Engine Counterweight . Machinists have used this formula to calculate bobweight for decades. A crankshaft’s counterweights are tasked with counterweighting the weight of the pistons and rods on the opposing side to keep. The counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually by. For higher frequencies you need. With counterweights on the crankshaft you can influence the balance only in the first order. A typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. Engineers know the weight of the pistons and rods and design the crank counterweights accordingly, making drilling to balance them the quickest method for production. With internally balanced engines, the counterweights on the crankshaft are big enough to cancel out the rotating mass of the pistons and connecting rods. With this type of balance, there is less weight on the nose of the crank. If the mass of the counterweight equals the weight of the upper half of the rod, piston, wrist pin and rings, the forces will be balanced and the engine will run smoothly. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the rotating mass, and equal half the weight of the reciprocating mass.

from autotrends.org

A crankshaft’s counterweights are tasked with counterweighting the weight of the pistons and rods on the opposing side to keep. For higher frequencies you need. The counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually by. With counterweights on the crankshaft you can influence the balance only in the first order. With internally balanced engines, the counterweights on the crankshaft are big enough to cancel out the rotating mass of the pistons and connecting rods. Machinists have used this formula to calculate bobweight for decades. A typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the rotating mass, and equal half the weight of the reciprocating mass. Engineers know the weight of the pistons and rods and design the crank counterweights accordingly, making drilling to balance them the quickest method for production. With this type of balance, there is less weight on the nose of the crank.

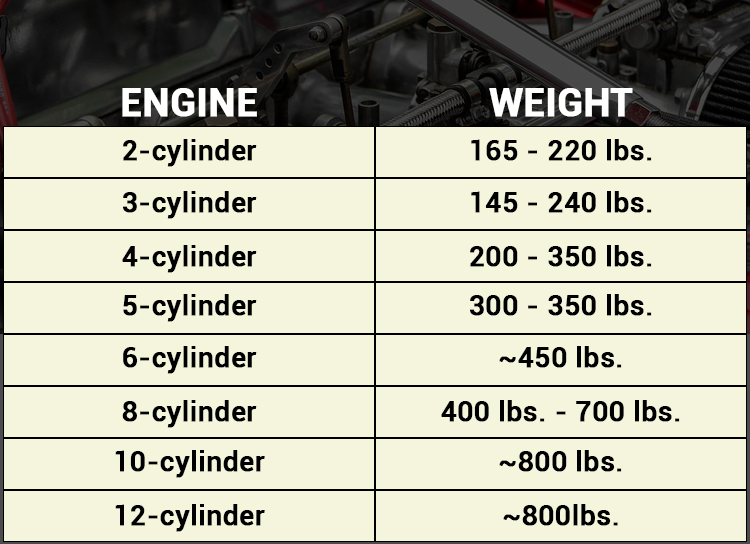

How Much Does a Car Engine Weigh? Auto Trends Magazine

Engine Counterweight For higher frequencies you need. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the rotating mass, and equal half the weight of the reciprocating mass. A crankshaft’s counterweights are tasked with counterweighting the weight of the pistons and rods on the opposing side to keep. With internally balanced engines, the counterweights on the crankshaft are big enough to cancel out the rotating mass of the pistons and connecting rods. With this type of balance, there is less weight on the nose of the crank. A typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. If the mass of the counterweight equals the weight of the upper half of the rod, piston, wrist pin and rings, the forces will be balanced and the engine will run smoothly. The counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually by. With counterweights on the crankshaft you can influence the balance only in the first order. Machinists have used this formula to calculate bobweight for decades. For higher frequencies you need. Engineers know the weight of the pistons and rods and design the crank counterweights accordingly, making drilling to balance them the quickest method for production.

From www.enginehistory.org

Crankshaft Counterweight Capers at Allison Engine Counterweight Machinists have used this formula to calculate bobweight for decades. With counterweights on the crankshaft you can influence the balance only in the first order. Engineers know the weight of the pistons and rods and design the crank counterweights accordingly, making drilling to balance them the quickest method for production. A typical “stock” crankshaft is balanced by drilling the counterweights. Engine Counterweight.

