Grinding Spherical Surfaces . Grinding marks are regard as a great obstacle to manufacture spherical and aspheric surfaces with higher surface quality, lower. Some works focused on the methodologies for grinding of spherical surfaces. Planar and spherical optical elements, with their straightforward geometries, can achieve high surface accuracy through traditional. A new method for predicting the surface roughness in spherical grinding was developed. Spherical grinding typically uses a. The ground spherical surfaces were examined using laser interferometry, wyko optical interferometry, and scanning electron. Rotational grinding was adopted for the generation of spherical convex surfaces using metal and resin bonded cup wheels.

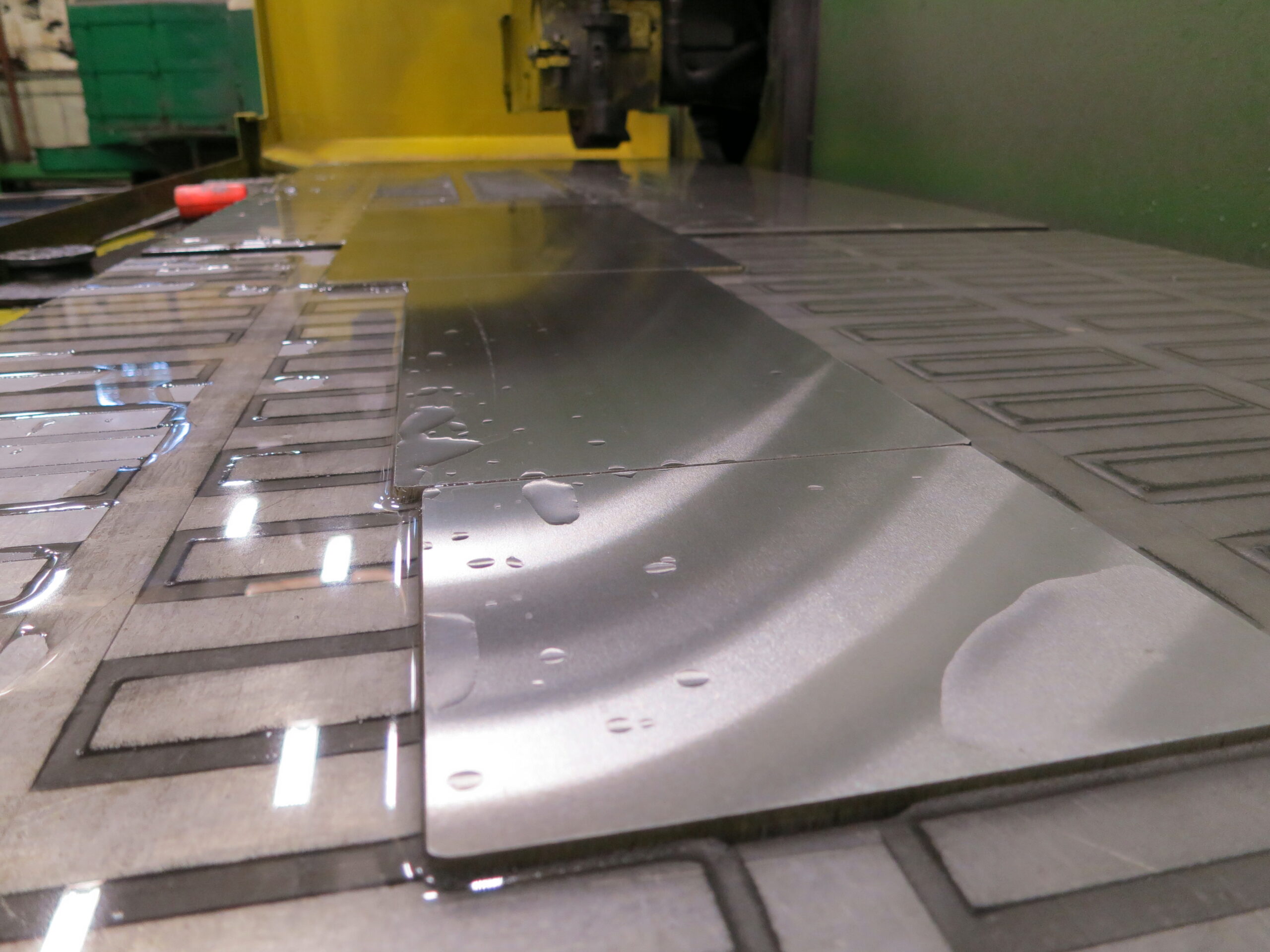

from pgisteel.com

Grinding marks are regard as a great obstacle to manufacture spherical and aspheric surfaces with higher surface quality, lower. The ground spherical surfaces were examined using laser interferometry, wyko optical interferometry, and scanning electron. Planar and spherical optical elements, with their straightforward geometries, can achieve high surface accuracy through traditional. A new method for predicting the surface roughness in spherical grinding was developed. Some works focused on the methodologies for grinding of spherical surfaces. Rotational grinding was adopted for the generation of spherical convex surfaces using metal and resin bonded cup wheels. Spherical grinding typically uses a.

Surface Grinding Precision Grinding, Inc.

Grinding Spherical Surfaces Grinding marks are regard as a great obstacle to manufacture spherical and aspheric surfaces with higher surface quality, lower. Some works focused on the methodologies for grinding of spherical surfaces. Grinding marks are regard as a great obstacle to manufacture spherical and aspheric surfaces with higher surface quality, lower. Planar and spherical optical elements, with their straightforward geometries, can achieve high surface accuracy through traditional. A new method for predicting the surface roughness in spherical grinding was developed. The ground spherical surfaces were examined using laser interferometry, wyko optical interferometry, and scanning electron. Rotational grinding was adopted for the generation of spherical convex surfaces using metal and resin bonded cup wheels. Spherical grinding typically uses a.

