Can You Solder Wire Upside Down . There's no problem with soldering 'upside down' fittings, just a little skill and experience required. For components with only two leads it's easy enough to tin the corner of one of the through hole pads and hold the component in place with one hand while the other wicks that bit of solder to. Use a 20 to 30 watt soldering iron, use solder. Use soldering paste to prevent fresh solder from flowing to places you don't want. Place the tip of the iron on the wire and let it heat for a few seconds. Soldering copper pipe upside down requires careful preparation, proper techniques, and attention to detail. Then add some solder until the wire is soaked with solder. Prepare and heat as usual,. To solder upside down, you'll need to optimize your workspace and master specialized techniques. Repeat the tinning process on the other wire. If it is a thick wire, you should turn up the heat on your iron (if possible) to make the wire heat up faster.

from www.youtube.com

Use soldering paste to prevent fresh solder from flowing to places you don't want. Prepare and heat as usual,. To solder upside down, you'll need to optimize your workspace and master specialized techniques. Use a 20 to 30 watt soldering iron, use solder. Repeat the tinning process on the other wire. For components with only two leads it's easy enough to tin the corner of one of the through hole pads and hold the component in place with one hand while the other wicks that bit of solder to. Then add some solder until the wire is soaked with solder. There's no problem with soldering 'upside down' fittings, just a little skill and experience required. Soldering copper pipe upside down requires careful preparation, proper techniques, and attention to detail. Place the tip of the iron on the wire and let it heat for a few seconds.