From www.chevydiy.com

Chevy BigBlock Performance Pistons, Connecting Rods and Crankshafts Engine Counterweight Machinists have used this formula to calculate bobweight for decades. The counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually by. A crankshaft’s counterweights are tasked with counterweighting the weight of the pistons and rods on the opposing side to keep. For higher frequencies. Engine Counterweight.

From www.vandijkheavyequipment.com

Caterpillar Counterweight D8T 2015 Counterweight Van Dijk Heavy Equipment Engine Counterweight Machinists have used this formula to calculate bobweight for decades. The counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually by. With this type of balance, there is less weight on the nose of the crank. With counterweights on the crankshaft you can influence. Engine Counterweight.

From fixenginedellendirectosr.z4.web.core.windows.net

Diesel Engine Weight Chart Engine Counterweight Engineers know the weight of the pistons and rods and design the crank counterweights accordingly, making drilling to balance them the quickest method for production. A typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. With this type of balance, there is less weight on the nose of the crank. Machinists and engine builders have long been. Engine Counterweight.

From www.vehiclesmechanic.com

How Much Does a Duramax Engine Weigh? [12 Engine Models Weight] Engine Counterweight With this type of balance, there is less weight on the nose of the crank. Machinists have used this formula to calculate bobweight for decades. If the mass of the counterweight equals the weight of the upper half of the rod, piston, wrist pin and rings, the forces will be balanced and the engine will run smoothly. The counterweights are. Engine Counterweight.

From carolinadunebuggies.com

69MM COUNTERWEIGHTED CRANKSHAFT Engine Counterweight A typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. With this type of balance, there is less weight on the nose of the crank. The counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually by. If the mass of the. Engine Counterweight.

From www.dreamstime.com

Fragment of the Diesel Engine. Counterweight Stock Image Image of engine, industry 189057073 Engine Counterweight Engineers know the weight of the pistons and rods and design the crank counterweights accordingly, making drilling to balance them the quickest method for production. For higher frequencies you need. With counterweights on the crankshaft you can influence the balance only in the first order. Machinists have used this formula to calculate bobweight for decades. A typical “stock” crankshaft is. Engine Counterweight.

From www.eng-tips.com

Crankshaft counterweight shape ? Engine & fuel engineering EngTips Engine Counterweight The counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually by. A crankshaft’s counterweights are tasked with counterweighting the weight of the pistons and rods on the opposing side to keep. With internally balanced engines, the counterweights on the crankshaft are big enough to. Engine Counterweight.

From www.youtube.com

SolidWorks Tutorial Stirling Engine 4.Counterweight A YouTube Engine Counterweight Machinists have used this formula to calculate bobweight for decades. The counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually by. A typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. With this type of balance, there is less weight on. Engine Counterweight.

From dieselsales.com

DIESEL ENGINE AND TRANSMISSION WEIGHT CHART Engine Counterweight A crankshaft’s counterweights are tasked with counterweighting the weight of the pistons and rods on the opposing side to keep. Engineers know the weight of the pistons and rods and design the crank counterweights accordingly, making drilling to balance them the quickest method for production. With internally balanced engines, the counterweights on the crankshaft are big enough to cancel out. Engine Counterweight.

From www.dragzine.com

Engine Balancing with Tom Lieb from Scat Enterprises Engine Counterweight Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the rotating mass, and equal half the weight of the reciprocating mass. A crankshaft’s counterweights are tasked with counterweighting the weight of the pistons and rods on the opposing side to keep. Engineers know the weight of the pistons and. Engine Counterweight.

From autotrends.org

How Much Does a Car Engine Weigh? Auto Trends Magazine Engine Counterweight Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the rotating mass, and equal half the weight of the reciprocating mass. A crankshaft’s counterweights are tasked with counterweighting the weight of the pistons and rods on the opposing side to keep. With internally balanced engines, the counterweights on the. Engine Counterweight.