From www.intime-eng.com

Cylindrical & Surface Grinding Intime Engineering Grinding Spherical Surfaces A new method for predicting the surface roughness in spherical grinding was developed. The ground spherical surfaces were examined using laser interferometry, wyko optical interferometry, and scanning electron. Spherical grinding typically uses a. Grinding marks are regard as a great obstacle to manufacture spherical and aspheric surfaces with higher surface quality, lower. Rotational grinding was adopted for the generation of. Grinding Spherical Surfaces.

From eureka.patsnap.com

Fixture for grinding outer spherical surfaces of spherical washers Grinding Spherical Surfaces The ground spherical surfaces were examined using laser interferometry, wyko optical interferometry, and scanning electron. Grinding marks are regard as a great obstacle to manufacture spherical and aspheric surfaces with higher surface quality, lower. Spherical grinding typically uses a. Some works focused on the methodologies for grinding of spherical surfaces. Rotational grinding was adopted for the generation of spherical convex. Grinding Spherical Surfaces.

From eureka.patsnap.com

Fixture for grinding outer spherical surfaces of spherical washers Grinding Spherical Surfaces A new method for predicting the surface roughness in spherical grinding was developed. Spherical grinding typically uses a. Grinding marks are regard as a great obstacle to manufacture spherical and aspheric surfaces with higher surface quality, lower. The ground spherical surfaces were examined using laser interferometry, wyko optical interferometry, and scanning electron. Planar and spherical optical elements, with their straightforward. Grinding Spherical Surfaces.

From www.youtube.com

Lapmaster SPL3 SPHERICAL SPINDLE LAPPING POLISHING MACHINE YouTube Grinding Spherical Surfaces Some works focused on the methodologies for grinding of spherical surfaces. Grinding marks are regard as a great obstacle to manufacture spherical and aspheric surfaces with higher surface quality, lower. The ground spherical surfaces were examined using laser interferometry, wyko optical interferometry, and scanning electron. A new method for predicting the surface roughness in spherical grinding was developed. Spherical grinding. Grinding Spherical Surfaces.

