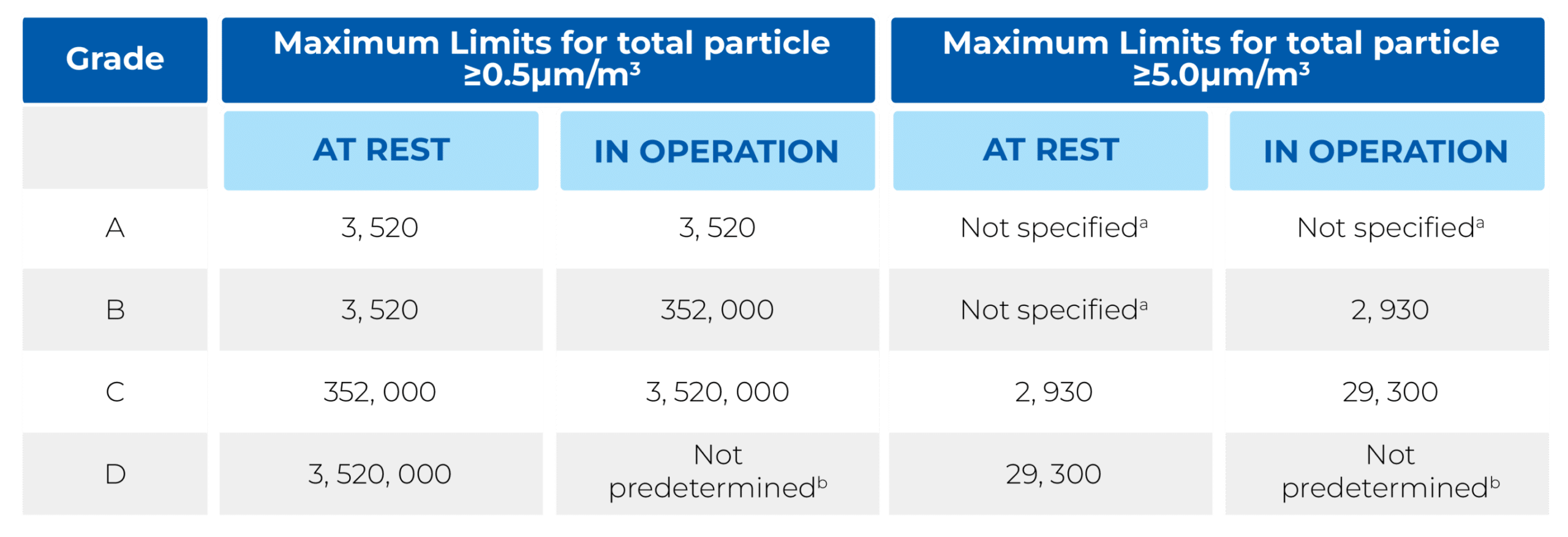

Clean Room Equipment Classification . The gmp clean air grades and classifications define the environment in which sterile drugs and biological products should be manufactured. 11 rows a cleanroom classification measures the level of cleanliness by calculating the size and quantity of particles per cubic volume of air. The clean room class is the level of cleanliness the room complies with, according to the quantity and size of particles per cubic meters of air. Use a particle counter that will automatically find the upper confidence limit to determine where your statistically significant particle. When selecting cleanroom equipment, several critical factors must be evaluated: A cleanroom must have less than 352,000 particles >0.5 micron per cubic meter and 60hepa filtered air changes per hour. The fs209e cleanroom classification system has six cleanroom cleanliness classes: The units begin at iso 1 and go to iso 9,. The primary authority in the us and canada. The iso 7 is a common clean cleanroom classification. Under the gmp requirements, the. Class 1, class 10, class 100, class 1,000, class 10,000, and class 100,000.

from brindapharma.com

The primary authority in the us and canada. A cleanroom must have less than 352,000 particles >0.5 micron per cubic meter and 60hepa filtered air changes per hour. The fs209e cleanroom classification system has six cleanroom cleanliness classes: The clean room class is the level of cleanliness the room complies with, according to the quantity and size of particles per cubic meters of air. The gmp clean air grades and classifications define the environment in which sterile drugs and biological products should be manufactured. Under the gmp requirements, the. The units begin at iso 1 and go to iso 9,. When selecting cleanroom equipment, several critical factors must be evaluated: The iso 7 is a common clean cleanroom classification. Use a particle counter that will automatically find the upper confidence limit to determine where your statistically significant particle.