From www.billetrotary.com.au

Rotary Engine Counterweight Locking Tool billetrotarystore Engine Counterweight With counterweights on the crankshaft you can influence the balance only in the first order. Machinists have used this formula to calculate bobweight for decades. For higher frequencies you need. The counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually by. Machinists and engine. Engine Counterweight.

From thebloughs.net

Understanding Crankshaft Counterweights Tom's Maker Site Engine Counterweight Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the rotating mass, and equal half the weight of the reciprocating mass. For higher frequencies you need. Machinists have used this formula to calculate bobweight for decades. Engineers know the weight of the pistons and rods and design the crank. Engine Counterweight.

From www.youtube.com

Aluminum VS Iron LS Engine Weight Comparison YouTube Engine Counterweight For higher frequencies you need. Engineers know the weight of the pistons and rods and design the crank counterweights accordingly, making drilling to balance them the quickest method for production. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the rotating mass, and equal half the weight of the. Engine Counterweight.

From www.howacarworks.com

How the crankshaft works All the details How a Car Works Engine Counterweight A typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the rotating mass, and equal half the weight of the reciprocating mass. With this type of balance, there is less weight on the nose of the crank.. Engine Counterweight.

From thebloughs.net

Understanding Crankshaft Counterweights Tom's Maker Site Engine Counterweight With internally balanced engines, the counterweights on the crankshaft are big enough to cancel out the rotating mass of the pistons and connecting rods. With counterweights on the crankshaft you can influence the balance only in the first order. With this type of balance, there is less weight on the nose of the crank. For higher frequencies you need. A. Engine Counterweight.

From www.agrieuro.co.uk

Engine Counterweight kit for Eurosystems P70 , best deal on AgriEuro Engine Counterweight If the mass of the counterweight equals the weight of the upper half of the rod, piston, wrist pin and rings, the forces will be balanced and the engine will run smoothly. A crankshaft’s counterweights are tasked with counterweighting the weight of the pistons and rods on the opposing side to keep. Engineers know the weight of the pistons and. Engine Counterweight.

From borowskirace.com

Callies Center Counterweight (CCW) Magnum Crank for LS Engines Borowski Race Engines Engine Counterweight If the mass of the counterweight equals the weight of the upper half of the rod, piston, wrist pin and rings, the forces will be balanced and the engine will run smoothly. For higher frequencies you need. With this type of balance, there is less weight on the nose of the crank. Machinists have used this formula to calculate bobweight. Engine Counterweight.

From axlewise.com

How Heavy Is An Engine? [Car Motor Weight Chart] Engine Counterweight A typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. A crankshaft’s counterweights are tasked with counterweighting the weight of the pistons and rods on the opposing side to keep. If the mass of the counterweight equals the weight of the upper half of the rod, piston, wrist pin and rings, the forces will be balanced and. Engine Counterweight.

From www.sub5zero.com

Ariel Atom 500 V8 Highest Power to Weight Ratio Ever! Engine Counterweight If the mass of the counterweight equals the weight of the upper half of the rod, piston, wrist pin and rings, the forces will be balanced and the engine will run smoothly. A typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. With internally balanced engines, the counterweights on the crankshaft are big enough to cancel out. Engine Counterweight.

From www.youtube.com

1 Cylinder Crankshaft Counter Weights Clearance and Torque YouTube Engine Counterweight If the mass of the counterweight equals the weight of the upper half of the rod, piston, wrist pin and rings, the forces will be balanced and the engine will run smoothly. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the rotating mass, and equal half the weight. Engine Counterweight.

From zrp-rods.com

Billet Crankshafts Features ZRP Engine Counterweight With counterweights on the crankshaft you can influence the balance only in the first order. The counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually by. A typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. With this type of balance,. Engine Counterweight.

From www.ebay.com

Crankshaft crank counterweight balancer Briggs Stratton 331777 20 hp engine eBay Engine Counterweight The counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually by. With this type of balance, there is less weight on the nose of the crank. With counterweights on the crankshaft you can influence the balance only in the first order. If the mass. Engine Counterweight.

