Distillation Column Condenser Types . The plate, or tray column is the most widely used type of distillation column. It can get confusing when it comes time to select distillation overheads for your reactor system. Both tray and packed columns are integral to the distillation process, with their selection depending on factors such as the nature of. The number of trays or stages in the column is dependent on the. In this post we’ll focus on overhead design options, and how to size a condenser. These are located at the top of the column and allow the separated vapor components to exit the column and proceed to the condenser. 6 control 6.1 distillation columns the operation of a distillation column is usually coupled to the column pressure control. Feed entry into the distillation. There are many ways in which this can be done. What are the two types of distillation columns? Positioned at the top of the column, the condenser cools down the vaporized components, causing them to condense back into liquid form.

from mungfali.com

It can get confusing when it comes time to select distillation overheads for your reactor system. In this post we’ll focus on overhead design options, and how to size a condenser. Positioned at the top of the column, the condenser cools down the vaporized components, causing them to condense back into liquid form. Feed entry into the distillation. These are located at the top of the column and allow the separated vapor components to exit the column and proceed to the condenser. What are the two types of distillation columns? There are many ways in which this can be done. The number of trays or stages in the column is dependent on the. The plate, or tray column is the most widely used type of distillation column. 6 control 6.1 distillation columns the operation of a distillation column is usually coupled to the column pressure control.

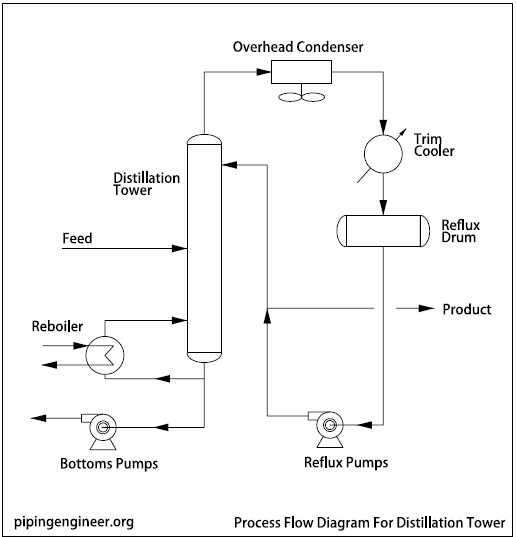

Distillation Column Diagram

Distillation Column Condenser Types There are many ways in which this can be done. The number of trays or stages in the column is dependent on the. Feed entry into the distillation. In this post we’ll focus on overhead design options, and how to size a condenser. It can get confusing when it comes time to select distillation overheads for your reactor system. These are located at the top of the column and allow the separated vapor components to exit the column and proceed to the condenser. Positioned at the top of the column, the condenser cools down the vaporized components, causing them to condense back into liquid form. There are many ways in which this can be done. Both tray and packed columns are integral to the distillation process, with their selection depending on factors such as the nature of. The plate, or tray column is the most widely used type of distillation column. What are the two types of distillation columns? 6 control 6.1 distillation columns the operation of a distillation column is usually coupled to the column pressure control.

From www.savree.com

Distillation Column Explained saVRee Distillation Column Condenser Types In this post we’ll focus on overhead design options, and how to size a condenser. Both tray and packed columns are integral to the distillation process, with their selection depending on factors such as the nature of. The plate, or tray column is the most widely used type of distillation column. What are the two types of distillation columns? The. Distillation Column Condenser Types.

From enggcyclopedia.com

Distillation Column EnggCyclopedia Distillation Column Condenser Types Positioned at the top of the column, the condenser cools down the vaporized components, causing them to condense back into liquid form. Feed entry into the distillation. The number of trays or stages in the column is dependent on the. 6 control 6.1 distillation columns the operation of a distillation column is usually coupled to the column pressure control. It. Distillation Column Condenser Types.

From www.gustawater.com

The Ultimate Guide to Distillation and Distillation Columns Distillation Column Condenser Types In this post we’ll focus on overhead design options, and how to size a condenser. Both tray and packed columns are integral to the distillation process, with their selection depending on factors such as the nature of. The number of trays or stages in the column is dependent on the. It can get confusing when it comes time to select. Distillation Column Condenser Types.

