What Is Internal Grinding . The surface may be straight, tapered, grooved or profiled. Types of internal grinding machine with diagram explained. Grinding is a precise mechanical machining process that removes material from a workpiece surface using a rotating grinding wheel. Broadly there are three different types of internal grinding machine as follows: Internal grinding is used for finishing the internal surfaces of components. It involves a small grinding wheel. Internal grinding or inner diameter (id) grinding is used to grind the inner diameter of holes in parts. Composed of abrasive particles, the wheel acts like numerous sharp cutting tools, scraping away layers of material to achieve desired shapes and surface finishes. Internal grinding is a precision machining process used to finish the inner surfaces of cylindrical components, achieving tight tolerances and. This machine is used to produce internal cylindrical surface. An internal grinder machine is a powerful tool used in machining operations to produce precise and accurate internal holes or bores in components.

from www.teiken-corporation-en.com

Internal grinding or inner diameter (id) grinding is used to grind the inner diameter of holes in parts. The surface may be straight, tapered, grooved or profiled. This machine is used to produce internal cylindrical surface. It involves a small grinding wheel. Broadly there are three different types of internal grinding machine as follows: Internal grinding is used for finishing the internal surfaces of components. Internal grinding is a precision machining process used to finish the inner surfaces of cylindrical components, achieving tight tolerances and. Composed of abrasive particles, the wheel acts like numerous sharp cutting tools, scraping away layers of material to achieve desired shapes and surface finishes. An internal grinder machine is a powerful tool used in machining operations to produce precise and accurate internal holes or bores in components. Grinding is a precise mechanical machining process that removes material from a workpiece surface using a rotating grinding wheel.

GRIDING METHODGrinding Stone TEIKEN Corporation

What Is Internal Grinding It involves a small grinding wheel. Broadly there are three different types of internal grinding machine as follows: An internal grinder machine is a powerful tool used in machining operations to produce precise and accurate internal holes or bores in components. Internal grinding or inner diameter (id) grinding is used to grind the inner diameter of holes in parts. Internal grinding is used for finishing the internal surfaces of components. Grinding is a precise mechanical machining process that removes material from a workpiece surface using a rotating grinding wheel. Composed of abrasive particles, the wheel acts like numerous sharp cutting tools, scraping away layers of material to achieve desired shapes and surface finishes. The surface may be straight, tapered, grooved or profiled. Types of internal grinding machine with diagram explained. Internal grinding is a precision machining process used to finish the inner surfaces of cylindrical components, achieving tight tolerances and. This machine is used to produce internal cylindrical surface. It involves a small grinding wheel.

From ontariochrome.com

Internal Grinding Ontario Chrome What Is Internal Grinding This machine is used to produce internal cylindrical surface. Types of internal grinding machine with diagram explained. Grinding is a precise mechanical machining process that removes material from a workpiece surface using a rotating grinding wheel. The surface may be straight, tapered, grooved or profiled. Composed of abrasive particles, the wheel acts like numerous sharp cutting tools, scraping away layers. What Is Internal Grinding.

From themechanicalengineering.com

Grinding Machine Definition, Parts, Working Principle, Operation What Is Internal Grinding Types of internal grinding machine with diagram explained. Broadly there are three different types of internal grinding machine as follows: Internal grinding is used for finishing the internal surfaces of components. An internal grinder machine is a powerful tool used in machining operations to produce precise and accurate internal holes or bores in components. Internal grinding is a precision machining. What Is Internal Grinding.

From finemetalworking.com

What is Centerless Grinding? How Does the Machine Work? What Is Internal Grinding Internal grinding is a precision machining process used to finish the inner surfaces of cylindrical components, achieving tight tolerances and. This machine is used to produce internal cylindrical surface. Internal grinding is used for finishing the internal surfaces of components. Composed of abrasive particles, the wheel acts like numerous sharp cutting tools, scraping away layers of material to achieve desired. What Is Internal Grinding.

From agir-technologies.com

Internal Grinding Machines What Is Internal Grinding The surface may be straight, tapered, grooved or profiled. Composed of abrasive particles, the wheel acts like numerous sharp cutting tools, scraping away layers of material to achieve desired shapes and surface finishes. Broadly there are three different types of internal grinding machine as follows: It involves a small grinding wheel. Internal grinding or inner diameter (id) grinding is used. What Is Internal Grinding.