Top Clean Room Equipment Manufacturers In India

Clean Room Equipment Classification Use a particle counter that will automatically find the upper confidence limit to determine where your statistically significant particle. Under the gmp requirements, the. The iso 7 is a common clean cleanroom classification. Use a particle counter that will automatically find the upper confidence limit to determine where your statistically significant particle. The fs209e cleanroom classification system has six cleanroom cleanliness classes: The units begin at iso 1 and go to iso 9,. The gmp clean air grades and classifications define the environment in which sterile drugs and biological products should be manufactured. 11 rows a cleanroom classification measures the level of cleanliness by calculating the size and quantity of particles per cubic volume of air. A cleanroom must have less than 352,000 particles >0.5 micron per cubic meter and 60hepa filtered air changes per hour. The clean room class is the level of cleanliness the room complies with, according to the quantity and size of particles per cubic meters of air. Class 1, class 10, class 100, class 1,000, class 10,000, and class 100,000. When selecting cleanroom equipment, several critical factors must be evaluated: The primary authority in the us and canada.

From www.lmairtech.com

Cleanroom Classification & Design Guidelines LM AIR TECHNOLOGY Clean Room Equipment Classification Use a particle counter that will automatically find the upper confidence limit to determine where your statistically significant particle. The fs209e cleanroom classification system has six cleanroom cleanliness classes: The primary authority in the us and canada. Class 1, class 10, class 100, class 1,000, class 10,000, and class 100,000. 11 rows a cleanroom classification measures the level of cleanliness. Clean Room Equipment Classification.

From www.slideshare.net

Cleanroom, Classification, Design and Clean Room Equipment Classification Class 1, class 10, class 100, class 1,000, class 10,000, and class 100,000. The iso 7 is a common clean cleanroom classification. The clean room class is the level of cleanliness the room complies with, according to the quantity and size of particles per cubic meters of air. 11 rows a cleanroom classification measures the level of cleanliness by calculating. Clean Room Equipment Classification.

From www.mecart-cleanrooms.com

Cleanroom Classifications (ISO 8, ISO 7, ISO 6, ISO 5) Clean Room Equipment Classification Use a particle counter that will automatically find the upper confidence limit to determine where your statistically significant particle. The primary authority in the us and canada. 11 rows a cleanroom classification measures the level of cleanliness by calculating the size and quantity of particles per cubic volume of air. A cleanroom must have less than 352,000 particles >0.5 micron. Clean Room Equipment Classification.

From pharmastate.academy

Cleanroom Classifications, Classes and ISO Standards Clean Room Equipment Classification When selecting cleanroom equipment, several critical factors must be evaluated: Under the gmp requirements, the. 11 rows a cleanroom classification measures the level of cleanliness by calculating the size and quantity of particles per cubic volume of air. The units begin at iso 1 and go to iso 9,. The clean room class is the level of cleanliness the room. Clean Room Equipment Classification.

From www.presentationeze.com

Cleanroom Classification ISO 14644PresentationEZE Clean Room Equipment Classification Class 1, class 10, class 100, class 1,000, class 10,000, and class 100,000. The gmp clean air grades and classifications define the environment in which sterile drugs and biological products should be manufactured. Under the gmp requirements, the. 11 rows a cleanroom classification measures the level of cleanliness by calculating the size and quantity of particles per cubic volume of. Clean Room Equipment Classification.

From pharmacyscope.com

Clean Area Classification Pharmacy Scope Clean Room Equipment Classification When selecting cleanroom equipment, several critical factors must be evaluated: The iso 7 is a common clean cleanroom classification. The primary authority in the us and canada. The gmp clean air grades and classifications define the environment in which sterile drugs and biological products should be manufactured. Under the gmp requirements, the. A cleanroom must have less than 352,000 particles. Clean Room Equipment Classification.

From us.ngscleanrooms.com

Cleanroom Classification ISO 14644 FED STD 209 GMP Annex Clean Room Equipment Classification The iso 7 is a common clean cleanroom classification. Under the gmp requirements, the. When selecting cleanroom equipment, several critical factors must be evaluated: The fs209e cleanroom classification system has six cleanroom cleanliness classes: Use a particle counter that will automatically find the upper confidence limit to determine where your statistically significant particle. The clean room class is the level. Clean Room Equipment Classification.

