Spur Gear Gear Module Formula . Understanding gear profile and gear module. One important tool in performing spur gear calculations is the spur gear calculator. The outputs are tip, base, root diameters, contact ratio, profile shift, addendum modification, and tooth thickness. Module = pitch diameter (mm) / number of teeth; In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. Commonly used in metric gear design, the module measurement defines the size. This notebook documents the procedure to find spur gear geometry based on design requirements. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The module is crucial because it directly impacts the gear. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. The geometry of a simple spur gear tooth is complex. It is calculated by dividing the reference diameter of the gear by the number of teeth. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. (inch units applicable for constants) spur gear design calculator. A spur gear calculator is a software program or online.

from www.mechical.com

This notebook documents the procedure to find spur gear geometry based on design requirements. A spur gear calculator is a software program or online. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. The geometry of a simple spur gear tooth is complex. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. (inch units applicable for constants) spur gear design calculator. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. One important tool in performing spur gear calculations is the spur gear calculator. The module is crucial because it directly impacts the gear.

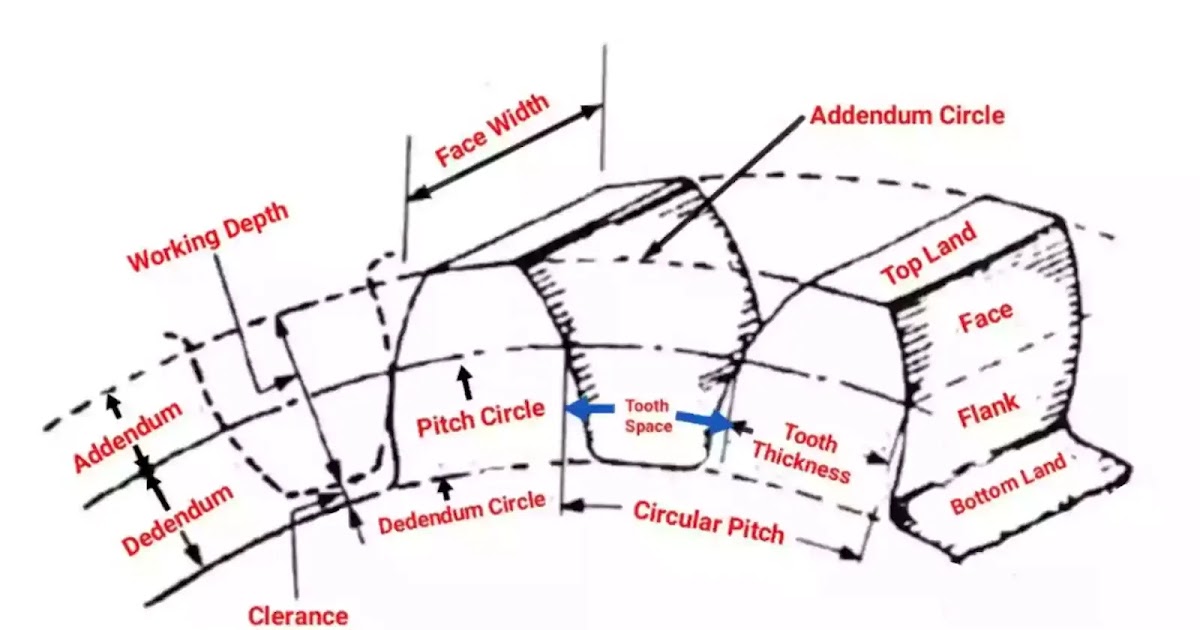

Terminology of Spur Gear and Their Formulas

Spur Gear Gear Module Formula Understanding gear profile and gear module. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. A spur gear calculator is a software program or online. One important tool in performing spur gear calculations is the spur gear calculator. Understanding gear profile and gear module. Module = pitch diameter (mm) / number of teeth; It is calculated by dividing the reference diameter of the gear by the number of teeth. This notebook documents the procedure to find spur gear geometry based on design requirements. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. (inch units applicable for constants) spur gear design calculator. Commonly used in metric gear design, the module measurement defines the size. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. The module is crucial because it directly impacts the gear. The outputs are tip, base, root diameters, contact ratio, profile shift, addendum modification, and tooth thickness. The geometry of a simple spur gear tooth is complex. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth.

