Spur Gear Load Distribution . Figure 1 shows the load distribution for a c14 spur gear at fzg load stage k11. In the standardized method iso 6336, the load distribution of spur gear stages is taken into account by the face load factors khβ and kfβ. Spur gear is the most basic gear used to transmit power between two parallel shafts with almost 99% efficiency. It requires the better analysis. The purpose of this study was to construct and demonstrate a prediction method based on a frictional loaded tooth contact. These results indicate that there is a clear influence of. Gear dissipates during operation, but understanding how the power loss develops along the path of contact is fundamental to design. In this study, for spur gear pair, an improved analytical load distribution model considering the effects of corner contact and.

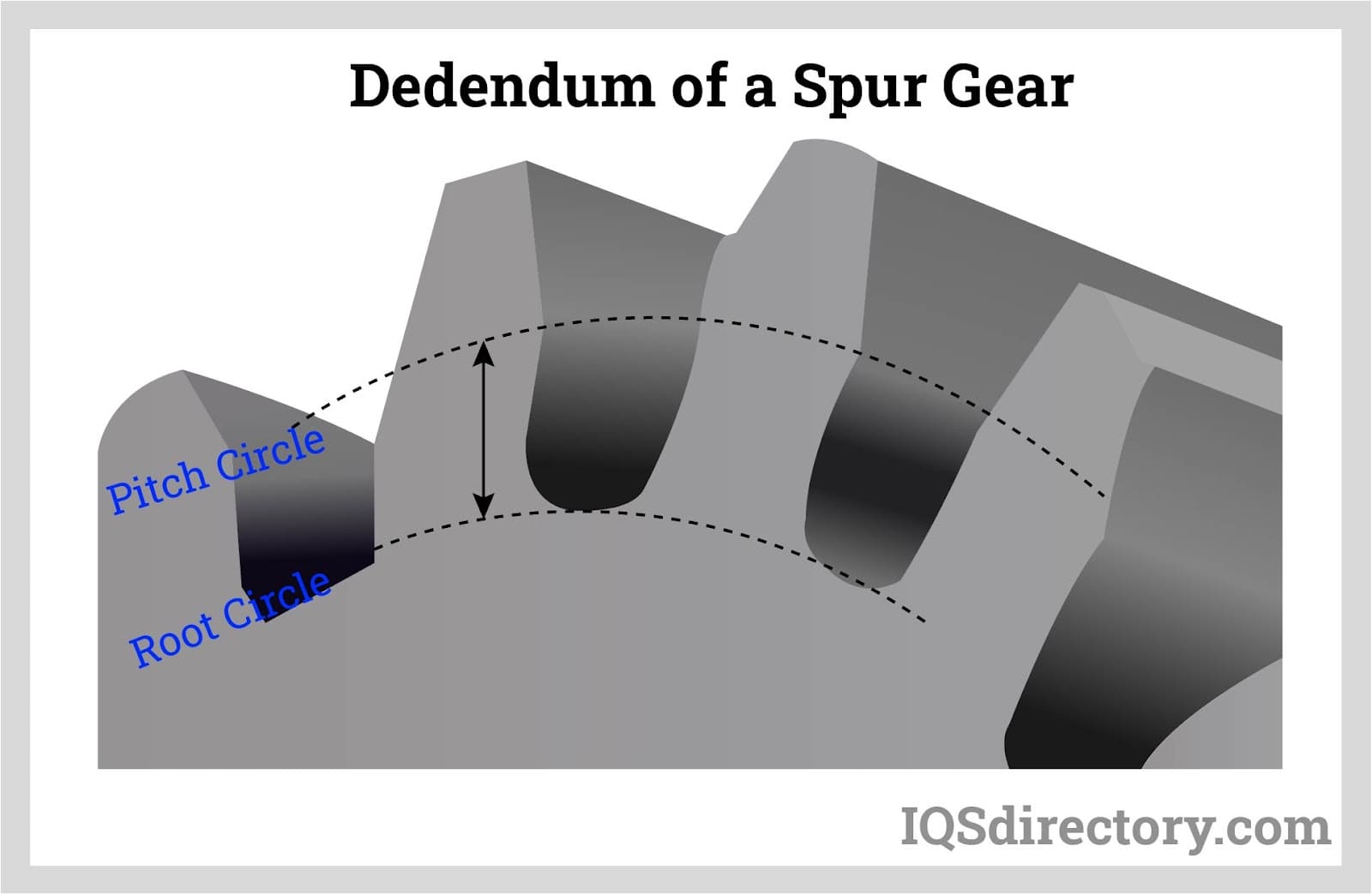

from www.iqsdirectory.com

It requires the better analysis. In the standardized method iso 6336, the load distribution of spur gear stages is taken into account by the face load factors khβ and kfβ. In this study, for spur gear pair, an improved analytical load distribution model considering the effects of corner contact and. Spur gear is the most basic gear used to transmit power between two parallel shafts with almost 99% efficiency. These results indicate that there is a clear influence of. Figure 1 shows the load distribution for a c14 spur gear at fzg load stage k11. The purpose of this study was to construct and demonstrate a prediction method based on a frictional loaded tooth contact. Gear dissipates during operation, but understanding how the power loss develops along the path of contact is fundamental to design.

Spur Gears Types, Uses, Benefits, and Manufacturing

Spur Gear Load Distribution These results indicate that there is a clear influence of. In the standardized method iso 6336, the load distribution of spur gear stages is taken into account by the face load factors khβ and kfβ. It requires the better analysis. In this study, for spur gear pair, an improved analytical load distribution model considering the effects of corner contact and. Spur gear is the most basic gear used to transmit power between two parallel shafts with almost 99% efficiency. Gear dissipates during operation, but understanding how the power loss develops along the path of contact is fundamental to design. Figure 1 shows the load distribution for a c14 spur gear at fzg load stage k11. The purpose of this study was to construct and demonstrate a prediction method based on a frictional loaded tooth contact. These results indicate that there is a clear influence of.