From www.iqsdirectory.com

Cleanroom What is it? ISO Standards and Classifications, Design, Types Clean Room Equipment Classification The units begin at iso 1 and go to iso 9,. A cleanroom must have less than 352,000 particles >0.5 micron per cubic meter and 60hepa filtered air changes per hour. When selecting cleanroom equipment, several critical factors must be evaluated: The fs209e cleanroom classification system has six cleanroom cleanliness classes: The iso 7 is a common clean cleanroom classification.. Clean Room Equipment Classification.

From www.slideserve.com

PPT Seminar on Aseptic Processing operation by Ranjith Kumar kankala Clean Room Equipment Classification The primary authority in the us and canada. The iso 7 is a common clean cleanroom classification. When selecting cleanroom equipment, several critical factors must be evaluated: Use a particle counter that will automatically find the upper confidence limit to determine where your statistically significant particle. The gmp clean air grades and classifications define the environment in which sterile drugs. Clean Room Equipment Classification.

From www.americancleanrooms.com

What is an ISO7 Cleanroom Classification? Clean Room Equipment Classification 11 rows a cleanroom classification measures the level of cleanliness by calculating the size and quantity of particles per cubic volume of air. Use a particle counter that will automatically find the upper confidence limit to determine where your statistically significant particle. The fs209e cleanroom classification system has six cleanroom cleanliness classes: The iso 7 is a common clean cleanroom. Clean Room Equipment Classification.

From www.aroundlabnews.com

AROUND LAB NEWS / EN » Understanding Cleanroom Classifications Clean Room Equipment Classification The clean room class is the level of cleanliness the room complies with, according to the quantity and size of particles per cubic meters of air. Use a particle counter that will automatically find the upper confidence limit to determine where your statistically significant particle. When selecting cleanroom equipment, several critical factors must be evaluated: A cleanroom must have less. Clean Room Equipment Classification.

From isocleanroom.co.uk

ISO 6 Defining Cleanroom Classification Guidelines ISO Cleanroom Clean Room Equipment Classification The clean room class is the level of cleanliness the room complies with, according to the quantity and size of particles per cubic meters of air. Class 1, class 10, class 100, class 1,000, class 10,000, and class 100,000. 11 rows a cleanroom classification measures the level of cleanliness by calculating the size and quantity of particles per cubic volume. Clean Room Equipment Classification.

From www.rep.com

Cleanroom Guide Midstates Marketing, Inc. Clean Room Equipment Classification When selecting cleanroom equipment, several critical factors must be evaluated: The fs209e cleanroom classification system has six cleanroom cleanliness classes: Under the gmp requirements, the. The iso 7 is a common clean cleanroom classification. The units begin at iso 1 and go to iso 9,. 11 rows a cleanroom classification measures the level of cleanliness by calculating the size and. Clean Room Equipment Classification.

From www.liberty-ind.com

A Guide to Cleanroom Cleaning & Maintenance Liberty Industries Clean Room Equipment Classification Use a particle counter that will automatically find the upper confidence limit to determine where your statistically significant particle. Class 1, class 10, class 100, class 1,000, class 10,000, and class 100,000. The units begin at iso 1 and go to iso 9,. The gmp clean air grades and classifications define the environment in which sterile drugs and biological products. Clean Room Equipment Classification.

From www.lingdohvac.com

Clean Room Classifications HVAC Equipment Supplier Clean Room Equipment Classification When selecting cleanroom equipment, several critical factors must be evaluated: The iso 7 is a common clean cleanroom classification. Class 1, class 10, class 100, class 1,000, class 10,000, and class 100,000. Under the gmp requirements, the. 11 rows a cleanroom classification measures the level of cleanliness by calculating the size and quantity of particles per cubic volume of air.. Clean Room Equipment Classification.

From www.airchecklab.com

Applying Cleanroom Specifications to Compressed Air and Gases Clean Room Equipment Classification The units begin at iso 1 and go to iso 9,. The gmp clean air grades and classifications define the environment in which sterile drugs and biological products should be manufactured. The primary authority in the us and canada. When selecting cleanroom equipment, several critical factors must be evaluated: 11 rows a cleanroom classification measures the level of cleanliness by. Clean Room Equipment Classification.