From www.mdpi.com

A Numerical Analysis of Hybrid Spur Gears with Asymmetric Teeth Stress Spur Gear Gear Module Formula In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations. Spur Gear Gear Module Formula.

From drivetrainhub.com

Spur Gears Geometry of spur gears and gear meshes Spur Gear Gear Module Formula This notebook documents the procedure to find spur gear geometry based on design requirements. A spur gear calculator is a software program or online. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Module = pitch diameter (mm) / number of teeth; The module is crucial because it directly. Spur Gear Gear Module Formula.

From www.pinterest.com

Figure 10 Fundamentals of Modern Drafting Figure 2054 Draw the Spur Gear Gear Module Formula One important tool in performing spur gear calculations is the spur gear calculator. Commonly used in metric gear design, the module measurement defines the size. It is calculated by dividing the reference diameter of the gear by the number of teeth. Understanding gear profile and gear module. The outputs are tip, base, root diameters, contact ratio, profile shift, addendum modification,. Spur Gear Gear Module Formula.

From mechheart.com

Spur Gear Applications, Design, and Operation MECHHEART Spur Gear Gear Module Formula In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. Understanding gear profile and gear module. The geometry of a simple spur gear tooth is complex. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Gear dimensions are determined in accordance with their. Spur Gear Gear Module Formula.

From exovpltat.blob.core.windows.net

Spur Gear Formula Module at Robert Beck blog Spur Gear Gear Module Formula One important tool in performing spur gear calculations is the spur gear calculator. Understanding gear profile and gear module. A spur gear calculator is a software program or online. It is calculated by dividing the reference diameter of the gear by the number of teeth. (inch units applicable for constants) spur gear design calculator. In the previous pages, we introduced. Spur Gear Gear Module Formula.

From mungfali.com

Spur Gear Tooth Dimensions Spur Gear Gear Module Formula Understanding gear profile and gear module. A spur gear calculator is a software program or online. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. One important tool. Spur Gear Gear Module Formula.

From evolventdesign.com

Spur Gear Calculator Hub Evolvent Design Spur Gear Gear Module Formula Commonly used in metric gear design, the module measurement defines the size. A spur gear calculator is a software program or online. It is calculated by dividing the reference diameter of the gear by the number of teeth. Module = pitch diameter (mm) / number of teeth; One important tool in performing spur gear calculations is the spur gear calculator.. Spur Gear Gear Module Formula.

From learningsnarpirqs.z14.web.core.windows.net

Gear Calculation Excel Sheet Spur Gear Gear Module Formula A spur gear calculator is a software program or online. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. Understanding gear profile and gear module. (inch units applicable for constants) spur gear design calculator. The module is crucial because it directly impacts the. Spur Gear Gear Module Formula.

From www.iqsdirectory.com

Spur Gears Types, Uses, Benefits, and Manufacturing Spur Gear Gear Module Formula The geometry of a simple spur gear tooth is complex. The module is crucial because it directly impacts the gear. Module = pitch diameter (mm) / number of teeth; Understanding gear profile and gear module. This notebook documents the procedure to find spur gear geometry based on design requirements. Numerous dimensional parameters define the shape of the tooth profile, determine. Spur Gear Gear Module Formula.

From studylib.net

Design of Spur Gears Spur Gear Gear Module Formula In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. It is calculated by dividing the reference diameter of the gear by the number of teeth. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Module = pitch diameter (mm) / number of. Spur Gear Gear Module Formula.

From www.researchgate.net

Geometry and specification of spur gear module = 1.5; pressure angle Spur Gear Gear Module Formula Understanding gear profile and gear module. The geometry of a simple spur gear tooth is complex. Module = pitch diameter (mm) / number of teeth; Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. A spur gear calculator is a software program or. Spur Gear Gear Module Formula.

From engineconstalaranceqtt.z21.web.core.windows.net

Gear Reduction Ratio Calculator Spur Gear Gear Module Formula The geometry of a simple spur gear tooth is complex. The module is crucial because it directly impacts the gear. It is calculated by dividing the reference diameter of the gear by the number of teeth. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the. Spur Gear Gear Module Formula.

