Wire Rope Sheave Groove . A sheave is basically a wheel with a groove or track on it which guides the wire rope. “it should be greater if the fleet angle ex¬ceeds. Today, iso 16625 (2013) specifically permits groove angles between 45° and 60° and notes: Choose from our selection of wire rope sheaves, including. We recommend only sheaves made of steel or cast steel. This is indicated when a rope is showing two parallel planes of. The following are recommended values: Read on for some basic use, maintenance and safety information on today’s wire rope sheaves. A tight sheave will cause increased groove pressures at the point of contact. Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. To calculate the maximum bore and groove pressure acting on the sheave, substitute the maximum line pull for the rope to be used into.

from www.mazzellacompanies.com

Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. The following are recommended values: To calculate the maximum bore and groove pressure acting on the sheave, substitute the maximum line pull for the rope to be used into. Choose from our selection of wire rope sheaves, including. A sheave is basically a wheel with a groove or track on it which guides the wire rope. Read on for some basic use, maintenance and safety information on today’s wire rope sheaves. “it should be greater if the fleet angle ex¬ceeds. A tight sheave will cause increased groove pressures at the point of contact. Today, iso 16625 (2013) specifically permits groove angles between 45° and 60° and notes: We recommend only sheaves made of steel or cast steel.

How Sheave Size Affects Wire Rope Strength and Efficiency

Wire Rope Sheave Groove Today, iso 16625 (2013) specifically permits groove angles between 45° and 60° and notes: “it should be greater if the fleet angle ex¬ceeds. Choose from our selection of wire rope sheaves, including. Read on for some basic use, maintenance and safety information on today’s wire rope sheaves. This is indicated when a rope is showing two parallel planes of. To calculate the maximum bore and groove pressure acting on the sheave, substitute the maximum line pull for the rope to be used into. Today, iso 16625 (2013) specifically permits groove angles between 45° and 60° and notes: A sheave is basically a wheel with a groove or track on it which guides the wire rope. We recommend only sheaves made of steel or cast steel. Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. The following are recommended values: A tight sheave will cause increased groove pressures at the point of contact.

From www.indiamart.com

Mild Steel Double Sheave Wire Rope Pulley, Capacity 2 Ton, Multi Wire Rope Sheave Groove This is indicated when a rope is showing two parallel planes of. Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. “it should be greater if the fleet angle ex¬ceeds. The following are recommended values: We recommend only sheaves made of steel or cast steel. Read on for some basic use, maintenance and safety information. Wire Rope Sheave Groove.

From www.alamy.com

wire rope in the sheave groove for lifting equipment Stock Photo Alamy Wire Rope Sheave Groove A tight sheave will cause increased groove pressures at the point of contact. Choose from our selection of wire rope sheaves, including. This is indicated when a rope is showing two parallel planes of. “it should be greater if the fleet angle ex¬ceeds. Today, iso 16625 (2013) specifically permits groove angles between 45° and 60° and notes: A sheave is. Wire Rope Sheave Groove.

From www.alibaba.com

Precision Custom Machining V Groove Pulley Wire Rope Sheave Buy Rope Wire Rope Sheave Groove Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. Choose from our selection of wire rope sheaves, including. We recommend only sheaves made of steel or cast steel. To calculate the maximum bore and groove pressure acting on the sheave, substitute the maximum line pull for the rope to be used into. This is indicated. Wire Rope Sheave Groove.

From www.alamy.com

wire rope in the sheave groove for lifting equipment Stock Photo Alamy Wire Rope Sheave Groove “it should be greater if the fleet angle ex¬ceeds. The following are recommended values: Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. Read on for some basic use, maintenance and safety information on today’s wire rope sheaves. To calculate the maximum bore and groove pressure acting on the sheave, substitute the maximum line pull. Wire Rope Sheave Groove.

From marinersrepository.blogspot.com

Mariners Repository LIFTING EQUIPMENT SHEAVES, BLOCKS , DRUMS WITH Wire Rope Sheave Groove A sheave is basically a wheel with a groove or track on it which guides the wire rope. We recommend only sheaves made of steel or cast steel. Choose from our selection of wire rope sheaves, including. The following are recommended values: Today, iso 16625 (2013) specifically permits groove angles between 45° and 60° and notes: Learn how optimizing cable. Wire Rope Sheave Groove.