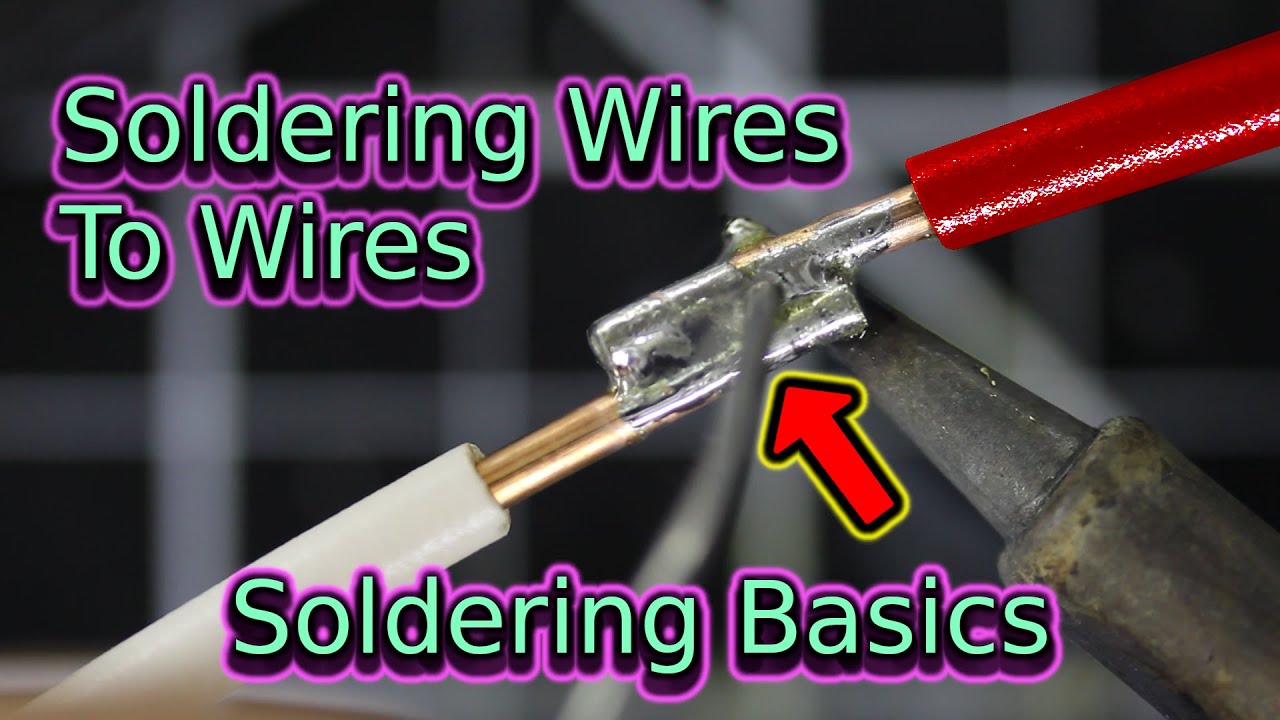

Soldering Wires to Wires Soldering Basics Soldering for Beginners

Can You Solder Wire Upside Down Place the tip of the iron on the wire and let it heat for a few seconds. Then add some solder until the wire is soaked with solder. For components with only two leads it's easy enough to tin the corner of one of the through hole pads and hold the component in place with one hand while the other wicks that bit of solder to. Use a 20 to 30 watt soldering iron, use solder. To solder upside down, you'll need to optimize your workspace and master specialized techniques. Repeat the tinning process on the other wire. Soldering copper pipe upside down requires careful preparation, proper techniques, and attention to detail. Place the tip of the iron on the wire and let it heat for a few seconds. Use soldering paste to prevent fresh solder from flowing to places you don't want. There's no problem with soldering 'upside down' fittings, just a little skill and experience required. If it is a thick wire, you should turn up the heat on your iron (if possible) to make the wire heat up faster. Prepare and heat as usual,.

From www.electronicsandyou.com

How to Solder Wires Together Correctly Like a Pro (Easy Tips and Tricks) Can You Solder Wire Upside Down Then add some solder until the wire is soaked with solder. Use a 20 to 30 watt soldering iron, use solder. Use soldering paste to prevent fresh solder from flowing to places you don't want. There's no problem with soldering 'upside down' fittings, just a little skill and experience required. If it is a thick wire, you should turn up. Can You Solder Wire Upside Down.

From www.youtube.com

Soldering Wires to Wires Soldering Basics Soldering for Beginners Can You Solder Wire Upside Down For components with only two leads it's easy enough to tin the corner of one of the through hole pads and hold the component in place with one hand while the other wicks that bit of solder to. To solder upside down, you'll need to optimize your workspace and master specialized techniques. If it is a thick wire, you should. Can You Solder Wire Upside Down.

From guidemanualyippee.z13.web.core.windows.net

How To Solder Wires To A Circuit Board Can You Solder Wire Upside Down Place the tip of the iron on the wire and let it heat for a few seconds. Repeat the tinning process on the other wire. To solder upside down, you'll need to optimize your workspace and master specialized techniques. For components with only two leads it's easy enough to tin the corner of one of the through hole pads and. Can You Solder Wire Upside Down.

From www.youtube.com

How to solder wires together for beginners Like a PRO (Tips and tricks Can You Solder Wire Upside Down If it is a thick wire, you should turn up the heat on your iron (if possible) to make the wire heat up faster. Use soldering paste to prevent fresh solder from flowing to places you don't want. Place the tip of the iron on the wire and let it heat for a few seconds. Prepare and heat as usual,.. Can You Solder Wire Upside Down.

From wcigco.netfirms.com

How To Solder Wires Like A Pro, 50 OFF Can You Solder Wire Upside Down Place the tip of the iron on the wire and let it heat for a few seconds. Use soldering paste to prevent fresh solder from flowing to places you don't want. There's no problem with soldering 'upside down' fittings, just a little skill and experience required. Prepare and heat as usual,. Then add some solder until the wire is soaked. Can You Solder Wire Upside Down.

From www.wiringwork.com

how to solder wires correctly Wiring Work Can You Solder Wire Upside Down If it is a thick wire, you should turn up the heat on your iron (if possible) to make the wire heat up faster. Then add some solder until the wire is soaked with solder. Use soldering paste to prevent fresh solder from flowing to places you don't want. Soldering copper pipe upside down requires careful preparation, proper techniques, and. Can You Solder Wire Upside Down.