From evolventdesign.com

Spur Gear Calculator Hub Evolvent Design Spur Gear Gear Module Formula Module = pitch diameter (mm) / number of teeth; Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. The module is crucial because it directly impacts the gear. This notebook documents the procedure to find spur gear geometry based on design requirements. 40. Spur Gear Gear Module Formula.

From khkgears.net

Calculation of Gear Dimensions KHK Gears Spur Gear Gear Module Formula It is calculated by dividing the reference diameter of the gear by the number of teeth. The module is crucial because it directly impacts the gear. This notebook documents the procedure to find spur gear geometry based on design requirements. The outputs are tip, base, root diameters, contact ratio, profile shift, addendum modification, and tooth thickness. A spur gear calculator. Spur Gear Gear Module Formula.

From www.mechical.com

Terminology of Spur Gear and Their Formulas Spur Gear Gear Module Formula This notebook documents the procedure to find spur gear geometry based on design requirements. The geometry of a simple spur gear tooth is complex. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. (inch units applicable for constants) spur gear design calculator. One important tool in performing spur gear. Spur Gear Gear Module Formula.

From www.iqsdirectory.com

Spur Gears Types, Uses, Benefits, and Manufacturing Spur Gear Gear Module Formula Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The outputs are tip, base, root diameters, contact ratio, profile shift, addendum modification, and tooth thickness. One important tool in performing spur gear calculations is the spur gear calculator. A spur gear calculator is a software program or online. 40. Spur Gear Gear Module Formula.

From www.mechanicdrive.com

Spur gear calculation Spur Gear Gear Module Formula One important tool in performing spur gear calculations is the spur gear calculator. It is calculated by dividing the reference diameter of the gear by the number of teeth. Module = pitch diameter (mm) / number of teeth; The outputs are tip, base, root diameters, contact ratio, profile shift, addendum modification, and tooth thickness. Commonly used in metric gear design,. Spur Gear Gear Module Formula.

From www.wikihow.com

4 Easy Ways to Determine Gear Ratio (with Pictures) Spur Gear Gear Module Formula (inch units applicable for constants) spur gear design calculator. The module is crucial because it directly impacts the gear. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. Commonly used in metric gear design, the module measurement defines the size. Understanding gear profile. Spur Gear Gear Module Formula.

From gearcutting.blogspot.com

Gear Manufacturing (By Cutting) Spur Gear Formulas Spur Gear Gear Module Formula In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. The outputs are tip, base, root diameters, contact ratio, profile shift, addendum modification, and tooth thickness. (inch units applicable for constants) spur gear design calculator. It is calculated by dividing the reference diameter of the gear by the number. Spur Gear Gear Module Formula.

From www.youtube.com

Spur gear calculation, Design Details Spur Gear Formula spur gear Spur Gear Gear Module Formula The module is crucial because it directly impacts the gear. Module = pitch diameter (mm) / number of teeth; (inch units applicable for constants) spur gear design calculator. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. A spur gear calculator is a software program or online. The geometry. Spur Gear Gear Module Formula.

From www.iqsdirectory.com

Spur Gears Types, Uses, Benefits, and Manufacturing Spur Gear Gear Module Formula The geometry of a simple spur gear tooth is complex. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. This notebook documents the procedure to find spur gear geometry based on design requirements. Understanding gear profile and gear module. The outputs are tip, base, root diameters, contact ratio, profile. Spur Gear Gear Module Formula.

From www.slideserve.com

PPT Blueprint Reading for the Machine Trades, Sixth Edition Unit 15 Spur Gear Gear Module Formula (inch units applicable for constants) spur gear design calculator. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Module = pitch diameter (mm) / number of teeth; Commonly used in metric gear design, the. Spur Gear Gear Module Formula.

From www.automotioncomponents.co.uk

Automotion Components Spur Gears Technical Page Automotion Spur Gear Gear Module Formula The module is crucial because it directly impacts the gear. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. Commonly used in metric gear design, the module measurement defines the size. (inch units applicable for constants) spur gear design calculator. In the previous. Spur Gear Gear Module Formula.

From www.chegg.com

Solved Problem 16 Spur Gear Design and Analysis (ref Spur Gear Gear Module Formula 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. This notebook documents the procedure to find spur gear geometry based on design requirements. The outputs are tip, base, root diameters, contact ratio, profile shift, addendum modification, and tooth thickness. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit. Spur Gear Gear Module Formula.