From nathanandrews.z21.web.core.windows.net

Ford Engine Weight Chart Engine Counterweight With counterweights on the crankshaft you can influence the balance only in the first order. Engineers know the weight of the pistons and rods and design the crank counterweights accordingly, making drilling to balance them the quickest method for production. If the mass of the counterweight equals the weight of the upper half of the rod, piston, wrist pin and. Engine Counterweight.

From www.youtube.com

Briggs and Stratton LHead Counterweight Timing Crankshaft Gear Timing Mark Covered by Bearing Engine Counterweight With internally balanced engines, the counterweights on the crankshaft are big enough to cancel out the rotating mass of the pistons and connecting rods. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the rotating mass, and equal half the weight of the reciprocating mass. With counterweights on the. Engine Counterweight.

From www.onallcylinders.com

Finding Balance (Part 3) Getting Beyond the of Traditional Engine Balancing Engine Counterweight Machinists have used this formula to calculate bobweight for decades. For higher frequencies you need. A typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. Engineers know the weight of the pistons and rods and design the crank counterweights accordingly, making drilling to balance them the quickest method for production. If the mass of the counterweight equals. Engine Counterweight.

From www.enginebuildermag.com

Weighing in on Balancing Work Engine Builder Magazine Engine Counterweight A typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. For higher frequencies you need. The counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually by. If the mass of the counterweight equals the weight of the upper half of the. Engine Counterweight.

From www.semanticscholar.org

Figure 1 from An investigation of the effect of counterweight configuration on main bearing load Engine Counterweight With this type of balance, there is less weight on the nose of the crank. The counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually by. Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the. Engine Counterweight.

From ljaircooledengines.com

Cast Counterweight Crankshaft VW Journal LJ AirCooled Engines Engine Counterweight Machinists and engine builders have long been taught that, when balancing a crankshaft, its counterweights should equal the weight of the rotating mass, and equal half the weight of the reciprocating mass. With internally balanced engines, the counterweights on the crankshaft are big enough to cancel out the rotating mass of the pistons and connecting rods. A crankshaft’s counterweights are. Engine Counterweight.

From www.enginehistory.org

Floating Crankshaft Counterweight Engine Counterweight With this type of balance, there is less weight on the nose of the crank. For higher frequencies you need. Machinists have used this formula to calculate bobweight for decades. A typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. A crankshaft’s counterweights are tasked with counterweighting the weight of the pistons and rods on the opposing. Engine Counterweight.

From repairenginelemann77.z19.web.core.windows.net

Ford Engine Sizes Chart Engine Counterweight With this type of balance, there is less weight on the nose of the crank. Engineers know the weight of the pistons and rods and design the crank counterweights accordingly, making drilling to balance them the quickest method for production. With counterweights on the crankshaft you can influence the balance only in the first order. Machinists and engine builders have. Engine Counterweight.

From www.atkinsrotary.com

7485 13B Front Counterweight (N30411511) Engine Counterweight With this type of balance, there is less weight on the nose of the crank. A typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. The counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually by. If the mass of the. Engine Counterweight.

From www.agrieuro.co.uk

Engine Counterweight kit for Eurosystems P70 , best deal on AgriEuro Engine Counterweight A crankshaft’s counterweights are tasked with counterweighting the weight of the pistons and rods on the opposing side to keep. For higher frequencies you need. Engineers know the weight of the pistons and rods and design the crank counterweights accordingly, making drilling to balance them the quickest method for production. If the mass of the counterweight equals the weight of. Engine Counterweight.

From mechaniclistsmalms123.z22.web.core.windows.net

Ford Engine Weight Chart Engine Counterweight A crankshaft’s counterweights are tasked with counterweighting the weight of the pistons and rods on the opposing side to keep. Engineers know the weight of the pistons and rods and design the crank counterweights accordingly, making drilling to balance them the quickest method for production. If the mass of the counterweight equals the weight of the upper half of the. Engine Counterweight.