From www.chemicals.co.uk

What is Fractional Distillation? The Chemistry Blog Distillation Column Condenser Types It can get confusing when it comes time to select distillation overheads for your reactor system. There are many ways in which this can be done. Both tray and packed columns are integral to the distillation process, with their selection depending on factors such as the nature of. What are the two types of distillation columns? The plate, or tray. Distillation Column Condenser Types.

From www.researchgate.net

Schematic diagram of assembly for water distillation. The boiler Distillation Column Condenser Types Both tray and packed columns are integral to the distillation process, with their selection depending on factors such as the nature of. In this post we’ll focus on overhead design options, and how to size a condenser. It can get confusing when it comes time to select distillation overheads for your reactor system. The plate, or tray column is the. Distillation Column Condenser Types.

From www.artofit.org

How a distillation column works column distillation Artofit Distillation Column Condenser Types 6 control 6.1 distillation columns the operation of a distillation column is usually coupled to the column pressure control. Feed entry into the distillation. Positioned at the top of the column, the condenser cools down the vaporized components, causing them to condense back into liquid form. There are many ways in which this can be done. The number of trays. Distillation Column Condenser Types.

From www.pinterest.com

TYPES OF DISTILLATION COLUMNS petrochemicalindustry the type of column Distillation Column Condenser Types It can get confusing when it comes time to select distillation overheads for your reactor system. 6 control 6.1 distillation columns the operation of a distillation column is usually coupled to the column pressure control. Feed entry into the distillation. The number of trays or stages in the column is dependent on the. In this post we’ll focus on overhead. Distillation Column Condenser Types.

From chemistry.stackexchange.com

experimental chemistry Choosing the right condenser Chemistry Stack Distillation Column Condenser Types There are many ways in which this can be done. Positioned at the top of the column, the condenser cools down the vaporized components, causing them to condense back into liquid form. It can get confusing when it comes time to select distillation overheads for your reactor system. These are located at the top of the column and allow the. Distillation Column Condenser Types.

From easywayscience78.blogspot.com

Distillation Easy way to learn science Distillation Column Condenser Types These are located at the top of the column and allow the separated vapor components to exit the column and proceed to the condenser. Positioned at the top of the column, the condenser cools down the vaporized components, causing them to condense back into liquid form. There are many ways in which this can be done. In this post we’ll. Distillation Column Condenser Types.

From www.webbusterz.org

What is a distillation column? 6 types to read about now Distillation Column Condenser Types There are many ways in which this can be done. The plate, or tray column is the most widely used type of distillation column. Positioned at the top of the column, the condenser cools down the vaporized components, causing them to condense back into liquid form. The number of trays or stages in the column is dependent on the. In. Distillation Column Condenser Types.

From www.researchgate.net

Schematic diagram of the packed distillation column. Download Distillation Column Condenser Types The plate, or tray column is the most widely used type of distillation column. Positioned at the top of the column, the condenser cools down the vaporized components, causing them to condense back into liquid form. These are located at the top of the column and allow the separated vapor components to exit the column and proceed to the condenser.. Distillation Column Condenser Types.

From www.mechanical-knowledge.com

DISTILLATION COLUMN HOW IT WORK AND IT'S COMPONENTS Distillation Column Condenser Types It can get confusing when it comes time to select distillation overheads for your reactor system. The plate, or tray column is the most widely used type of distillation column. There are many ways in which this can be done. Positioned at the top of the column, the condenser cools down the vaporized components, causing them to condense back into. Distillation Column Condenser Types.

From www.researchgate.net

General Structure of an Internally Heat Integrated Distillation Column Distillation Column Condenser Types Both tray and packed columns are integral to the distillation process, with their selection depending on factors such as the nature of. These are located at the top of the column and allow the separated vapor components to exit the column and proceed to the condenser. There are many ways in which this can be done. The plate, or tray. Distillation Column Condenser Types.

From imgbin.com

Distillation Fractionating Column Condenser McCabeThiele Method Liquid Distillation Column Condenser Types The number of trays or stages in the column is dependent on the. In this post we’ll focus on overhead design options, and how to size a condenser. Positioned at the top of the column, the condenser cools down the vaporized components, causing them to condense back into liquid form. Feed entry into the distillation. The plate, or tray column. Distillation Column Condenser Types.