From www.dreamstime.com

Internal Grinding Machine. Shop for Metal Machining Stock Image Image What Is Internal Grinding An internal grinder machine is a powerful tool used in machining operations to produce precise and accurate internal holes or bores in components. Broadly there are three different types of internal grinding machine as follows: Composed of abrasive particles, the wheel acts like numerous sharp cutting tools, scraping away layers of material to achieve desired shapes and surface finishes. Types. What Is Internal Grinding.

From metalcutting.com

Specialized Methods of Internal Grinding Metal Cutting Corporation What Is Internal Grinding It involves a small grinding wheel. Types of internal grinding machine with diagram explained. Internal grinding is used for finishing the internal surfaces of components. This machine is used to produce internal cylindrical surface. The surface may be straight, tapered, grooved or profiled. Internal grinding is a precision machining process used to finish the inner surfaces of cylindrical components, achieving. What Is Internal Grinding.

From www.youtube.com

Internal Grinding Machine FMB 200 YouTube What Is Internal Grinding The surface may be straight, tapered, grooved or profiled. This machine is used to produce internal cylindrical surface. It involves a small grinding wheel. Broadly there are three different types of internal grinding machine as follows: Internal grinding or inner diameter (id) grinding is used to grind the inner diameter of holes in parts. Types of internal grinding machine with. What Is Internal Grinding.

From www.indiamart.com

Internal Grinding Service, in On Site at Rs 200/hour in Sas Nagar ID What Is Internal Grinding Composed of abrasive particles, the wheel acts like numerous sharp cutting tools, scraping away layers of material to achieve desired shapes and surface finishes. The surface may be straight, tapered, grooved or profiled. Internal grinding is a precision machining process used to finish the inner surfaces of cylindrical components, achieving tight tolerances and. This machine is used to produce internal. What Is Internal Grinding.

From www.youtube.com

Internal grinding machine for large workpieces OVERBECK ILD YouTube What Is Internal Grinding Internal grinding or inner diameter (id) grinding is used to grind the inner diameter of holes in parts. Broadly there are three different types of internal grinding machine as follows: It involves a small grinding wheel. Grinding is a precise mechanical machining process that removes material from a workpiece surface using a rotating grinding wheel. Internal grinding is used for. What Is Internal Grinding.