From suncorstainless.com

Stainless Steel Sheaves Selection and Use Suncor Stainless Wire Rope Sheave Groove Choose from our selection of wire rope sheaves, including. Read on for some basic use, maintenance and safety information on today’s wire rope sheaves. Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. This is indicated when a rope is showing two parallel planes of. The following are recommended values: To calculate the maximum bore. Wire Rope Sheave Groove.

From www.researchgate.net

Rope guide mechanism and the sheaves along with their degrees of Wire Rope Sheave Groove Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. Choose from our selection of wire rope sheaves, including. The following are recommended values: We recommend only sheaves made of steel or cast steel. “it should be greater if the fleet angle ex¬ceeds. To calculate the maximum bore and groove pressure acting on the sheave, substitute. Wire Rope Sheave Groove.

From ubicaciondepersonas.cdmx.gob.mx

Wire Rope Sheave Groove Dimensions ubicaciondepersonas.cdmx.gob.mx Wire Rope Sheave Groove This is indicated when a rope is showing two parallel planes of. Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. A sheave is basically a wheel with a groove or track on it which guides the wire rope. To calculate the maximum bore and groove pressure acting on the sheave, substitute the maximum line. Wire Rope Sheave Groove.

From mepsystems.com.sg

MORDEC WIRE ROPE SHEAVE GAUGE MEP Deck Solutions Wire Rope Sheave Groove The following are recommended values: Today, iso 16625 (2013) specifically permits groove angles between 45° and 60° and notes: A tight sheave will cause increased groove pressures at the point of contact. This is indicated when a rope is showing two parallel planes of. Read on for some basic use, maintenance and safety information on today’s wire rope sheaves. A. Wire Rope Sheave Groove.

From www.samselsupply.com

HOWTO Order Wire Rope Sheaves Wire Rope Sheave Groove Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. Read on for some basic use, maintenance and safety information on today’s wire rope sheaves. We recommend only sheaves made of steel or cast steel. To calculate the maximum bore and groove pressure acting on the sheave, substitute the maximum line pull for the rope to. Wire Rope Sheave Groove.