From mungfali.com

Distillation Column Diagram Distillation Column Condenser Types In this post we’ll focus on overhead design options, and how to size a condenser. The number of trays or stages in the column is dependent on the. The plate, or tray column is the most widely used type of distillation column. What are the two types of distillation columns? Both tray and packed columns are integral to the distillation. Distillation Column Condenser Types.

From chemicalengineeringworld.com

Types of Distillation Chemical Engineering World Distillation Column Condenser Types The plate, or tray column is the most widely used type of distillation column. There are many ways in which this can be done. Both tray and packed columns are integral to the distillation process, with their selection depending on factors such as the nature of. The number of trays or stages in the column is dependent on the. 6. Distillation Column Condenser Types.

From neutrium.net

Distillation Fundamentals Neutrium Distillation Column Condenser Types Both tray and packed columns are integral to the distillation process, with their selection depending on factors such as the nature of. Feed entry into the distillation. What are the two types of distillation columns? Positioned at the top of the column, the condenser cools down the vaporized components, causing them to condense back into liquid form. In this post. Distillation Column Condenser Types.

From www.chemicals.co.uk

What is the Distillation Process? The Chemistry Blog Distillation Column Condenser Types There are many ways in which this can be done. Positioned at the top of the column, the condenser cools down the vaporized components, causing them to condense back into liquid form. 6 control 6.1 distillation columns the operation of a distillation column is usually coupled to the column pressure control. Feed entry into the distillation. These are located at. Distillation Column Condenser Types.

From www.theengineeringconcepts.com

Types of Distillation The Engineering Concepts Distillation Column Condenser Types It can get confusing when it comes time to select distillation overheads for your reactor system. The number of trays or stages in the column is dependent on the. In this post we’ll focus on overhead design options, and how to size a condenser. Positioned at the top of the column, the condenser cools down the vaporized components, causing them. Distillation Column Condenser Types.

From medium.com

distillation column. distillation is process where component… by Distillation Column Condenser Types Positioned at the top of the column, the condenser cools down the vaporized components, causing them to condense back into liquid form. 6 control 6.1 distillation columns the operation of a distillation column is usually coupled to the column pressure control. These are located at the top of the column and allow the separated vapor components to exit the column. Distillation Column Condenser Types.

From www.researchgate.net

Package type distillation column. Left Schematics of a package tube Distillation Column Condenser Types Feed entry into the distillation. These are located at the top of the column and allow the separated vapor components to exit the column and proceed to the condenser. There are many ways in which this can be done. Positioned at the top of the column, the condenser cools down the vaporized components, causing them to condense back into liquid. Distillation Column Condenser Types.

From www.researchgate.net

Schematic diagram of distillation column. Download Scientific Diagram Distillation Column Condenser Types Positioned at the top of the column, the condenser cools down the vaporized components, causing them to condense back into liquid form. These are located at the top of the column and allow the separated vapor components to exit the column and proceed to the condenser. The plate, or tray column is the most widely used type of distillation column.. Distillation Column Condenser Types.

From encyclopedia.che.engin.umich.edu

Distillation Columns Visual Encyclopedia of Chemical Engineering Distillation Column Condenser Types It can get confusing when it comes time to select distillation overheads for your reactor system. In this post we’ll focus on overhead design options, and how to size a condenser. Both tray and packed columns are integral to the distillation process, with their selection depending on factors such as the nature of. The plate, or tray column is the. Distillation Column Condenser Types.

From www.reddit.com

Distillation Column Internals Nomenclature ChemEngineeringWorld Distillation Column Condenser Types It can get confusing when it comes time to select distillation overheads for your reactor system. 6 control 6.1 distillation columns the operation of a distillation column is usually coupled to the column pressure control. What are the two types of distillation columns? The number of trays or stages in the column is dependent on the. In this post we’ll. Distillation Column Condenser Types.

From mavink.com

Distillation Column Types Distillation Column Condenser Types The plate, or tray column is the most widely used type of distillation column. There are many ways in which this can be done. 6 control 6.1 distillation columns the operation of a distillation column is usually coupled to the column pressure control. Both tray and packed columns are integral to the distillation process, with their selection depending on factors. Distillation Column Condenser Types.