From www.dreamstime.com

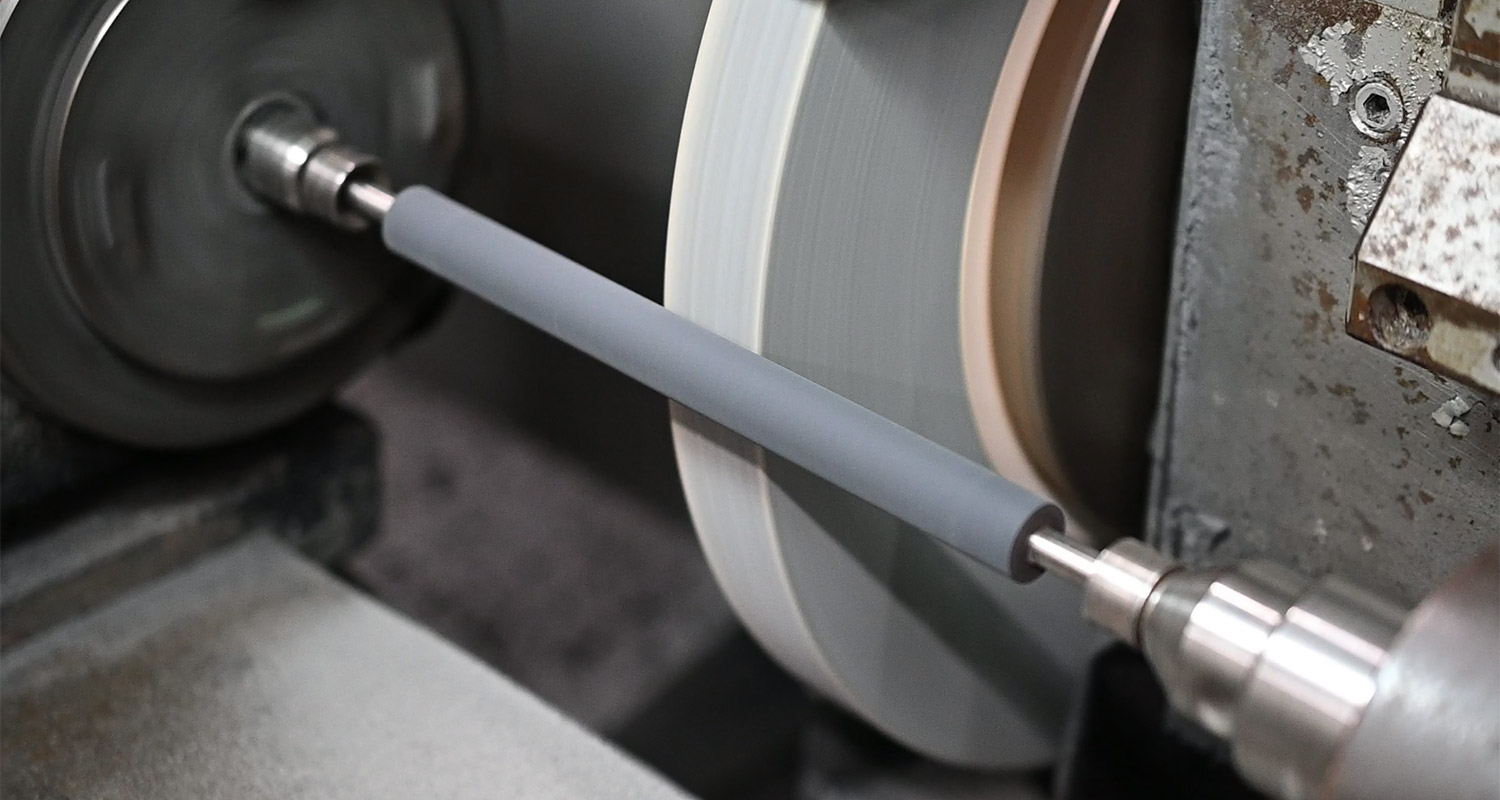

Internal Grinding of a Cylindrical Part with an Abrasive Wheel on a What Is Internal Grinding Types of internal grinding machine with diagram explained. It involves a small grinding wheel. Composed of abrasive particles, the wheel acts like numerous sharp cutting tools, scraping away layers of material to achieve desired shapes and surface finishes. This machine is used to produce internal cylindrical surface. Internal grinding is a precision machining process used to finish the inner surfaces. What Is Internal Grinding.

From www.superabrasivetools.com

19 How to Choose Internal Grinding Wheels ? Newdiamondtools What Is Internal Grinding Types of internal grinding machine with diagram explained. The surface may be straight, tapered, grooved or profiled. Internal grinding or inner diameter (id) grinding is used to grind the inner diameter of holes in parts. Grinding is a precise mechanical machining process that removes material from a workpiece surface using a rotating grinding wheel. This machine is used to produce. What Is Internal Grinding.

From www.youtube.com

Internal Grinding Machine Morara YouTube What Is Internal Grinding Grinding is a precise mechanical machining process that removes material from a workpiece surface using a rotating grinding wheel. It involves a small grinding wheel. Types of internal grinding machine with diagram explained. Composed of abrasive particles, the wheel acts like numerous sharp cutting tools, scraping away layers of material to achieve desired shapes and surface finishes. Broadly there are. What Is Internal Grinding.

From www.laxmiusedmachine.com

INTERNAL GRINDER, VOUMARD 52A Laxmi Metal & Machines, Rohtak What Is Internal Grinding This machine is used to produce internal cylindrical surface. The surface may be straight, tapered, grooved or profiled. Broadly there are three different types of internal grinding machine as follows: Grinding is a precise mechanical machining process that removes material from a workpiece surface using a rotating grinding wheel. An internal grinder machine is a powerful tool used in machining. What Is Internal Grinding.

From www.dreamstime.com

Internal Grinding on a Circular Grinding Machine and is Processed by an What Is Internal Grinding It involves a small grinding wheel. The surface may be straight, tapered, grooved or profiled. Internal grinding is a precision machining process used to finish the inner surfaces of cylindrical components, achieving tight tolerances and. An internal grinder machine is a powerful tool used in machining operations to produce precise and accurate internal holes or bores in components. This machine. What Is Internal Grinding.

From www.superabrasivetools.com

2019 Tips To Solving the Internal Grinding Problems Newdiamondtools What Is Internal Grinding Broadly there are three different types of internal grinding machine as follows: Composed of abrasive particles, the wheel acts like numerous sharp cutting tools, scraping away layers of material to achieve desired shapes and surface finishes. Internal grinding or inner diameter (id) grinding is used to grind the inner diameter of holes in parts. This machine is used to produce. What Is Internal Grinding.