From henginheavy.com

Grinding Mill Spherical Tile Grinding Spherical Surfaces Grinding marks are regard as a great obstacle to manufacture spherical and aspheric surfaces with higher surface quality, lower. Planar and spherical optical elements, with their straightforward geometries, can achieve high surface accuracy through traditional. Spherical grinding typically uses a. The ground spherical surfaces were examined using laser interferometry, wyko optical interferometry, and scanning electron. Some works focused on the. Grinding Spherical Surfaces.

From www.youtube.com

S131 Sphere grinding YouTube Grinding Spherical Surfaces Rotational grinding was adopted for the generation of spherical convex surfaces using metal and resin bonded cup wheels. Some works focused on the methodologies for grinding of spherical surfaces. A new method for predicting the surface roughness in spherical grinding was developed. Spherical grinding typically uses a. The ground spherical surfaces were examined using laser interferometry, wyko optical interferometry, and. Grinding Spherical Surfaces.

From henginheavy.com

Grinding Mill Spherical Tile Grinding Spherical Surfaces Rotational grinding was adopted for the generation of spherical convex surfaces using metal and resin bonded cup wheels. A new method for predicting the surface roughness in spherical grinding was developed. Spherical grinding typically uses a. Grinding marks are regard as a great obstacle to manufacture spherical and aspheric surfaces with higher surface quality, lower. Planar and spherical optical elements,. Grinding Spherical Surfaces.

From www.opticalquartzglass.com

36rpm Optical Manufacturing Equipment Spherical Surface Milling Grinding Grinding Spherical Surfaces Grinding marks are regard as a great obstacle to manufacture spherical and aspheric surfaces with higher surface quality, lower. The ground spherical surfaces were examined using laser interferometry, wyko optical interferometry, and scanning electron. Spherical grinding typically uses a. A new method for predicting the surface roughness in spherical grinding was developed. Planar and spherical optical elements, with their straightforward. Grinding Spherical Surfaces.

From www.researchgate.net

The geometric classification of surfaces. Spherical surfaces (D=0 Grinding Spherical Surfaces Spherical grinding typically uses a. Rotational grinding was adopted for the generation of spherical convex surfaces using metal and resin bonded cup wheels. Planar and spherical optical elements, with their straightforward geometries, can achieve high surface accuracy through traditional. The ground spherical surfaces were examined using laser interferometry, wyko optical interferometry, and scanning electron. Grinding marks are regard as a. Grinding Spherical Surfaces.

From www.pinterest.com

Pin on Machining & Grinding Grinding Spherical Surfaces Some works focused on the methodologies for grinding of spherical surfaces. A new method for predicting the surface roughness in spherical grinding was developed. Planar and spherical optical elements, with their straightforward geometries, can achieve high surface accuracy through traditional. Rotational grinding was adopted for the generation of spherical convex surfaces using metal and resin bonded cup wheels. Grinding marks. Grinding Spherical Surfaces.

From www.yhabrasives.com

Grinding of the spherical surface by the grinding wheel Yihong Abrasives Grinding Spherical Surfaces Some works focused on the methodologies for grinding of spherical surfaces. Rotational grinding was adopted for the generation of spherical convex surfaces using metal and resin bonded cup wheels. Spherical grinding typically uses a. The ground spherical surfaces were examined using laser interferometry, wyko optical interferometry, and scanning electron. Planar and spherical optical elements, with their straightforward geometries, can achieve. Grinding Spherical Surfaces.

