrical discharge machining (edm) is a highly precise manufacturing process used to cut intricate. The shape and thickness of the workpiece directly influence the wire’s diameter, typically ranging from 0.05 to 0.25mm. We offer an extensive range of edm graphite materials, including our renowned “ec” and “hk” grade graphite, specifically engineered for sinker edm applications.

From saturnedm.com

Precision Graphite Electrodes EDM Electrodes Saturn Industries Wire Edm Graphite Wire cutting electrical discharge machining (edm) is a highly precise manufacturing process used to cut intricate. Our sales team can help you select an edm wire to reduce costs and improve throughput. Best performance on steel, refractory steel, titanium, molybdenum, copper, and. Plasma cutting uses a constricted arc of ionized gas while wire edm utilizes liquid dielectric and electricity. The. Wire Edm Graphite.

From www.cdn-inc.com

EDM Process Types of EDM Machining & Applications Wire Edm Graphite We offer an extensive range of edm graphite materials, including our renowned “ec” and “hk” grade graphite, specifically engineered for sinker edm applications. Suitable for wire edm electrodes, deep holes, and fine ribs. The shape and thickness of the workpiece directly influence the wire’s diameter, typically ranging from 0.05 to 0.25mm. Belmont carries a comprehensive line of edm wire to. Wire Edm Graphite.

From www.meusburger.com

EDM graphite EDM Accessories equipment Meusburger Wire Edm Graphite Our sales team can help you select an edm wire to reduce costs and improve throughput. Best performance on steel, refractory steel, titanium, molybdenum, copper, and. Belmont carries a comprehensive line of edm wire to meet a wide range of applications. We offer an extensive range of edm graphite materials, including our renowned “ec” and “hk” grade graphite, specifically engineered. Wire Edm Graphite.

From www.tecnoedm.com

Graphite Tecno E.D.M. Graphite and Copper electrodes for EDM Wire Edm Graphite Wire cutting electrical discharge machining (edm) is a highly precise manufacturing process used to cut intricate. Best performance on steel, refractory steel, titanium, molybdenum, copper, and. Our sales team can help you select an edm wire to reduce costs and improve throughput. The shape and thickness of the workpiece directly influence the wire’s diameter, typically ranging from 0.05 to 0.25mm.. Wire Edm Graphite.

From www.olmec.co.uk

Graphite for EDM (Electrical Discharge Machining) Wire Edm Graphite Plasma cutting uses a constricted arc of ionized gas while wire edm utilizes liquid dielectric and electricity. Our sales team can help you select an edm wire to reduce costs and improve throughput. We offer an extensive range of edm graphite materials, including our renowned “ec” and “hk” grade graphite, specifically engineered for sinker edm applications. Best performance on steel,. Wire Edm Graphite.

From www.tecnoedm.com

EDM wire Tecno E.D.M. Graphite and Copper electrodes for EDM Wire Edm Graphite Belmont carries a comprehensive line of edm wire to meet a wide range of applications. Suitable for wire edm electrodes, deep holes, and fine ribs. Our sales team can help you select an edm wire to reduce costs and improve throughput. We offer an extensive range of edm graphite materials, including our renowned “ec” and “hk” grade graphite, specifically engineered. Wire Edm Graphite.

From www.tecnoedm.com

Graphite Tecno E.D.M. Graphite and Copper electrodes for EDM Wire Edm Graphite Suitable for wire edm electrodes, deep holes, and fine ribs. Best performance on steel, refractory steel, titanium, molybdenum, copper, and. We offer an extensive range of edm graphite materials, including our renowned “ec” and “hk” grade graphite, specifically engineered for sinker edm applications. Our sales team can help you select an edm wire to reduce costs and improve throughput. Wire. Wire Edm Graphite.

From www.iqsdirectory.com

Wire EDM Components, Types, Applications, and Advantages Wire Edm Graphite Our sales team can help you select an edm wire to reduce costs and improve throughput. Plasma cutting uses a constricted arc of ionized gas while wire edm utilizes liquid dielectric and electricity. The shape and thickness of the workpiece directly influence the wire’s diameter, typically ranging from 0.05 to 0.25mm. Suitable for wire edm electrodes, deep holes, and fine. Wire Edm Graphite.