From www.savree.com

Distillation Column Explained saVRee Distillation Column Condenser Types The plate, or tray column is the most widely used type of distillation column. There are many ways in which this can be done. In this post we’ll focus on overhead design options, and how to size a condenser. 6 control 6.1 distillation columns the operation of a distillation column is usually coupled to the column pressure control. These are. Distillation Column Condenser Types.

From www.gustawater.com

The Ultimate Guide to Distillation and Distillation Columns Distillation Column Condenser Types These are located at the top of the column and allow the separated vapor components to exit the column and proceed to the condenser. The plate, or tray column is the most widely used type of distillation column. Feed entry into the distillation. There are many ways in which this can be done. 6 control 6.1 distillation columns the operation. Distillation Column Condenser Types.

From www.mechanical-knowledge.com

DISTILLATION COLUMN HOW IT WORK AND IT'S COMPONENTS Distillation Column Condenser Types It can get confusing when it comes time to select distillation overheads for your reactor system. In this post we’ll focus on overhead design options, and how to size a condenser. Feed entry into the distillation. 6 control 6.1 distillation columns the operation of a distillation column is usually coupled to the column pressure control. Positioned at the top of. Distillation Column Condenser Types.

From mungfali.com

Distillation Column Diagram Distillation Column Condenser Types Positioned at the top of the column, the condenser cools down the vaporized components, causing them to condense back into liquid form. Both tray and packed columns are integral to the distillation process, with their selection depending on factors such as the nature of. There are many ways in which this can be done. The plate, or tray column is. Distillation Column Condenser Types.

From www.chemengghelp.com

Batch Distillation Column Operation & Controls ChemEnggHelp Distillation Column Condenser Types Positioned at the top of the column, the condenser cools down the vaporized components, causing them to condense back into liquid form. 6 control 6.1 distillation columns the operation of a distillation column is usually coupled to the column pressure control. The number of trays or stages in the column is dependent on the. In this post we’ll focus on. Distillation Column Condenser Types.

From enggyd.blogspot.com

Engineers Guide MULTI COMPONENT DISTILLATION COLUMN DIAGRAM Distillation Column Condenser Types Positioned at the top of the column, the condenser cools down the vaporized components, causing them to condense back into liquid form. 6 control 6.1 distillation columns the operation of a distillation column is usually coupled to the column pressure control. Feed entry into the distillation. It can get confusing when it comes time to select distillation overheads for your. Distillation Column Condenser Types.

From www.researchgate.net

BinaryDistillation Column With Single Feed and Total Condenser Distillation Column Condenser Types It can get confusing when it comes time to select distillation overheads for your reactor system. The plate, or tray column is the most widely used type of distillation column. These are located at the top of the column and allow the separated vapor components to exit the column and proceed to the condenser. In this post we’ll focus on. Distillation Column Condenser Types.

From design.udlvirtual.edu.pe

Types Of Continuous Distillation Column Design Talk Distillation Column Condenser Types Feed entry into the distillation. It can get confusing when it comes time to select distillation overheads for your reactor system. 6 control 6.1 distillation columns the operation of a distillation column is usually coupled to the column pressure control. In this post we’ll focus on overhead design options, and how to size a condenser. Both tray and packed columns. Distillation Column Condenser Types.

From mungfali.com

Distillation Column Diagram Distillation Column Condenser Types The plate, or tray column is the most widely used type of distillation column. Feed entry into the distillation. In this post we’ll focus on overhead design options, and how to size a condenser. The number of trays or stages in the column is dependent on the. What are the two types of distillation columns? These are located at the. Distillation Column Condenser Types.

From chemengvirtual.uwaterloo.ca

Distillation Column 360° Interactive 3D VR Distillation Laboratory Distillation Column Condenser Types The plate, or tray column is the most widely used type of distillation column. The number of trays or stages in the column is dependent on the. It can get confusing when it comes time to select distillation overheads for your reactor system. In this post we’ll focus on overhead design options, and how to size a condenser. Positioned at. Distillation Column Condenser Types.