From www.youtube.com

Internal grinding large bore YouTube What Is Internal Grinding Internal grinding is used for finishing the internal surfaces of components. It involves a small grinding wheel. Internal grinding is a precision machining process used to finish the inner surfaces of cylindrical components, achieving tight tolerances and. This machine is used to produce internal cylindrical surface. Grinding is a precise mechanical machining process that removes material from a workpiece surface. What Is Internal Grinding.

From www.factorneed.com

Grinding Machines Internal Grinding What Is Internal Grinding Composed of abrasive particles, the wheel acts like numerous sharp cutting tools, scraping away layers of material to achieve desired shapes and surface finishes. This machine is used to produce internal cylindrical surface. Types of internal grinding machine with diagram explained. Internal grinding is a precision machining process used to finish the inner surfaces of cylindrical components, achieving tight tolerances. What Is Internal Grinding.

From www.allied-material.co.jp

Various grinding methods|A.L.M.T. Corp. What Is Internal Grinding The surface may be straight, tapered, grooved or profiled. Broadly there are three different types of internal grinding machine as follows: Types of internal grinding machine with diagram explained. This machine is used to produce internal cylindrical surface. It involves a small grinding wheel. Internal grinding is used for finishing the internal surfaces of components. Internal grinding or inner diameter. What Is Internal Grinding.

From www.researchgate.net

View of the machining zone of internal cylindrical grinding process What Is Internal Grinding This machine is used to produce internal cylindrical surface. Types of internal grinding machine with diagram explained. The surface may be straight, tapered, grooved or profiled. Internal grinding is used for finishing the internal surfaces of components. Composed of abrasive particles, the wheel acts like numerous sharp cutting tools, scraping away layers of material to achieve desired shapes and surface. What Is Internal Grinding.

From www.etechtw.com

Introduction of CNC Internal Grinding Machine Blog Etech Machinery What Is Internal Grinding The surface may be straight, tapered, grooved or profiled. Internal grinding is a precision machining process used to finish the inner surfaces of cylindrical components, achieving tight tolerances and. Internal grinding or inner diameter (id) grinding is used to grind the inner diameter of holes in parts. This machine is used to produce internal cylindrical surface. Types of internal grinding. What Is Internal Grinding.

From www.dreamstime.com

Internal Grinding of a Cylindrical Mandrel with a Watercooled Abrasive What Is Internal Grinding The surface may be straight, tapered, grooved or profiled. Composed of abrasive particles, the wheel acts like numerous sharp cutting tools, scraping away layers of material to achieve desired shapes and surface finishes. Broadly there are three different types of internal grinding machine as follows: It involves a small grinding wheel. Grinding is a precise mechanical machining process that removes. What Is Internal Grinding.

From finemetalworking.com

What is Centerless Grinding? How Does the Machine Work? What Is Internal Grinding Broadly there are three different types of internal grinding machine as follows: Grinding is a precise mechanical machining process that removes material from a workpiece surface using a rotating grinding wheel. The surface may be straight, tapered, grooved or profiled. Internal grinding or inner diameter (id) grinding is used to grind the inner diameter of holes in parts. Types of. What Is Internal Grinding.

From www.superabrasivetools.com

2019 Tips To Solving the Internal Grinding Problems Newdiamondtools What Is Internal Grinding The surface may be straight, tapered, grooved or profiled. Grinding is a precise mechanical machining process that removes material from a workpiece surface using a rotating grinding wheel. It involves a small grinding wheel. An internal grinder machine is a powerful tool used in machining operations to produce precise and accurate internal holes or bores in components. Types of internal. What Is Internal Grinding.

From www.teiken-corporation-en.com

GRIDING METHODGrinding Stone TEIKEN Corporation What Is Internal Grinding Composed of abrasive particles, the wheel acts like numerous sharp cutting tools, scraping away layers of material to achieve desired shapes and surface finishes. Internal grinding or inner diameter (id) grinding is used to grind the inner diameter of holes in parts. The surface may be straight, tapered, grooved or profiled. Internal grinding is a precision machining process used to. What Is Internal Grinding.

From finemetalworking.com

Cylindrical Grinding Fine MetalWorking What Is Internal Grinding Composed of abrasive particles, the wheel acts like numerous sharp cutting tools, scraping away layers of material to achieve desired shapes and surface finishes. The surface may be straight, tapered, grooved or profiled. This machine is used to produce internal cylindrical surface. It involves a small grinding wheel. An internal grinder machine is a powerful tool used in machining operations. What Is Internal Grinding.