From www.instructables.com

The Ultimate Wire Soldering Guide for Beginners 5 Steps (with Can You Solder Wire Upside Down Use soldering paste to prevent fresh solder from flowing to places you don't want. If it is a thick wire, you should turn up the heat on your iron (if possible) to make the wire heat up faster. Soldering copper pipe upside down requires careful preparation, proper techniques, and attention to detail. Then add some solder until the wire is. Can You Solder Wire Upside Down.

From www.pinterest.com

How to Solder Wires Together ( Best Tips ) Solder wire, Soldering Can You Solder Wire Upside Down For components with only two leads it's easy enough to tin the corner of one of the through hole pads and hold the component in place with one hand while the other wicks that bit of solder to. Prepare and heat as usual,. Soldering copper pipe upside down requires careful preparation, proper techniques, and attention to detail. Use a 20. Can You Solder Wire Upside Down.

From solderingironguide.com

How to Solder Wires to Each Other and Circuit Boards? Solderingironguide Can You Solder Wire Upside Down Soldering copper pipe upside down requires careful preparation, proper techniques, and attention to detail. Then add some solder until the wire is soaked with solder. For components with only two leads it's easy enough to tin the corner of one of the through hole pads and hold the component in place with one hand while the other wicks that bit. Can You Solder Wire Upside Down.

From www.youtube.com

How to Solder Wires Together (Best tips and tricks) YouTube Can You Solder Wire Upside Down Repeat the tinning process on the other wire. Soldering copper pipe upside down requires careful preparation, proper techniques, and attention to detail. Use soldering paste to prevent fresh solder from flowing to places you don't want. Then add some solder until the wire is soaked with solder. Use a 20 to 30 watt soldering iron, use solder. For components with. Can You Solder Wire Upside Down.

From partdiagramverdikkievq.z14.web.core.windows.net

Solder For Electrical Wire Can You Solder Wire Upside Down Use soldering paste to prevent fresh solder from flowing to places you don't want. Place the tip of the iron on the wire and let it heat for a few seconds. Use a 20 to 30 watt soldering iron, use solder. For components with only two leads it's easy enough to tin the corner of one of the through hole. Can You Solder Wire Upside Down.

From manualfixtyrone.z19.web.core.windows.net

How To Solder Electric Wire Can You Solder Wire Upside Down Use soldering paste to prevent fresh solder from flowing to places you don't want. Repeat the tinning process on the other wire. To solder upside down, you'll need to optimize your workspace and master specialized techniques. Place the tip of the iron on the wire and let it heat for a few seconds. There's no problem with soldering 'upside down'. Can You Solder Wire Upside Down.

From diagramkuckelandk4.z14.web.core.windows.net

How To Properly Solder Wires For Electronics Can You Solder Wire Upside Down Repeat the tinning process on the other wire. To solder upside down, you'll need to optimize your workspace and master specialized techniques. Place the tip of the iron on the wire and let it heat for a few seconds. There's no problem with soldering 'upside down' fittings, just a little skill and experience required. Then add some solder until the. Can You Solder Wire Upside Down.

From www.youtube.com

How To Solder Intro/Joining Stranded Wires Part 1 YouTube Can You Solder Wire Upside Down For components with only two leads it's easy enough to tin the corner of one of the through hole pads and hold the component in place with one hand while the other wicks that bit of solder to. Prepare and heat as usual,. If it is a thick wire, you should turn up the heat on your iron (if possible). Can You Solder Wire Upside Down.

From www.youtube.com

How to solder two wires together Crutchfield YouTube Can You Solder Wire Upside Down There's no problem with soldering 'upside down' fittings, just a little skill and experience required. Prepare and heat as usual,. Place the tip of the iron on the wire and let it heat for a few seconds. Soldering copper pipe upside down requires careful preparation, proper techniques, and attention to detail. For components with only two leads it's easy enough. Can You Solder Wire Upside Down.

From knowhow.napaonline.com

KnowHow Notes How to Solder WiresNAPA Know How Blog Can You Solder Wire Upside Down To solder upside down, you'll need to optimize your workspace and master specialized techniques. There's no problem with soldering 'upside down' fittings, just a little skill and experience required. For components with only two leads it's easy enough to tin the corner of one of the through hole pads and hold the component in place with one hand while the. Can You Solder Wire Upside Down.