From www.presentationeze.com

Cleanroom Classification Information & current Best Clean Room Equipment Classification The primary authority in the us and canada. A cleanroom must have less than 352,000 particles >0.5 micron per cubic meter and 60hepa filtered air changes per hour. Under the gmp requirements, the. When selecting cleanroom equipment, several critical factors must be evaluated: Class 1, class 10, class 100, class 1,000, class 10,000, and class 100,000. The units begin at. Clean Room Equipment Classification.

From www.presentationeze.com

Cleanroom Classification ISO 14644PresentationEZE Clean Room Equipment Classification The units begin at iso 1 and go to iso 9,. A cleanroom must have less than 352,000 particles >0.5 micron per cubic meter and 60hepa filtered air changes per hour. The primary authority in the us and canada. Class 1, class 10, class 100, class 1,000, class 10,000, and class 100,000. The fs209e cleanroom classification system has six cleanroom. Clean Room Equipment Classification.

From www.golighthouse.com

Cleanroom Classifications Explained Lighthouse Worldwide Solutions Clean Room Equipment Classification The iso 7 is a common clean cleanroom classification. Class 1, class 10, class 100, class 1,000, class 10,000, and class 100,000. The clean room class is the level of cleanliness the room complies with, according to the quantity and size of particles per cubic meters of air. 11 rows a cleanroom classification measures the level of cleanliness by calculating. Clean Room Equipment Classification.

From cleanroomindustry.com

How To Properly Clean A Cleanroom Cleanroom Industry Clean Room Equipment Classification Under the gmp requirements, the. The iso 7 is a common clean cleanroom classification. Use a particle counter that will automatically find the upper confidence limit to determine where your statistically significant particle. The primary authority in the us and canada. 11 rows a cleanroom classification measures the level of cleanliness by calculating the size and quantity of particles per. Clean Room Equipment Classification.

From www.angstromcleanroomsupply.com

Cleanroom Classification Angstrom Supply Clean Room Equipment Classification The primary authority in the us and canada. The fs209e cleanroom classification system has six cleanroom cleanliness classes: When selecting cleanroom equipment, several critical factors must be evaluated: A cleanroom must have less than 352,000 particles >0.5 micron per cubic meter and 60hepa filtered air changes per hour. Under the gmp requirements, the. Class 1, class 10, class 100, class. Clean Room Equipment Classification.

From searose.com.au

The Clean Room Standards for Pharmaceuticals Searose Clean Room Equipment Classification The units begin at iso 1 and go to iso 9,. Use a particle counter that will automatically find the upper confidence limit to determine where your statistically significant particle. A cleanroom must have less than 352,000 particles >0.5 micron per cubic meter and 60hepa filtered air changes per hour. The clean room class is the level of cleanliness the. Clean Room Equipment Classification.

From brindapharma.com

Top Clean Room Equipment Manufacturers In India Clean Room Equipment Classification Class 1, class 10, class 100, class 1,000, class 10,000, and class 100,000. The primary authority in the us and canada. The iso 7 is a common clean cleanroom classification. The clean room class is the level of cleanliness the room complies with, according to the quantity and size of particles per cubic meters of air. A cleanroom must have. Clean Room Equipment Classification.

From hibnhaat.blogspot.com

Iso Clean Room Classification An Overview of ISO 14644 Clean Room Clean Room Equipment Classification When selecting cleanroom equipment, several critical factors must be evaluated: Class 1, class 10, class 100, class 1,000, class 10,000, and class 100,000. The clean room class is the level of cleanliness the room complies with, according to the quantity and size of particles per cubic meters of air. A cleanroom must have less than 352,000 particles >0.5 micron per. Clean Room Equipment Classification.

From brindapharma.com

Top Clean Room Equipment Manufacturers In India Clean Room Equipment Classification Use a particle counter that will automatically find the upper confidence limit to determine where your statistically significant particle. The fs209e cleanroom classification system has six cleanroom cleanliness classes: The clean room class is the level of cleanliness the room complies with, according to the quantity and size of particles per cubic meters of air. When selecting cleanroom equipment, several. Clean Room Equipment Classification.

From pharmagxp.com

Clean Room and Classification Summary of 4 Different Standards Clean Room Equipment Classification The gmp clean air grades and classifications define the environment in which sterile drugs and biological products should be manufactured. Class 1, class 10, class 100, class 1,000, class 10,000, and class 100,000. Use a particle counter that will automatically find the upper confidence limit to determine where your statistically significant particle. 11 rows a cleanroom classification measures the level. Clean Room Equipment Classification.