From www.dreamstime.com

Internal Grinding Operation on a Cylindrical Grinding Machine with What Is Internal Grinding This machine is used to produce internal cylindrical surface. Types of internal grinding machine with diagram explained. Internal grinding is used for finishing the internal surfaces of components. Composed of abrasive particles, the wheel acts like numerous sharp cutting tools, scraping away layers of material to achieve desired shapes and surface finishes. It involves a small grinding wheel. Broadly there. What Is Internal Grinding.

From www.dreamstime.com

Metal Grinding, Internal Grinding with an Abrasive Wheel on a High What Is Internal Grinding The surface may be straight, tapered, grooved or profiled. Internal grinding is used for finishing the internal surfaces of components. Grinding is a precise mechanical machining process that removes material from a workpiece surface using a rotating grinding wheel. Types of internal grinding machine with diagram explained. Internal grinding or inner diameter (id) grinding is used to grind the inner. What Is Internal Grinding.

From www.researchgate.net

Illustration of internal grinding process Download Scientific Diagram What Is Internal Grinding The surface may be straight, tapered, grooved or profiled. Internal grinding or inner diameter (id) grinding is used to grind the inner diameter of holes in parts. This machine is used to produce internal cylindrical surface. Internal grinding is a precision machining process used to finish the inner surfaces of cylindrical components, achieving tight tolerances and. Internal grinding is used. What Is Internal Grinding.

From www.northernplating.com

Internal Grinding Northern Plating What Is Internal Grinding Internal grinding is used for finishing the internal surfaces of components. Broadly there are three different types of internal grinding machine as follows: Internal grinding is a precision machining process used to finish the inner surfaces of cylindrical components, achieving tight tolerances and. The surface may be straight, tapered, grooved or profiled. An internal grinder machine is a powerful tool. What Is Internal Grinding.

From www.dreamstime.com

Internal Grinding of a Cylindrical Mandrel with a Watercooled Abrasive What Is Internal Grinding It involves a small grinding wheel. Internal grinding is used for finishing the internal surfaces of components. Internal grinding or inner diameter (id) grinding is used to grind the inner diameter of holes in parts. Internal grinding is a precision machining process used to finish the inner surfaces of cylindrical components, achieving tight tolerances and. Grinding is a precise mechanical. What Is Internal Grinding.

From learnmech.com

Types of Grinding Machines LearnMech What Is Internal Grinding Composed of abrasive particles, the wheel acts like numerous sharp cutting tools, scraping away layers of material to achieve desired shapes and surface finishes. Broadly there are three different types of internal grinding machine as follows: Internal grinding is used for finishing the internal surfaces of components. The surface may be straight, tapered, grooved or profiled. Grinding is a precise. What Is Internal Grinding.

From www.allied-material.co.jp

Various grinding methods|A.L.M.T. Corp. What Is Internal Grinding Types of internal grinding machine with diagram explained. This machine is used to produce internal cylindrical surface. Internal grinding or inner diameter (id) grinding is used to grind the inner diameter of holes in parts. Composed of abrasive particles, the wheel acts like numerous sharp cutting tools, scraping away layers of material to achieve desired shapes and surface finishes. Internal. What Is Internal Grinding.

From www.youtube.com

Nakanishi internal grinding 60000 rpm Lipemec RC250 YouTube What Is Internal Grinding Grinding is a precise mechanical machining process that removes material from a workpiece surface using a rotating grinding wheel. Composed of abrasive particles, the wheel acts like numerous sharp cutting tools, scraping away layers of material to achieve desired shapes and surface finishes. This machine is used to produce internal cylindrical surface. Broadly there are three different types of internal. What Is Internal Grinding.

From pt.slideshare.net

Chapter 25 (grinding) What Is Internal Grinding An internal grinder machine is a powerful tool used in machining operations to produce precise and accurate internal holes or bores in components. Internal grinding is a precision machining process used to finish the inner surfaces of cylindrical components, achieving tight tolerances and. Types of internal grinding machine with diagram explained. This machine is used to produce internal cylindrical surface.. What Is Internal Grinding.

From www.northernplating.com

Internal Grinding Northern Plating What Is Internal Grinding Internal grinding is used for finishing the internal surfaces of components. Types of internal grinding machine with diagram explained. The surface may be straight, tapered, grooved or profiled. This machine is used to produce internal cylindrical surface. Grinding is a precise mechanical machining process that removes material from a workpiece surface using a rotating grinding wheel. Broadly there are three. What Is Internal Grinding.