From www.build-electronic-circuits.com

How To Solder A Simple Guide For Beginners and Hobbyists Can You Solder Wire Upside Down Prepare and heat as usual,. There's no problem with soldering 'upside down' fittings, just a little skill and experience required. Place the tip of the iron on the wire and let it heat for a few seconds. Then add some solder until the wire is soaked with solder. To solder upside down, you'll need to optimize your workspace and master. Can You Solder Wire Upside Down.

From www.youtube.com

How to solder electrical wiring (Soldering basics tutorial) YouTube Can You Solder Wire Upside Down Use soldering paste to prevent fresh solder from flowing to places you don't want. For components with only two leads it's easy enough to tin the corner of one of the through hole pads and hold the component in place with one hand while the other wicks that bit of solder to. Soldering copper pipe upside down requires careful preparation,. Can You Solder Wire Upside Down.

From www.electriciantalk.com

Soldering upside down awkward Electrician Talk Can You Solder Wire Upside Down If it is a thick wire, you should turn up the heat on your iron (if possible) to make the wire heat up faster. There's no problem with soldering 'upside down' fittings, just a little skill and experience required. Place the tip of the iron on the wire and let it heat for a few seconds. To solder upside down,. Can You Solder Wire Upside Down.

From www.youtube.com

How To solder upside down ??? YouTube Can You Solder Wire Upside Down For components with only two leads it's easy enough to tin the corner of one of the through hole pads and hold the component in place with one hand while the other wicks that bit of solder to. Use soldering paste to prevent fresh solder from flowing to places you don't want. Place the tip of the iron on the. Can You Solder Wire Upside Down.

From knowhow.napaonline.com

How to Solder Wires Tips And Tricks For Making A Solid Connection Can You Solder Wire Upside Down Place the tip of the iron on the wire and let it heat for a few seconds. If it is a thick wire, you should turn up the heat on your iron (if possible) to make the wire heat up faster. Repeat the tinning process on the other wire. Prepare and heat as usual,. Use a 20 to 30 watt. Can You Solder Wire Upside Down.

From diagramlibisaac.z5.web.core.windows.net

How To Solder Electrical Wire Connections Can You Solder Wire Upside Down Then add some solder until the wire is soaked with solder. Use soldering paste to prevent fresh solder from flowing to places you don't want. Soldering copper pipe upside down requires careful preparation, proper techniques, and attention to detail. There's no problem with soldering 'upside down' fittings, just a little skill and experience required. To solder upside down, you'll need. Can You Solder Wire Upside Down.

From www.thespruce.com

How to Solder Wires Can You Solder Wire Upside Down Use a 20 to 30 watt soldering iron, use solder. Soldering copper pipe upside down requires careful preparation, proper techniques, and attention to detail. Place the tip of the iron on the wire and let it heat for a few seconds. Use soldering paste to prevent fresh solder from flowing to places you don't want. There's no problem with soldering. Can You Solder Wire Upside Down.

From www.wiringwork.com

how to solder wires correctly Wiring Work Can You Solder Wire Upside Down Prepare and heat as usual,. Soldering copper pipe upside down requires careful preparation, proper techniques, and attention to detail. Then add some solder until the wire is soaked with solder. Use a 20 to 30 watt soldering iron, use solder. Place the tip of the iron on the wire and let it heat for a few seconds. There's no problem. Can You Solder Wire Upside Down.

From knowhow.napaonline.com

How to Solder Wires Tips And Tricks For Making A Solid Connection Can You Solder Wire Upside Down Then add some solder until the wire is soaked with solder. Soldering copper pipe upside down requires careful preparation, proper techniques, and attention to detail. To solder upside down, you'll need to optimize your workspace and master specialized techniques. If it is a thick wire, you should turn up the heat on your iron (if possible) to make the wire. Can You Solder Wire Upside Down.