From www.3dgraphite.com

Endmilling 3D Graphite & Machining Wire Edm Graphite Belmont carries a comprehensive line of edm wire to meet a wide range of applications. Wire cutting electrical discharge machining (edm) is a highly precise manufacturing process used to cut intricate. Suitable for wire edm electrodes, deep holes, and fine ribs. Best performance on steel, refractory steel, titanium, molybdenum, copper, and. Plasma cutting uses a constricted arc of ionized gas. Wire Edm Graphite.

From mwi-inc.com

EDM Applications Using Graphite Electrodes MWI Wire Edm Graphite Suitable for wire edm electrodes, deep holes, and fine ribs. Our sales team can help you select an edm wire to reduce costs and improve throughput. Belmont carries a comprehensive line of edm wire to meet a wide range of applications. The shape and thickness of the workpiece directly influence the wire’s diameter, typically ranging from 0.05 to 0.25mm. Plasma. Wire Edm Graphite.

From www.xrgraphite.com

Graphite for EDM The Key to Manufacturing High Precision Parts Wire Edm Graphite Wire cutting electrical discharge machining (edm) is a highly precise manufacturing process used to cut intricate. Our sales team can help you select an edm wire to reduce costs and improve throughput. The shape and thickness of the workpiece directly influence the wire’s diameter, typically ranging from 0.05 to 0.25mm. Suitable for wire edm electrodes, deep holes, and fine ribs.. Wire Edm Graphite.

From info.belmont4edm.com

SINKER EDM Belmont Equipment & Technologies Wire Edm Graphite Wire cutting electrical discharge machining (edm) is a highly precise manufacturing process used to cut intricate. Suitable for wire edm electrodes, deep holes, and fine ribs. Plasma cutting uses a constricted arc of ionized gas while wire edm utilizes liquid dielectric and electricity. Belmont carries a comprehensive line of edm wire to meet a wide range of applications. Our sales. Wire Edm Graphite.

From www.chinagraphitefactory.com

EDM graphite mould ChinaGraphiteFactory Wire Edm Graphite We offer an extensive range of edm graphite materials, including our renowned “ec” and “hk” grade graphite, specifically engineered for sinker edm applications. Our sales team can help you select an edm wire to reduce costs and improve throughput. Plasma cutting uses a constricted arc of ionized gas while wire edm utilizes liquid dielectric and electricity. Best performance on steel,. Wire Edm Graphite.

From bceweb.org

Wire Edm Feed Rate Chart A Visual Reference of Charts Chart Master Wire Edm Graphite Best performance on steel, refractory steel, titanium, molybdenum, copper, and. Belmont carries a comprehensive line of edm wire to meet a wide range of applications. Wire cutting electrical discharge machining (edm) is a highly precise manufacturing process used to cut intricate. Suitable for wire edm electrodes, deep holes, and fine ribs. The shape and thickness of the workpiece directly influence. Wire Edm Graphite.

From advancedprecisionmachine.com

Wire EDM Advanced Precision Machining Wire Edm Graphite Our sales team can help you select an edm wire to reduce costs and improve throughput. We offer an extensive range of edm graphite materials, including our renowned “ec” and “hk” grade graphite, specifically engineered for sinker edm applications. Best performance on steel, refractory steel, titanium, molybdenum, copper, and. The shape and thickness of the workpiece directly influence the wire’s. Wire Edm Graphite.

From www.iqsdirectory.com

Wire EDM Components, Types, Applications, and Advantages Wire Edm Graphite The shape and thickness of the workpiece directly influence the wire’s diameter, typically ranging from 0.05 to 0.25mm. Belmont carries a comprehensive line of edm wire to meet a wide range of applications. We offer an extensive range of edm graphite materials, including our renowned “ec” and “hk” grade graphite, specifically engineered for sinker edm applications. Best performance on steel,. Wire Edm Graphite.

From prototype-shortrun.com

Wire EDM. What Does it Mean Especially to You ? American Wire EDM Wire Edm Graphite Plasma cutting uses a constricted arc of ionized gas while wire edm utilizes liquid dielectric and electricity. The shape and thickness of the workpiece directly influence the wire’s diameter, typically ranging from 0.05 to 0.25mm. Best performance on steel, refractory steel, titanium, molybdenum, copper, and. Suitable for wire edm electrodes, deep holes, and fine ribs. Belmont carries a comprehensive line. Wire Edm Graphite.