From www.mdpi.com

Micromachines Free FullText Geometric Error Analysis and Grinding Spherical Surfaces Planar and spherical optical elements, with their straightforward geometries, can achieve high surface accuracy through traditional. Spherical grinding typically uses a. Grinding marks are regard as a great obstacle to manufacture spherical and aspheric surfaces with higher surface quality, lower. The ground spherical surfaces were examined using laser interferometry, wyko optical interferometry, and scanning electron. Some works focused on the. Grinding Spherical Surfaces.

From www.youtube.com

cnc grinding machine tool spherical surface grinding automatically Grinding Spherical Surfaces Spherical grinding typically uses a. Grinding marks are regard as a great obstacle to manufacture spherical and aspheric surfaces with higher surface quality, lower. Rotational grinding was adopted for the generation of spherical convex surfaces using metal and resin bonded cup wheels. A new method for predicting the surface roughness in spherical grinding was developed. Some works focused on the. Grinding Spherical Surfaces.

From pgisteel.com

Surface Grinding Precision Grinding, Inc. Grinding Spherical Surfaces A new method for predicting the surface roughness in spherical grinding was developed. Planar and spherical optical elements, with their straightforward geometries, can achieve high surface accuracy through traditional. The ground spherical surfaces were examined using laser interferometry, wyko optical interferometry, and scanning electron. Grinding marks are regard as a great obstacle to manufacture spherical and aspheric surfaces with higher. Grinding Spherical Surfaces.

From www.youtube.com

Refraction through a spherical surface formula derivation!! Class 12th Grinding Spherical Surfaces Planar and spherical optical elements, with their straightforward geometries, can achieve high surface accuracy through traditional. A new method for predicting the surface roughness in spherical grinding was developed. Rotational grinding was adopted for the generation of spherical convex surfaces using metal and resin bonded cup wheels. Spherical grinding typically uses a. Grinding marks are regard as a great obstacle. Grinding Spherical Surfaces.

From www.glassfab.com

Surface Grinding & Spherical Generating Glass Fab, Inc. Grinding Spherical Surfaces The ground spherical surfaces were examined using laser interferometry, wyko optical interferometry, and scanning electron. Planar and spherical optical elements, with their straightforward geometries, can achieve high surface accuracy through traditional. Some works focused on the methodologies for grinding of spherical surfaces. Spherical grinding typically uses a. Grinding marks are regard as a great obstacle to manufacture spherical and aspheric. Grinding Spherical Surfaces.

From www.precision-surface.com

What is Surface Grinding & Reciprocating grinding? Grinding Spherical Surfaces The ground spherical surfaces were examined using laser interferometry, wyko optical interferometry, and scanning electron. A new method for predicting the surface roughness in spherical grinding was developed. Planar and spherical optical elements, with their straightforward geometries, can achieve high surface accuracy through traditional. Grinding marks are regard as a great obstacle to manufacture spherical and aspheric surfaces with higher. Grinding Spherical Surfaces.

From www.youtube.com

Vertical Grinding concave spherical.wmv YouTube Grinding Spherical Surfaces Planar and spherical optical elements, with their straightforward geometries, can achieve high surface accuracy through traditional. A new method for predicting the surface roughness in spherical grinding was developed. The ground spherical surfaces were examined using laser interferometry, wyko optical interferometry, and scanning electron. Grinding marks are regard as a great obstacle to manufacture spherical and aspheric surfaces with higher. Grinding Spherical Surfaces.

From eureka.patsnap.com

Integrated precision grinding system and method for extralarge Grinding Spherical Surfaces Rotational grinding was adopted for the generation of spherical convex surfaces using metal and resin bonded cup wheels. Some works focused on the methodologies for grinding of spherical surfaces. Planar and spherical optical elements, with their straightforward geometries, can achieve high surface accuracy through traditional. The ground spherical surfaces were examined using laser interferometry, wyko optical interferometry, and scanning electron.. Grinding Spherical Surfaces.