From paulbupejr.com

Wood Clock Gears with Motor Drive Part 1 of 3 Paul Bupe, Jr Spur Gear Gear Module Formula One important tool in performing spur gear calculations is the spur gear calculator. (inch units applicable for constants) spur gear design calculator. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Module = pitch diameter (mm) / number of teeth; Numerous dimensional parameters define the shape of the tooth profile, determine how the gears. Spur Gear Gear Module Formula.

From www.youtube.com

Design Of Spur Gear with Equation in SolidWorks YouTube Spur Gear Gear Module Formula Understanding gear profile and gear module. The geometry of a simple spur gear tooth is complex. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the. Spur Gear Gear Module Formula.

From www.youtube.com

CALCULATION RACK AND SPUR GEAR EXCEL FORMULA YouTube Spur Gear Gear Module Formula Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. The geometry of a simple spur gear tooth is complex. (inch units applicable for constants) spur gear design calculator. The outputs are tip, base, root diameters, contact ratio, profile shift, addendum modification, and tooth. Spur Gear Gear Module Formula.

From www.mech4study.com

Gear Terminology Basic Definition Used in Gear Mech4study Spur Gear Gear Module Formula It is calculated by dividing the reference diameter of the gear by the number of teeth. (inch units applicable for constants) spur gear design calculator. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth. Spur Gear Gear Module Formula.

From khkgears.net

Basic Gear Terminology and Calculation KHK Gears Spur Gear Gear Module Formula Understanding gear profile and gear module. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. This notebook documents the procedure to find spur gear geometry based on design requirements. Module = pitch diameter (mm) / number of teeth; The outputs are tip, base,. Spur Gear Gear Module Formula.

From selmec.org.uk

The Theory of Meccano Gears Part 1 — Spur Gears — South East London Spur Gear Gear Module Formula Commonly used in metric gear design, the module measurement defines the size. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. It is calculated by dividing the reference diameter of the gear by the number of teeth. The outputs are tip, base, root diameters, contact ratio, profile shift, addendum modification, and tooth thickness. One. Spur Gear Gear Module Formula.

From www.youtube.com

Spur Gear Calculation and Design (MITCalc03) YouTube Spur Gear Gear Module Formula Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. The geometry of a simple spur gear tooth is complex. It is calculated by dividing the reference diameter of the gear by the number of teeth. Module = pitch diameter (mm) / number of. Spur Gear Gear Module Formula.

From qlerobh.weebly.com

Spur gear formulas qlerobh Spur Gear Gear Module Formula Understanding gear profile and gear module. (inch units applicable for constants) spur gear design calculator. The outputs are tip, base, root diameters, contact ratio, profile shift, addendum modification, and tooth thickness. It is calculated by dividing the reference diameter of the gear by the number of teeth. One important tool in performing spur gear calculations is the spur gear calculator.. Spur Gear Gear Module Formula.

From www.yogiemachinery.com

Formula for calculating the modulus of the gear rack Industry Spur Gear Gear Module Formula (inch units applicable for constants) spur gear design calculator. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Understanding gear profile and gear module. The geometry of a simple spur gear tooth is complex. One important tool in performing spur gear calculations is the spur gear calculator. Commonly used in metric gear design, the. Spur Gear Gear Module Formula.

From www.sidiros.gr

SPUR GEAR MODULE 1.5 Z=017 WITH HUB Spur Gear Gear Module Formula (inch units applicable for constants) spur gear design calculator. Module = pitch diameter (mm) / number of teeth; This notebook documents the procedure to find spur gear geometry based on design requirements. A spur gear calculator is a software program or online. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify. Spur Gear Gear Module Formula.

From members.tripod.com

Spur Gear Geometry Picture Spur Gear Gear Module Formula Understanding gear profile and gear module. The module is crucial because it directly impacts the gear. One important tool in performing spur gear calculations is the spur gear calculator. Commonly used in metric gear design, the module measurement defines the size. Module = pitch diameter (mm) / number of teeth; Numerous dimensional parameters define the shape of the tooth profile,. Spur Gear Gear Module Formula.