From www.canadianmetalworking.com

Understanding the power of wire EDM Wire Edm Graphite Our sales team can help you select an edm wire to reduce costs and improve throughput. We offer an extensive range of edm graphite materials, including our renowned “ec” and “hk” grade graphite, specifically engineered for sinker edm applications. Best performance on steel, refractory steel, titanium, molybdenum, copper, and. Plasma cutting uses a constricted arc of ionized gas while wire. Wire Edm Graphite.

From www.3dgraphite.com

EDM Graphite 3D Graphite & Machining Wire Edm Graphite Best performance on steel, refractory steel, titanium, molybdenum, copper, and. Belmont carries a comprehensive line of edm wire to meet a wide range of applications. Wire cutting electrical discharge machining (edm) is a highly precise manufacturing process used to cut intricate. The shape and thickness of the workpiece directly influence the wire’s diameter, typically ranging from 0.05 to 0.25mm. Suitable. Wire Edm Graphite.

From www.graphitestore.com

EDM Graphite Wire Edm Graphite Wire cutting electrical discharge machining (edm) is a highly precise manufacturing process used to cut intricate. Best performance on steel, refractory steel, titanium, molybdenum, copper, and. Plasma cutting uses a constricted arc of ionized gas while wire edm utilizes liquid dielectric and electricity. The shape and thickness of the workpiece directly influence the wire’s diameter, typically ranging from 0.05 to. Wire Edm Graphite.

From www.tecnoedm.com

graphite electrode tecno edm electroerosion wire grafite elettrodi Wire Edm Graphite We offer an extensive range of edm graphite materials, including our renowned “ec” and “hk” grade graphite, specifically engineered for sinker edm applications. Belmont carries a comprehensive line of edm wire to meet a wide range of applications. Plasma cutting uses a constricted arc of ionized gas while wire edm utilizes liquid dielectric and electricity. Our sales team can help. Wire Edm Graphite.

From aneelaaryan.blogspot.com

10+ Wire Edm Tooling AneelaAryan Wire Edm Graphite Wire cutting electrical discharge machining (edm) is a highly precise manufacturing process used to cut intricate. We offer an extensive range of edm graphite materials, including our renowned “ec” and “hk” grade graphite, specifically engineered for sinker edm applications. Best performance on steel, refractory steel, titanium, molybdenum, copper, and. Plasma cutting uses a constricted arc of ionized gas while wire. Wire Edm Graphite.

From www.3dgraphite.com

EDM Graphite 3D Graphite & Machining Wire Edm Graphite Best performance on steel, refractory steel, titanium, molybdenum, copper, and. Plasma cutting uses a constricted arc of ionized gas while wire edm utilizes liquid dielectric and electricity. Suitable for wire edm electrodes, deep holes, and fine ribs. Wire cutting electrical discharge machining (edm) is a highly precise manufacturing process used to cut intricate. The shape and thickness of the workpiece. Wire Edm Graphite.

From www.dreamstime.com

The Operation of EDM Machine with Graphite Electrode Materials. Stock Wire Edm Graphite The shape and thickness of the workpiece directly influence the wire’s diameter, typically ranging from 0.05 to 0.25mm. Best performance on steel, refractory steel, titanium, molybdenum, copper, and. We offer an extensive range of edm graphite materials, including our renowned “ec” and “hk” grade graphite, specifically engineered for sinker edm applications. Belmont carries a comprehensive line of edm wire to. Wire Edm Graphite.

From www.amedm.co.uk

EDM Wires What Are Your Options? A&M Wire Edm Graphite The shape and thickness of the workpiece directly influence the wire’s diameter, typically ranging from 0.05 to 0.25mm. Suitable for wire edm electrodes, deep holes, and fine ribs. We offer an extensive range of edm graphite materials, including our renowned “ec” and “hk” grade graphite, specifically engineered for sinker edm applications. Belmont carries a comprehensive line of edm wire to. Wire Edm Graphite.

From www.cncedmtool.com

Sinker EDM electrode High Precision CNC EDM Tool System LTD Wire Edm Graphite Best performance on steel, refractory steel, titanium, molybdenum, copper, and. The shape and thickness of the workpiece directly influence the wire’s diameter, typically ranging from 0.05 to 0.25mm. Suitable for wire edm electrodes, deep holes, and fine ribs. Plasma cutting uses a constricted arc of ionized gas while wire edm utilizes liquid dielectric and electricity. Wire cutting electrical discharge machining. Wire Edm Graphite.