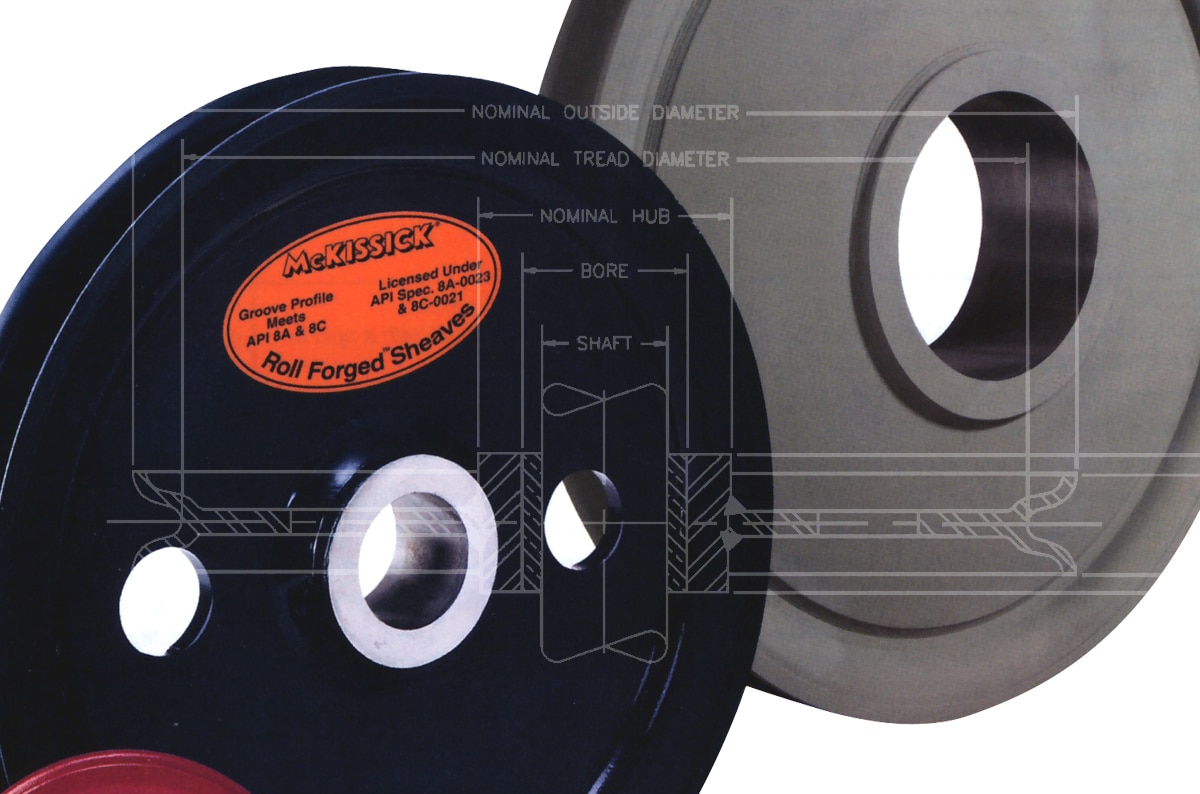

From www.mazzellacompanies.com

Crosby McKissick Wire Rope Sheaves Mazzella Companies Wire Rope Sheave Groove This is indicated when a rope is showing two parallel planes of. “it should be greater if the fleet angle ex¬ceeds. Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. We recommend only sheaves made of steel or cast steel. To calculate the maximum bore and groove pressure acting on the sheave, substitute the maximum. Wire Rope Sheave Groove.

From suncorstainless.com

Stainless Steel Sheaves Selection and Use Suncor Stainless Wire Rope Sheave Groove Today, iso 16625 (2013) specifically permits groove angles between 45° and 60° and notes: Read on for some basic use, maintenance and safety information on today’s wire rope sheaves. “it should be greater if the fleet angle ex¬ceeds. We recommend only sheaves made of steel or cast steel. The following are recommended values: To calculate the maximum bore and groove. Wire Rope Sheave Groove.

From www.alamy.com

wire rope in the sheave groove for lifting equipment Stock Photo Alamy Wire Rope Sheave Groove To calculate the maximum bore and groove pressure acting on the sheave, substitute the maximum line pull for the rope to be used into. Choose from our selection of wire rope sheaves, including. This is indicated when a rope is showing two parallel planes of. Today, iso 16625 (2013) specifically permits groove angles between 45° and 60° and notes: A. Wire Rope Sheave Groove.

From www.alamy.com

wire rope in the sheave groove for lifting equipment Stock Photo Alamy Wire Rope Sheave Groove To calculate the maximum bore and groove pressure acting on the sheave, substitute the maximum line pull for the rope to be used into. The following are recommended values: Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. A tight sheave will cause increased groove pressures at the point of contact. We recommend only sheaves. Wire Rope Sheave Groove.

From www.aliexpress.com

Grooved steel wire rope sling sheave groove U groove POM POM nylon Wire Rope Sheave Groove A sheave is basically a wheel with a groove or track on it which guides the wire rope. Read on for some basic use, maintenance and safety information on today’s wire rope sheaves. This is indicated when a rope is showing two parallel planes of. “it should be greater if the fleet angle ex¬ceeds. We recommend only sheaves made of. Wire Rope Sheave Groove.

From www.salvex.com

NOV 78 Wire Rope Sheaves (4 Units) and 64 Grooved Pulley Sheave (16 Wire Rope Sheave Groove A tight sheave will cause increased groove pressures at the point of contact. We recommend only sheaves made of steel or cast steel. A sheave is basically a wheel with a groove or track on it which guides the wire rope. Choose from our selection of wire rope sheaves, including. Today, iso 16625 (2013) specifically permits groove angles between 45°. Wire Rope Sheave Groove.