From knowhow.napaonline.com

KnowHow Notes How to Solder WiresNAPA Know How Blog Can You Solder Wire Upside Down If it is a thick wire, you should turn up the heat on your iron (if possible) to make the wire heat up faster. There's no problem with soldering 'upside down' fittings, just a little skill and experience required. To solder upside down, you'll need to optimize your workspace and master specialized techniques. Then add some solder until the wire. Can You Solder Wire Upside Down.

From www.electriciantalk.com

Soldering upside down awkward Electrician Talk Can You Solder Wire Upside Down There's no problem with soldering 'upside down' fittings, just a little skill and experience required. Soldering copper pipe upside down requires careful preparation, proper techniques, and attention to detail. To solder upside down, you'll need to optimize your workspace and master specialized techniques. Repeat the tinning process on the other wire. Prepare and heat as usual,. Use soldering paste to. Can You Solder Wire Upside Down.

From www.conro.com

How to solder wires? ConRo Electronics Can You Solder Wire Upside Down Place the tip of the iron on the wire and let it heat for a few seconds. For components with only two leads it's easy enough to tin the corner of one of the through hole pads and hold the component in place with one hand while the other wicks that bit of solder to. There's no problem with soldering. Can You Solder Wire Upside Down.

From www.youtube.com

How to Solder Properly 5 Soldering Joint Splices YouTube Can You Solder Wire Upside Down There's no problem with soldering 'upside down' fittings, just a little skill and experience required. Use a 20 to 30 watt soldering iron, use solder. For components with only two leads it's easy enough to tin the corner of one of the through hole pads and hold the component in place with one hand while the other wicks that bit. Can You Solder Wire Upside Down.

From www.youtube.com

How to Solder Wires like A Pro Wire Soldering Techniques YouTube Can You Solder Wire Upside Down Use a 20 to 30 watt soldering iron, use solder. If it is a thick wire, you should turn up the heat on your iron (if possible) to make the wire heat up faster. Prepare and heat as usual,. To solder upside down, you'll need to optimize your workspace and master specialized techniques. There's no problem with soldering 'upside down'. Can You Solder Wire Upside Down.

From www.pinterest.com

How To EASILY Solder Wires Together!(Best Method) Soldering Can You Solder Wire Upside Down Use soldering paste to prevent fresh solder from flowing to places you don't want. Prepare and heat as usual,. There's no problem with soldering 'upside down' fittings, just a little skill and experience required. To solder upside down, you'll need to optimize your workspace and master specialized techniques. Then add some solder until the wire is soaked with solder. If. Can You Solder Wire Upside Down.

From www.youtube.com

How to Properly Solder Wire Beginner's Guide YouTube Can You Solder Wire Upside Down For components with only two leads it's easy enough to tin the corner of one of the through hole pads and hold the component in place with one hand while the other wicks that bit of solder to. Then add some solder until the wire is soaked with solder. There's no problem with soldering 'upside down' fittings, just a little. Can You Solder Wire Upside Down.

From www.katrinasiegfried.com

Soldering Techniques for Two Wires Can You Solder Wire Upside Down Then add some solder until the wire is soaked with solder. Prepare and heat as usual,. If it is a thick wire, you should turn up the heat on your iron (if possible) to make the wire heat up faster. To solder upside down, you'll need to optimize your workspace and master specialized techniques. Use soldering paste to prevent fresh. Can You Solder Wire Upside Down.

From www.youtube.com

How To Solder Two Wires Together YouTube Can You Solder Wire Upside Down If it is a thick wire, you should turn up the heat on your iron (if possible) to make the wire heat up faster. To solder upside down, you'll need to optimize your workspace and master specialized techniques. Use a 20 to 30 watt soldering iron, use solder. Prepare and heat as usual,. There's no problem with soldering 'upside down'. Can You Solder Wire Upside Down.

From www.youtube.com

UpsideDown Soldering with a Mirror YouTube Can You Solder Wire Upside Down Use a 20 to 30 watt soldering iron, use solder. Repeat the tinning process on the other wire. To solder upside down, you'll need to optimize your workspace and master specialized techniques. Prepare and heat as usual,. If it is a thick wire, you should turn up the heat on your iron (if possible) to make the wire heat up. Can You Solder Wire Upside Down.