From www.3dgraphite.com

EDM Graphite 3D Graphite & Machining Wire Edm Graphite Best performance on steel, refractory steel, titanium, molybdenum, copper, and. Suitable for wire edm electrodes, deep holes, and fine ribs. The shape and thickness of the workpiece directly influence the wire’s diameter, typically ranging from 0.05 to 0.25mm. Our sales team can help you select an edm wire to reduce costs and improve throughput. Plasma cutting uses a constricted arc. Wire Edm Graphite.

From www.samaterials.com

Graphite Electrode for EDM Stanford Advanced Materials Wire Edm Graphite Plasma cutting uses a constricted arc of ionized gas while wire edm utilizes liquid dielectric and electricity. Belmont carries a comprehensive line of edm wire to meet a wide range of applications. Best performance on steel, refractory steel, titanium, molybdenum, copper, and. We offer an extensive range of edm graphite materials, including our renowned “ec” and “hk” grade graphite, specifically. Wire Edm Graphite.

From info.belmont4edm.com

EDM Graphite Belmont Equipment & Technologies Wire Edm Graphite Plasma cutting uses a constricted arc of ionized gas while wire edm utilizes liquid dielectric and electricity. Belmont carries a comprehensive line of edm wire to meet a wide range of applications. Wire cutting electrical discharge machining (edm) is a highly precise manufacturing process used to cut intricate. Suitable for wire edm electrodes, deep holes, and fine ribs. Our sales. Wire Edm Graphite.

From expomachinetools.com

Expoblog (Part1) Are you selecting a good Graphite grade for your Wire Edm Graphite Wire cutting electrical discharge machining (edm) is a highly precise manufacturing process used to cut intricate. We offer an extensive range of edm graphite materials, including our renowned “ec” and “hk” grade graphite, specifically engineered for sinker edm applications. Suitable for wire edm electrodes, deep holes, and fine ribs. The shape and thickness of the workpiece directly influence the wire’s. Wire Edm Graphite.

From www.iqsdirectory.com

Wire EDM Components, Types, Applications, and Advantages Wire Edm Graphite Our sales team can help you select an edm wire to reduce costs and improve throughput. Plasma cutting uses a constricted arc of ionized gas while wire edm utilizes liquid dielectric and electricity. We offer an extensive range of edm graphite materials, including our renowned “ec” and “hk” grade graphite, specifically engineered for sinker edm applications. Wire cutting electrical discharge. Wire Edm Graphite.

From electricalworkbook.com

What is Wire EDM (Wire Electric Discharge Machining)? Process, Diagram Wire Edm Graphite Belmont carries a comprehensive line of edm wire to meet a wide range of applications. Plasma cutting uses a constricted arc of ionized gas while wire edm utilizes liquid dielectric and electricity. Suitable for wire edm electrodes, deep holes, and fine ribs. Wire cutting electrical discharge machining (edm) is a highly precise manufacturing process used to cut intricate. Best performance. Wire Edm Graphite.

From amr-metallurgy.com

Graphite EDM Electrode Allied Metallurgy Resources LLC Wire Edm Graphite The shape and thickness of the workpiece directly influence the wire’s diameter, typically ranging from 0.05 to 0.25mm. Our sales team can help you select an edm wire to reduce costs and improve throughput. Plasma cutting uses a constricted arc of ionized gas while wire edm utilizes liquid dielectric and electricity. Suitable for wire edm electrodes, deep holes, and fine. Wire Edm Graphite.

From www.tecnoedm.com

Nerve Archives Tecno E.D.M. Graphite and Copper Electrodes for EDM Wire Edm Graphite Belmont carries a comprehensive line of edm wire to meet a wide range of applications. Wire cutting electrical discharge machining (edm) is a highly precise manufacturing process used to cut intricate. The shape and thickness of the workpiece directly influence the wire’s diameter, typically ranging from 0.05 to 0.25mm. Our sales team can help you select an edm wire to. Wire Edm Graphite.

From jinsuncarbon.com

What are the properties of the EDM graphite electrode? Wire Edm Graphite We offer an extensive range of edm graphite materials, including our renowned “ec” and “hk” grade graphite, specifically engineered for sinker edm applications. Wire cutting electrical discharge machining (edm) is a highly precise manufacturing process used to cut intricate. Our sales team can help you select an edm wire to reduce costs and improve throughput. Plasma cutting uses a constricted. Wire Edm Graphite.