From www.researchgate.net

Theoretical spur gear load transfer points. Download Scientific Diagram Spur Gear Load Distribution It requires the better analysis. In this study, for spur gear pair, an improved analytical load distribution model considering the effects of corner contact and. The purpose of this study was to construct and demonstrate a prediction method based on a frictional loaded tooth contact. Figure 1 shows the load distribution for a c14 spur gear at fzg load stage. Spur Gear Load Distribution.

From www.researchgate.net

Load distribution curves of spur gear. Download Scientific Diagram Spur Gear Load Distribution Spur gear is the most basic gear used to transmit power between two parallel shafts with almost 99% efficiency. In this study, for spur gear pair, an improved analytical load distribution model considering the effects of corner contact and. Figure 1 shows the load distribution for a c14 spur gear at fzg load stage k11. It requires the better analysis.. Spur Gear Load Distribution.

From www.zhygear.com

Finite element analysis of spur gears based on AnsysWorkbench ZHY Gear Spur Gear Load Distribution The purpose of this study was to construct and demonstrate a prediction method based on a frictional loaded tooth contact. These results indicate that there is a clear influence of. It requires the better analysis. In this study, for spur gear pair, an improved analytical load distribution model considering the effects of corner contact and. Spur gear is the most. Spur Gear Load Distribution.

From koyo.jtekt.co.jp

Calculation of loads Basic Bearing Knowledge Koyo Bearings /JTEKT Spur Gear Load Distribution In this study, for spur gear pair, an improved analytical load distribution model considering the effects of corner contact and. The purpose of this study was to construct and demonstrate a prediction method based on a frictional loaded tooth contact. Figure 1 shows the load distribution for a c14 spur gear at fzg load stage k11. Gear dissipates during operation,. Spur Gear Load Distribution.

From www.semanticscholar.org

Figure 3 from Determination of the ISO face load factor in spur gear Spur Gear Load Distribution The purpose of this study was to construct and demonstrate a prediction method based on a frictional loaded tooth contact. It requires the better analysis. Figure 1 shows the load distribution for a c14 spur gear at fzg load stage k11. Gear dissipates during operation, but understanding how the power loss develops along the path of contact is fundamental to. Spur Gear Load Distribution.