From appsystems.com.sg

Flat / Spherical Grinding Machines » APP Systems Services Grinding Spherical Surfaces The ground spherical surfaces were examined using laser interferometry, wyko optical interferometry, and scanning electron. Some works focused on the methodologies for grinding of spherical surfaces. Rotational grinding was adopted for the generation of spherical convex surfaces using metal and resin bonded cup wheels. Planar and spherical optical elements, with their straightforward geometries, can achieve high surface accuracy through traditional.. Grinding Spherical Surfaces.

From appsystems.com.sg

Flat / Spherical Grinding Machines » APP Systems Services Grinding Spherical Surfaces Rotational grinding was adopted for the generation of spherical convex surfaces using metal and resin bonded cup wheels. A new method for predicting the surface roughness in spherical grinding was developed. Grinding marks are regard as a great obstacle to manufacture spherical and aspheric surfaces with higher surface quality, lower. Some works focused on the methodologies for grinding of spherical. Grinding Spherical Surfaces.

From www.youtube.com

Haas Multigrind® Sphere Grinding YouTube Grinding Spherical Surfaces Rotational grinding was adopted for the generation of spherical convex surfaces using metal and resin bonded cup wheels. Grinding marks are regard as a great obstacle to manufacture spherical and aspheric surfaces with higher surface quality, lower. A new method for predicting the surface roughness in spherical grinding was developed. Some works focused on the methodologies for grinding of spherical. Grinding Spherical Surfaces.

From www.multigrind.co.uk

Surface Grinding Services For Surfaces Up To 300mm x 650mm Grinding Spherical Surfaces Some works focused on the methodologies for grinding of spherical surfaces. Grinding marks are regard as a great obstacle to manufacture spherical and aspheric surfaces with higher surface quality, lower. A new method for predicting the surface roughness in spherical grinding was developed. The ground spherical surfaces were examined using laser interferometry, wyko optical interferometry, and scanning electron. Rotational grinding. Grinding Spherical Surfaces.

From www.duvalgrinding.com

OD Grinding Spherical Objects Grinding Spherical Surfaces Some works focused on the methodologies for grinding of spherical surfaces. Rotational grinding was adopted for the generation of spherical convex surfaces using metal and resin bonded cup wheels. A new method for predicting the surface roughness in spherical grinding was developed. Spherical grinding typically uses a. The ground spherical surfaces were examined using laser interferometry, wyko optical interferometry, and. Grinding Spherical Surfaces.

From www.duvalgrinding.com

OD Grinding Spherical Objects Grinding Spherical Surfaces Rotational grinding was adopted for the generation of spherical convex surfaces using metal and resin bonded cup wheels. The ground spherical surfaces were examined using laser interferometry, wyko optical interferometry, and scanning electron. Grinding marks are regard as a great obstacle to manufacture spherical and aspheric surfaces with higher surface quality, lower. Planar and spherical optical elements, with their straightforward. Grinding Spherical Surfaces.

From pgisteel.com

Surface Grinding Precision Grinding, Inc. Grinding Spherical Surfaces Some works focused on the methodologies for grinding of spherical surfaces. Rotational grinding was adopted for the generation of spherical convex surfaces using metal and resin bonded cup wheels. Spherical grinding typically uses a. A new method for predicting the surface roughness in spherical grinding was developed. Grinding marks are regard as a great obstacle to manufacture spherical and aspheric. Grinding Spherical Surfaces.

From www.olympus-global.com

Lens Processing System Meeting the challenge of number one Grinding Spherical Surfaces Rotational grinding was adopted for the generation of spherical convex surfaces using metal and resin bonded cup wheels. Some works focused on the methodologies for grinding of spherical surfaces. The ground spherical surfaces were examined using laser interferometry, wyko optical interferometry, and scanning electron. A new method for predicting the surface roughness in spherical grinding was developed. Planar and spherical. Grinding Spherical Surfaces.