From www.mazzellacompanies.com

Why Sheave Design is Critical to Wire Rope Service Life Wire Rope Sheave Groove This is indicated when a rope is showing two parallel planes of. We recommend only sheaves made of steel or cast steel. A sheave is basically a wheel with a groove or track on it which guides the wire rope. The following are recommended values: Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. Read. Wire Rope Sheave Groove.

From www.cumberlandsalescompany.com

Sheaves & Cable Sheaves Cumberland Sales Cumberland Sales Wire Rope Sheave Groove Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. This is indicated when a rope is showing two parallel planes of. The following are recommended values: A sheave is basically a wheel with a groove or track on it which guides the wire rope. Today, iso 16625 (2013) specifically permits groove angles between 45° and. Wire Rope Sheave Groove.

From www.alibaba.com

1006 Wire Rope Sheaves Pulley,U Groove V Groove Plastic Rope Wire Guide Wire Rope Sheave Groove Today, iso 16625 (2013) specifically permits groove angles between 45° and 60° and notes: Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. This is indicated when a rope is showing two parallel planes of. To calculate the maximum bore and groove pressure acting on the sheave, substitute the maximum line pull for the rope. Wire Rope Sheave Groove.

From suncorstainless.com

Stainless Steel Sheaves Selection and Use Suncor Stainless Wire Rope Sheave Groove Choose from our selection of wire rope sheaves, including. This is indicated when a rope is showing two parallel planes of. A tight sheave will cause increased groove pressures at the point of contact. “it should be greater if the fleet angle ex¬ceeds. Read on for some basic use, maintenance and safety information on today’s wire rope sheaves. A sheave. Wire Rope Sheave Groove.

From www.alamy.com

wire rope in the sheave groove for lifting equipment Stock Photo Alamy Wire Rope Sheave Groove Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. Choose from our selection of wire rope sheaves, including. The following are recommended values: A sheave is basically a wheel with a groove or track on it which guides the wire rope. To calculate the maximum bore and groove pressure acting on the sheave, substitute the. Wire Rope Sheave Groove.

From www.smithberger.com

Smith Berger Marine VERTICAL GUIDE SHEAVES Wire Rope Sheave Groove A sheave is basically a wheel with a groove or track on it which guides the wire rope. Choose from our selection of wire rope sheaves, including. “it should be greater if the fleet angle ex¬ceeds. To calculate the maximum bore and groove pressure acting on the sheave, substitute the maximum line pull for the rope to be used into.. Wire Rope Sheave Groove.

From www.dreamstime.com

Wire Rope In The Sheave Groove For Lifting Equipment Stock Image Wire Rope Sheave Groove Today, iso 16625 (2013) specifically permits groove angles between 45° and 60° and notes: “it should be greater if the fleet angle ex¬ceeds. Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. This is indicated when a rope is showing two parallel planes of. A tight sheave will cause increased groove pressures at the point. Wire Rope Sheave Groove.

From www.dreamstime.com

Closeup of the Groove and Rope of Tensioning Sheave Stock Image Image Wire Rope Sheave Groove Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. We recommend only sheaves made of steel or cast steel. A tight sheave will cause increased groove pressures at the point of contact. Choose from our selection of wire rope sheaves, including. “it should be greater if the fleet angle ex¬ceeds. To calculate the maximum bore. Wire Rope Sheave Groove.

From www.allwherecrane.com

China Precision Custom Machining V Groove Pulley Wire Rope Sheave Wire Rope Sheave Groove To calculate the maximum bore and groove pressure acting on the sheave, substitute the maximum line pull for the rope to be used into. This is indicated when a rope is showing two parallel planes of. The following are recommended values: Today, iso 16625 (2013) specifically permits groove angles between 45° and 60° and notes: Choose from our selection of. Wire Rope Sheave Groove.

From www.aliexpress.com

5*26.5*10mm U groove rolling double bearing plastic sheave, wire rope Wire Rope Sheave Groove Today, iso 16625 (2013) specifically permits groove angles between 45° and 60° and notes: A tight sheave will cause increased groove pressures at the point of contact. Choose from our selection of wire rope sheaves, including. “it should be greater if the fleet angle ex¬ceeds. To calculate the maximum bore and groove pressure acting on the sheave, substitute the maximum. Wire Rope Sheave Groove.