From uk.rs-online.com

Spur Gears A Complete Guide RS Spur Gear Load Distribution It requires the better analysis. Figure 1 shows the load distribution for a c14 spur gear at fzg load stage k11. In this study, for spur gear pair, an improved analytical load distribution model considering the effects of corner contact and. These results indicate that there is a clear influence of. Gear dissipates during operation, but understanding how the power. Spur Gear Load Distribution.

From www.researchgate.net

Loads at spur gear teeth Download Scientific Diagram Spur Gear Load Distribution Spur gear is the most basic gear used to transmit power between two parallel shafts with almost 99% efficiency. Figure 1 shows the load distribution for a c14 spur gear at fzg load stage k11. These results indicate that there is a clear influence of. It requires the better analysis. Gear dissipates during operation, but understanding how the power loss. Spur Gear Load Distribution.

From www.zhygear.com

Load distribution coefficient model of involute spur gear at low speed Spur Gear Load Distribution In this study, for spur gear pair, an improved analytical load distribution model considering the effects of corner contact and. The purpose of this study was to construct and demonstrate a prediction method based on a frictional loaded tooth contact. These results indicate that there is a clear influence of. In the standardized method iso 6336, the load distribution of. Spur Gear Load Distribution.

From dokumen.tips

(PDF) Method of measuring the load distribution of spur gear stages Spur Gear Load Distribution Spur gear is the most basic gear used to transmit power between two parallel shafts with almost 99% efficiency. Figure 1 shows the load distribution for a c14 spur gear at fzg load stage k11. It requires the better analysis. In this study, for spur gear pair, an improved analytical load distribution model considering the effects of corner contact and.. Spur Gear Load Distribution.

From www.zhygear.com

Understanding the Load Distribution in HighPerformance Spur Gear ZHY Spur Gear Load Distribution Spur gear is the most basic gear used to transmit power between two parallel shafts with almost 99% efficiency. In this study, for spur gear pair, an improved analytical load distribution model considering the effects of corner contact and. Gear dissipates during operation, but understanding how the power loss develops along the path of contact is fundamental to design. In. Spur Gear Load Distribution.

From www.youtube.com

Spur Gear Calculation and Design (MITCalc03) YouTube Spur Gear Load Distribution These results indicate that there is a clear influence of. Gear dissipates during operation, but understanding how the power loss develops along the path of contact is fundamental to design. In the standardized method iso 6336, the load distribution of spur gear stages is taken into account by the face load factors khβ and kfβ. The purpose of this study. Spur Gear Load Distribution.

From khkgears.net

Bending Strength of Spur and Helical Gears KHK Gears Spur Gear Load Distribution In the standardized method iso 6336, the load distribution of spur gear stages is taken into account by the face load factors khβ and kfβ. Gear dissipates during operation, but understanding how the power loss develops along the path of contact is fundamental to design. In this study, for spur gear pair, an improved analytical load distribution model considering the. Spur Gear Load Distribution.

From www.iqsdirectory.com

Spur Gears Types, Uses, Benefits, and Manufacturing Spur Gear Load Distribution The purpose of this study was to construct and demonstrate a prediction method based on a frictional loaded tooth contact. In the standardized method iso 6336, the load distribution of spur gear stages is taken into account by the face load factors khβ and kfβ. Gear dissipates during operation, but understanding how the power loss develops along the path of. Spur Gear Load Distribution.

From www.researchgate.net

Load distribution curve of spur gear tooth surface before and after Spur Gear Load Distribution Spur gear is the most basic gear used to transmit power between two parallel shafts with almost 99% efficiency. These results indicate that there is a clear influence of. Figure 1 shows the load distribution for a c14 spur gear at fzg load stage k11. It requires the better analysis. Gear dissipates during operation, but understanding how the power loss. Spur Gear Load Distribution.

From www.slideserve.com

PPT Chapter 9 Spur Gear Design PowerPoint Presentation, free download Spur Gear Load Distribution These results indicate that there is a clear influence of. The purpose of this study was to construct and demonstrate a prediction method based on a frictional loaded tooth contact. Figure 1 shows the load distribution for a c14 spur gear at fzg load stage k11. In this study, for spur gear pair, an improved analytical load distribution model considering. Spur Gear Load Distribution.