From www.youtube.com

MUYEA Spherical Grinding Machine Video YouTube Grinding Spherical Surfaces Some works focused on the methodologies for grinding of spherical surfaces. The ground spherical surfaces were examined using laser interferometry, wyko optical interferometry, and scanning electron. Grinding marks are regard as a great obstacle to manufacture spherical and aspheric surfaces with higher surface quality, lower. A new method for predicting the surface roughness in spherical grinding was developed. Spherical grinding. Grinding Spherical Surfaces.

From www.youtube.com

CNC spherical grinding machine QM100 YouTube Grinding Spherical Surfaces A new method for predicting the surface roughness in spherical grinding was developed. Spherical grinding typically uses a. Some works focused on the methodologies for grinding of spherical surfaces. Grinding marks are regard as a great obstacle to manufacture spherical and aspheric surfaces with higher surface quality, lower. Rotational grinding was adopted for the generation of spherical convex surfaces using. Grinding Spherical Surfaces.

From www.caminix.com

Caminix QM880 Spherical Grinding Machine Jobsite Grinding Spherical Surfaces The ground spherical surfaces were examined using laser interferometry, wyko optical interferometry, and scanning electron. Planar and spherical optical elements, with their straightforward geometries, can achieve high surface accuracy through traditional. Some works focused on the methodologies for grinding of spherical surfaces. Rotational grinding was adopted for the generation of spherical convex surfaces using metal and resin bonded cup wheels.. Grinding Spherical Surfaces.

From www.sakabrasives.com

Surface Grinding Surface Grinding Wheels Manufacturer SAK Abrasives Grinding Spherical Surfaces Spherical grinding typically uses a. Some works focused on the methodologies for grinding of spherical surfaces. Rotational grinding was adopted for the generation of spherical convex surfaces using metal and resin bonded cup wheels. The ground spherical surfaces were examined using laser interferometry, wyko optical interferometry, and scanning electron. Planar and spherical optical elements, with their straightforward geometries, can achieve. Grinding Spherical Surfaces.

From www.rk-int.com

Delta LC 400 Rotary Table Surface Grinding Machine with Vertical Grinding Spherical Surfaces Grinding marks are regard as a great obstacle to manufacture spherical and aspheric surfaces with higher surface quality, lower. Rotational grinding was adopted for the generation of spherical convex surfaces using metal and resin bonded cup wheels. Spherical grinding typically uses a. Some works focused on the methodologies for grinding of spherical surfaces. Planar and spherical optical elements, with their. Grinding Spherical Surfaces.

From www.satisloh.com

SPM150 Grinding of spheres with Ø 10150 mm Satisloh Grinding Spherical Surfaces A new method for predicting the surface roughness in spherical grinding was developed. Spherical grinding typically uses a. Grinding marks are regard as a great obstacle to manufacture spherical and aspheric surfaces with higher surface quality, lower. The ground spherical surfaces were examined using laser interferometry, wyko optical interferometry, and scanning electron. Rotational grinding was adopted for the generation of. Grinding Spherical Surfaces.

From www.researchgate.net

Schematic of the cup wheel grinding of a large aspheric surface Grinding Spherical Surfaces Some works focused on the methodologies for grinding of spherical surfaces. Planar and spherical optical elements, with their straightforward geometries, can achieve high surface accuracy through traditional. Spherical grinding typically uses a. Rotational grinding was adopted for the generation of spherical convex surfaces using metal and resin bonded cup wheels. A new method for predicting the surface roughness in spherical. Grinding Spherical Surfaces.

From www.glassfab.com

Surface Grinding & Spherical Generating Glass Fab, Inc. Grinding Spherical Surfaces Grinding marks are regard as a great obstacle to manufacture spherical and aspheric surfaces with higher surface quality, lower. Some works focused on the methodologies for grinding of spherical surfaces. A new method for predicting the surface roughness in spherical grinding was developed. Spherical grinding typically uses a. Planar and spherical optical elements, with their straightforward geometries, can achieve high. Grinding Spherical Surfaces.