From cmmonline.com

Basic Cleanroom Requirements and Classifications Clean Room Equipment Classification Under the gmp requirements, the. The gmp clean air grades and classifications define the environment in which sterile drugs and biological products should be manufactured. When selecting cleanroom equipment, several critical factors must be evaluated: The units begin at iso 1 and go to iso 9,. The iso 7 is a common clean cleanroom classification. The fs209e cleanroom classification system. Clean Room Equipment Classification.

From www.aeroex.com

Clean Room Classification Chart Aeroex Technologies Clean Room Equipment Classification Class 1, class 10, class 100, class 1,000, class 10,000, and class 100,000. The units begin at iso 1 and go to iso 9,. The fs209e cleanroom classification system has six cleanroom cleanliness classes: The primary authority in the us and canada. 11 rows a cleanroom classification measures the level of cleanliness by calculating the size and quantity of particles. Clean Room Equipment Classification.

From www.iqsdirectory.com

Types of Cleanrooms Clean Room Equipment Classification Under the gmp requirements, the. The primary authority in the us and canada. The iso 7 is a common clean cleanroom classification. The units begin at iso 1 and go to iso 9,. The fs209e cleanroom classification system has six cleanroom cleanliness classes: When selecting cleanroom equipment, several critical factors must be evaluated: A cleanroom must have less than 352,000. Clean Room Equipment Classification.

From angstromtechnology.com

Cleanroom Classifications & Standards Angstrom Technology Clean Room Equipment Classification The gmp clean air grades and classifications define the environment in which sterile drugs and biological products should be manufactured. When selecting cleanroom equipment, several critical factors must be evaluated: The iso 7 is a common clean cleanroom classification. Under the gmp requirements, the. The fs209e cleanroom classification system has six cleanroom cleanliness classes: The primary authority in the us. Clean Room Equipment Classification.

From www.iqsdirectory.com

Cleanroom What is it? ISO Standards and Classifications, Design, Types Clean Room Equipment Classification A cleanroom must have less than 352,000 particles >0.5 micron per cubic meter and 60hepa filtered air changes per hour. The gmp clean air grades and classifications define the environment in which sterile drugs and biological products should be manufactured. When selecting cleanroom equipment, several critical factors must be evaluated: The clean room class is the level of cleanliness the. Clean Room Equipment Classification.

From operonstrategist.com

Clean Room Classification for Injection Molding and Assembly (A Clean Room Equipment Classification The primary authority in the us and canada. The gmp clean air grades and classifications define the environment in which sterile drugs and biological products should be manufactured. 11 rows a cleanroom classification measures the level of cleanliness by calculating the size and quantity of particles per cubic volume of air. Class 1, class 10, class 100, class 1,000, class. Clean Room Equipment Classification.

From us.ngscleanrooms.com

Cleanroom Classification ISO 14644 FED STD 209 GMP Annex Clean Room Equipment Classification Class 1, class 10, class 100, class 1,000, class 10,000, and class 100,000. When selecting cleanroom equipment, several critical factors must be evaluated: The clean room class is the level of cleanliness the room complies with, according to the quantity and size of particles per cubic meters of air. The fs209e cleanroom classification system has six cleanroom cleanliness classes: 11. Clean Room Equipment Classification.

From greendii.com

CLEAN ROOM EQUIPMENT Clean Room Equipment Classification Class 1, class 10, class 100, class 1,000, class 10,000, and class 100,000. Under the gmp requirements, the. The primary authority in the us and canada. A cleanroom must have less than 352,000 particles >0.5 micron per cubic meter and 60hepa filtered air changes per hour. The fs209e cleanroom classification system has six cleanroom cleanliness classes: The units begin at. Clean Room Equipment Classification.

From medium.com

Quality Control in the Lab Choosing the Right Clean Room Equipment Clean Room Equipment Classification Under the gmp requirements, the. 11 rows a cleanroom classification measures the level of cleanliness by calculating the size and quantity of particles per cubic volume of air. The clean room class is the level of cleanliness the room complies with, according to the quantity and size of particles per cubic meters of air. The iso 7 is a common. Clean Room Equipment Classification.