From www.slideserve.com

PPT Chapter 9 Spur Gear Design PowerPoint Presentation, free download Spur Gear Load Distribution These results indicate that there is a clear influence of. In this study, for spur gear pair, an improved analytical load distribution model considering the effects of corner contact and. It requires the better analysis. In the standardized method iso 6336, the load distribution of spur gear stages is taken into account by the face load factors khβ and kfβ.. Spur Gear Load Distribution.

From www.researchgate.net

Load distribution factor (ζ) of spur gear considering different basic Spur Gear Load Distribution Gear dissipates during operation, but understanding how the power loss develops along the path of contact is fundamental to design. In the standardized method iso 6336, the load distribution of spur gear stages is taken into account by the face load factors khβ and kfβ. In this study, for spur gear pair, an improved analytical load distribution model considering the. Spur Gear Load Distribution.

From www.researchgate.net

Load distribution coefficient between front teeth of spur gear Spur Gear Load Distribution These results indicate that there is a clear influence of. Gear dissipates during operation, but understanding how the power loss develops along the path of contact is fundamental to design. In this study, for spur gear pair, an improved analytical load distribution model considering the effects of corner contact and. In the standardized method iso 6336, the load distribution of. Spur Gear Load Distribution.

From www.mdpi.com

A Numerical Analysis of Hybrid Spur Gears with Asymmetric Teeth Stress Spur Gear Load Distribution Figure 1 shows the load distribution for a c14 spur gear at fzg load stage k11. These results indicate that there is a clear influence of. Gear dissipates during operation, but understanding how the power loss develops along the path of contact is fundamental to design. The purpose of this study was to construct and demonstrate a prediction method based. Spur Gear Load Distribution.

From www.researchgate.net

Load distribution of spur gear tooth surface before and after parabolic Spur Gear Load Distribution Spur gear is the most basic gear used to transmit power between two parallel shafts with almost 99% efficiency. These results indicate that there is a clear influence of. In this study, for spur gear pair, an improved analytical load distribution model considering the effects of corner contact and. In the standardized method iso 6336, the load distribution of spur. Spur Gear Load Distribution.

From gear.com.my

Spur Gear Malaysia, Spur Gear Supplier Malaysia Spur Gear Load Distribution Spur gear is the most basic gear used to transmit power between two parallel shafts with almost 99% efficiency. These results indicate that there is a clear influence of. The purpose of this study was to construct and demonstrate a prediction method based on a frictional loaded tooth contact. In the standardized method iso 6336, the load distribution of spur. Spur Gear Load Distribution.

From www.researchgate.net

Example for the distribution of nodes for a gear shaft with spur gear Spur Gear Load Distribution In the standardized method iso 6336, the load distribution of spur gear stages is taken into account by the face load factors khβ and kfβ. Figure 1 shows the load distribution for a c14 spur gear at fzg load stage k11. Gear dissipates during operation, but understanding how the power loss develops along the path of contact is fundamental to. Spur Gear Load Distribution.

From engineersedge.com

AGMA Worm and Spur Gear Design Equations and Calculators Spur Gear Load Distribution These results indicate that there is a clear influence of. Spur gear is the most basic gear used to transmit power between two parallel shafts with almost 99% efficiency. In the standardized method iso 6336, the load distribution of spur gear stages is taken into account by the face load factors khβ and kfβ. Gear dissipates during operation, but understanding. Spur Gear Load Distribution.

From www.researchgate.net

Load distribution factor (z) of spur gear considering different basic Spur Gear Load Distribution In this study, for spur gear pair, an improved analytical load distribution model considering the effects of corner contact and. Gear dissipates during operation, but understanding how the power loss develops along the path of contact is fundamental to design. These results indicate that there is a clear influence of. In the standardized method iso 6336, the load distribution of. Spur Gear Load Distribution.

From khkgears.net

Surface Durability of Spur and Helical Gears KHK Spur Gear Load Distribution Spur gear is the most basic gear used to transmit power between two parallel shafts with almost 99% efficiency. Figure 1 shows the load distribution for a c14 spur gear at fzg load stage k11. Gear dissipates during operation, but understanding how the power loss develops along the path of contact is fundamental to design. The purpose of this study. Spur Gear Load Distribution.