From www.konecranes.com

Wire rope sheaves and ropes Konecranes USA Wire Rope Sheave Groove We recommend only sheaves made of steel or cast steel. Choose from our selection of wire rope sheaves, including. “it should be greater if the fleet angle ex¬ceeds. Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. This is indicated when a rope is showing two parallel planes of. A tight sheave will cause increased. Wire Rope Sheave Groove.

From rooneyirving.ca

Sheave grooves worn with rope pattern Rooney Irving & Associates Wire Rope Sheave Groove Read on for some basic use, maintenance and safety information on today’s wire rope sheaves. “it should be greater if the fleet angle ex¬ceeds. We recommend only sheaves made of steel or cast steel. The following are recommended values: A tight sheave will cause increased groove pressures at the point of contact. A sheave is basically a wheel with a. Wire Rope Sheave Groove.

From www.allwherecrane.com

China Precision Custom Machining V Groove Pulley Wire Rope Sheave Wire Rope Sheave Groove Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. Today, iso 16625 (2013) specifically permits groove angles between 45° and 60° and notes: A sheave is basically a wheel with a groove or track on it which guides the wire rope. Choose from our selection of wire rope sheaves, including. Read on for some basic. Wire Rope Sheave Groove.

From www.fittingflange.com

Wire Rope Sheave Langfang Dingyang Flange & Pipe Fitting Co.,Ltd Wire Rope Sheave Groove Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. The following are recommended values: A sheave is basically a wheel with a groove or track on it which guides the wire rope. To calculate the maximum bore and groove pressure acting on the sheave, substitute the maximum line pull for the rope to be used. Wire Rope Sheave Groove.

From www.mdpi.com

Materials Free FullText Sliding Friction and Wear Characteristics Wire Rope Sheave Groove We recommend only sheaves made of steel or cast steel. A tight sheave will cause increased groove pressures at the point of contact. Read on for some basic use, maintenance and safety information on today’s wire rope sheaves. To calculate the maximum bore and groove pressure acting on the sheave, substitute the maximum line pull for the rope to be. Wire Rope Sheave Groove.

From www.alibaba.com

China Manufacturer Plastic Nylon V Groove Sheave Buy Wire Rope Wire Rope Sheave Groove To calculate the maximum bore and groove pressure acting on the sheave, substitute the maximum line pull for the rope to be used into. A sheave is basically a wheel with a groove or track on it which guides the wire rope. Choose from our selection of wire rope sheaves, including. The following are recommended values: Today, iso 16625 (2013). Wire Rope Sheave Groove.

From suncorstainless.com

Stainless Steel Sheaves Selection and Use Suncor Stainless Wire Rope Sheave Groove The following are recommended values: A sheave is basically a wheel with a groove or track on it which guides the wire rope. Choose from our selection of wire rope sheaves, including. To calculate the maximum bore and groove pressure acting on the sheave, substitute the maximum line pull for the rope to be used into. “it should be greater. Wire Rope Sheave Groove.

From www.mazzellacompanies.com

How Sheave Size Affects Wire Rope Strength and Efficiency Wire Rope Sheave Groove Choose from our selection of wire rope sheaves, including. Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. Today, iso 16625 (2013) specifically permits groove angles between 45° and 60° and notes: A sheave is basically a wheel with a groove or track on it which guides the wire rope. Read on for some basic. Wire Rope Sheave Groove.

From zdcpucn.en.made-in-china.com

Custom V Groove Wire Rope Sheave Roller Bearing Polyamide Bushing for Wire Rope Sheave Groove Today, iso 16625 (2013) specifically permits groove angles between 45° and 60° and notes: This is indicated when a rope is showing two parallel planes of. To calculate the maximum bore and groove pressure acting on the sheave, substitute the maximum line pull for the rope to be used into. A tight sheave will cause increased groove pressures at the. Wire Rope Sheave Groove.