From www.researchgate.net

Variation curves of load distribution factor (ζ) of spur gear Spur Gear Load Distribution Figure 1 shows the load distribution for a c14 spur gear at fzg load stage k11. These results indicate that there is a clear influence of. Gear dissipates during operation, but understanding how the power loss develops along the path of contact is fundamental to design. It requires the better analysis. In this study, for spur gear pair, an improved. Spur Gear Load Distribution.

From www.linkedin.com

Understanding Spur Gears The Basics and Applications Spur Gear Load Distribution Gear dissipates during operation, but understanding how the power loss develops along the path of contact is fundamental to design. In this study, for spur gear pair, an improved analytical load distribution model considering the effects of corner contact and. In the standardized method iso 6336, the load distribution of spur gear stages is taken into account by the face. Spur Gear Load Distribution.

From www.mdpi.com

Machines Free FullText Load Distribution and Dynamic Response in Spur Gear Load Distribution The purpose of this study was to construct and demonstrate a prediction method based on a frictional loaded tooth contact. In this study, for spur gear pair, an improved analytical load distribution model considering the effects of corner contact and. Gear dissipates during operation, but understanding how the power loss develops along the path of contact is fundamental to design.. Spur Gear Load Distribution.

From www.zhygear.com

Boundary conditions and loading of twodimensional contact analysis of Spur Gear Load Distribution Gear dissipates during operation, but understanding how the power loss develops along the path of contact is fundamental to design. These results indicate that there is a clear influence of. Spur gear is the most basic gear used to transmit power between two parallel shafts with almost 99% efficiency. In this study, for spur gear pair, an improved analytical load. Spur Gear Load Distribution.

From www.researchgate.net

2 Schematic Diagram of Spur Gears in Mesh Download Scientific Diagram Spur Gear Load Distribution These results indicate that there is a clear influence of. Figure 1 shows the load distribution for a c14 spur gear at fzg load stage k11. The purpose of this study was to construct and demonstrate a prediction method based on a frictional loaded tooth contact. It requires the better analysis. In the standardized method iso 6336, the load distribution. Spur Gear Load Distribution.

From www.researchgate.net

nfluence of wear on tooth load distributionsSpur gear example Spur Gear Load Distribution In this study, for spur gear pair, an improved analytical load distribution model considering the effects of corner contact and. These results indicate that there is a clear influence of. Figure 1 shows the load distribution for a c14 spur gear at fzg load stage k11. Spur gear is the most basic gear used to transmit power between two parallel. Spur Gear Load Distribution.

From www.scribd.com

Analysis of Stress Distribution in a Spur Gear Under Torque Load Using Spur Gear Load Distribution These results indicate that there is a clear influence of. In the standardized method iso 6336, the load distribution of spur gear stages is taken into account by the face load factors khβ and kfβ. It requires the better analysis. Spur gear is the most basic gear used to transmit power between two parallel shafts with almost 99% efficiency. The. Spur Gear Load Distribution.

From www.slideserve.com

PPT Chapter 15 Helical, Bevel, and Worm Gears PowerPoint Spur Gear Load Distribution In this study, for spur gear pair, an improved analytical load distribution model considering the effects of corner contact and. Figure 1 shows the load distribution for a c14 spur gear at fzg load stage k11. Spur gear is the most basic gear used to transmit power between two parallel shafts with almost 99% efficiency. Gear dissipates during operation, but. Spur Gear Load Distribution.

From www.youtube.com

Spur Gears Force Components Force on Bearings Example 2 YouTube Spur Gear Load Distribution In the standardized method iso 6336, the load distribution of spur gear stages is taken into account by the face load factors khβ and kfβ. It requires the better analysis. Figure 1 shows the load distribution for a c14 spur gear at fzg load stage k11. These results indicate that there is a clear influence of. The purpose of this. Spur Gear Load Distribution.

From www.researchgate.net

Load distribution of spur gear tooth surface before and after parabolic Spur Gear Load Distribution Gear dissipates during operation, but understanding how the power loss develops along the path of contact is fundamental to design. Figure 1 shows the load distribution for a c14 spur gear at fzg load stage k11. Spur gear is the most basic gear used to transmit power between two parallel shafts with almost 99% efficiency. In the standardized method iso. Spur Gear Load Distribution.